Are you struggling to pick the right stamping press for your manufacturing needs? Choosing the correct stamping press is crucial for optimizing production efficiency and ensuring high-quality output. This guide breaks down the key factors to consider, from material type to production volume, helping you make an informed decision. Dive in to learn how to match your press selection to your specific stamping requirements, ensuring a successful and cost-effective investment.

A stamping press is a commonly used processing machine in the manufacturing industry, used for forging, stamping, and plate processing. It is an extensive machine in itself.

Stamping presses come in many different types, so when purchasing one, it is important to consider the finished products being manufactured, the type of stamping die, the stamping process characteristics, production efficiency, and investment budget. Careful consideration and research will help ensure a positive return on investment for the stamping press.

The selection of a stamping press primarily focuses on two critical factors: the type and specification.

Selection of Stamping Press Type

There are numerous types of stamping presses, and the selection of type is primarily based on the material, specifications, dimensions, and size requirements of the finished products.

Selection Based on Stamped Part Product Type

The selection of punch type is largely determined by the type of stamped part, including the material, specifications, and final size of the stamped part.

For instance, a C-frame punch is suitable for small to medium-sized metal blanking parts, bending parts, or shallow drawing parts. However, the elastic deformation of its frame can compromise the uniform distribution of the die gap, affecting the accuracy of the finished stamped products and reducing the lifespan of the die.

Despite these limitations, the C-frame punch has several advantages, such as its open frame on three sides, which makes it easy to operate and install molds, feeders, and automatic mold-changing devices for automated production, and its economical cost.

For large, medium-sized, or high-precision stamped products, it is recommended to choose an H-frame punch or double-shaft punch.

For specialized stamping processes such as leveling, bending correction, and shaping, a stamping press with high strength and rigidity should be selected. If a high level of machining accuracy is a priority, a stamping press with high rigidity or a punch with a high capacity (one with enough pressure capacity for the machining process) should be selected.

However, even if a large capacity punch is used with a C-frame punch, it will not have a significant impact. It is important to note that a stamping press with high rigidity should be chosen in this scenario.

Selection Based on Stamping Part Production Efficiency

When manual feeding is used, it is important not to choose a stamping press with too many strokes. During automatic stamping, a punch with more strokes should be selected whenever possible.

However, during deep drawing, a punch with too many strokes should not be chosen, as the drawing process would be too fast, leaving the material no time to fully deform, which could result in cracking of the parts.

If the production volume is over 3000 batches, it is more beneficial to use automatic feeding.

For multiple batches and large quantities, it is recommended to consider continuous processing methods such as high-speed automatic punches and transfer punches. The choice between a universal punch or an automatic punch should also take into account future production plans, market conditions, and technical trends.

After selecting the type of stamping press, the specification of the equipment must also be determined. This is accomplished by coordinating the die size and equipment parameters according to the processing plan and the results of the processing calculations.

The selection of stamping equipment specifications is primarily based on the following technical parameters.

(1) Nominal pressure

The force generated by the press slider during the downward motion is referred to as the stamping pressure. The pressure of a mechanical stamping press changes depending on the downward position of the slider (or the angle of crank rotation in the case of a crank punch).

The nominal pressure is the maximum impact force that the slider can withstand at a specific distance before reaching the bottom dead center, or at a specific angle of crank rotation before reaching the bottom dead center. This specific distance is referred to as the nominal pressure stroke, and the corresponding crank angle is the nominal pressure angle. The nominal pressure reflects the impact force that the punch itself can bear.

Nominal pressure is a critical technical parameter in selecting punch specifications. To ensure the safety of the stamping process, the tonnage of the selected punch must be greater than the actual stamping pressure and must ensure that the part load curve does not exceed the allowable load curve of the punch.

The general tonnage selection principles are:

For combined blanking, bending, or drawing stamping, the tonnage value should be determined based on the specific conditions and the allowable load curve of the machine tool being used.

When stamping thicker parts, it is important to consider not only the allowable pressure of the punch, but also its power.

The change in punching force during stamping varies for different stamping types, and the maximum impact force of the punch slider also changes.

Therefore, the nominal pressure should be selected based on the allowable pressure curve of the punch and the actual force curve of a specific stamping process, so that the actual stamping pressure curve remains below the allowable pressure curve of the punch.

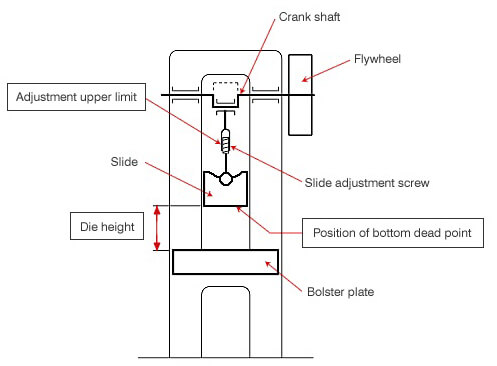

(2) Closing height and die mounting height

When the press slider is at the bottom dead center, the distance between its lower end face and the top surface of the worktable is referred to as the closing height of the press.

The difference between the closing height of the press and the thickness of the machine tool’s base plate is referred to as the die mounting height.

If an inorganic mattress board is used, the closing height is equal to the die mounting height.

The adjusting screw in the connecting rod can adjust the die mounting height within a certain range.

When the slider is adjusted to the upper limit, the die mounting height reaches its maximum value, which is the maximum die mounting height.

Conversely, when the slider is adjusted to the lower limit, the die mounting height is at its minimum value, which is the minimum die mounting height. The difference between the two is the range of adjustment for the die mounting height.

When selecting a press, the closing height of the stamping die should be between the maximum and minimum closing heights of the press.

Since the connecting rod may shorten over time due to wear and the closing height of the stamping die may decrease with future repairs, the height of the stamping die is typically designed to be close to the die mounting height of the stamping press.

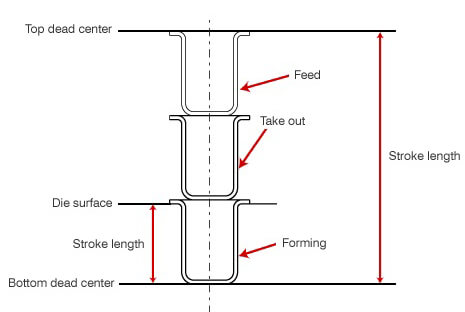

(3) Slider stroke

The slider stroke refers to the distance traveled by the slider from the top dead center to the bottom dead center.

For crank punches, the slider stroke is equal to twice the crank radius, which reflects the working range of the punch. A longer stroke allows for punching parts with a higher height.

The selection of the slider stroke is mainly based on the ease of inserting the stamping blank into the die and removing the stamped parts. It is generally recommended that the slider stroke be twice the height of the stamped part.

When manual feeding is involved, it is best to avoid selecting a stamping press with too many strokes. For automatic stamping, it is preferable to choose a stamping press with a larger stroke. However, during deep drawing, a stamping press with too many strokes should not be selected, as the fast drawing speed can cause the material to not fully deform, leading to cracking of the parts.

(4) Number of strokes

The number of strokes per minute of a stamping press refers to the frequency of the sliding block moving from the top dead center to the bottom dead center and back in a minute.

The number of strokes greatly affects the productivity of the stamping process and is mainly determined based on the production demands, the material’s acceptable deformation speed, and the feasibility of continuous operation.

(5) Worktable size

The size of the punch table shall be determined based on the size of the mold that is actually installed. If the mold is large, the size of the worktable can be adjusted to accommodate the customer’s needs.

The punch table (or backing plate surface) must be larger than the horizontal size of the lower die. It is recommended that each side be 50-70mm larger to facilitate the installation of the die.

Additionally, the size of the lower die’s surface must be larger than the size of the worktable face. It is generally 45-50mm larger on each side. The size of the worktable hole must be larger than the size of any potential missing parts.

(6) Die handle hole size

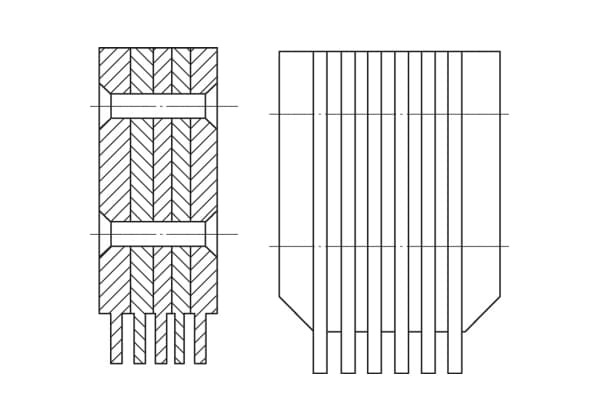

A hole for the die handle is located at the center of the lower end of the sliding block of small and medium-sized punches to make it easier to install the upper die.

The diameter of the die handle should match the diameter of the hole for the die handle on the punch, and the length of the clamping portion of the die handle should be slightly shorter than the depth of the hole for the die handle on the punch.

When selecting stamping equipment, the actual conditions of the production site should also be taken into account.

If there is no suitable equipment available, existing equipment should be utilized to carry out the stamping production.

When more than one piece of equipment meets the requirements, the production needs for other products and the efficient use of equipment resources should be considered comprehensively.

Easy Maintenance

Stamping presses with high output, large batch production, high flexibility, and easy maintenance are highly reliable and can have a significant impact on overall production.

Safety

Stamping is a hazardous operation, and safety cannot be ignored.

When selecting a punch, it is important to choose one that is equipped with safety features, ensuring that even if there is an error in operation, accidents can be prevented and operations can be conducted safely.

Environmental Protection

Environmental protection is becoming a more pressing issue. In the future, choosing a punch with low noise and low vibration levels will be an important development direction in the industry.

How to choose the die for the stamping press?

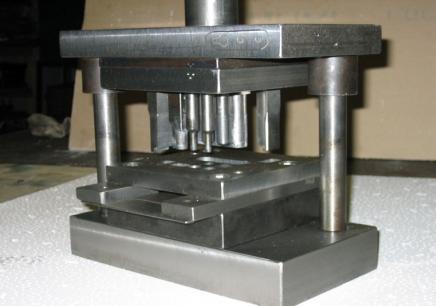

Selecting the appropriate punch die for a stamping press is crucial for achieving optimal performance and product quality. The selection process involves several key considerations:

1. Press Capacity and Blanking Force:

Begin by evaluating the blanking force of your stamping press. This determines the maximum force the press can exert and directly influences die selection. Ensure the chosen die can withstand the press’s maximum tonnage without deformation or failure.

2. Dimensional Compatibility:

Accurately measure the press’s shut height (distance between the bolster and slide at bottom dead center) and die seat dimensions. Select a die unit that fits these specifications precisely to ensure proper alignment and operation.

3. Workpiece Material:

The material of the product being processed significantly influences die selection. Different materials require varying levels of hardness, wear resistance, and toughness in the die. For example:

4. Die Material Properties:

Optimal die performance requires a balance between hardness, toughness, and wear resistance. Contrary to common belief, maximizing hardness isn’t always ideal. Excessively hard dies can be brittle and prone to cracking under high stamping forces. Consider the following:

5. Manufacturing Precision:

The die manufacturer’s capabilities in terms of machining accuracy, heat treatment control, and surface finishing are critical. Ensure they can meet or exceed your required tolerances, typically in the range of ±0.0005″ to ±0.0002″ (0.013 mm to 0.005 mm) for precision stamping.

6. Die Design and Features:

Consider additional features that enhance die performance and longevity:

7. Production Volume and Lifecycle Cost:

While initial cost is a factor, evaluate the total lifecycle cost including maintenance, refurbishment, and replacement frequency. Higher-quality dies from reputable manufacturers often provide better long-term value through increased durability and consistent performance.

8. Manufacturer Reputation and Support:

Choose a die manufacturer with a proven track record in your industry. Consider factors such as technical support, lead times for replacements, and ability to provide custom solutions for complex stamping operations.

By carefully considering these factors, you can select a punch die that not only meets your immediate production needs but also ensures long-term efficiency, accuracy, and cost-effectiveness in your stamping operations.