Are you overwhelmed by the fluctuating prices of fiber laser cutting machines? From basic models to advanced configurations, prices can vary significantly. This article breaks down the factors influencing these costs, including brand, bed size, power, and key components. You’ll discover how to navigate these variables to make an informed decision, ensuring you invest in the right machine for your needs.

No matter what kind of equipment, price factors have a great impact on customers’ purchase intention.

Laser cutting machines are no exception.

When consulting, the first sentence the customer asked was: “how much is the price of a laser cutting machine?”.

Customers usually shop around before buying laser cutting machines, and the quotations given by different manufacturers are often different.

The following price list of fiber laser cutting machine comes from a well-known manufacturer in China in 2021:

| Model | Power (W) | Laser Source | ||

|---|---|---|---|---|

| IPG (USD) | nLight (USD) | Raycus (USD) | ||

| 1530 | 500 | 18,571 | 17,857 | 17,500 |

| 700 | 21,786 | 21,429 | 20,714 | |

| 1000 | 26,429 | 25,714 | 23,214 | |

| 1500 | 33,929 | 32,143 | 28,929 | |

| 2000 | 48,214 | 45,000 | 41,429 | |

| 3000 | 75,714 | 61,071 | 51,429 | |

| 4000 | 84,286 | 82,143 | 64,286 | |

| 1540 | 500 | 20,000 | 19,286 | 18,571 |

| 700 | 23,571 | 22,500 | 22,143 | |

| 1000 | 27,857 | 27,143 | 24,286 | |

| 1500 | 35,357 | 33,571 | 30,357 | |

| 2000 | 49,286 | 46,429 | 42,500 | |

| 3000 | 77,143 | 62,143 | 52,857 | |

| 4000 | 86,429 | 83,571 | 65,714 | |

| 2040 | 500 | 21,429 | 20,714 | 20,000 |

| 700 | 24,286 | 23,571 | 23,214 | |

| 1000 | 28,929 | 28,571 | 25,714 | |

| 1500 | 36,429 | 35,000 | 31,429 | |

| 2000 | 50,714 | 47,857 | 43,929 | |

| 3000 | 78,571 | 63,571 | 54,286 | |

| 4000 | 87,500 | 83,571 | 67,143 | |

| 1560 | 500 | 22,500 | 22,143 | 21,429 |

| 700 | 25,714 | 25,000 | 24,643 | |

| 1000 | 30,357 | 29,643 | 27,143 | |

| 1500 | 37,857 | 36,071 | 32,857 | |

| 2000 | 52,143 | 48,929 | 45,000 | |

| 3000 | 80,000 | 65,000 | 55,714 | |

| 4000 | 88,571 | 86,429 | 68,571 | |

| 6020 | 500 | 24,286 | 23,214 | 22,857 |

| 700 | 27,143 | 26,429 | 25,714 | |

| 1000 | 31,429 | 31,071 | 28,571 | |

| 1500 | 39,286 | 37,500 | 34,286 | |

| 2000 | 53,571 | 50,357 | 46,429 | |

| 3000 | 81,071 | 66,429 | 56,786 | |

| 4000 | 90,000 | 87,500 | 69,643 | |

| 2560 | 500 | 25,000 | 24,643 | 23,929 |

| 700 | 28,571 | 27,857 | 27,143 | |

| 1000 | 32,857 | 32,143 | 29,643 | |

| 1500 | 40,714 | 38,571 | 35,714 | |

| 2000 | 54,643 | 51,429 | 47,857 | |

| 3000 | 82,143 | 67,857 | 57,857 | |

| 4000 | 91,429 | 101,429 | 70,714 | |

Why are the prices of the same things so different from those of different manufacturers?” is a question that customers will inevitably ask. Today, I’ll answer that question by helping you understand the price of a laser cutting machine.

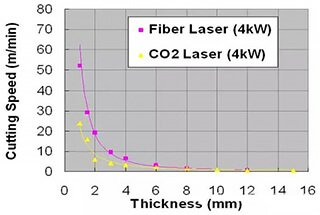

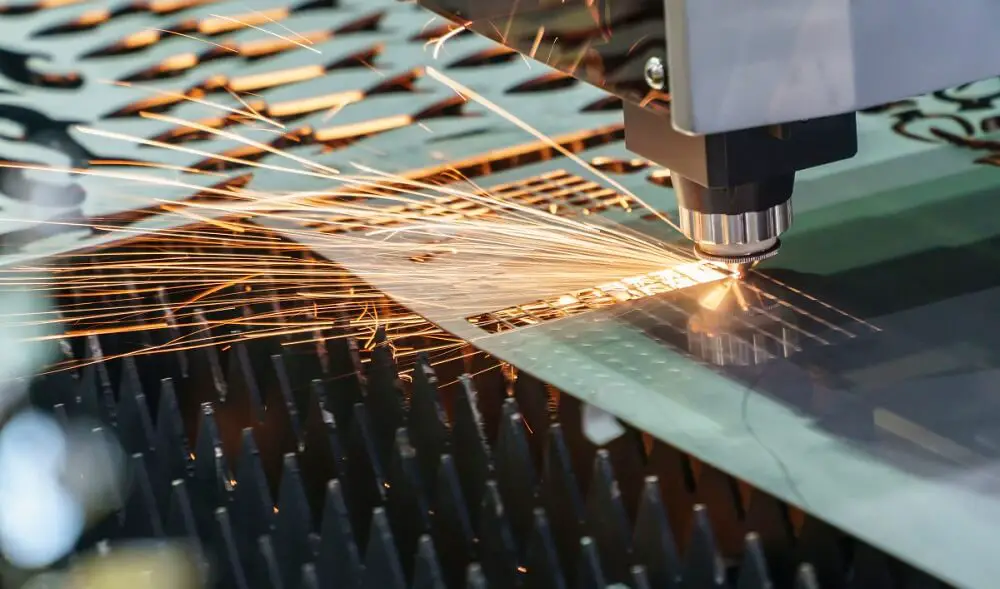

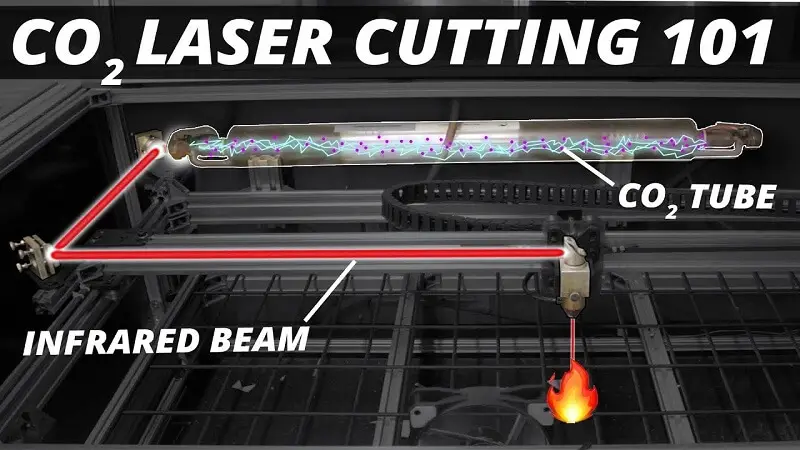

In recent years, with the growth of the laser industry, the benefits of laser cutting have become increasingly apparent. From traditional plasma cutting machines and carbon dioxide laser cutting machines to CNC punch and solid-state laser cutting machines, more and more customers are choosing the effective, economic, and environmentally friendly optical fiber laser cutting machine.

As a new product that aligns with market trends, the laser cutting machine has been widely embraced by users due to its precision and high cutting speed. This is a positive development for those who use laser cutting machines.

However, the market for laser cutting machines is now filled with a mixture of options, and prices vary greatly: some are tens of thousands of dollars, while others are hundreds of thousands, and some businesses even falsely advertise “6000 XX laser cutting machines”. Additionally, some sellers only list the price, obscure the location, or don’t list the location at all, making it difficult for customers who can’t visit to determine if the seller is a small workshop.

The more information a customer seeks about the price of a laser cutting machine, the more confused they may become. With the advancement of laser technology, lasers are becoming increasingly popular in industries such as sheet metal processing, environmental protection equipment, cabinet making, agricultural machinery, kitchenware and bathroom fixtures, auto parts, sports equipment, elevator equipment, and advertising signs.

As a tool, the price of lasers has decreased significantly compared to a few years ago. However, the price of a fiber laser cutting machine is still higher than that of an ordinary carbon dioxide laser cutting machine.

The price of a 1000W fiber laser cutting machine ranges from 30,000 USD to 80,000 USD. Despite the high cost and significant investment required in the beginning, fiber laser cutting machines offer several benefits in the long run, such as fast cutting speed, high efficiency, and precision.

So, why do prices vary so greatly among different manufacturers? The quotes for laser cutting machines from different manufacturers can differ greatly due to differences in accessories used, configuration, performance, and after-sales service.

Think of it like buying a car; the process doesn’t end once you make the purchase. The same is true for a large-scale fiber laser cutting machine; the service is just beginning for the enterprise that buys it.

Laser cutting machines are selected based on the production process and the level of precision required, so the performance of the machine will vary. This, in turn, leads to different quotes from different manufacturers.

Price is just one factor to consider when purchasing a machine, and blindly pursuing the lowest price may result in losses outweighing any gains.

What affects the price of metal laser cutting machines?

When purchasing machinery, it’s important not to solely focus on price and not to believe in misleading advertisements claiming cheap prices and high quality. The adage “you get what you pay for” applies in the production process, regardless of whether the machinery is imported or domestically produced.

In recent years, the widely accepted view is that cheap goods are not of good quality, and good quality goods are not cheap, especially in the laser industry. The cost of a cutting machine primarily lies in accessories and labor.

Many fiber laser cutting machine manufacturers have established agents for expanding their sales network, but the prices offered by agents are typically higher than those directly from the manufacturer, leading to differences in fiber laser cutting machine prices. The factory price of a laser cutting machine is typically the lowest, before it is shipped from the factory.

To select a laser cutting machine manufacturer, you can refer to the ranking of the top 10 laser cutting machine manufacturers. The price of a fiber laser cutting machine will vary, whether it’s the factory price before it leaves the factory or the supply price from an agent dealer.

This is because the cost of the fiber laser cutting machine remains the same, but the operating costs differ, resulting in varying sales prices.

Factors affecting the price of metal laser cutting machines are:

The brand size plays a role in determining the price of the equipment, which is a more abstract concept. It’s worth noting that established, well-known brands are generally more secure in terms of equipment quality, parts, performance, technology, and after-sales service compared to smaller factories.

This added value is a common characteristic in the laser cutting machine market, and as a result, the price of well-known brands will be higher than that of smaller brands.

Laser cutting machine manufacturers typically offer several standard bed sizes, and they can also customize non-standard machine tools to meet customers’ specific requirements. The standard size is a constant specification offered by the manufacturer, but the non-standard size requires customization, making the laser cutting machine with a custom bed more expensive than one with a standard size.

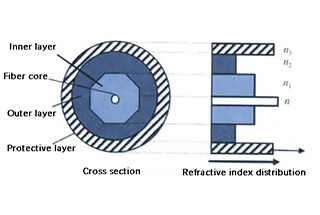

As we all know, the laser source is the core optical component of a laser cutting machine. The brands of laser cutting machines vary, resulting in differences in laser beam quality, and the price of the laser source also varies greatly among different brands.

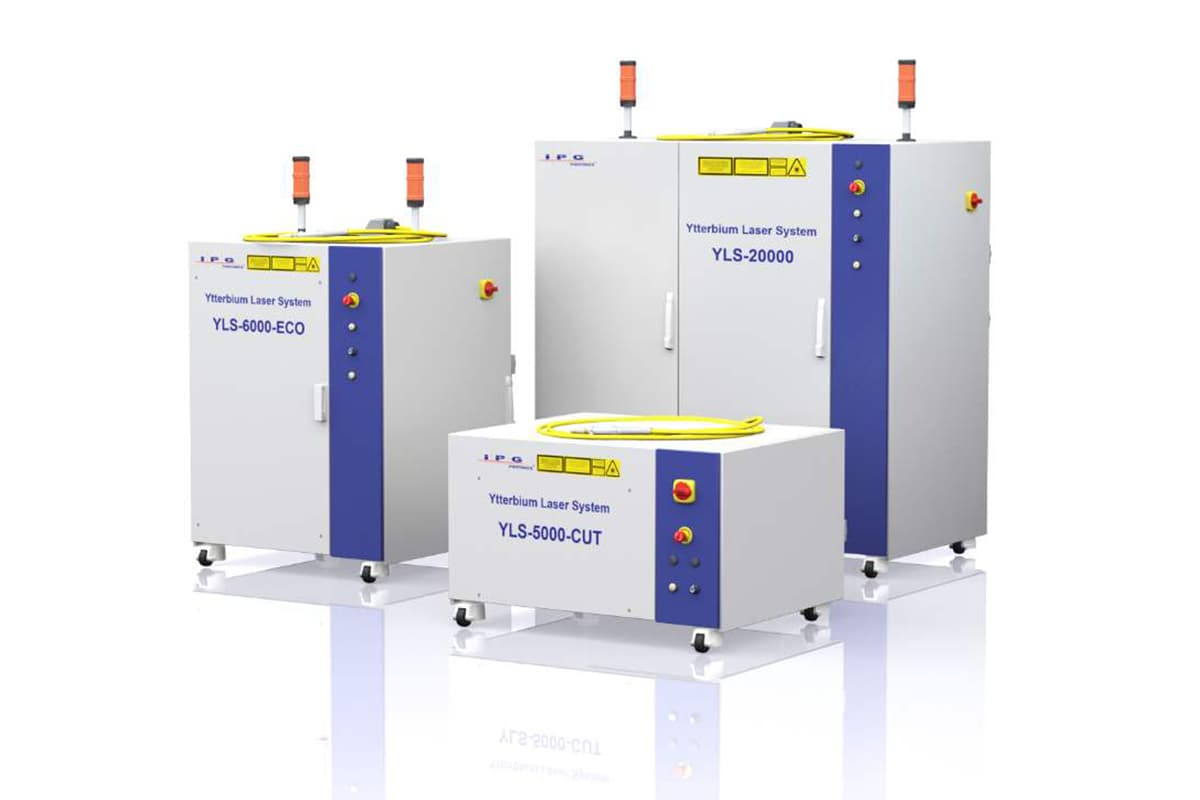

Currently, established laser source brands include IPG, Nlight, and Raycus.

The brand and quality of other key components, such as the guide rail, rack and pinion, and servo motor, also contribute to differences in price. When purchasing a laser cutting machine, it’s important to consider the specific configuration and not be swayed solely by low prices.

For manufacturers of the same brand, the equipment’s power level directly affects its price, with higher power leading to a higher price. Before making an inquiry, it’s important to know the material and thickness you want to cut, as well as your desired cutting speed and production capacity.

Brand awareness can often influence customers’ decisions to purchase a laser cutting machine. In reality, when buying a laser cutting machine, users should consider the brand, power, and after-sales service.

An excellent laser cutting machine manufacturer should have a good reputation and offer a range of laser cutting machines with different powers to meet the needs of their customers. Additionally, good after-sales service is crucial for a positive user experience, especially when considering the use of the equipment.

As we have seen, the price of a laser cutting machine is influenced by many factors, including brand, bed size, configuration, parts, and others. These factors lead to significant differences in the price of laser cutting machines. When choosing a laser cutting machine, it’s important to consider the key points mentioned in this post before making a decision.

By comparing options, you can purchase the equipment that best suits your needs.