Have you ever wondered why some steel products have surface imperfections? This article uncovers common defects in hot-rolled steel, such as pressed-in oxide scale and blisters. By understanding their causes and prevention, you’ll gain insights into improving steel quality and production efficiency. Dive in to learn more!

Steel rolling is a critical metal forming process that alters the shape and dimensions of steel ingots or billets by applying compressive forces through rotating rolls. This process is categorized into two main types: hot rolling and cold rolling, each with distinct characteristics and applications.

Hot rolling is conducted at elevated temperatures, typically between 1100°C and 1250°C (2012°F to 2282°F). At these temperatures, steel exhibits increased ductility and reduced deformation resistance, allowing for significant shape changes with relatively lower energy input. This process is particularly effective for large-scale deformation and producing semi-finished products like plates, sheets, and structural shapes.

Hot-rolled steel strips represent a quintessential application of the hot rolling process. The production of these strips involves a series of precisely controlled rolling passes, often in a continuous or semi-continuous mill configuration. This process not only shapes the steel but also refines its grain structure, contributing to improved mechanical properties.

In modern steel manufacturing, hot-rolled strip production has reached a high level of technological sophistication. Advanced control systems, coupled with state-of-the-art instrumentation and sensors, enable precise management of rolling parameters such as temperature, roll gap, rolling speed, and cooling rates. This level of control results in consistent product quality and high production line efficiency, with operating rates often exceeding 90%.

Despite these advancements, the inherent complexity of the hot rolling process presents ongoing challenges. The interplay between various process parameters, equipment conditions, and material properties can lead to quality issues in the final product. Common defects include thickness variations, surface imperfections, shape defects (e.g., edge waves or center buckles), and inconsistencies in mechanical properties along the strip length or width.

To mitigate these challenges, modern hot strip mills employ advanced process control strategies, such as model-based predictive control, adaptive systems, and real-time quality monitoring. Additionally, ongoing research focuses on developing more robust alloy designs, optimizing roll pass schedules, and implementing machine learning algorithms for defect prediction and prevention.

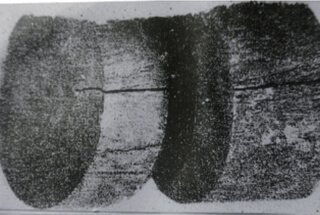

Pressed-in oxide scale is a surface defect formed by the compression of oxide scale into the surface of the steel strip during hot rolling. Depending on its cause, it can be divided into furnace-generated (primary) oxide scale, rolling-generated (secondary) oxide scale, or oxide scale from the roll surface that comes off and is compressed into the steel strip (secondary).

①Severe longitudinal cracks on the surface of the steel billet;

②Improper heating process or heating operation of the steel billet, making it difficult to remove primary scale;

③Low pressure in the high-pressure descaling water or nozzle blockage during the rolling process, resulting in the production of oxide scale being compressed into the steel strip surface;

④Too fast rolling pace or poor cooling of the rolls, causing the oxide film on the roll surface to peel off and be compressed into the steel strip surface.

It affects the surface quality of the steel strip and the coating effect.

①Strengthen the quality inspection of the steel billet. Billets with severe longitudinal cracks on the surface should be cleaned and qualified before use;

②Develop a reasonable heating process for the steel billet, and heat it according to the specifications;

③Regularly check the equipment of the high-pressure descaling water system to ensure descaling water pressure and avoid nozzle blockage;

④Reasonably control the rolling pace, ensure the cooling effect of the rolls, and prevent the oxide film on the roll surface from peeling off.

Scar is an irregularly shaped, raised metal sheet attached to the surface of the steel strip, showing leaf-like, feather-like, bar-like, fish-scale-like, tongue-end-like, etc.

There are two types of scars: one is connected to the body of the steel and folds onto the surface of the plate, not easy to fall off; the other is not connected to the body of the steel but is bonded to the surface of the plate and is easy to fall off, forming a relatively smooth pit after falling off.

①The original scar or heavy skin defect on the surface of the billet was not cleaned up and remained on the surface of the steel strip after rolling;

②Residues of flame cleaning on the surface of the billet, which were pressed into the surface of the steel strip during rolling.

It can lead to metal peeling or holes during subsequent processing and use.

Strengthen the quality inspection of the billet, and clean up any scars or residues of flame cleaning on the surface of the billet before rolling.

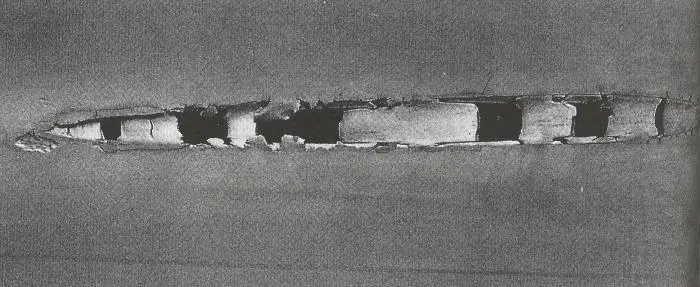

Blisters are circular or elliptical bulges on the surface of the steel strip that are irregularly distributed. Their outer edge is relatively smooth. After the blisters are crushed, the steel strip surface may have cracks or flaking.

Some blisters do not protrude and have a shiny surface after being flattened, and the cut surface shows a layered structure.

①Too much gas is accumulated inside the billet due to poor deoxidation or improper nitrogen blowing;

②The billet has been in the furnace for a long time, and the subcutaneous bubbles are exposed and accumulate.

It may cause layering or poor welding during subsequent processing and use.

①Strengthen the quality inspection of the billet and avoid using billets with exposed bubble defects;

②Strictly follow the specifications to heat the billet and avoid keeping the billet in the furnace for too long.

The phenomenon of multiple layers overlapping or rolling, piercing, tearing, etc. on the surface of the steel strip is called rolling crush.

①Improper adjustment of roll clearance or poor matching between roll shape and incoming billet shape, resulting in uneven extension of the steel strip;

②Uneven local heating temperature of the billet or uneven temperature of the rolled piece;

③The setting of the opening degree of the finishing side guide plate is unreasonable;

④The flow rate during precision rolling is mismatched.

The steel plate with rolling crush defects cannot be used due to the interruption of the rolling process.

①Configure roll shapes reasonably and pay attention to roll clearance adjustment;

②Strengthen the control of billet heating temperature and ensure uniform temperature of the rolled piece;

③Reasonably set the opening degree of the finishing side guide plate;

④Maintain consistent flow rate during continuous rolling.

Roll marks are concave-convex defects with irregular shapes that are periodically distributed on the surface of the steel strip.

Rolls are cracked, have localized spalling, or have foreign objects adhered to their surface, resulting in a concave-convex surface on the roll, which is pressed into the surface of the steel strip during rolling or finishing processing, forming concave-convex defects.

Convex roll marks may cause folding defects during subsequent rolling processes, while concave roll marks may cause holes during subsequent rolling processes.

①Regularly inspect the surface quality of the rolls, and deal with rolls with spalling or foreign objects in a timely manner;

②During the rolling process, check the surface quality of the rolls in time when abnormal situations such as steel jamming, tail throwing, and rolling crush occur, and prevent roll surface damage or foreign object adhesion;

③Immediately stop the machine to check the surface quality of the rolls when roll marks are found.

The phenomenon of steel coils appearing oval-shaped is called flattening.

①The steel coil is subjected to excessive impact during handling;

②The tension of the steel coil during coiling is too low, and the coils are stacked horizontally or with multiple layers.

It affects the packaging and handling of steel coils, and severely flattened coils cannot be used.

①Handle steel coils carefully;

②Reasonably set the coiling tension, control the number of layers of horizontal stacking, and use vertical stacking if necessary.