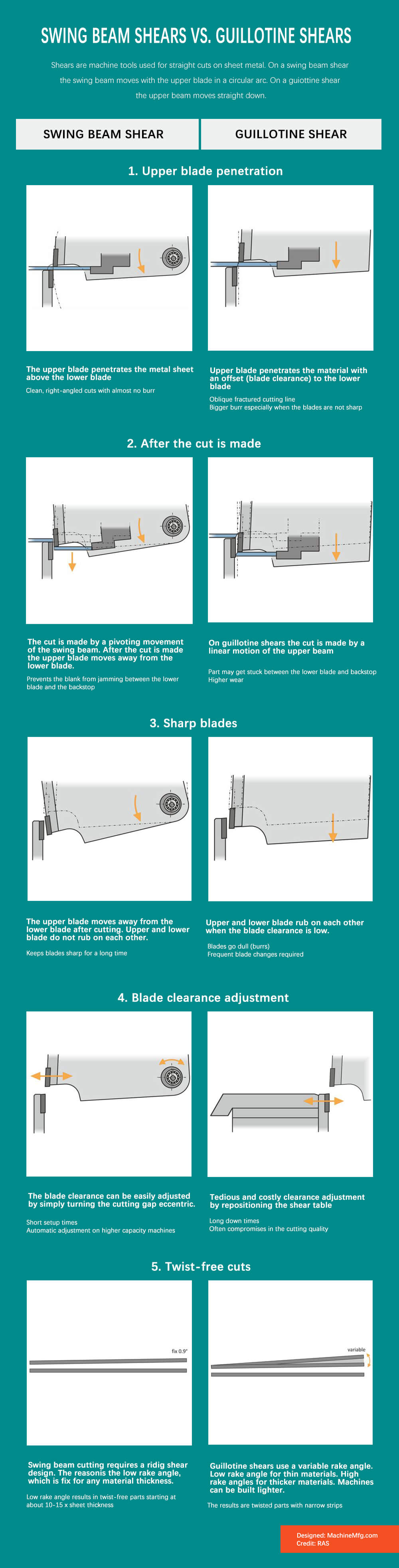

What sets hydraulic guillotine shears apart from swing beam shears, and why do these distinctions matter for your metalworking projects? This article explores the key differences, including blade movement, shear force, and cutting accuracy. By understanding these distinctions, you’ll learn which shear is best suited for different applications, helping you make informed decisions to enhance precision and efficiency in your work.

Many people have doubts about the division of hydraulic shearing machines into swing beam shears (fixed angle shears) and guillotine shears (variable angle shears).

What distinguishes the hydraulic swing beam shear from the guillotine shear?

Why do most users prefer guillotine shears?

What are the advantages of the hydraulic guillotine shear compared to the hydraulic swing beam shear?

Today, I will explain the differences between the swing beam shearing machine and the guillotine shearing machine.

The following table outlines the key differences between the QC12 series swing beam shear and the QC11 series hydraulic guillotine shear:

| Difference | QC12K/Y Series | QC11K/Y Series | |

| Hydraulic Swing Beam Shears | Hydraulic Guillotine Shears | ||

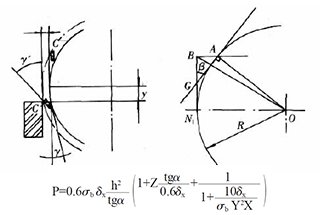

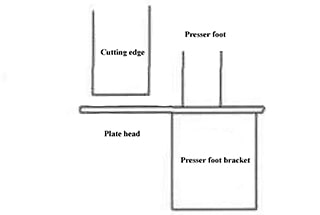

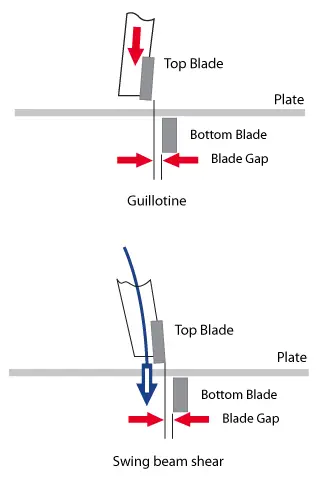

| 1 | Blade carrier cutting movement | – Unipivot support,lever principle; – Do arc-shaped curvilinear motion around the rear fulcrum. | – Three-point support rolling guide (Lower eccentric shaft, front support shaft,upper eccentric shaft) – Do linear vertical motion. |

| 2 | Shear force | – Hydraulic oil cylinder fixed in oblique direction; – 75% acting force, 25% loss. | – Hydraulic oil cylinder do linear vertical motion; -100% hydraulic pressure acting on cutting edge. |

| 3 | Blade style | – Top blade in prismatic shape, can only use two bevel angle cutting edge; – Lower blade in rectangular shape, four cutting edge can be used. | – Both upper and lower blade are in rectangular shape; – All four cutting edge can be used. |

| 4 | Cutting angle adjustment | – Fixed cutting angle and blade carrier angle; – Can only cut in specific angle whatever the thickness of the plate. | – Adjustable cutting angle, different cutting angles are applied for cutting plate with different thickness. – Adopt smaller cutting angle can effectively reduce the distortion of sheet metal, and increase cutting speed; – Can also increase the shear angle to increase the shear force. |

| 5 | Lubrication point | Bevel gears are heavily worn and require frequent lubrication to increase service life. | Most use self-lubricating spherical plain bearings, basically don’t need to manually lubricate. |

| 6 | Blade carrier return device | Nitrogen return cylinder, easy to leak, often need to repair. | The bladder-type accumulator returns are stable and reliable. |

| 7 | Use range | Ordinary small and medium workpieces, common requirements for the cutting surface. | Large and medium-sized ultra-long sheet shear, require high precision for the cutting surface. |

| 8 | Backstop structure (optional) | – 500W AC motor + universal connection twisted shaft; – Easy to cause gaps, no spring buffer, no retract function. | – Inverter + speed motor + encoder + electronic digital display; – Stepless speed regulation, low noise, spring retraction and buffer function. |

| 9 | Fuel tank (optional) | If ordinary plates are not handled, the long time, the easier to rust, causing the hydraulic parts to block and wear. | The overall plating treatment, no rust, not easy to react with the oil. |

You can click here to download the high-resolution version of the infographic above.

Both the blade clearance of the swing beam shear and guillotine shear is 0.04 mm.

However, the bearing connection between the swing arm and the pendulum body of the swing beam shearing machine cannot completely eliminate clearance.

As a result, the accuracy errors between gaps and blade edge clearance are typically above 0.1 mm, making the accuracy of the swing beam shearing machine theoretically worse than that of the guillotine shearing machine.

The guillotine shearing machine’s rear guide rail is pressed by a bearing with a compression spring pad in the back, ensuring there are no gaps between the front and rear guide rails.

This keeps the accuracy of the gap between clearance and the blade edge gap below 0.04 mm, resulting in smoother material shearing with no burrs.

Since the tool holder of the swing beam shearing machine has a curved shape, it makes an arc point contact to ensure the straightness of the material being sheared.

The guillotine shearing machine ensures the straightness of the material being sheared with its straight tool holder, resulting in greater precision.

However, the swing beam shearing machine experiences significant blade back-off in the middle, resulting in some cutting materials having burrs. This issue cannot be prevented.

When cutting sheets with a thickness less than 20 mm, the shear angle of the swing beam shearing machine cannot be adjusted, causing the material being cut to become twisted. The narrower the cut material, the greater the distortion.

In contrast, the guillotine shearing machine allows for stepless adjustment of the shear angle, making it less likely for the cut sheet to become distorted and deformed, thus maintaining the accuracy of the workpiece.

More importantly, the shear force is stronger after the shear angle is increased.

The hydraulic swing beam shearing machine cannot utilize all four edges of the blade to cut metal plates due to its curved blade movement.

As a result, only the diamond-shaped cutting edge can be used for double-sided cutting.

In contrast, the tool holder of the guillotine shearing machine moves up and down in a linear motion, allowing both its upper and lower blades to be cut with all four edges.

This results in the blade on the guillotine shearing machine having a service life that is twice as long as that of the swing beam shearing machine.

The hydraulic guillotine shearing machine does not rely on nitrogen to return the blade, eliminating the inconvenience caused by air leakage. It uses a double-acting hydraulic cylinder.

In comparison, the design of the swing beam shears still has many unresolved issues, such as:

Nowadays, renowned shearing machine manufacturers worldwide primarily produce hydraulic guillotine shearing machines, which are slightly more expensive.

Compared to the hydraulic swing beam shearing machine, the hydraulic guillotine shearing machine boasts high shearing precision, adjustable shear angle, and a long-lasting cutting edge.

In simpler terms, guillotine shears are the second-generation hydraulic shears and an upgraded version of the swing beam shear.

However, if you have a limited budget, the swing beam shear can still be a good option.

If you want to purchase a shearing machine from one machine manufacturer with reliable quality, you can refer to the top 10 shearing machine manufacturer list.