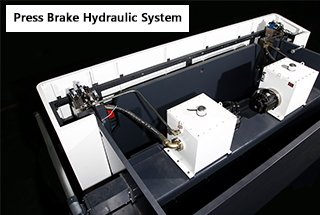

Ever wondered what keeps a CNC press brake running smoothly? The answer lies in the hydraulic oil. This essential fluid ensures optimal performance and longevity of the machine. Our article dives into the types of hydraulic oil best suited for different temperatures, the importance of regular maintenance, and tips for avoiding common pitfalls. By understanding these key elements, you’ll be equipped to maintain your press brake efficiently and prevent costly breakdowns. Ready to master your machine’s maintenance? Read on to learn more!

The hydraulic oil used in this CNC press brake should have a viscosity of 32-46 cSt (ISO VG 32-46) at 40°C. This corresponds to approximately 4-5°E (Engler viscosity) at 50°C.

For optimal performance, it is recommended to use ISO VG 68 anti-wear hydraulic oil in warmer conditions and ISO VG 46 in colder environments. These grades provide suitable viscosity across typical operating temperatures.

Maintaining hydraulic system cleanliness is critical, as contamination is the primary cause of system failures. Before initial oil filling, thoroughly clean the reservoir to remove all debris and contaminants.

Fill the cleaned tank with hydraulic oil that has been fine-filtered to 10 μm or better. Refer to the machine’s technical specifications for the correct oil capacity.

It’s important to note that even newly purchased hydraulic oil may not meet cleanliness standards required for precision hydraulic systems.

After the initial 500 hours of operation, drain and clean the reservoir, then refill with fresh, finely filtered hydraulic oil. Subsequently, perform oil changes and tank cleaning every 2000 operating hours or annually, whichever comes first.

Operation at low temperatures (below -5°C) is not recommended. If unavoidable, allow for an extended warm-up period under no-load conditions. Consider installing an oil heater for cold-weather operations.

Under normal conditions, maintain oil temperature below 70°C. For high-temperature environments or intensive use, install an oil cooler using the provided tank interface to ensure optimal fluid viscosity and system longevity.

Regularly monitor oil condition using particle counting and viscosity tests to maintain system efficiency and prevent premature component wear.

Proper maintenance of the CNC press brake machine is critical, with particular emphasis on the management and replacement of hydraulic oil. Regular monitoring and replacement of the oil are essential for optimal machine performance and longevity.

For newly commissioned CNC press brakes, the initial hydraulic oil change schedule and maintenance protocol are as follows:

Additional key maintenance points for CNC press brakes include:

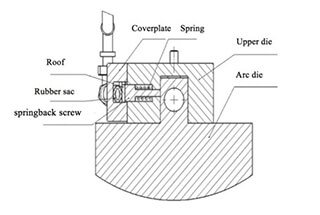

Hydraulic oil leakage in a press brake can significantly impact machine performance, precision, and safety. Common causes of oil leakage include:

To effectively address hydraulic oil leakage, a systematic approach involving thorough inspection, accurate diagnosis, and proper repair or replacement of affected components is essential. Regular maintenance, including oil analysis and system pressure checks, can help prevent leaks and extend the press brake’s operational life.

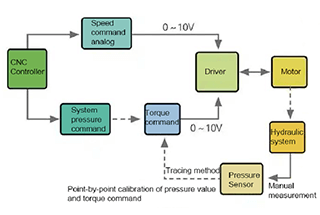

Hydraulic oil heating is typically unnecessary, except in extremely cold environments. However, precise temperature control is crucial for optimal press brake performance. In sub-zero conditions, excessively cold oil can become viscous, leading to sluggish operation and increased wear on components. Conversely, if the oil temperature rises too high, it becomes less viscous, potentially causing inconsistent pressure transmission and compromising machine precision.

For situations requiring oil heating, a simple electric heating system can be implemented. This typically involves installing thermostatically controlled heating elements directly in the hydraulic reservoir or along the return line. The ideal operating temperature range for most hydraulic oils used in press brakes is between 40°C to 60°C (104°F to 140°F). Maintaining the oil within this range ensures optimal viscosity for efficient power transmission, proper lubrication, and extended oil life.

It’s important to note that modern hydraulic systems often incorporate temperature sensors and automated heating/cooling systems to maintain optimal oil temperature. This proactive approach helps prevent both cold-start issues and overheating, ensuring consistent press brake performance across varying environmental conditions.

Press brakes typically utilize ISO VG 46 anti-wear hydraulic oil, which is specifically formulated for high-pressure hydraulic systems in industrial machinery. This grade of oil offers optimal viscosity and thermal stability for press brake operations. The anti-wear additives in the oil form a protective film on metal surfaces, significantly reducing friction and wear on critical components such as pumps, valves, and cylinders.

Using ISO VG 46 anti-wear hydraulic oil provides several benefits:

It’s crucial to avoid using standard ISO VG 46 hydraulic oil without anti-wear additives, as this can lead to premature component wear, increased system temperatures, and potential damage to valve and cylinder seals. The lack of proper additives may also result in reduced efficiency and increased energy consumption.

For optimal press brake performance and longevity, always consult the manufacturer’s specifications and use the recommended hydraulic oil type and grade.

The frequency of hydraulic oil replacement in press brakes depends on several factors, but generally, it is recommended to change the oil every 2,000 to 4,000 operating hours or once a year, whichever comes first. However, this schedule can vary based on the machine’s usage, environmental conditions, and oil quality.

Regular oil analysis is crucial for optimal press brake performance. It’s advisable to check the oil monthly and perform a comprehensive analysis quarterly. This analysis should include viscosity, water content, particle count, and additive levels. If the analysis reveals significant degradation or contamination, immediate oil replacement is necessary.

Key indicators that hydraulic oil needs immediate replacement include:

Proper oil maintenance not only extends the life of hydraulic components but also ensures consistent press brake performance and accuracy. Always refer to the manufacturer’s recommendations for specific oil types and change intervals, as these can vary between different press brake models and brands.