Are your press brake tools wearing out too quickly? This article dives into essential repair techniques to extend the lifespan of your tooling, ensuring optimal performance in your sheet metal processing. From identifying wear patterns to precise grinding methods, learn how to maintain your press brake dies effectively. By following these tips, you’ll enhance product quality and machine efficiency, saving time and costs in the long run.

The repair and regrinding of press brake tooling is an essential process for sheet metal processing plants to fix worn molds in the later stages.

No manufacturer will continue to use a set of press brake tooling without repairing and regrinding it for several years, which is detrimental to both the bending machine and the molds.

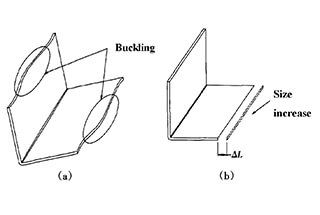

The main cause of wear on the bending machine die is due to the sheet metal processing process. Local bending leads to the die being worn down at the fixed point from the bending pressure over a long period of time. Excessive pressure can also scratch the lower die, which will further increase the degree of wear on both the upper and lower dies.

The best solution to address the wear caused by local bending is to process multiple workpieces at the same time, which can distribute the pressure on the bending machine and prevent damage to the die caused by pressure concentration.

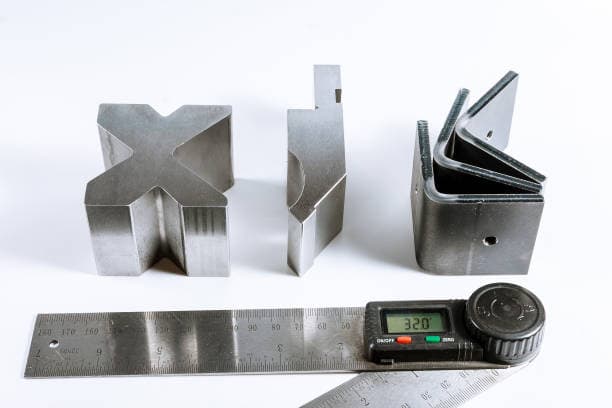

Die polishing for bending machines is essential when the bent workpiece exhibits significant angle deviation or excessive surface roughness. Prompt die maintenance not only corrects these issues but also extends the tool’s service life.

Prior to initiating any bending operation, the sheet metal operator must meticulously inspect both the upper and lower dies. If visible wear patterns, scratches, or deformations are detected on the die surfaces, immediate refurbishment is necessary. This proactive approach ensures consistent bending quality and prevents potential workpiece defects.

Strategically minimizing die grinding frequency and optimizing the number of bending cycles can significantly enhance die longevity. This approach yields multiple benefits: improved workpiece quality, reduced stress on the bending machine, increased product qualification rates, and ultimately, enhanced operational efficiency. Implementing a well-planned die maintenance schedule, based on material types processed and production volumes, can help achieve these goals while balancing productivity and tool life.

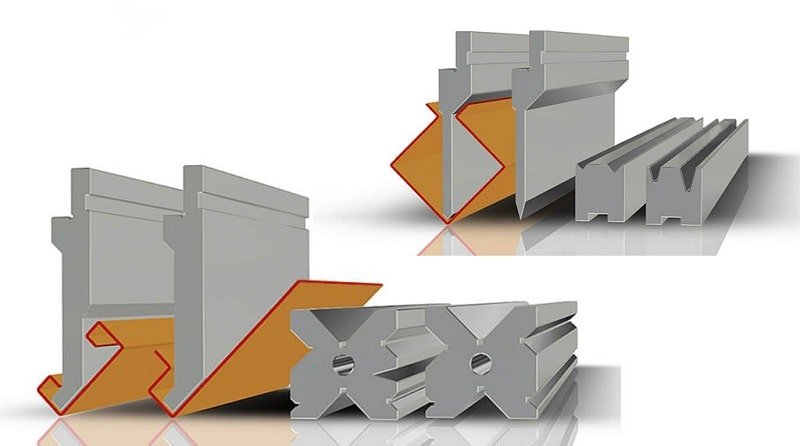

Various methods exist for grinding bending machine molds, with the most prevalent approach involving mounting the mold on a specialized fixture and utilizing a precision surface grinder. This technique is particularly crucial for arc molds (R-type) and forming dies, which demand high-precision grinding wheels and specialized mold repair tools.

During the grinding process, maintaining a consistent tool clearance of 0.03mm to 0.05mm is essential for optimal results. This precise clearance ensures uniform material removal and helps preserve the mold’s intended geometry.

It’s important to note that repeated grinding sessions are generally not recommended. This practice not only fails to achieve complete mold processing but can also lead to significant damage to the mold’s surface and integrity. Instead, a more effective approach is to make appropriate corrections to the majority of grindable areas in a single session, followed by a final fine grinding pass.

This two-step method – initial correction followed by fine grinding – offers several advantages. It enhances the overall accuracy of the NC bending machine die, improves surface finish, and facilitates easier installation and commissioning. Additionally, this approach helps maintain the mold’s longevity by minimizing unnecessary material removal and reducing the risk of thermal stress induced by multiple grinding cycles.

To further optimize the grinding process, consider factors such as:

By adhering to these best practices and adopting a strategic grinding approach, manufacturers can significantly improve the quality, performance, and lifespan of their bending machine molds.

In conclusion, proper regrinding of press brake machine dies is an important process for sheet metal fabrication enterprises. Improving the accuracy and lifespan of the dies is another way to boost the benefits of the enterprise.