How can you ensure your bolted connections are both strong and reliable? This article delves into practical techniques to enhance bolt strength, covering crucial areas like load distribution, stress reduction, and manufacturing improvements. By understanding and applying these methods, you can significantly increase the durability and performance of your bolted assemblies. Read on to discover expert tips for maximizing the strength of your bolt connections.

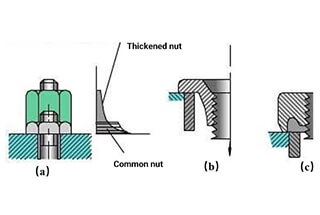

When the standard nut is used, the distribution of axial load is not consistent.

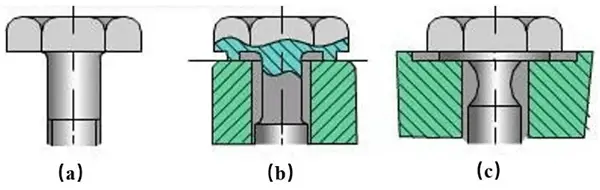

As illustrated in Figure 1(a), the load on the first thread is the highest on the bearing surface of the nut and then decreases.

Theoretical analysis and experimentation have demonstrated that the more turns there are, the more pronounced the uneven load distribution becomes. After the 8th to 10th turns, the thread is essentially free of any load.

As a result, a thicker nut with more turns does not enhance the connection strength.

If the tension nut in Figure 1(b) is used, the conical mounting section of the nut and the bolt rod undergo tensile deformation, which helps to reduce the difference in screw moment between the nut and bolt rod and make the load distribution more consistent.

Fig. 1 (c) shows a ring groove nut, whose function is similar to that of a mounting nut.

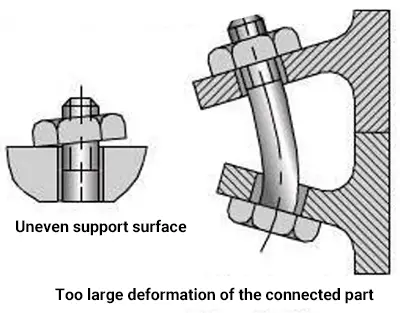

Due to poor design, production, or installation practices, bolts may experience additional bending stress (as shown in Figure 2), which significantly impacts their fatigue strength and should be avoided.

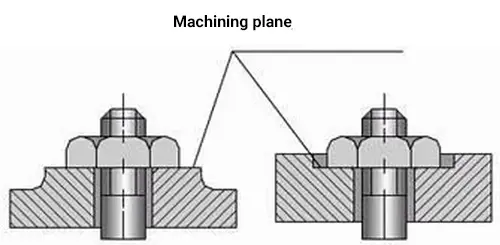

For instance, when installing bolts on rough surfaces such as castings or forgings, structures such as bosses or countersunk seats are often employed to provide flat bearing surfaces after cutting (as illustrated in Figure 3).

The root of the thread and the junction between the bolt head and rod are stress concentration points that are prone to fracture.

The stress concentration at the thread root has a significant impact on the fatigue strength of the bolt.

The stress concentration can be reduced by increasing the fillet radius at the thread root, adding a fillet in the transition area of the bolt head (as shown in Figure 4(a)), or cutting an unloading groove (as illustrated in Figures 4(b) and 4(c)).

When the maximum stress in a bolt remains constant, the higher the fatigue strength is, the smaller the stress amplitude.

With the same working load and residual preload, reducing the stiffness of the bolt or increasing the stiffness of connected parts can reduce stress amplitude (as shown in Figure 5), but it requires increasing the preload.

Ways to decrease the stiffness of the bolt include: extending the bolt’s length appropriately, reducing the diameter of the bolt partially or creating a hollow structure, such as a flexible bolt.

An elastic component (as depicted in Figure 6) installed beneath the nut can also serve as a flexible bolt.

A flexible bolt has high deformation capabilities, strong energy absorption, and is well-suited for handling impact and vibration.

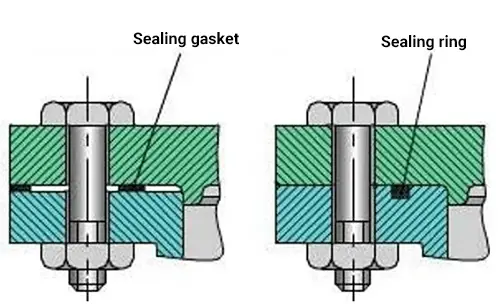

To enhance the stiffness of the connected system, using a gasket with low stiffness is not recommended. Instead, it is preferable to use a sealing ring for the sealing connection as depicted in Figure 7.

The production process significantly affects the fatigue strength of bolts, particularly for high strength steel bolts.

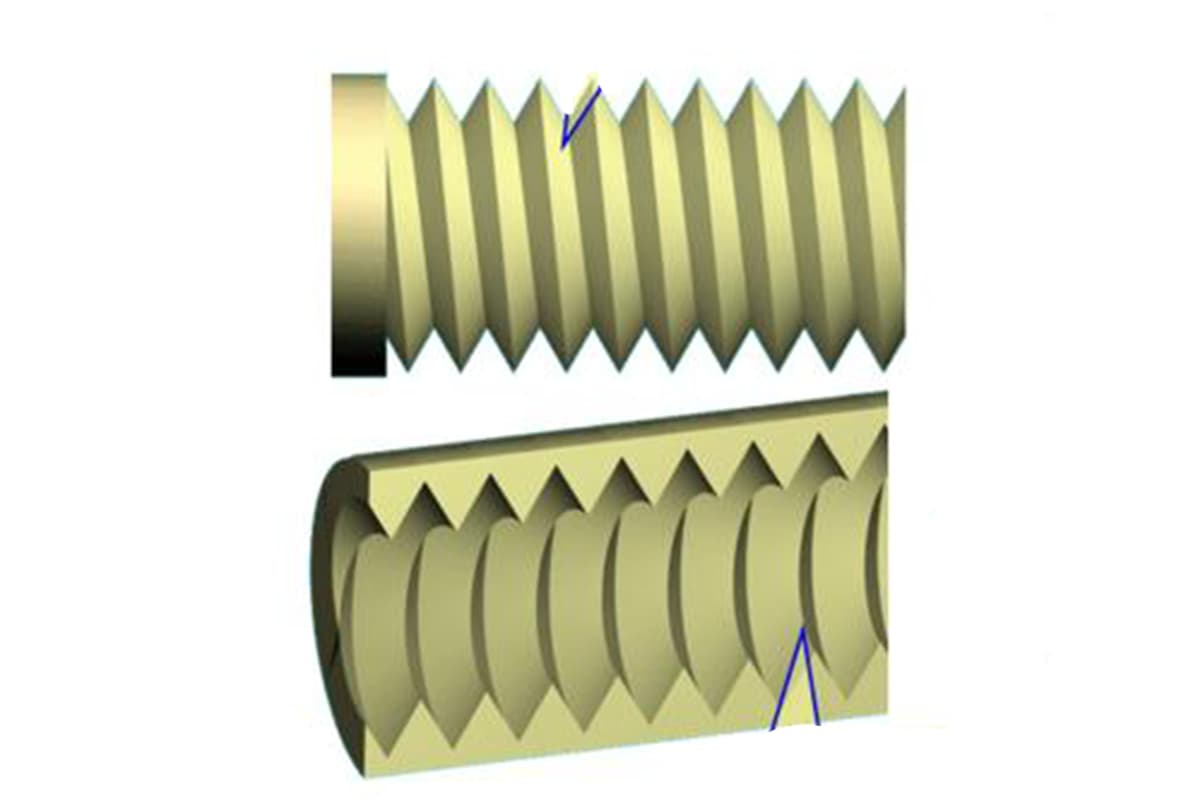

When the thread is rolled, the effect of cold work hardening results in residual compressive stress in the surface layer, the metal structure is optimized, and the fatigue strength of the bolt is superior to that of turning.

Methods such as carbonitriding, nitriding, and shot peening can improve the fatigue strength of bolts.