Have you ever wondered about the hidden dangers behind the bright sparks of welding? In this article, we explore the harmful effects of argon arc welding on the human body. You’ll learn about the risks involved and the necessary precautions to ensure safety.

Argon arc welding has a higher degree of harm compared to electrode arc welding, but it is not cause for alarm. The level of infrared radiation produced during argon arc welding is about 1 to 1.5 times greater than that of ordinary electrode arc welding, and the ultraviolet radiation generated is about 5 to 20 times greater.

In confined spaces, the concentration of ozone can reach a dangerous level during the welding process. Additionally, harmful gases such as carbon dioxide, carbon monoxide, and metal dust are produced, which can harm the welder.

Therefore, it is important to take necessary precautions during the welding process, such as using protective equipment and selecting electrode materials with low radioactivity, such as cerium tungsten. Additionally, wearing masks and gloves when grinding electrodes and washing hands after work can help minimize hazards.

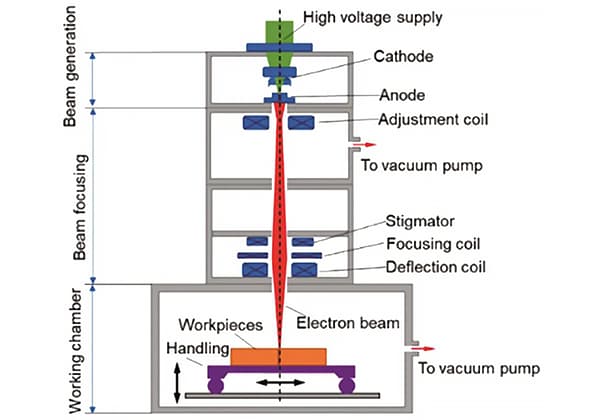

The high-frequency oscillator is often used in welding, with a frequency ranging from 200 to 500 KHz, a voltage of 2500 to 3500 volts, and an electric field strength of 140 to 190V/m. During arc striking, the high-frequency electromagnetic field intensity generated is between 60 to 110V/m, which is several times higher than the reference hygiene standard of 20V/m.

In non-melting electrode argon arc welding, plasma arc welding and cutting, the high-frequency oscillator is often used to excite the arc, and some AC argon arc welding machines also use it to stabilize the arc. The human body absorbs some radiation energy and experiences biological effects, primarily thermal effects, under the action of the high-frequency electromagnetic field.

The intensity of the high-frequency electromagnetic field can vary based on factors such as distance; the closer the oscillator and oscillation circuit, the higher the field strength. It also depends on the shielding of the high-frequency component.

Long-term exposure to a high-frequency electromagnetic field by a welder can lead to autonomic nerve dysfunction and neurasthenia, resulting in symptoms such as general discomfort, dizziness, headache, fatigue, loss of appetite, insomnia, and low blood pressure.

While the impact of using the high-frequency oscillator for arc striking is relatively small due to the short time, frequent or continuous use of the oscillator as an arc stabilizing device in the welding process can make the high-frequency electromagnetic field a harmful factor.

Thorium tungsten, used in argon arc welding, contains 1% to 1.2% thorium oxide, which is a radioactive element that emits α, β, and γ rays. During welding and contact with thorium tungsten rods, one may be exposed to radiation.

According to numerous investigations, the daily consumption of thorium tungsten rods is only 100 to 200mg, and the resulting radiation dose is small and has little impact on the human body. However, if welding is performed in a poorly ventilated container, the concentration of radioactive particles in the smoke may exceed hygiene standards. Additionally, during the grinding of thorium tungsten rods and in storage areas for thorium tungsten rods, the concentration of radioactive aerosols and dust can reach or exceed hygiene standards.

If radioactive substances enter the body, they can lead to chronic radioactive diseases and internal irradiation, causing symptoms such as a weakened overall functional state, obvious weakness, decreased resistance to infectious diseases, weight loss, and others.

Encyclopedia:

Radioactive aerosols are particles, either solid or liquid, containing radionuclides that are suspended in air or other gases. They are created by a dispersion system in which solid or liquid radioactive particles are suspended in air or other gases.

The defining characteristic of aerosols is their instability. Particles smaller than 0.1 microns move through the gas due to Brownian motion and do not settle due to gravity. Particles between 1 to 10 microns settle slowly and remain suspended in the air for extended periods of time.

Radioactive aerosols are highly ionizing, have low concentrations, and are easily charged by radioactive decay. They pose the main threat to human body irradiation.

Welding arc radiation mainly consists of visible light, infrared, and ultraviolet. These types of radiation can affect the human body by being absorbed into human tissue, leading to thermal, photochemical, or ionization damage.

The brightness of visible light is about 10,000 times stronger than what is normally tolerated by the naked eye. When the eyes are exposed to visible light radiation, it can cause pain, blurred vision, and temporary loss of work ability, commonly referred to as “dazzling.”

Infrared radiation’s harm to the human body primarily comes from its thermal effect on tissue. In welding processes, the eyes are exposed to strong infrared radiation, which can cause immediate burning pain and flash illusion. Long-term exposure can lead to infrared cataracts, vision loss, and even blindness in severe cases.

Ultraviolet radiation (UV), also known as ultraviolet light, refers to electromagnetic waves with a wavelength range of 100-400 nm. While a moderate amount of ultraviolet radiation can have positive effects on the human body, excessive exposure, such as from welding, can have adverse effects.

The harm of ultraviolet radiation to the human body mainly comes from its photochemical action, causing damage to the skin and eyes. Prolonged skin exposure to strong ultraviolet radiation can cause dermatitis, diffuse erythema, blisters, burning, and itching. In severe cases, it can also cause systemic symptoms such as headaches, dizziness, fatigue, nerve excitement, fever, and insomnia.

Excessive exposure of the eyes to ultraviolet radiation can cause acute corneal and conjunctivitis, also known as electro-optic ophthalmia. Its symptoms include photophobia, excessive tearing, foreign body sensation, tingling, eyelid swelling, spasm, headache, and blurred vision.

During welding, a significant amount of metal welding dust is produced. This metal powder has a small diameter, making it easy to inhale into the lungs. Due to its small size, it is challenging to remove from the body, leading to lesions.

The welding current intensity has a direct relationship with the dust concentration, with higher intensity leading to higher concentration.

Without proper dust removal measures, long-term exposure to high concentrations of welding dust can result in occupational diseases such as welder pneumoconiosis, manganese poisoning, and metal heat.

Reproductive toxicity

Over the past decade, various studies have been conducted both domestically and internationally on the reproductive toxicity of electric welding. These studies mainly focus on the semen quality of male workers, the reproductive outcomes of female workers, and the underlying mechanisms of damage.

The results indicate that female welding workers experience a higher incidence of menstrual volume, cycle shortening, menstrual period prolongation, increased leucorrhea, spontaneous abortion, premature delivery, and dysmenorrhea compared to the control group.

Male workers with manganese poisoning were found to have a uniform gray-white appearance in their semen with normal PH value and a longer average liquefaction time compared to the control group. These workers were also found to have a lower average ejaculation volume, total sperm count, sperm survival rate, and motile sperm rate and a significantly higher sperm deformity rate compared to the control group.

It is believed that manganese can negatively impact the spermatogenic system of male workers by having a direct toxic effect on sperm development, resulting in changes to male semen quality.

Studies conducted abroad have also reported that changes in sex hormone secretion and a decline in sperm quality do not affect the sex ratio of offspring.

During welding, high temperature and strong ultraviolet radiation from the welding arc can result in the formation of harmful gases around the arc. These gases include ozone, nitrogen oxides, carbon monoxide, and hydrogen fluoride.

Ozone is a toxic, light blue gas that can be irritating. At high concentrations, it has a fishy odor and a slightly sour taste. Ozone’s main harm to the human body is its strong irritation to the respiratory system and lungs, causing symptoms such as coughing, chest tightness, loss of appetite, fatigue, dizziness, systemic pain, and in severe cases, bronchitis and pulmonary edema.

Nitrogen oxides are also irritant toxic gases, with nitrogen dioxide being reddish-brown and having a distinct odor. The harm to the human body comes from its stimulating effect on lung tissue, causing nitric acid and nitrite to form after entering the respiratory tract. This strong stimulation and corrosion of lung tissue can result in poisoning.

Chronic poisoning symptoms include neurasthenia, such as insomnia, headaches, loss of appetite, and weight loss. High concentrations of nitrogen oxides can cause acute poisoning, with mild toxicity resulting in acute bronchitis and severe poisoning causing severe coughing, dyspnea, collapse, weakness, and other symptoms. The effects of nitrogen oxides on the human body are reversible and decrease over time.

In TIG welding, if proper ventilation measures are not taken, the concentration of nitrogen oxides can exceed hygienic standards by more than ten to twenty times. The hygienic standard for nitrogen oxides in China is 5mg/m3. In the welding process, ozone and nitrogen oxides often exist together, making them more toxic. The toxicity of these two gases combined is generally 15-20 times higher than that of a single gas.

(1) Ventilation measures

A proper ventilation system should be provided at the argon arc welding site to eliminate harmful gases and smoke.

In addition to the general ventilation of the area, multiple axial flow fans can be installed at high-workload welding areas where welding machines are concentrated for external exhaust.

Local ventilation measures can also be taken to remove harmful gases near the arc, such as an open arc smoke exhaust hood, a smoke exhaust welding gun, a portable small fan, etc.

(2) Radiation protection measures

When possible, it is recommended to use cerium tungsten electrodes with a very low radiation dose.

When grinding thorium tungsten electrodes and cerium tungsten electrodes, a sealed or suction grinding wheel should be used.

Operators should wear personal protective equipment, such as masks and gloves, and wash their hands and face after handling the electrodes.

Both thorium tungsten electrodes and cerium tungsten electrodes should be stored in an aluminum container.

(3) Measures for high-frequency protection

To reduce and mitigate the effects of high-frequency electromagnetic fields, the following measures should be taken:

(4) Other personal protective measures

During argon arc welding, due to the strong effects of ozone and ultraviolet light, it is recommended to wear work clothing made of materials other than cotton, such as acid-resistant tweed or tussah silk.

In situations where welding takes place in a confined space and local ventilation cannot be used, personal protective measures such as an air supply helmet, air supply mask, or gas mask should be used.

Argon welding, commonly used in various industrial applications, poses significant respiratory health risks due to the generation of hazardous fumes. These fumes can contain harmful gases and particulate matter that can adversely affect the respiratory system. Understanding the acute and chronic effects of these exposures is crucial for implementing effective safety measures.

Exposure to fumes from argon welding can cause immediate respiratory issues. The inhalation of gases such as ozone and nitrogen oxides can irritate the respiratory tract, leading to symptoms like dryness of the throat, coughing, and chest tightness. For instance, a study by the National Institute for Occupational Safety and Health (NIOSH) found that welders frequently report these symptoms following short-term exposure to welding fumes.

Moreover, inhaling metal fumes can result in metal fume fever, a condition characterized by flu-like symptoms including fever, chills, nausea, headache, fatigue, joint pains, and chest pains. This condition typically appears several hours after exposure and can last for 24 to 48 hours.

Long-term exposure to welding fumes can lead to chronic respiratory conditions. One of the most serious is chronic obstructive pulmonary disease (COPD), which progressively impairs airflow and causes persistent respiratory symptoms such as shortness of breath, wheezing, and chest tightness. COPD results from the chronic inflammation and damage to the lung tissue caused by inhaling toxic particles and gases.

Occupational asthma is another significant chronic condition linked to welding fumes. It involves recurrent episodes of severe shortness of breath, wheezing, coughing, and chest tightness. Research has shown that prolonged exposure to welding fumes can sensitize the respiratory system, leading to the development of asthma.

Welders are at an increased risk of developing various occupational lung diseases due to continuous exposure to hazardous welding fumes. These diseases include bronchitis, emphysema, and pneumoconiosis. Bronchitis is characterized by inflammation of the bronchial tubes, leading to a persistent cough and mucus production. Emphysema involves the destruction of the alveoli, reducing the lungs’ capacity to exchange gases efficiently.

Pneumoconiosis, a type of lung disease caused by inhaling dust, results in lung scarring and reduced lung function. Studies have documented cases of pneumoconiosis among welders exposed to high levels of metal particles over extended periods.

Long-term exposure to welding fumes has been associated with an elevated risk of developing lung cancer. The International Agency for Research on Cancer (IARC) has classified welding fumes as Group 1 carcinogens, indicating sufficient evidence of their carcinogenicity to humans. Epidemiological studies have shown higher incidences of lung cancer among welders compared to the general population.

In addition to lung cancer, there is also an increased risk of cancers of the larynx and urinary tract among welders exposed to welding fumes over long periods. These findings highlight the severe long-term health risks associated with continuous exposure to welding fumes.

To mitigate the respiratory health risks associated with argon welding, it is essential to implement effective safety measures. Proper ventilation systems should be installed to reduce the concentration of harmful fumes in the air. Local exhaust ventilation and fume extractors can significantly decrease exposure levels, ensuring a safer working environment.

Welders should also wear appropriate respiratory protection, such as respirators, to safeguard their lungs from toxic fumes. Regular medical check-ups and adherence to workplace exposure limits are crucial for early detection and prevention of long-term respiratory health issues. Moreover, employers should provide training on the correct use of protective equipment and the importance of maintaining a clean working environment to minimize exposure to hazardous substances.

Ensuring a comprehensive approach to safety can significantly reduce the respiratory health risks associated with argon welding, protecting workers from both acute and chronic respiratory conditions.

Understanding the risks associated with argon asphyxiation in welding is crucial for ensuring the safety of workers in the field. Argon gas, while inert and non-toxic, can displace oxygen in the air, leading to potentially fatal asphyxiation, especially in confined or enclosed spaces.

Argon is heavier than air and can quickly displace oxygen, creating an oxygen-deficient atmosphere. During welding processes such as MIG, MAG, and TIG welding, argon is used as a shielding gas to protect the weld area from atmospheric gases. In confined spaces or areas with poor ventilation, the accumulation of argon can lead to dangerously low oxygen levels. For example, a case study reported an incident where a welder lost consciousness due to argon buildup in a poorly ventilated tank, highlighting the real-world implications of this hazard.

Reduced oxygen levels from argon displacement can cause symptoms of asphyxiation. Initial symptoms include headache, rapid breathing, dizziness, weakness, and fatigue. As oxygen levels drop further, more severe symptoms such as confusion, sleepiness, tremors, loss of coordination, impaired judgment, and lightheadedness can occur. At higher concentrations of argon, symptoms can escalate to nausea, vomiting, unconsciousness, coma, and potentially death if not promptly addressed.

One particularly dangerous aspect of argon-induced asphyxiation is the rapid onset of unconsciousness. The body does not sense the typical breathlessness associated with oxygen deficiency, leading to a sudden loss of consciousness within seconds. This lack of warning can result in a critical situation where the individual becomes incapacitated before they can react. For instance, in another documented case, a worker collapsed within minutes due to argon accumulation, emphasizing the need for immediate response measures.

Welding in confined spaces significantly increases the risk of asphyxiation due to the potential for argon gas to accumulate quickly. Processes like purge damming, which contain gases within the fabrication, can exacerbate the buildup of argon, creating an oxygen-deficient environment. To mitigate these risks, several safety measures should be implemented:

In the event of argon asphyxiation, immediate medical intervention is critical. Treatment involves establishing a rapid and ample oxygen supply, which may include mechanical ventilation. Rescue breathing and the administration of 100% oxygen are recommended to restore normal oxygen levels in the affected individual.

Employers and workers must be educated on the risks associated with argon welding and trained in proper safety procedures. This includes the use of RPE, the importance of maintaining adequate ventilation, and the monitoring of oxygen levels to ensure a safe working environment. By implementing these safety measures and maintaining awareness of the risks, the incidence of asphyxiation due to argon welding can be significantly reduced, ensuring a safer work environment for welders.

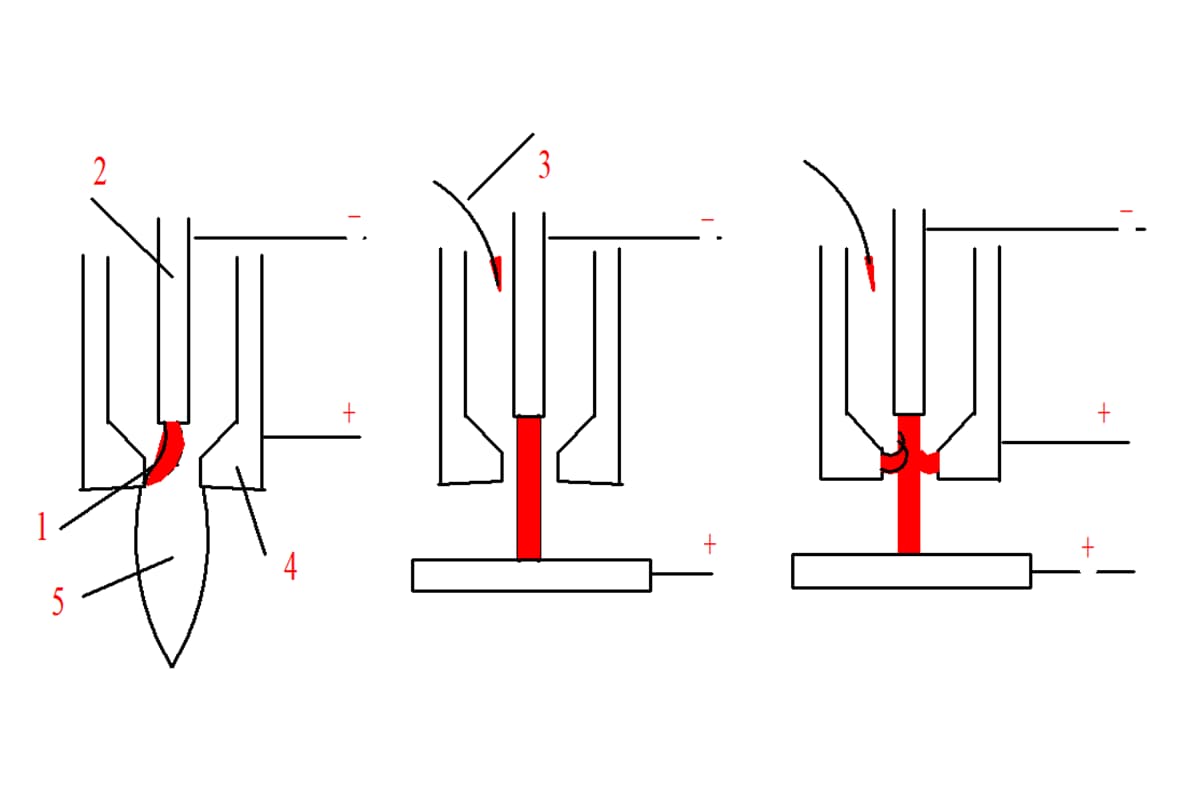

Argon welding is a type of welding process that utilizes argon gas as a shielding gas to protect the weld area from atmospheric gases like oxygen, nitrogen, and water vapor. This technique is commonly used in processes such as MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW), and TIG (Tungsten Inert Gas) welding, also known as Gas Tungsten Arc Welding (GTAW). Argon welding is favored for its ability to produce high-quality, clean welds with minimal contamination.

Exposure to manganese, a component often found in welding fumes, can lead to significant neurological effects. Studies have shown that prolonged inhalation of manganese particles can result in symptoms similar to those of Parkinson’s disease. These symptoms include:

According to occupational health studies, welders exposed to high levels of manganese over extended periods are at a greater risk of developing neurological disorders. For instance, a study published in the “Journal of Occupational and Environmental Medicine” found that welders with prolonged exposure to manganese had a higher incidence of motor function impairments compared to those with lower exposure levels.

Metal fume fever is another health issue that can arise from welding fumes. This condition is caused by exposure to fumes containing metals such as zinc, magnesium, aluminum, and copper. Symptoms of metal fume fever include:

These symptoms typically appear several hours after exposure and can last for 24 to 48 hours. While metal fume fever is generally short-lived, repeated episodes can lead to chronic health issues.

Chronic exposure to welding fumes can result in various central nervous system issues. These include:

Long-term exposure to manganese is particularly concerning, as it can lead to irreversible neurological damage. A study in the “American Journal of Industrial Medicine” highlighted that welders with chronic manganese exposure exhibited significant declines in cognitive and motor functions over time.

Manganese particles, when inhaled, can be absorbed into the bloodstream and transported to the brain, causing systemic neurological damage. This underscores the importance of maintaining strict exposure controls in welding environments.

Other metals present in welding fumes, such as lead and nickel, can also have chronic effects on the nervous system. Lead exposure, for example, can result in lead poisoning, which affects the nervous system, kidneys, digestive system, and mental capacity.

To mitigate the risks associated with argon welding, it is crucial to implement effective safety measures. These include:

By understanding the neurological effects of argon welding and implementing appropriate safety measures, the risks to welders can be significantly reduced.

Welding poses several health risks primarily due to the intense light and heat produced during the process. These risks are influenced by the type of welding being performed. Argon is commonly used in Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW), which are known for producing high levels of ultraviolet (UV) and infrared (IR) radiation.

Arc eye, also known as welder’s flash, is a painful condition caused by exposure to UV radiation from the welding arc. This radiation can damage the cornea and conjunctiva, leading to symptoms such as:

These symptoms can appear several hours after exposure and may last for up to 48 hours. In severe cases, repeated exposure can lead to permanent vision damage.

Conjunctivitis, or inflammation of the conjunctiva, can result from UV radiation exposure. This condition leads to redness, swelling, and irritation of the eye. Protective eyewear is essential to prevent this condition.

Long-term exposure to UV and IR radiation from welding increases the risk of developing cataracts, which cloud the eye’s lens and impair vision. Additionally, there is a heightened risk of ocular melanoma, a rare but serious cancer of the eye. Statistics show that welders have a significantly higher incidence of these conditions compared to the general population, underscoring the importance of proper eye protection.

Direct exposure to UV radiation from welding can cause skin burns similar to sunburn. Symptoms include:

These burns can occur rapidly, even after brief exposure, and can range from mild redness to severe blistering.

Prolonged exposure to UV radiation increases the risk of skin cancer, including melanoma and non-melanoma types. Studies have shown that welders have a higher incidence of skin cancer, making it crucial to wear protective clothing that covers all exposed skin.

Apart from UV radiation, welders may experience skin irritation and dermatitis from contact with weld fumes or other substances released during welding. Symptoms include redness, itching, and blistering. Protective gloves and clothing can help mitigate these risks.

While argon itself is an inert gas and does not directly cause skin or eye irritation, it is essential to understand the associated risks:

By adhering to industry standards for safety equipment and practices, welders can significantly reduce the risks associated with UV and IR radiation, thereby protecting their eyes and skin from serious harm.

Argon welding, while effective for producing high-quality welds, presents several health risks that must be carefully managed to ensure worker safety. These risks stem from the inhalation of welding fumes, exposure to intense radiation, and physical hazards associated with the welding environment.

Welding fumes contain a mixture of metallic oxides, silicates, and fluorides, which can pose significant health risks when inhaled. Studies have shown that welders are at increased risk of developing respiratory conditions such as chronic obstructive pulmonary disease (COPD) and asthma. For instance, research published by the American Welding Society indicates that prolonged exposure to welding fumes can lead to a 30% increase in the prevalence of respiratory issues among welders. Chronic exposure to hazardous substances like manganese, chromium, and nickel found in welding fumes can also contribute to lung cancer.

The welding process generates ultraviolet (UV) and infrared (IR) radiation, which can cause a range of health issues. UV radiation can lead to skin burns and an increased risk of skin cancer. Prolonged exposure can cause cataracts and other eye damage. Using protective gear, including welding helmets with appropriate filter lenses and flame-resistant clothing, is essential to mitigate these risks.

The physical environment in which welding is performed can pose various health risks. These include injuries from heavy machinery, burns from hot metal and welding sparks, and the potential for slips, trips, and falls due to cluttered workspaces. Ensuring a clean and organized work area, along with the use of appropriate personal protective equipment (PPE), can help reduce the incidence of these physical hazards.

Argon gas, used as a shielding gas in welding, is heavier than air and can displace oxygen in confined spaces. This displacement can lead to asphyxiation, characterized by symptoms such as dizziness, headache, nausea, and in severe cases, unconsciousness or death. Proper ventilation and the use of oxygen monitors are critical in preventing asphyxiation incidents.

Ingesting or inhaling certain metals found in welding fumes, such as chromium, nickel, and cadmium, can lead to gastrointestinal problems. These issues can include stomach ulcers and other digestive disturbances. Adequate protective measures, such as the use of respirators and maintaining good hygiene practices, are essential to prevent ingestion of these harmful substances.

Chronic exposure to manganese and other metals present in welding fumes can lead to neurological symptoms similar to those of Parkinson’s disease. These symptoms include tremors, difficulty with coordination, speech and balance disorders, and cognitive impairments. Continuous monitoring of air quality and implementing strict exposure controls can help minimize these neurological risks.

To mitigate the health risks associated with argon welding, it is vital to implement comprehensive safety protocols. These include:

By adhering to these preventive measures, the health risks associated with argon welding can be significantly reduced, ensuring a safer working environment for welders.

Welding fumes are a complex mixture of metallic particles and gases generated during welding processes. These fumes can contain a variety of hazardous substances, including metals like cadmium, chromium, nickel, and manganese, as well as gases such as ozone and nitrogen oxides. The composition of welding fumes depends on factors such as the type of welding being performed, the materials being welded, and the specific welding techniques used. Prolonged exposure to these fumes poses significant health risks to welders.

One of the most significant chronic health risks associated with welding fumes is the development of respiratory diseases. Chronic Obstructive Pulmonary Disease (COPD) is a major concern, characterized by persistent respiratory symptoms and airflow limitation due to airway and alveolar abnormalities. Studies have shown that welders have a higher prevalence of COPD compared to the general population. For example, a study conducted by the American Thoracic Society found that welders had a 16% higher risk of developing COPD.

Welders are also at a higher risk of developing occupational asthma, a condition that causes recurrent episodes of wheezing, breathlessness, chest tightness, and coughing. Long-term exposure to welding fumes can exacerbate these conditions, leading to a progressive decline in lung function.

Welding fumes are classified as carcinogenic to humans (Group 1) by the International Agency for Research on Cancer (IARC). Prolonged inhalation of carcinogenic substances such as hexavalent chromium and nickel significantly increases the risk of lung cancer. Epidemiological studies have shown a higher incidence of lung cancer among welders compared to the general population. For instance, research published in the Journal of Occupational and Environmental Medicine reported that welders had a 30% increased risk of lung cancer.

Welding fumes containing metals like cadmium, lead, and chromium can cause kidney damage over time. Chronic exposure to these metals can lead to chronic kidney disease (CKD) or acute kidney injury (AKI). Cadmium, for example, is known to accumulate in the kidneys and cause tubular damage, leading to impaired kidney function. Similarly, hexavalent chromium can cause renal toxicity, resulting in long-term health complications.

Chronic exposure to manganese in welding fumes can result in neurological damage, manifesting as symptoms similar to Parkinson’s disease. These symptoms include tremors, slow and decreased movement, muscle stiffness, and balance problems. The long-term inhalation of manganese can cause irreversible damage to the nervous system, highlighting the need for stringent exposure controls in welding environments.

In addition to lung cancer, there is evidence suggesting an increased risk of other cancers among welders, including kidney cancer and bladder cancer. The presence of various carcinogenic substances in welding fumes contributes to this heightened risk. For example, exposure to cadmium has been linked to an increased risk of kidney cancer, while hexavalent chromium exposure is associated with bladder cancer.

Chronic exposure to certain metals found in welding fumes, such as chromium, nickel, and cadmium, can lead to gastrointestinal problems. Ingesting or inhaling these metals can cause stomach ulcers and other digestive disturbances. Ensuring adequate protective measures, such as the use of respirators and maintaining good hygiene practices, is essential to prevent ingestion of these harmful substances.

To mitigate the chronic health effects associated with welding fumes, it is crucial to implement effective safety measures.

Installing and maintaining adequate ventilation systems, such as local exhaust ventilation (LEV) and general ventilation, can significantly reduce the concentration of harmful fumes in the air.

Using appropriate PPE such as respirators, gloves, and protective clothing is essential to safeguard against fume inhalation and skin contact. Respirators should be selected based on the specific hazards present and should be fit-tested to ensure proper protection.

Conducting regular monitoring of air quality and exposure levels is important to ensure compliance with occupational safety standards. This can include personal air sampling and area monitoring to identify and control exposure sources.

Scheduling regular medical check-ups for early detection and management of any health issues related to welding fume exposure is vital. Medical surveillance programs can help identify symptoms of respiratory, renal, or neurological damage at an early stage.

Providing comprehensive training and education for welders on the risks associated with welding fumes and the importance of adhering to safety protocols is essential. Training should cover the proper use of PPE, the importance of ventilation, and best practices for minimizing exposure.

By adhering to these preventive measures, the chronic health risks associated with welding can be significantly reduced, ensuring a safer working environment for welders.

Below are answers to some frequently asked questions:

Argon welding, like other welding processes, poses significant respiratory health risks due to the inhalation of harmful fumes and gases. Acute respiratory effects include irritation of the respiratory tract, leading to symptoms such as throat dryness, coughing, and chest tightness. Inhalation of weld fumes can also cause metal fume fever, presenting with flu-like symptoms like fever, chills, nausea, headache, fatigue, muscle aches, and joint pains. Additionally, welding in confined spaces with argon can displace oxygen, increasing the risk of asphyxiation.

Chronic respiratory health effects are more severe and include occupational asthma, which results from repeated exposure to metals like hexavalent chromium, nickel, and cobalt, leading to symptoms such as shortness of breath, wheezing, and coughing. Long-term exposure to welding fumes can also contribute to the development of Chronic Obstructive Pulmonary Disease (COPD), a group of lung diseases that obstruct airflow. Furthermore, prolonged inhalation of carcinogenic substances in welding fumes increases the risk of lung cancer. Welders are also at higher risk for pneumonia, including Welder’s Anthrax, and a condition known as siderosis or welder’s lungs, caused by iron deposits in the lungs, resulting in persistent cough and shortness of breath.

To mitigate these risks, it is crucial to ensure proper ventilation, use respiratory protection, and follow safety guidelines to minimize exposure to harmful fumes and gases during welding operations.

Argon gas can cause asphyxiation during welding primarily by displacing oxygen in the environment. Since argon is an inert and heavier-than-air gas, it tends to accumulate in low-lying areas and confined spaces, such as inside pipes or enclosed fabrications. When argon is used in welding processes, it can create an oxygen-deficient atmosphere, making it dangerous for individuals who enter these spaces. Without sufficient oxygen, individuals can experience symptoms like rapid breathing, increased heart rate, headaches, nausea, and, in severe cases, loss of consciousness and death if oxygen levels drop significantly. The rapid onset of asphyxiation can occur within seconds without any prior warning, making it critical to adhere to safety protocols, such as using oxygen detectors and ensuring proper ventilation, to prevent accidental exposure.

Neurological symptoms resulting from argon welding are primarily linked to the inhalation of welding fumes, particularly those containing manganese. Manganese exposure is a significant concern in welding, especially when working with mild steel. Chronic exposure to manganese can lead to neurological symptoms similar to Parkinson’s disease, including speech and balance disorders, slowness of movement, stiffness in the arms and legs, reduction of facial expression, tremors, and difficulties with motor skills. Studies have indicated that even exposure levels below current regulatory limits can lead to these parkinsonian symptoms, with the severity increasing with prolonged and intense exposure. Additionally, workers exposed to high levels of manganese and other welding fumes may experience mood changes and decreased intellectual capacity. These systemic effects underscore the importance of effective controls and monitoring to mitigate these adverse health outcomes.

Argon welding affects the skin and eyes primarily through the emission of ultraviolet (UV) radiation and exposure to hazardous substances. For the skin, UV radiation from argon welding, especially in processes like TIG welding, can cause severe burns similar to intense sunburns. These burns can occur quickly, even through clothing, leading to redness, pain, and peeling of the skin. Prolonged exposure to UV radiation also increases the risk of skin cancer due to its carcinogenic properties. Additionally, welding can release metals such as nickel and chromium, which may cause allergic contact dermatitis.

For the eyes, UV radiation from argon welding can result in “arc eye” or conjunctivitis, characterized by symptoms like pain, tearing, redness, a gritty sensation, and light sensitivity, often appearing hours after exposure. Long-term exposure to UV radiation can lead to serious conditions like ocular melanoma, a rare eye cancer, and cataracts, which affect the lens of the eye. The intense visible light from welding can also cause temporary blinding and eye fatigue.

To protect against these risks, it is essential to use personal protective equipment such as welding helmets with UV-protective lenses, long-sleeved clothing, gloves, flash jackets, and throat protectors. Ensuring good ventilation in the welding area is also crucial to minimize exposure to harmful fumes and gases.

Argon welding poses several general health risks, primarily due to the environment and by-products associated with the welding process rather than the argon gas itself. One significant risk is asphyxiation and oxygen deficiency, as argon can displace oxygen in the air, especially in confined spaces, leading to symptoms like dizziness, weakness, and potentially fatal outcomes. Welding fumes and particulates generated during the process can contain harmful substances such as iron oxides, nickel, and chromium, posing risks of occupational lung diseases, including lung cancer, chronic bronchitis, and emphysema. Acute respiratory effects include throat irritation, coughing, and fluid in the lungs. Neurological effects from exposure to substances like manganese in the fumes can mimic Parkinson’s disease, with symptoms affecting speech and balance. Additionally, there are risks to ocular health, such as arc-eye and ocular melanoma, and skin and eye irritation from contact with welding by-products. Preventive measures like proper ventilation, use of personal protective equipment, and monitoring oxygen levels are crucial to minimize these health risks.

Long-term exposure to welding fumes, including those produced during argon welding, can lead to several chronic and severe health effects. One of the most significant risks is the development of Chronic Obstructive Pulmonary Disease (COPD), which encompasses conditions like emphysema and chronic bronchitis, characterized by progressive shortness of breath, chest tightness, and wheezing. Occupational asthma is another concern, triggered by repeated exposure to metals such as hexavalent chromium, nickel, and cobalt, resulting in episodes of severe shortness of breath, wheezing, coughing, and chest tightness.

Prolonged inhalation of carcinogenic substances found in welding fumes, such as hexavalent chromium and nickel, significantly increases the risk of lung cancer. The International Agency for Research on Cancer (IARC) classifies all welding fumes as carcinogenic to humans. Additionally, exposure to metals like cadmium, lead, and chromium can cause chronic kidney disease or acute kidney injury due to their accumulation in the kidneys.

Neurological effects are also notable, particularly from exposure to manganese, which can lead to symptoms resembling Parkinson’s disease, including speech and balance disorders. Other potential chronic health risks include increased risks of kidney and bladder cancers, reduced lung function, and conditions like pneumoconiosis and other forms of pulmonary fibrosis. Welders may also face a higher risk of developing severe pneumonia, and chronic exposure to certain metals can cause stomach ulcers and nervous system damage.

These chronic health effects highlight the critical importance of using proper ventilation, respiratory protection, and adhering to safety guidelines to minimize exposure to harmful welding fumes.