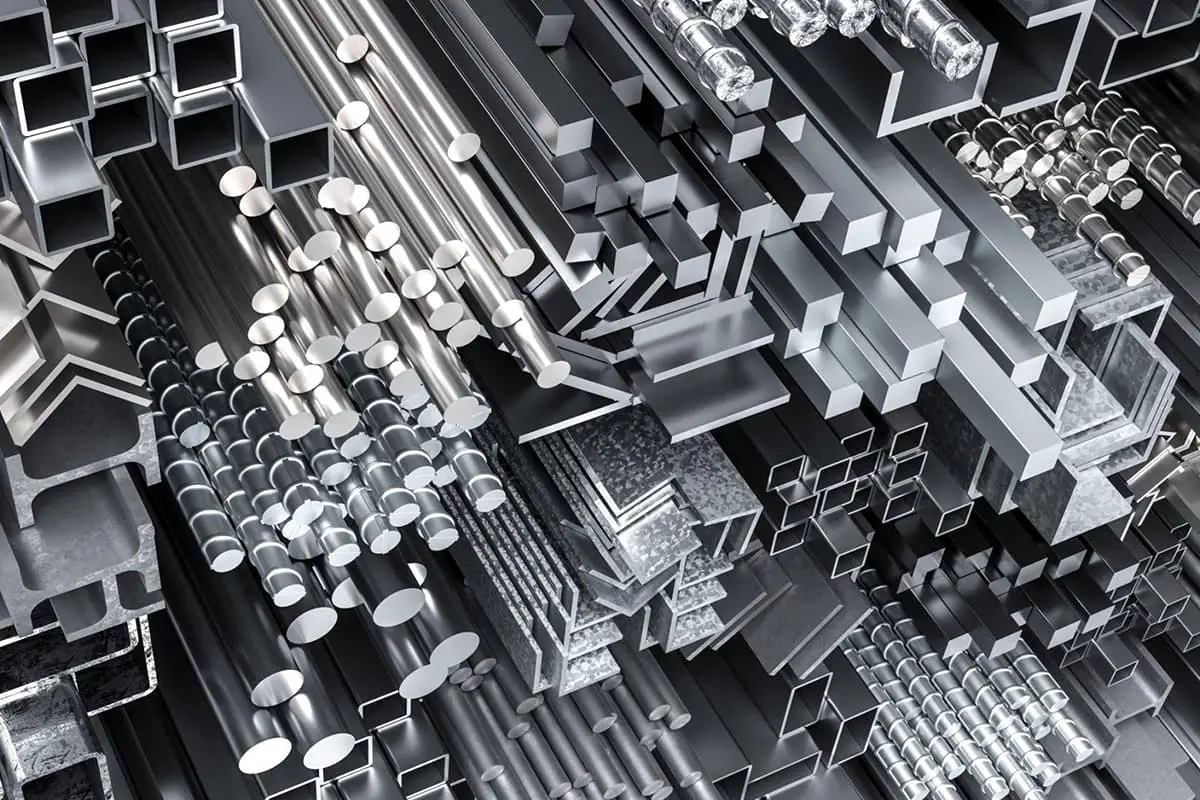

What happens when metal is rolled at over 1000°C versus room temperature? The difference between hot rolling and cold rolling impacts the steel’s structure, properties, and uses. This article breaks down these two processes, explaining their benefits, drawbacks, and applications. Discover how each method affects the steel’s surface quality, mechanical properties, and formability. Understanding these differences will help you choose the right type of rolled steel for your specific needs. Dive in to find out more!

Hot rolling and cold rolling are both procedures for forming steel plates or profiles, and they significantly affect the structure and properties of the steel.

The primary method for rolling steel is hot rolling, while cold rolling is generally used only for producing small-sized steel and thin plates requiring precise dimensions.

Defined technically, steel ingots or billets are difficult to deform and process at room temperature, generally requiring heating to between 1100 and 1250°C for rolling. This rolling process is referred to as hot rolling.

The completion temperature for hot rolling typically ranges from 800 to 900°C, after which the material is commonly cooled in air, making the hot rolling condition analogous to normalizing.

Most steel materials are rolled using the hot rolling method. Steel delivered in a hot-rolled state, due to the high temperatures, develops an oxidized iron skin on the surface, providing a certain degree of corrosion resistance, suitable for outdoor storage.

However, this oxidized iron skin also roughens the surface of the hot-rolled steel and causes significant size variability.

Therefore, for steel materials requiring a smooth surface, precise dimensions, and good mechanical properties, hot-rolled semi-finished or finished materials are used as raw materials for further cold rolling production.

Advantages:

Hot rolling offers rapid shaping, high output, and does not damage the coating. It can create a variety of cross-sectional shapes to meet the needs of different use conditions.

Cold rolling can induce significant plastic deformation in steel materials, thereby enhancing the yield point of the steel.

Disadvantages:

1. Despite not undergoing hot plastic compression in the forming process, there remain residual stresses within the cross-section, inevitably affecting the overall and local buckling characteristics of the steel.

2. Cold-rolled steel sections are typically open cross-sections, resulting in low free torsional stiffness. This can lead to twisting under bending and flexural-torsional buckling under compression, exhibiting poor torsion resistance.

3. The thickness of cold-formed steel walls is relatively small, and there is no thickening at the corners where plate parts are joined, thus displaying a weak ability to withstand localized concentrated loads.

Hot rolling begins with unwinding, followed by continuous welding, officially entering the cold-rolling procedure: After pickling, it goes into the mill for rolling, producing hard-rolled coils. The cleaned, hard-rolled coils then enter the heat treatment stage.

Cold rolling refers to a rolling method that manipulates the shape of steel by applying pressure with rollers at room temperature.

Despite a temperature increase in the steel during the process, it is still referred to as cold rolling.

More specifically, cold rolling involves utilizing hot-rolled steel coils as raw materials, which, after acid washing to remove the oxide scale, undergo pressure processing, resulting in hard-rolled coils as the finished product.

Cold-rolled steels such as galvanized and color-coated sheets generally undergo annealing, which results in good plasticity and elongation rates.

They are widely used in industries such as automotive, home appliances, and hardware. The surface of cold-rolled sheets has a certain degree of smoothness and feels rather glossy, mainly due to acid washing.

Hot-rolled sheets generally do not meet the required surface smoothness, so hot-rolled steel strips need to be cold-rolled.

Also, the minimum thickness of hot-rolled steel strips is typically 1.0mm, while cold-rolling can achieve 0.1mm. Hot-rolling is performed above the crystallization temperature, while cold-rolling occurs below the crystallization temperature.

The shape changes in steel due to cold-rolling pertain to continuous cold deformation. The cold hardening that happens during this process increases the strength and hardness of the rolled hard coil while decreasing its toughness and plasticity indices.

From an end-use perspective, cold-rolling deteriorates the stamping performance, making the product suitable for parts requiring simple deformation.

Advantages:

Cold-rolling can disrupt the casting structure of the steel ingot, refine the grains of the steel, and eliminate microscopic structural defects, thereby making the steel structure compact and improving its mechanical properties. This improvement is primarily seen in the direction of rolling, making the steel to some extent anisotropic rather than isotropic. Bubbles, cracks, and looseness formed during casting can also be welded under high temperature and pressure.

Disadvantages:

1. After hot rolling, non-metallic inclusions (mainly sulfides and oxides, as well as silicates) within the steel are pressed into thin layers, resulting in a phenomenon known as delamination.

Delamination significantly deteriorates the steel’s tensile properties along the thickness direction and may cause inter-laminar tearing during weld shrinkage. The local strain induced by weld shrinkage often reaches several times the yield point strain, much greater than the strain caused by the load.

2. Residual stress caused by uneven cooling. Residual stress is an internally balanced stress in the absence of external forces. All types of hot-rolled steel sections have this kind of residual stress, and the larger the section size of the general steel, the greater the residual stress.

Although residual stress is self-balancing, it still has a certain impact on the performance of steel components under external forces. For instance, it may have adverse effects on deformation, stability, and fatigue resistance.

The primary distinction between cold rolling and hot rolling lies in the temperature during the rolling process; “cold” indicates room temperature, while “hot” signifies high temperature.

From a metallurgical perspective, the demarcation between cold rolling and hot rolling should be based on the recrystallization temperature.

That is, rolling conducted below the recrystallization temperature is considered cold rolling, and rolling above this temperature is considered hot rolling. The recrystallization temperature for steel ranges from 450 to 600°C.

The primary differences between hot rolling and cold rolling are:

1. Appearance and Surface Quality:

Cold-rolled sheets, being derived from hot-rolled sheets subjected to cold rolling processes, often undergo various surface finishing techniques. As a result, they have superior surface quality (e.g., reduced surface roughness) compared to hot-rolled sheets.

Therefore, if high-quality paint application or similar coatings are required in subsequent product stages, cold-rolled sheets are usually preferred.

Hot-rolled sheets can be further classified into acid-washed and non-acid-washed. Acid-washed sheets, having undergone acid washing, exhibit a regular metallic color, but their surface quality is not as high as cold-rolled sheets since they aren’t cold-rolled.

Non-acid-washed sheets often have an oxidized layer, appearing blackened or presenting a layer of black iron(III) oxide. In layman’s terms, they appear as if scorched by fire and often bear rust if stored in poor conditions.

2. Mechanical Properties:

Generally, in engineering applications, the mechanical properties of hot-rolled and cold-rolled sheets are considered identical, despite the cold-rolled sheets undergoing a degree of work hardening during the cold-rolling process. (However, if strict mechanical property requirements are needed, specific consideration is necessary.)

Cold-rolled sheets typically have slightly higher yield strength and surface hardness than hot-rolled sheets, although the exact values depend on the degree of annealing of the cold-rolled sheets. Regardless of the annealing process, the strength of cold-rolled sheets exceeds that of hot-rolled sheets.

3. Formability:

Given that the properties of cold-rolled and hot-rolled sheets are largely similar, their formability primarily depends on their surface quality differences.

As cold-rolled sheets have better surface quality, they usually provide better forming results than hot-rolled sheets of the same material.