What if the crucial seal in your pump fails unexpectedly? Pump seals, while often overlooked, are vital to preventing leaks and ensuring smooth operation. This article dives into the different types of pump seals, common failure points, and practical solutions to maintain and troubleshoot them. By understanding these aspects, you’ll learn how to enhance the reliability and longevity of your pump systems.

Leakage point

There is a variety of mechanical seals for pumps with various models, but there are five common leak points:

Phenomenon: Cracking or Bursting Sound during Operation

Possible Causes:

Solution:

Phenomenon: Continuous Seal Drip

Possible Causes:

Solution:

Phenomenon: Spring Failure

Possible Causes:

Solution:

Phenomenon: Screeching Sound during Operation

Possible Cause:

Solution:

Rubber Asbestos Packing XS250 (with a maximum operating temperature of 250℃) and Rubber Asbestos Packing XS350 (with a maximum operating temperature of 350℃) can be used with steam, water, and alkaline solutions.

Oil-Impregnated Asbestos Packing YS250 (with a maximum operating temperature of 250℃) and YS350 (with a maximum operating temperature of 350℃) has the unique characteristic of being lubricated with oil, resulting in a low friction coefficient and high compression capacity.

These packings are suitable for use with steam, air, industrial water, and heavy petroleum products.

Operating temperature range: -100℃ to 250℃

Suitable for use with: weak acids, strong alkalis, and other corrosive media.

Maximum operating temperature: 120℃

Suitable for use with: river water, tap water, groundwater, seawater, etc.

PTFE woven fiber filler is available in six different grades.

During usage, a minor amount of packing leakage is acceptable at the start.

Once a certain amount of time has passed, it is recommended to adjust the packing gland when the filler has reached a stable state.

It is important not to apply excessive pressure at the beginning to avoid damaging the packing.

Carbon fiber woven seal packing is a cutting-edge material with exceptional strength and modulus.

It boasts several advantages, including high strength, large elastic modulus, heat resistance, chemical resistance, excellent thermal conductivity, low thermal expansion coefficient, and self-lubricating properties, among others.

When starting the operation, it is recommended to lightly pack the gland, allowing for a small amount of media to leak.

After running for a certain period, gradually tighten the packing to bring it to a stable state.

If you encounter leakage during the operation of Carbon PTFE woven packing (FTH-1), you can repeatedly tighten the packing gland.

Phenolic fiber woven packing boasts several advantages, including heat resistance, resistance to acid corrosion, ability to adsorb, excellent thermal insulation, low friction coefficient, wear resistance, non-toxicity to both humans and the environment, and an affordable price.

It is primarily used as a packing seal for high-pressure plunger pumps, high-pressure water pumps, FRP acid pumps, methyl ammonia pumps, reciprocating pumps, and deep well oilfield pumps.

The performance of phenolic fiber woven packing can be seen in the following table.

It is suitable for a variety of media, including acids, alkalis, organic solvents, engine oil, steam, and water.

Expanded graphite (also known as flexible graphite) is a material with many exceptional qualities, including self-lubricating properties, corrosion resistance, resistance to extreme temperatures, radiation resistance, abrasion resistance, and a low coefficient of friction. Additionally, it has the benefits of being flexible, lightweight, and able to retain its shape even under compression, making it suitable for use over a wide range of temperatures.

Expanded graphite can be used with mediums that have a PH value ranging from 0 to 14. With the exception of aqua regia, concentrated nitric acid, concentrated sulfuric acid, and high-temperature dichromate (among a few other strong oxidizing media), it can be used with most other media.

When installing the stuffing ring, it should be cut with a razor blade prior to being loaded into the stuffing box. There should be a limited amount of axial twist, and it should be set onto the shaft and pressed into the stuffing box, with the cutouts being staggered every 900 or 1200 degrees per turn.

At the beginning of operation, a small amount of leakage is allowed, and the amount of leakage should decrease over time.

This material has excellent thermal conductivity, electrical conductivity, chemical stability, resistance to thermal shock, self-lubricating properties, and is easy to process.

In the pump industry, it is utilized for various applications such as end seals, up-ring seals, mechanical seal rings, axial seals, and rotary vane seals in centrifugal pumps, shielding pumps, diesel distribution pumps, submersible pumps, clean water pumps, high-temperature hot oil pumps, nuclear secondary pumps, boiler feed pumps, and gas pumps.

Natural Rubber: It is known for its excellent flexural resistance, good abrasion resistance, cold resistance, insulation, and high tear strength. However, it has poor weather resistance, aging resistance, oil resistance, and solvent resistance. The natural rubber pumps are suitable for working temperatures below 78°C and are ideal for conveying various abrasive slurry, weak acid and weak alkali solutions. However, they are not suitable for conveying strong acids, oils, aliphatic and aromatic solutions.

Nitrile Rubber: Nitrile rubber is the most widely used oil-resistant rubber, boasting superior properties such as higher abrasion resistance (30-45% higher than natural rubber) and better high-temperature resistance compared to natural rubber and styrene-butadiene rubber. However, its weathering resistance is poor. Nitrile rubber pumps can withstand temperatures up to 95°C and are resistant to animal and vegetable oils, mineral oil, and glycol.

Butyl Rubber: Butyl rubber lined pump parts are suitable for use with acid mud. The maximum temperature it can withstand is 100°C and it is resistant to strong acids and alkalis (such as hydrochloric acid and sodium hydroxide). However, high concentrations of oxidizing acids (such as concentrated sulfuric acid and concentrated nitric acid) will cause degradation of butyl rubber.

Fluorine Rubber: Fluorine rubber is known for its excellent heat resistance, ozone resistance, oil resistance, and resistance to various chemical erosions after vulcanization. However, it is worse in processing and bonding compared to general-purpose rubber and is more expensive. Fluoroelastomer pumps can be used up to 170°C in ordinary mediums.

Corundum ceramics (mainly composed of AI2O3):

It boasts high hardness, excellent abrasion resistance, chemical stability, high insulation, and a high melting point.

In the pump industry, it is primarily used in special working conditions, such as in ceramic pumps and mechanical seal rings.

Ceramics can withstand almost all corrosive media, including hot concentrated nitric acid, sulfuric acid, hydrochloric acid, aqua regia, salt solutions, and organic solvents, with the exception of hydrofluoric acid and some other substances containing fluorine and hot or concentrated alkali.

Silicon nitride ceramics:

It has better thermal shock resistance compared to alumina ceramics, and its other properties are similar to those of alumina ceramics.

Silicon carbide ceramics:

It has excellent chemical resistance, high mechanical strength, good abrasion resistance, high temperature resistance, self-lubrication, and a small coefficient of friction, making it suitable as a high-temperature structural material, mechanical seal for pumps, and magnetic pump shafts, offering more significant advantages than ordinary ceramics.

Silicon carbide is currently an ideal friction material, often paired with carbon-graphite.

Its dry sliding friction coefficient is lower than that of alumina and carbide, and its PV value is higher than that of alumina and carbide.

Silicon carbide ceramics have excellent wear resistance and can resist almost all chemical corrosion, except for hydrofluoric acid and a few other media, including concentrated nitric acid, sulfuric acid, hydrochloric acid, and other strong corrosive liquids.

Ferrite permanent magnets have several advantages over metal permanent magnets, such as a high coercive force, good insulation, resistance to external magnetic field interference, and a low price. These characteristics make ferrite permanent magnets ideal for use as magnets in both internal and external rotors of magnetic pumps.

Rare earth cobalt permanent magnets are known for their exceptional magnetic properties, particularly their highest coercive force and magnetic energy product compared to other types of permanent magnets.

Although these magnets are suitable for use as ground permanent magnets in magnetic pumps, they are not as widely used due to their high cost.

Pump Paint:

It serves the purpose of protection, decoration, and marking. It can be classified into several categories based on its usage, such as anti-rust paint, insulation paint, and acid paint, etc. It can also be categorized based on the level of painting, such as primer, topcoat, and putty, etc.

Paper Cushion Material for Centrifugal Pump:

Felt material is utilized in pumps as an oil seal to prevent the entry of water and dust. It helps to seal the lubricating oil at the point of friction. This material can be further divided into fine wool felt, semi-coarse wool felt, and coarse wool felt.

Industrial Vulcanized Rubber Sheet (GB5574-85):

This material includes various types of rubber sheets like ordinary rubber sheet, acid and alkali-resistant rubber sheet, oil-resistant rubber sheet, and heat-resistant rubber sheet.

The pump’s sealing device is primarily categorized into two types: static sealing and dynamic sealing.

Static sealing typically encompasses gasket seals, O-ring seals, and thread seals.

Dynamic sealing primarily includes soft packing seals, oil seals, labyrinth seals, spiral seals, dynamic seals, and mechanical seals.

Rubber O-rings are a popular choice for use in pumps due to their simple shape and low cost of manufacture. Despite the overall size of the O-ring, its cross-section is small, usually only a few millimeters, making it lightweight and efficient in terms of material consumption. These features also make it easy to install and disassemble.

One of the most notable advantages of O-rings is their excellent sealing capability and wide range of applications. The static seal can handle working pressures of over 100MPa, while the dynamic seal can withstand up to 30MPa. Additionally, the suitable temperature range for O-rings is -60 to 200 ℃, making it suitable for a variety of media.

As a result, O-rings are becoming increasingly popular in pump design. They are installed between the groove and the surface to be sealed and are subjected to a certain amount of compression, which generates a reaction force that applies initial compressive stress to the smooth surface and bottom of the groove, thus providing a seal.

When the pressure of the sealed liquid increases, the O-ring undergoes increased deformation, which transfers increased pressure to the sealing surface, enhancing the sealing effect. This is why O-rings are known for their good sealing ability.

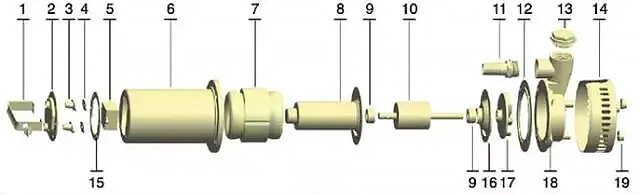

| NO. | Name | NO. | Name | NO. | Name |

| 1 | handle | 8 | stainless steel shield | 15 | gaskets |

| 2 | barrel cover | 9 | graphite bearings | 16 | joint |

| 3 | cable guard | 10 | rotors | 17 | impeller |

| 4 | line pressing gasket | 11 | drainage outlet | 18 | pump |

| 5 | capacitors | 12 | gaskets | 19 | footing |

| 6 | barrel | 13 | plug | ||

| 7 | stator (coil renewal group) | 14 | strainer |

A commonly used sealing method for chemical pumps is the gasket sealing method. The gasket is a critical component of the static seal in centrifugal pumps and is widely used. The selection of the gasket is mainly based on factors such as the conveyed medium, temperature, pressure, and corrosiveness of the chemical pump.

Gasket sealing mechanism:

Leakage refers to the flow of a medium from within to outside of a confined space or from outside to the interior of the confined space. This occurs through the interface of the internal and external space, i.e., the leaking sealing surface.

The cause of leakage is the presence of a gap on the contact surface, driven by the pressure and concentration differences on either side of the surface. Improper sealing surface form and machining accuracy can result in gaps that lead to leakage.

To reduce leakage, it is important to maximize the mating of the contact surface, reducing the cross-sectional area of the leakage channel and increasing the resistance to leakage to be greater than the driving force.

When stress increases to the point of causing significant plastic deformation on the surface, the gap on the sealing surface can be filled, blocking the leakage channel.

A gasket is used to take advantage of the material’s ability to undergo plastic deformation under compression load, which helps fill in small unevenness on the flange sealing surface to achieve a seal.

Gasket selection:

Chemical pump seals and gaskets play a critical role in ensuring the safety of the pump. The presence of corrosive, volatile, and potentially explosive materials in the pump’s extraction medium requires that the sealing performance of the pump body be significantly higher compared to other types of pumps.

Gasket sealing is a commonly used method in chemical pumps. The gasket is a key component of the centrifugal pump’s static seal and is widely used.

The selection of the gasket is mainly based on factors such as the chemical pump’s conveyance medium, temperature, pressure, and corrosiveness.

For chemical pumps with low-temperature and low-pressure conveyance media, non-metallic sealing gaskets are generally used. When the medium has medium pressure and high temperature, non-metallic and metal composite gaskets are chosen.

Non-metallic gaskets, made of materials such as paper, rubber, and polytetrafluoroethylene (PTFE), are widely used in pumps. For temperatures not exceeding 120°C and pressures below 1.0 MPa, green shell paper or die paper gaskets are typically used. For oil transmission media with temperatures between -30°C and 110°C, NBR with good aging resistance is usually selected. Fluororubber is a suitable choice for chemical pump media with temperatures between -50°C and 200°C due to its oil and heat resistance as well as its high mechanical strength.

In chemical pumps, due to the corrosive nature of the medium, PTFE is often used as a gasket material. As chemical pumps are becoming increasingly more widespread and are being used to transport a growing variety of media, it is important to refer to relevant information or conduct experiments to make the correct gasket material selection.

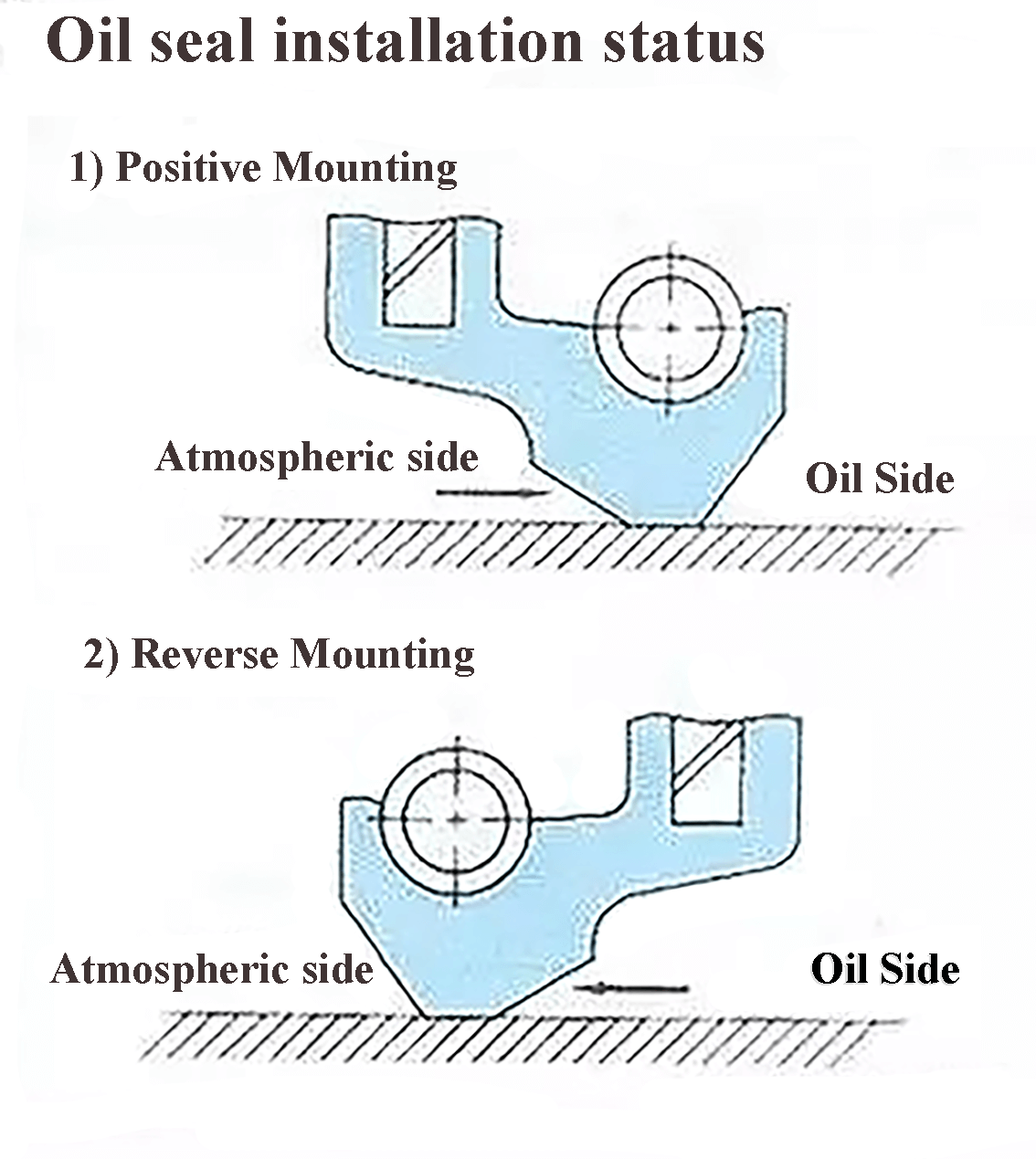

The chemical pump oil seal is a self-tightening lip seal that is characterized by its simple structure, compact size, low cost, ease of maintenance, low resistance torque, and the ability to prevent medium leakage, dust, and other harmful substances from entering. Additionally, it has a certain level of compensation for wear.

However, it is not designed for high-pressure applications and is typically used in low-pressure chemical pumps.

Chemical pumps work by utilizing the centrifugal principle to transfer liquid materials. These pumps, made from specialized materials, are ideal for transferring corrosive liquids from containers such as bottles, barrels, tanks, or pools.

Due to the inherent dangers posed by the medium being transferred, such as corrosion, volatility, and explosions, the sealing requirements for chemical pumps are significantly higher compared to other types of pumps.

To ensure proper sealing, the chemical pump oil seal should be installed on the shaft with a manufacturing accuracy of H8-H9 and a surface roughness of 1.6-0.8 μm, with a surface hardening treatment applied.

It is important to ensure that the sealing medium is free of solid particles and impurities, as this can cause rapid wear of the oil seal and shaft, rendering the seal ineffective.

When selecting this sealing method, it is important to consider the performance and requirements of the materials being transferred by the chemical pump to avoid leaks and potential accidents.

The main factors causing oil leakage of oil seal:

Oil leakage is often caused by poor sealing of the oil seal. If the seal diameter is too small, it may not make contact with the shaft, leading to leakage.

The following are the main factors causing poor sealing of the S195 diesel engine crankshaft oil seal:

It is important to address these factors to ensure proper sealing and prevent oil leakage.

Measures for oil leakage due to loose seal of oil seal:

(1) Familiarize yourself with the basics of identifying fake and substandard products and choose high-quality and standard oil seals.

(2) During installation, if the shaft diameter has low outer surface roughness or there are rust spots, burrs, or other defects, use a fine sand cloth or oilstone to polish and smooth it. Apply clean engine oil or lubricating grease to the corresponding position of the oil seal lip or shaft diameter.

Coat the outer ring of the oil seal with sealant, and wrap the keyway on the shaft with hard paper to prevent scratching the oil seal lip. Use special tools to rotate the oil seal inward, and do not use force to prevent deformation or damage to the spring.

If there is lip flanging, spring falling off, or oil seal skewing, remove and re-install it. Note that if the shaft diameter is not worn and the spring force of the oil seal is sufficient, do not tighten the inner spring without authorization.

(3) Oil seals used in machinery often face poor working conditions, large temperature swings, dust, and frequent vibration. When the force conditions of machine parts change frequently, it is important to check, maintain, and repair them regularly.

(4) If the shaft diameter and bearing wear are severe, repair or replace the oil seal rubber or spring as soon as possible.

(5) Remove any parts that are abnormally heating, and avoid mechanical overspeed and overload to prevent lip temperature rise, rubber aging, and early lip wear.

(6) Regularly check the oil level, and if there are too many impurities or metal scraps in the oil, replace it thoroughly. Choose a brand and quality of oil that meets seasonal requirements.

Consider adding Maitrey Super Sealant & Lubricant to the engine oil, as it is an excellent gearbox additive that forms an inert material film on components. This can slow down oil seal leakage, extend the service life of the oil seal gear, and reduce gearbox noise. This super sealing lubricant will not pollute or deteriorate the oil.

There are two common forms of thread seals in chemical pumps: screw joint gasket seal and screw thread plus filler seal. Both forms are used in sealing connections of small diameter threads.

The gasket acts as the sealing element in a screw electric diaphragm pump with gasket seal, while the thread only provides pressing force.

The roughness of the sealing surface and the precision of its relative geometric position with the threaded hole also greatly impact the sealing effect, in addition to the performance of the gasket.

When tightening the thread, the gasket is subjected to compression force and torque, which can cause it to deform or become damaged. As a result, gasket seals are only suitable for chemical pumps with low pressure. If the gasket is made of metal, it can handle pressures of over 30MPa.

Another form of thread sealing in chemical pumps is the use of a plug. To keep the cost of screw plug manufacturing low, the screw thread alone is not sufficient for sealing, and the thread gap is often filled with a filler such as raw tape or sealant.

The bearing capacity of the screw plug depends on the accuracy of its manufacturing and the material of the thread, and is not affected by the matching form of the plug and threaded hole.

Whether “cone to cone” or “column to cone” is used for the threaded hole and plug, the sealing effect is the same, but the areas of use differ.

When the design is sound, the processing is top-notch, the assembly is of high quality, and the rotating speed is high, the labyrinth sealing effect is very effective.

However, in real-world applications, chemical pump leaks are common, which is why labyrinth seals are not widely used in chemical pumps.

The reasons for this include:

The medium transported by the chemical pump poses a risk of corrosion, volatilization, and explosion, which is why the sealing performance of the pump must be significantly higher compared to other pump types.

However, the use of labyrinth seals increases the likelihood of material leaks in chemical pumps.

As a result, labyrinth seals are generally not used in chemical pumps.

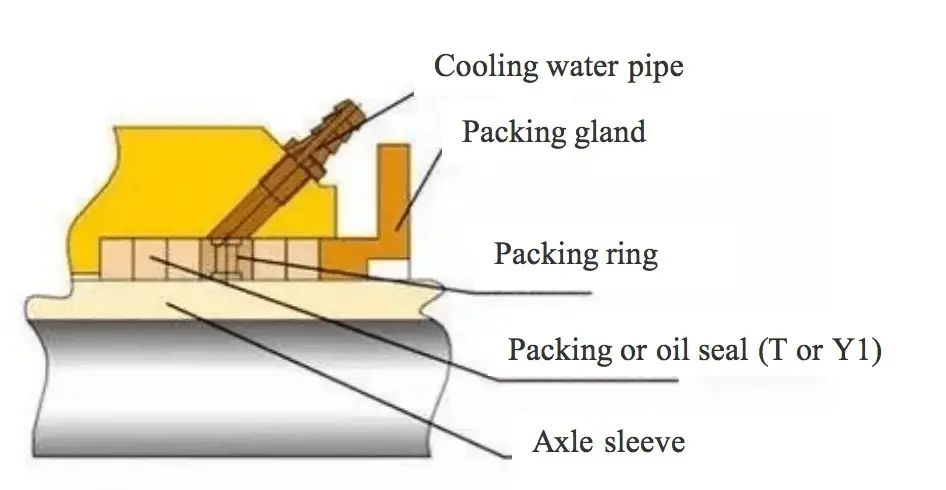

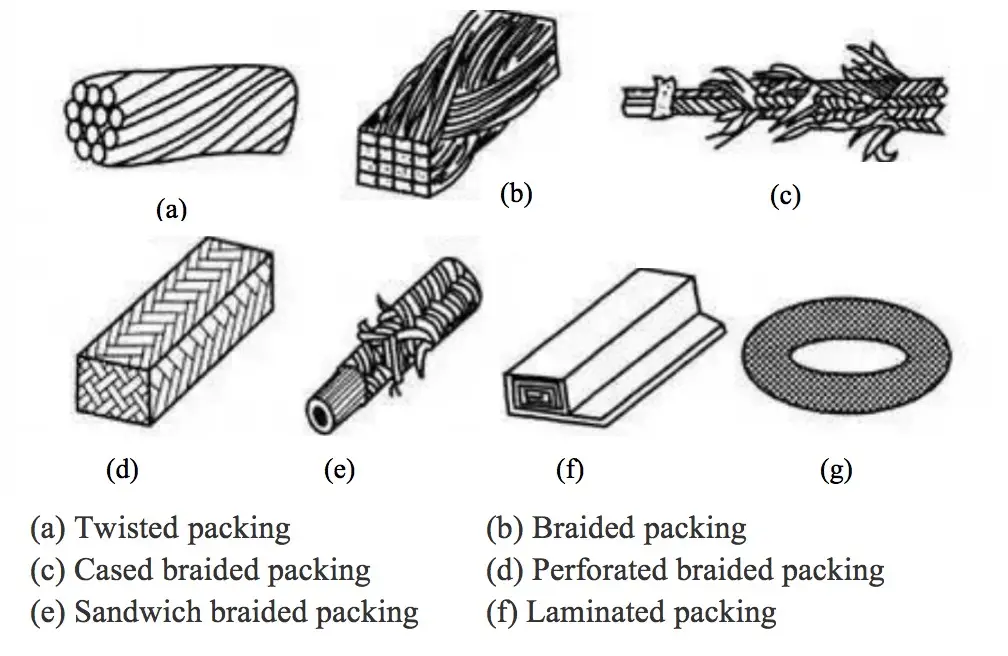

The packing seal of a chemical pump involves inserting a compressible and resilient packing into the stuffing box. The axial compression force exerted by the gland is then transformed into radial sealing force, providing a sealing effect.

This sealing method is referred to as a packing seal, with the packing material referred to as sealing packing.

The packing seal is a popular choice in chemical pump design due to its simple structure, ease of replacement, low cost, and versatility in adapting to different speeds, pressures, and media.

Principle of packing seal:

In the machinery industry, packing seals are mainly used as dynamic seals and are commonly found in centrifugal pumps, compressors, vacuum pumps, and mixers as shaft seals. The packing is placed in the packing chamber and compressed axially by the gland screw. When there is relative movement between the shaft and the packing, a radial force is generated and the packing closely contacts the shaft due to the plasticity of the filler. This also causes the lubricant within the packing to be squeezed out, forming an oil film between the contact surfaces.

However, due to the non-uniform contact state, some parts of the packing will contact the shaft while others won’t. This boundary lubrication state is referred to as the “bearing effect”. The contact and non-contact parts create an irregular labyrinth, which prevents the leakage of liquid flow, known as the “labyrinth effect.”

Good sealing is achieved by maintaining both the “bearing effect” and “labyrinth effect.” Poor lubrication or excessive pressure can cause the oil film to break, leading to dry friction between the packing and the shaft, eventually resulting in shaft damage and wear.

To avoid this, the compaction degree of the packing must be frequently adjusted to ensure proper lubrication and compression. Over time, the lubricant within the packing may be lost, so some lubricant must be squeezed out to compensate for the relaxation of compression force caused by the change in packing volume. However, frequent extrusion of the filler can eventually cause the impregnant to dry out, so the filler must be replaced regularly.

Finally, to maintain the liquid film and remove friction heat, a small amount of leakage must be allowed at the packing.

The problems of packing seal in the use of chemical pump:

The chemical pump is commonly equipped with a shaft seal, which boasts advantages such as wear resistance, heat resistance, good flexibility, and high strength.

However, the use of packing also has some drawbacks:

The rough surface of the packing leads to high friction coefficient and increased likelihood of leaks. Furthermore, the lubricant used for a long time may become depleted.

Initially, the shaft seal of newly repaired equipment performs well, but after a short period of operation, leaks start to occur more frequently. The need for adjusting the gland and replacing the packing becomes more frequent, and the shaft sleeve may become worn into a shape resembling a vase after just one cycle of operation. In severe cases, the shaft sleeve can even break and the water seal ring may be unable to play its sealing role due to rotted, irreplaceable packing.

The constant friction between the rotating packing and the shaft or shaft sleeve leads to wear and tear, necessitating regular or irregular replacement of the sleeve.

To ensure that the friction heat between the packing and the shaft or shaft sleeve dissipates in a timely manner, a certain amount of leakage must be maintained, which can be difficult to control.

Additionally, the friction between the packing and the shaft or shaft sleeve reduces the effectiveness of the packing seal, which affects the motor’s power output and increases energy consumption.

Performance and causes of packing seal failure:

According to the principle of packing seal, there are three sources of leakage in the sealing cavity:

The main faults and their causes are as follows:

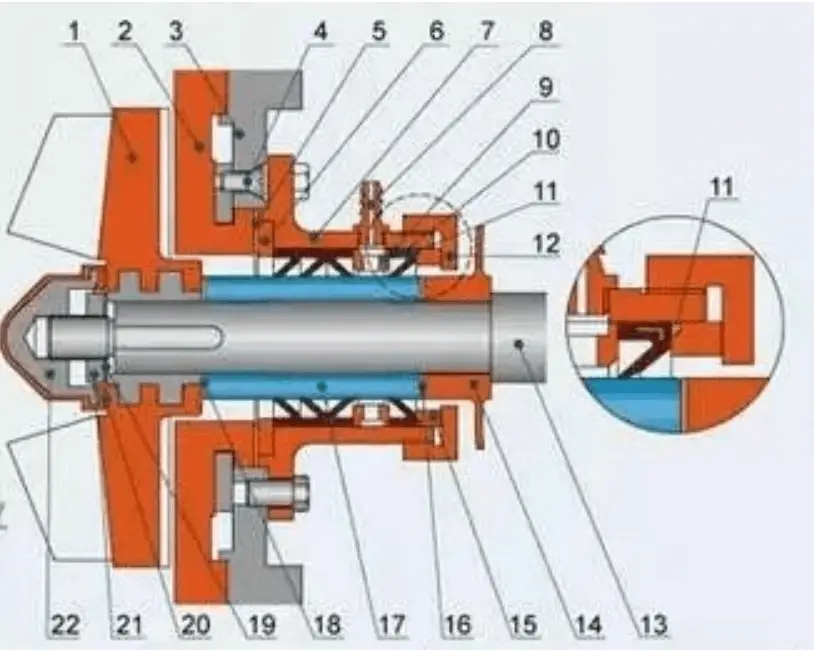

Partial view of K-type dynamic seal with cooling water

| 1. Impeller | 7. Sealing box | 13. Spindle | 19. Spring washer |

|---|---|---|---|

| 2. Pump | 8. Cooling water nozzle | 14. Block acid piece | 20. Lock nut L cushion |

| 3. Back shroud | 9. Water seal ring | 15. Top ring | 21. Locking nut |

| 4. Cross connecting screw | 10. K-ring | 16. Shaft sleeve gasket | 22. Locknut |

| 5. Sealing box gasket | 11. O-ring | 17. shaft sleeve | |

| 6. Gasket block of sealing box | 12. Sealing box cover | 18. Impeller pad |

When the chemical pump is in operation, the pressure generated by the auxiliary impeller balances the high-pressure liquid at the pump’s outlet, ensuring a proper seal.

During shutdown, the auxiliary impeller stops functioning, so it must be equipped with a shutdown sealing device to prevent chemical leaks.

The auxiliary impeller has a simple and reliable seal structure, with a long service life, ensuring there are no leaks during pump operation.

As a result, it is frequently used in pumps that convey impure media in the chemical industry.

There are various types of seals, including centrifugal seals, spiral seals, and magnetic fluid seals. The spiral seal is particularly promising.

The fully enclosed seal can be either diaphragm type or shielding type, among others.

1) Centrifugal power seal

The Principle of Centrifugal Power Seals:

A centrifugal dynamic seal works by expelling liquid media in a radial direction through centrifugal force, thus preventing liquid from entering the leakage gap to achieve a sealing effect. This type of seal is only suitable for liquid media and not for gas media.

Therefore, if airtightness is required in the application of a centrifugal seal, a combination of centrifugal seals and other sealing types must be used.

The most commonly used centrifugal seal is the oil slinger, which is widely used in various transmission devices to seal lubricating oil or other liquids. The higher the speed of the oil pan, the better the sealing performance. On the other hand, if the speed is too low or there is no rotation, the oil slinger seal becomes ineffective.

Additionally, the oil slinger seal is not limited by high temperature, making it a suitable option for high-temperature, high-speed applications such as a heat transfer oil pump. However, it cannot be used in high-pressure applications and is typically used in situations with a zero or near-zero pressure difference.

The centrifugal oil slinger has the advantages of a simple structure, low cost, no friction power consumption, no wear, and low maintenance, making it a widely used option.

The Structure of Centrifugal Seals:

A centrifugal seal is an oil slinger sealing device without an oil pan. On a smooth shaft, the adhesion of the liquid medium makes it easy for it to leak along the surface of the shaft. However, if there are one or two ring grooves on the axis, it becomes difficult for the liquid to cross the sharp interface on the ring groove. With the help of the centrifugal force from the rotating shaft, it is easy to shake off the liquid and ensure sealing.

The centrifugal oil slinger is integrated with the shaft, which blocks liquid trying to leak, and throws the liquid to the circumference of the sealing cover under the action of centrifugal force. The liquid then flows into the oil return hole below for oil return.

A ring groove is located at the junction of the sealing cover and the oil slinger, allowing liquid on the sealing cover wall to flow down the ring groove instead of into the gap between the sealing cover and the shaft.

When designing a centrifugal oil slinger sealing device, it is important to reduce the radial clearance and axial clearance between the oil slinger and the sealing cover as much as possible, in order to reduce the radial clearance between the sealing cover and the shaft. The ring groove of the sealing cover should be large enough, the oil throwing space between the sealing cover and the oil slinger should be large enough, and the oil return channel should be as smooth as possible.

The seal of the oil slinger impeller is equivalent to several pieces arranged on one or both sides of the oil pan, which supports the blowing effect produced by the impeller rotation. This throws leaked lubricating oil to the return hole along with radial flow, thus reducing lubricating oil deviation along the shaft.

The size of the impeller blades should not be excessive and there should not be too many of them. This is because a strong airflow combined with a mix of lubricating oil can cause foam to form, which impairs the return of oil and increases power consumption.

Back blade seals and auxiliary impeller seals are frequently used as shaft seals in centrifugal pumps.

In order to stabilize the flow and enhance sealing capacity, a set of fixed guide vanes are often placed within the seal chamber of the auxiliary impeller. This helps reduce the pressure on the smooth surface of the auxiliary impeller.

One of the benefits of centrifugal power seals is that they do not have direct friction contact and can accommodate a wide sealing gap. This makes them suitable for sealing media containing solid impurities and they have low wear, long service life, and a reliable design with zero leakage.

However, they have limited ability to handle pressure differences and consume a significant amount of power, sometimes up to one-third of the pump’s useful power.

Additionally, being a dynamic seal, the sealing capacity is lost as soon as the pump stops, and therefore, must be supplemented by a parking seal.

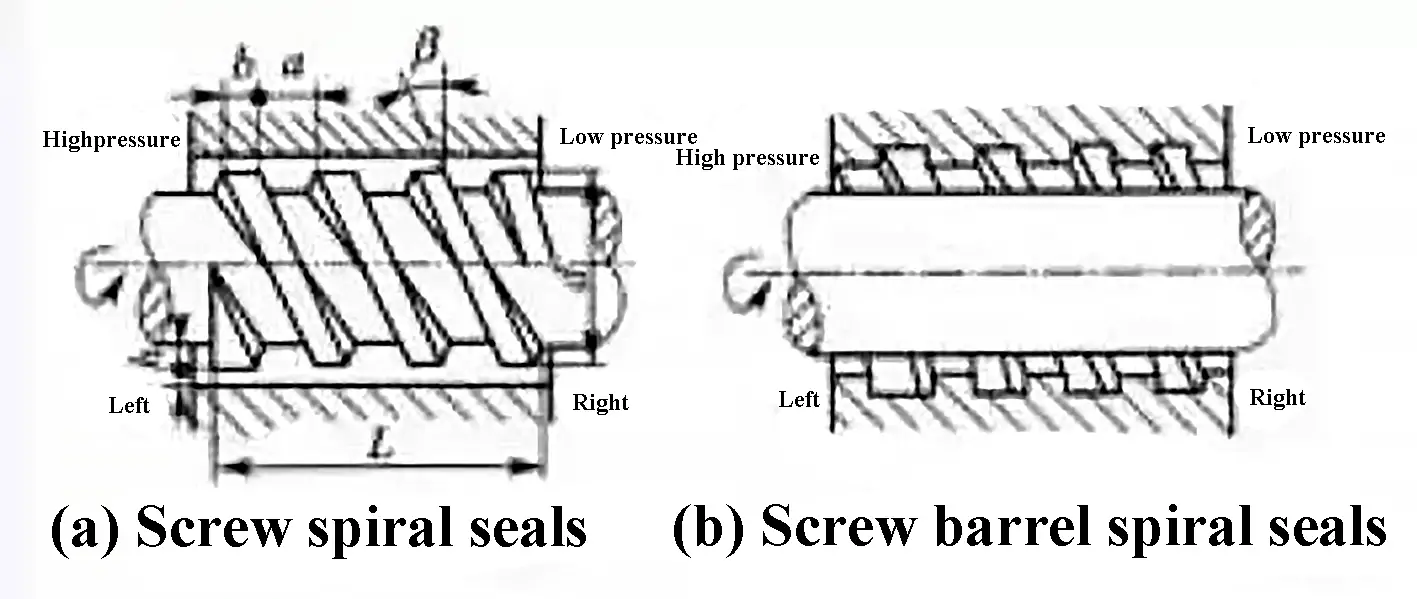

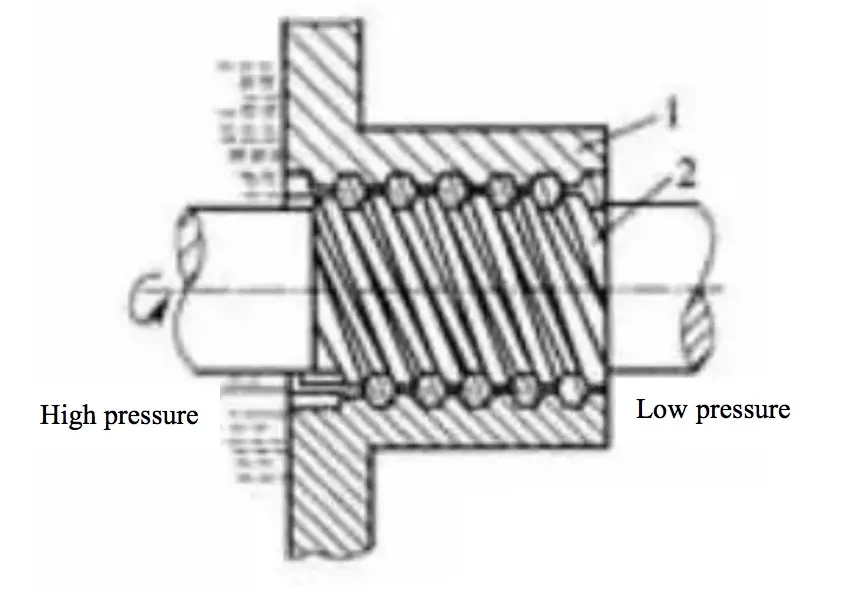

2) Spiral dynamic seal

The working principle of a screw dynamic seal is similar to that of a screw pump. If a screw thread is cut into the shaft (or the screw groove is engraved on the shell or both), the rotation of the shaft will be clockwise.

The friction between the liquid medium and the shell produces a counterclockwise force, and the component of this friction force F along the right-handed thread is to the right, causing the liquid to be pushed to the right, just as a nut moves along a screw.

As the volume decreases, the pressure head increases, balancing the established sealing pressure with the pressure of the fluid being sealed, thus preventing leaks.

When designing a screw seal device, it is important to pay attention to the direction of the screw oil displacement. If there is an error in this direction, the seal will not function properly and leaks may occur.

Note that the screw seal is a type of dynamic seal, and its sealing function may be lost when the device is at rest or operating at low speeds. In such cases, a stop seal may be necessary, which adds complexity to the device and requires adequate axial space.

8. Mechanical seal

The mechanical seal, also referred to as an end-face seal, is currently the most widely used form of seal in the chemical pump industry due to its low leakage and long service life. It is considered the main shaft sealing mode for this type of equipment globally.

According to relevant national standards, a mechanical seal is defined as a device that prevents fluid leakage through at least one pair of end-faces that are perpendicular to the rotating axis, relying on fluid pressure and the elastic (or magnetic) force of the compensation mechanism, in coordination with auxiliary seals.

The widely used corrosion-resistant PTFE mechanical seals are effective in preventing fluid leakage.

It is important to note that any form of seal must prevent the chemical centrifugal pump from idling, as idling can cause the seal to fail.

Principle of mechanical seal:

Mechanical seals, also referred to as end face seals, are shaft seal devices used in rotating machinery to prevent fluid leaks. They work by using a pair of end faces perpendicular to the rotating axis, along with the pressure of the liquid and the elastic force of a compensation mechanism, to create a tight seal.

Mechanical seals are commonly used in pumps, boilers, compressors, and other similar rotating shaft equipment. They are made up of a moving ring, static ring, pressing element, and sealing element.

The moving ring rotates with the pump shaft and fits closely against the static ring to form a sealing surface, which prevents the escape of the medium. The pressure of the liquid in the seal chamber presses the end face of the moving ring against the end face of the static ring, creating a thin liquid film and a proper specific pressure to achieve a seal.

The compression element generates pressure, keeping the end face of the pump close together when the pump is not running and preventing leaks and the entry of impurities. The sealing element includes an elastic element to buffer pump vibrations and impacts, as well as clearances between the moving ring and the shaft and between the static ring and the gland.

Mechanical seals are integrated with other parts of the pump during operation. The performance of the mechanical seal is dependent on its own components, the auxiliary sealing device, and the technical requirements for installation. To ensure the proper functioning of the mechanical seal, it is important to first meet these requirements.

The problems existing in the use of the mechanical seal in the chemical pump are as follows:

Mechanical seals in rotating equipment can fail due to various reasons, including wear on the seal faces, hot cracks, deformations, and damages. Over time, the springs can also become relaxed, fracture, and corroded.

Additionally, the auxiliary seal rings can experience cracks, twists, deformations, and fractures.

Failure performance and causes of mechanical seal:

The screw seal is a type of dynamic seal that is created by machining a spiral groove onto either the rotating shaft or the sleeve that surrounds the shaft. A sealing medium is filled between the shaft and sleeve to prevent fluid from leaking.

As the shaft rotates, the spiral groove creates a conveying effect similar to that of a pump, which helps to maintain the sealing fluid. The sealing capacity of the screw seal is influenced by factors such as the screw angle, pitch, tooth width, tooth height, action length of the tooth, and the clearance between the shaft and sleeve.

One of the advantages of the screw seal is its long service life, as there is no friction between the seals. However, the sealing ability is limited due to the short length of the screw, which is often constrained by structural space limitations. Additionally, when the pump is operated at a reduced speed, the sealing effect of the screw seal is greatly reduced.

The Dry Gas Seal, also known as the “Dry Running Gas Seal,” is a new type of shaft-end sealing technology that utilizes slotted seal technology for gas sealing and is considered a non-contact seal.

Principle of dry gas seal:

When a moving ring with a hydrodynamic groove (ranging from 2.5 to 10 micrometers) is positioned at the outer edge of the end face, the hydrodynamic groove creates a flow that pumps high-pressure isolated gas from the outer diameter (also known as the upstream side) into the sealing surface.

The pressure of the gas film increases progressively from the outer diameter towards the groove diameter and decreases gradually from the groove diameter towards the inner diameter.

As a result of the increased pressure at the end mask, the opening force is stronger than the closing force applied to the sealing ring.

A thin layer of air (1-3 millimeters) is created between the friction surfaces, allowing the seal to operate in a non-contact state.

This formed gas film effectively blocks the leakage of the relatively low-pressure sealing medium, achieving zero leakage or escape of the sealing medium.

The chemical pump is frequently used for transporting corrosive or toxic volatile substances, making its sealing performance a crucial factor in determining the quality of the pump.

When selecting a chemical pump, the following standards should be considered.

For static seals, only seal rings and gaskets are typically used, with O-rings being the most commonly used sealing rings.

For dynamic seals, packing seals are rarely used and are mainly replaced by mechanical seals, which can be further divided into single end face, double end face, balanced, and non-equilibrium types.

The balanced type is better suited for sealing high-pressure media, typically defined as pressures greater than 1.0 MPa.

Double end face mechanical seals are mainly used for media with high temperature, a tendency to crystallize, high viscosity, and the presence of particles or toxic volatilization.

An isolation liquid should be introduced into the sealing cavity, with a pressure that is generally 0.07 to 0.1 MPa higher than the medium pressure.

For chemical pump static sealing, fluororubber materials are commonly used. In special cases, PTFE materials may be used instead.