Ever wondered how modern manufacturing achieves such precision and efficiency? Enter the hydraulic ironworker—a versatile machine that cuts, punches, shears, and bends metal with ease. In this article, you’ll explore its functions, benefits, and why it’s indispensable in industries like bridges and military applications. Get ready to uncover the secrets behind this powerhouse tool!

A hydraulic ironworker is a versatile machine tool designed for multi-functional metal fabrication, integrating capabilities such as precision cutting, hole punching, shearing, and bending within a single unit. Also known as a hydraulic steelworker, this equipment utilizes hydraulic power to perform various metalworking operations efficiently.

Key features of hydraulic ironworkers include:

Hydraulic ironworkers have become indispensable in modern manufacturing industries, including:

While both hydraulic and mechanical ironworkers exist, this post will focus on the operation and advantages of hydraulic models, which offer superior control, versatility, and efficiency in metal processing applications.

The hydraulic ironworker machine offers exceptional versatility within its rated specifications, efficiently performing flat bar cutting, hole punching, and notching operations. This multifunctionality streamlines metal fabrication processes, reducing the need for multiple specialized machines.

With the addition of optional equipment, the machine’s capabilities expand significantly. It can execute specialized cutting, punching, and bending operations to produce complex shapes and profiles. This adaptability allows fabricators to tackle a wide range of custom projects without investing in separate machinery.

The steelworker machine incorporates a robust hydraulic driving system, ensuring consistent power delivery and smooth operation across various metalworking tasks. This hydraulic system is complemented by an advanced performance monitoring and overload protection device. This crucial safety feature safeguards both the operator and the machine by automatically adjusting or halting operations when load limits are approached, preventing potential damage and ensuring longevity of the equipment.

The integration of these features results in a highly efficient, versatile, and safe metal fabrication solution suitable for diverse industrial applications. The machine’s design prioritizes productivity without compromising on precision or operator safety, making it an invaluable asset in modern metalworking facilities.

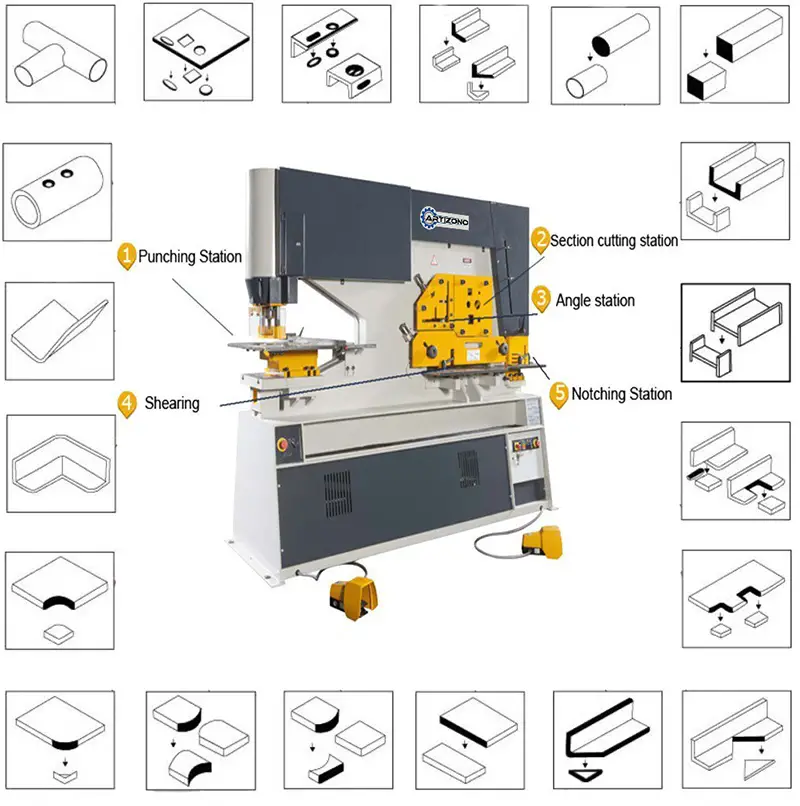

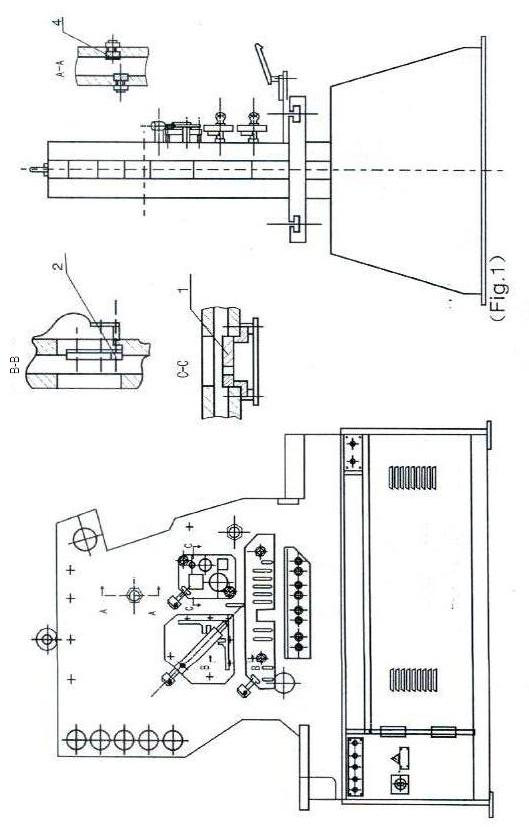

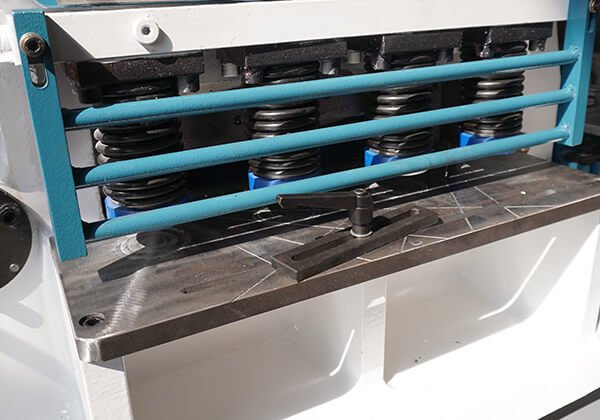

The bed can be seen in Fig. 1

The bed of the ironworker machine is composed of body, seat, bracket for the section, bracket for angle and cutting table.

The body and the seat are of welded construction, others are of bolt-connected ones which give the machine great strength and rigidity and allow easy dismounting during repairing the ironworker machine.

An adjustable pad for limiting the left-right movement of the blade is mounted on the left-right housing.

An adjustable hold-down for holding the angle to be cut is fitted on the angle cutting station.

With the square and round aperture of various sizes on the section cutting blade, the ironworker machine is able to cut various square and round bars.

The shearing table is fitted with a robust hold-down which is adjustable to any thickness of material and with a stop finger to allow accurate cutting of angle and flat bar at any angle.

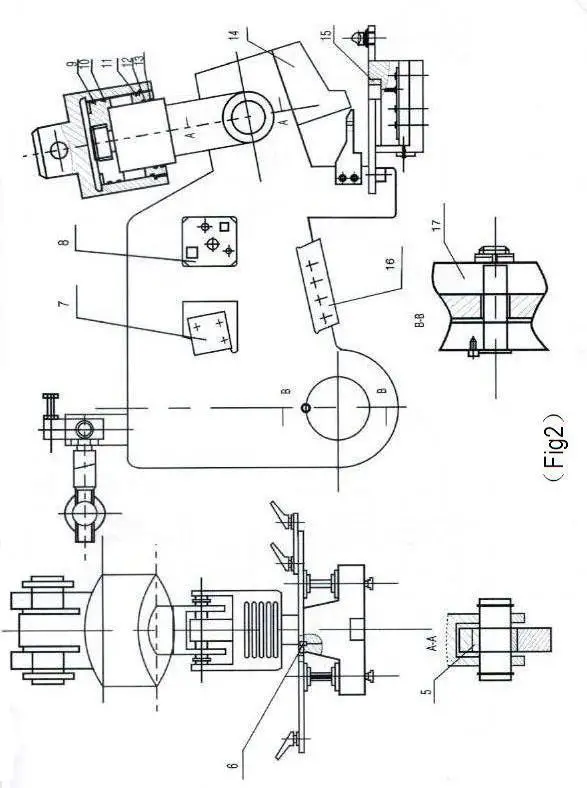

Section Cutting Station (Fig. 2)

This station is fitted as standard with blades which is a solid structure and has four apertures to cut angle, round, square, flat bars and notch steel plate.

With extra toolings on the square and round bars cutting apertures channel and joist bars cutting can also be performed.

The beam is connected with the oil cylinder of with the top end is hinged with the frame.

Driving by the oil cylinder the beam swings to perform cutting.

The upper notching blade is fixed on the beam.

There are 3 lower blades which are separately fixed on the die seat with booths, and the notching blades on both sides can be adjusted to allow sufficient cutting clearance.

A side gauge and a back gauge are fitted on the notching table to allow the plate to be notched on the correct position.

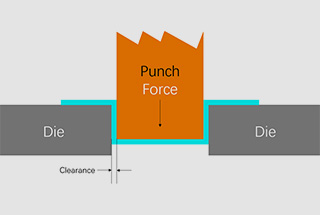

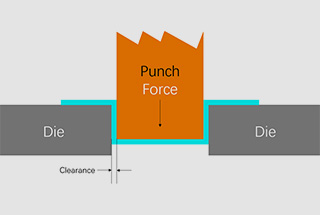

Punching Hole (Fig. 3)

The punch is fixed on the lower end of the piston rod of the oil cylinder with locking nut and the die is fixed in the adapter.

After the punch and die are aligned with each other, the bolts should be tightened.

To punch square and long round hole, there is a guide on the side surface of the piston rod, besides, along round positioning slot is milled on the pad and the top of the punch to prevent the punch from being turned.

With additional toolings on this station, bending, tube notching, louver punching, large hole punching, channel, joist, web punching work can all be performed.

1) After the motor is started, oil flow, which is compressed out from the pump (1), returns to the oil tank via the solenoid valve (4) to enable the pump to be discharged.

2) By turning the mode knob to the “SINGLE” position and depressing the foot pedal for punching hole, the electromagnet YV5b is turned on, hydraulic oil flows into the top chamber of the punching unit through the valve(3), the oil in the low chamber returns to the oil tank via the valve(3), so the punch moves downward to perform punching.

When the punch touches the limit switch at the lower dead point, YV5b is turned off, the pump is set to be discharged, so the punch is stopped. when the foot pedal is released and YV5a is turned on, the hydraulic oil flows to the lower chamber of the hydraulic cylinder, the punch moves upwards to touch the limit switch at the top dead point, so the YV5a is turned off and the punch is stopped at the top dead point.

In the same way, by depressing the foot pedal for cutting section, YV7b is turned on, oil enters the top chamber of the oil cylinder for cutting section, oil in the lower chamber returns to the oil tank via the solenoid valve(3), so the blade moves downward to perform cutting work.

When the blade touches the limit switch at the low dead point, YV7b is turn off, the blade is stopped at the dead point.

When the foot pedal is released, YV7a is turned on, oil enters the lower chamber in the oil cylinder for cutting cylinder, oil in the top chamber returns to the oil tank, so the blade moves upward, as the blade touches the limit switch at the top dead point, it is there.

3) By turning the mode knob to the “INCHING” position and depressing the foot pedal for punching hole, the electromagnet YV5b is turned on, a part of hydraulic oil enters the top chamber in the oil cylinder for punching hole,

4) Max working pressure in the hydraulic system is 250kgf/cm 2(24. 5MPa). The adjustment range of pressure in the overflow valve is 25MPa. The entire hydraulic system is protected against overload by the overflow valve.

5) The steelworker machine is fitted with a pressure gauge which is used to check the pressure in the hydraulic system and adjust pressure after replacing hydraulic elements.

To use it, the end screw on the valve block is removed, mount the pressure gauge and tighten it, then turn on the cock of the pressure gauge.

The pressure valve is shown on the gauge during operation.

The pressure in the hydraulic system before delivering the machine has been properly adjusted to the delivering the ironworker machine has been properly adjusted to the max working value, so please do not re-adjust at your option.

Here are the drawings:

Ironworker Hydraulic System Diagram 1

Ironworker Hydraulic System Diagram 2

Ironworker Hydraulic System Diagram 3

Ironworker Hydraulic System Diagram 4

Ironworker Hydraulic System Diagram 5

Ironworker Hydraulic System Diagram 6

(1) Introduction:

The hydraulic steelworker machine adopts the electric system of A. C 3-phase and 208/220/440V 50HZ in the main circuit and single-phase 24V and 6V comes from a transformer in the control circuit and signal circuit.

The section cutting station is fitted as standard with a push bottom for the emergency stop.

According to the request of machine technology, the electric system includes:

(2) Start and stop of Motor:

By pressing the button SB3, the motor for oil pump is started by pressing the button SB1 or SB2, the motor is stopped. Short circuit and overload protection are executed by an automation switch.

(3) Operating process:

1) Single stroke

By turning the switch SA4 to the “NORMAL” position mode and stepping the foot pedal SA6 or SA7, KA2 or KA4 get power, at the same time YU5b or YU7b get power also, so the piston for punching or the piston for section cutting moves downward. As soon as they touch the limit switch SQ2 or SQ5, KA1 or KA3 get power, KA2 or KA4 lose power YU5b or YU7b are turned off, the tow pistons stop moving downward, simultaneously, KA1 or KA3 turn on YV5a or YV7a turn on, the two pistons begin to return.

When they touch limit switch SQ1, SQ4 or SQ6, the return is over.

When the cylinder goes to the middle position. Release SA6 or SA7 to half position, KA2 or KA4 lose power. YV5b or YV7b lose power the cylinder stops.

When releasing the footswitch SA6 or SA7, it will return.

2) Lunching adjustment

By turning the switch SA4 to the “JOG” mode position and sapping the foot pedal SA6 or SA7, KA6 is turned on, so the piston for punching or the pistons for section cutting and notching move downward slowly, when they touch the limit switch SQ2 or SQ5, KA3 or KA6, YU5b or YU7b are turned off, so two pistons stop moving downward, when foot pedal SA6 or SA7 is released.

Two pistons cannot move upward. To then return to the top dead point, the switch SA4 must be turned to the “NORMAL” mode position.

3) Back-gauge device

When putting switch SA3 to auto position, turn the SA4 to “NORMAL” position, putting the cutting material to back-gauge pressing the switch SQ8.

The section cutting begins to perform after the time delayer KT2 delays a few seconds when the KA5 gets power.

When touching the limit switch SQ5, the section cutting cylinder returns to the top dead point. The cutting action is completed.

List of Electric Elements

| Symbol | No. Name | Technical Data | Quantity | Type |

|---|---|---|---|---|

| SB1-2 | Push button | Red Mushroom Head | 2 | XB2-BS542C |

| SB3 | Starting button | Green φ22 | 1 | XB2BW337B1C |

| SA3-5 | Limit switch | Black φ22 | 3 | XB2BD217 |

| SQ1-2 | Limit switch | 2 | Z-15GW22-B | |

| SQ4-6 | Limit switch | 3 | Z-15GW22-B | |

| QS | Load switch | V2 | 1 | VAR10 |

| KM1 | A. C. contactor | 24V | 1 | LC1-D3210 |

| KA1-4 | Intermediate repay | 24V 5A | 4 | MY4 |

| FU1-4 | Fuse | 6A | 4 | C45N |

| FU5-6 | Fuse | 6A | 2 | C45N |

| HL2 | Signal lamp | 24V green | 1 | XB2-EV136 |

| VC | Silicon rectifier | 2A | 1 | KBPC20-10 |

| V | Overcurrent suppressor | 1 | 3TX3-221A | |

| TC | Transformer | 440V 220V208V 250VA/29V 24V | 1 | JBK3-250 |

| SA6-7 | Pedal switch | SFM-1 | 2 | |

| SQ7 | Limit switch | 1 | 4MC-5000 | |

| QF | Motor breaker | 25-40A | 1 | GV2-M |

| SQ8 | Limit switch | 1 | Z-15G-B |

Hoisting

The hydraulic ironworker machine is fitted with a lifting ring, mounted on top of the machine.

All lifting and maneuvering should be carried out using this ring along with a suitably rated chain or sling.

The ring can be removed if desired after the final siting of the machine. Do not use chain and sling under ironworker machine.

Here are the drawings:

Hydraulic Ironworker Installation Diagram

The foundation with holes for anchor bolt should be prepared before setting the machine.

Only after the concrete foundation is hard set, the machine can be set on it.

Then level the machine with a level gauge, mount anchor bolts, our the liquid concrete into the bottom of the machine body and holes for the anchor bolts.

After the concrete is hard set, level the working table of the punching station of the machine (permissible coherence is 100:0. 2), then tighten the anchor bolts.

Preparation before Trial Running

Clean and remove rust-proof grease on the die and blade of the machine, inspect if all parts, power supply wire and earth line are in good condition, and all lubricating points should be lubricated.

The hydraulic ironworker machine employs a centralized lubrication system with a manual grease gun for efficient maintenance and prolonged equipment life. This system ensures consistent lubrication across all critical components, reducing wear and enhancing overall performance.

To optimize the lubricant’s viscosity and protective properties, a carefully formulated mixture is recommended. Combine ISO VG 68 hydraulic oil (equivalent to #35 mechanical oil) with calcium-based grease in a 4:1 ratio. This blend provides superior adherence to metal surfaces and excellent resistance to water washout, crucial for the demanding environment of metalworking operations.

For optimal machine performance and longevity, implement a daily lubrication routine. Operate the grease gun 2-3 times per day, ensuring all designated lubrication points receive an adequate supply of the lubricant mixture. This practice maintains proper component protection, reduces friction, and minimizes the risk of premature wear or failure.

Regular inspection of lubrication points and monitoring of grease consumption can help identify potential issues early, allowing for proactive maintenance and minimizing downtime. Adjust the lubrication frequency based on the machine’s workload and operating conditions to maintain peak efficiency.

1) Adjustment of Punching Stroke (Fig. 3)

There are stop blocks of upper-and lower limit switch, which can be vertically adjusted, on the right side of the punching station.

According to the required position, the blocks are fixed on the guide rod, which is mounted on the piston rod and can be moved with it, by set screw.

2) Adjustment of Punch & Die

Loosen the set screw of the die bolster and turn the knob to the “INCHING” position to make the piston rod in the punching cylinder move downward by inchmeal and the punch aligns itself with the die, ensure well-distributed around clearance between them.

Then fix the bolster on the working table by the set screw and make the punch return to the top dead point, so the adjustment before punching operation is finished.

There are two holes for mounting dies or the bolster large hole is used for mounting the die to punch a large hole on the thin plate other one is used for mounting the die to punch hole with a diameter less than 30mm and for punching hole on the flange of channel and angle bar.

3) Adjustment of Hold-down Unit

The hold-down unit must be correctly adjusted to allow the easy handling of materials.

In general, the distance between the bottom of the hold-down and the top of the die should be adjusted to 1. 2 times the thickness of the plate to be punched.

To adjust hold-down, it is only necessary to turn a nut with left or right thread connected with the hole-down unit.

4) Replacement of Punch & Die

Loosen the fixed nut by a wrench, the punch can be removed.

After mounting a new punch, the nut is tightened (mounting size of the ends of various punches are the same to allow easy replacement ).

Replace process of the die is very easy and simple.

Whether cutting flat bar, cutting profile or notching, clearance of blade should be properly adjusted first.

As shown in fig. 1there are six pads (4) on the life-right housing of the machine body.

By adjusting the screw and the nut on the pads, the proper clearance of the blade between the left housing and pads can be obtained.

1) Adjustment of Blade Clearance

Adjusting screws are positioned around the stable fixing screws to support and reset the shear blades, accessible when the shear table is removed.

By turning these screws, the suitable clearance between stable and movable blades will be obtained.

Even clearance between them along the entire blade length should be maintained.

In general, this clearance should be 10% the thickness of the plate to be cut.

After adjusting remount the shear table.

2) Replace Blade

Both top and bottom blade have four cutting edges.

After turning blades for 4 times, regrind or replace of the new blade should be carried out.

After replacing the re-adjustment clearance of blades should be taken into account.

1) Adjustment of Blade Clearance

The angle cutting unit is fitted with a stable blade which is composed of two blades which are in square to each other.

Adjusting screws are positioned around blade fixing screws to support cutting blades.

By turning the adjusting screws the proper clearance between the stable blade and movable blade on the carriage can be obtained.

Even clearance between stable and movable blades is important along the entire blade length and care should be taken to ensure that stable blade is parallel to movable one.

This clearance, in general, is 10% of even thickness of angle flange to be cut.

After adjustment, the angle supporter is mounted.

2) Replace Blade

Both horizontal and vertical blade of stable blade unite have four cutting edges.

Regrind or replace them with new blades after turning them four times.

The movable blade is fixed on a carriage by screws.

After regrinding or replacing the blunt blades, the blade clearance should be re-adjusted.

1 ) Adjust Clearance

There are two angle shape stop blocks, which support the stable blade and are fixed on the housing by screws, on both sides of the stable blade.

Adjusting screws are positioned around the fixing screws to adjust the clearance between the angle shape stop block and the housing, and the clearance between the supporting face nestled to the angle shape stop block and the stable blade, and the housing.

So the adjustment of clearance between the stable blade and the movable blade fixed on the carriage is carried out.

After doing this, the profile supporter is mounted.

2) Replace Blade

Remove the carriage and loosen the angle shape stop block to replace the old blade with a new one. After replacing clearance re-adjustment should be carried out.

1) Adjustment of Blade Clearance

By moving the bolster the top-end blade on, it is set to parallel to the one on the punch to allow proper clearance, then fix the bolster on the table by the screw.

Adjusting screws are positioned around the fixing screw to adjust the blades on both sides of the punch, ensuring proper clearance which is 10% of the thickness of the plate to be cut.

After doing this the notching table is mounted.

2) Replace Blade

All there blades on the die have four edges. After replacing four times it is necessary to regrind or replace with new ones.

Top blade is fixed on the punch by the screw, loosen the screw replace the old blade with a new one.

After replacing re-adjusting clearance should be performed.

Angle steel 45ºmiter cut can be performed at the section position of picture (1) B-B.

1) Pour enough filtered hydraulic oil (supplied by user yourselves) into the oil tank.

2) Check if clearance of Blades is proper, adjust it as necessary.

3) Turn on the power supply and check if the action of various electrical elements is correct, installation is proper.

Push and step all push buttons, limit switches, foot pedal etc, to observe of actions of electromagnet and replay are handy.

4) Star the motor to check if its running direction is correct, the pressure in the hydraulic system is in accord with the demands, overflow pressure in the overflow valve conforms to the demands and the action of the change-over valve is handy.

After finishing all preparation work before trial running, the trial running and operating process can be carried out.

The operating process is as follows:

1) Pushing the operating button and running on the power supply, a green signal lamp lights to indicate that the electric system has turned on and operation can be started.

2) Starting the motor, lubricating the top and lower chambers of punching cylinder and section cutting cylinder in order check if the punch and section cutting blade can reach the top and lower dead point.

3) Trial running in an idle cycle, test inching and single stroke for punching and section cutting in order.

During testing, the operation circumstances of various parts should be checked carefully. If any of them is out of order, after clearing these troubles, further test can be performed.

4) Pressure should be added step by step in the load test. The number of performing cut or punch test in max. capacity should not less than 3 times.

Protective covers are installed at each workstation. Never extend hands or tools beyond these covers. Additionally, adhere to the following critical safety and maintenance guidelines:

1) Operators must thoroughly familiarize themselves with the machine’s operation manual and develop proficient operating skills before use.

2) Regularly inspect and maintain proper electrical insulation and grounding connections to ensure safety.

3) Never perform punching and notching operations simultaneously, as this can overload the machine and compromise safety.

4) Avoid overloading the machine. Adhere to material specifications: maximum tensile strength of 450 N/mm² and hardness not exceeding HB 180.

5) Maintain sharp edges on all cutting blades through regular inspection and sharpening or replacement as needed.

6) Ensure workpieces are free from welding scars, burrs, or other surface irregularities before punching or cutting to prevent damage to tooling and ensure clean cuts.

7) Adjust the hold-down unit according to material thickness within the machine’s capacity to secure workpieces properly and prevent movement during operation.

8) After blade replacement, meticulously check and adjust clearances to maintain optimal cutting performance and prevent premature wear.

9) Conduct regular inspections of all mechanical connections and components. If any abnormalities are detected, immediately cease operation and perform necessary repairs or maintenance.

10) Adhere to a strict lubrication schedule for all designated points to prevent excessive wear on working surfaces and ensure smooth operation.

| No. | Name | Spec. | Qty |

|---|---|---|---|

| 1 | Sleeve | 1 | |

| 2 | Friction Block | 3 | |

| 3 | Stop Running Block | 1 | |

| 4 | YX Shape Seal Ring | D165 | 2 |

| 5 | O Shape Seal Ring | 130×3. 1 | 1 |

| 6 | -do- | 165×5. 7 | 1 |

| 7 | YX Shape Seal Ring | d125 | 1 |

| 8 | Dust-proof Ring | 125 | 1 |

| 9 | YX Shape Seal Ring | D200 | 2 |

| 10 | O Shape Seal Ring | 135×5. 7 | 2 |

| 11 | -do- | 200×5. 7 | 1 |

| 12 | YX Shape Seal Ring | d125 | 1 |

| 13 | Dust-proof Ring | 125 | 1 |

| 14 | SF-1 Compound Bearing of Compound Material | 5560 | 1 |

| No. | Name | Specification or Type | Qty |

|---|---|---|---|

| 1 | Foot Pedal | Y13-11 | 2pcs |

| 2 | Key to the Interlocking Device | 2pcs | |

| 3 | Hexagon Key Wrench | S=3-19 | 1set |

| 4 | Hook Shape Wrench | D=90-95 | 1pc. |

| 5 | Discharge Cock | 1pc. | |

| 6 | Manometer Unit | 1set | |

| 7 | O Shape Seal Ring | 130×3. 1(GB1235-76) | 1pc. |

| 8 | -do- | 165×5. 7(GB1235-76) | 1pc. |

| 9 | -do- | 200×5. 7(GB1235-76) | 1pc. |

| 10 | -do- | 135×5. 7(GB1235-76) | 2pc. |

| 11 | Dust-proof Ring | 125 | 2pcs |

| 12 | SF-1 Bearing of Compound Material | 5560(SF-1) | 1pc. |

| 13 | Oil gun | Capacity:200cm³ | 1 |

PACKING LIST

| No. | Name | Specification or Type | Qty |

|---|---|---|---|

| 1 | Operation Manual | 1copy | |

| 2 | Test Certificate | 1copy | |

| 3 | Packing List | 1copy | |

| 4 | Foot Pedal | SFM-1 | 2pcs |

| 5 | Earth Screw | M16×300 | 4pcs |

| 6 | Key to the Interlocking Unit | 2pcs | |

| 7 | Manometer Unit | 1set | |

| 8 | Hook Shape Wrench | D=90-95 | 1pc |

| 9 | Discharge Cook | 1pc | |

| 10 | Hexagon key Wrench | S=3-19 | 1set |

| 11 | O Shape Seal Ring | 130×3. 1(GB1235-76) | 1pc |

| 12 | -do- | 165×5. 7(GB1235-76) | 1pc |

| 13 | -do- | 200×5. 7(GB1235-76) | 1pc |

| 14 | -do- | 135×5. 7(GB1235*5. 7) | 2pc |

| 15 | Dust-proof Ring | 125 | 2pcs |

| 16 | SF-1 Bearing of Compound Material | 5560(SF-1) | 1pc |

| 17 | Oil gun | Capacity:200cm | 1 |