Have you ever wondered how those massive steel plates are cut with such precision? Enter the world of hydraulic shearing machines – the unsung heroes of the metal fabrication industry. In this blog post, we’ll dive into the fascinating mechanics behind these powerful machines and explore how they shape the world around us, from ships to skyscrapers. Get ready to be amazed by the sheer force and finesse of hydraulic shearing technology!

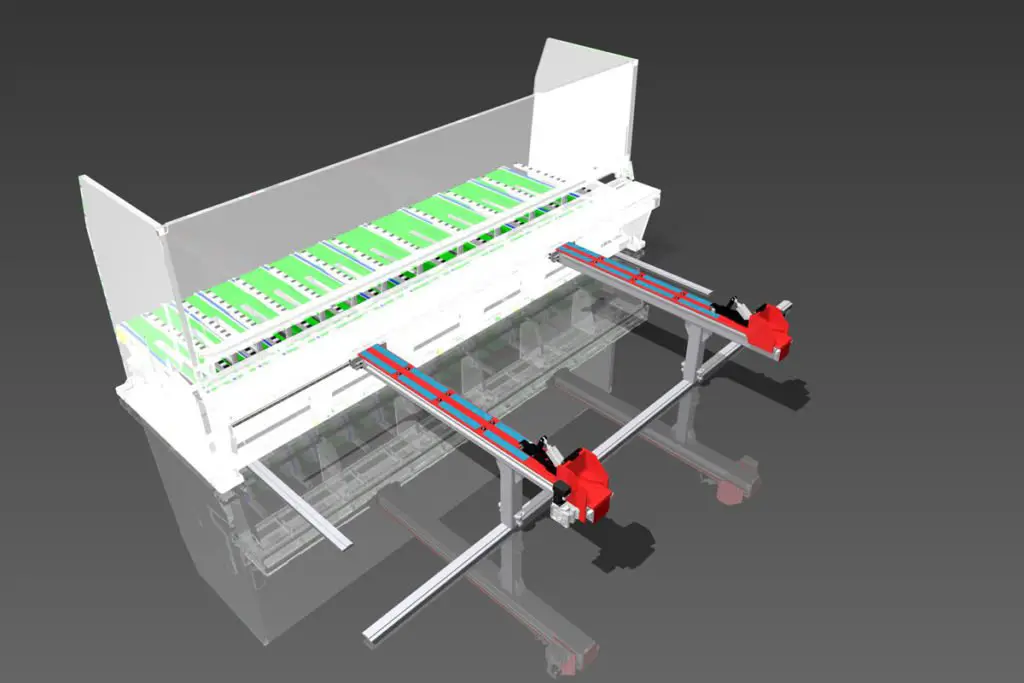

A hydraulic shearing machine is a specialized piece of equipment designed to cut metal plates with precision. It operates by using a moving upper blade and a fixed lower blade to apply a shearing force to metal plates of varying thicknesses. This process results in the separation of the metal plates into desired sizes, achieved by utilizing an appropriate blade clearance.

Hydraulic shearing machines are a type of forging machinery primarily used for metal processing. They are widely utilized across multiple industries due to their versatility and efficiency. Some of the key industries that benefit from hydraulic shearing machines include:

Hydraulic shearing machines play a crucial role in modern industrial production, providing precise and efficient metal cutting capabilities. Their widespread use across various industries highlights their importance in manufacturing and processing operations. By understanding the functionality and applications of these machines, industries can optimize their production processes and achieve high-quality results.

For a visual demonstration of a hydraulic shearing machine in action, please refer to the provided video below.

A hydraulic shearing machine is a type of industrial equipment used for cutting metal sheets and plates. It operates using a hydraulic system to generate the necessary force for shearing. This machine is widely utilized in various industries due to its precision, efficiency, and ability to handle different thicknesses of metal materials.

Hydraulic shearing machines are used in a variety of industries due to their versatility and efficiency. Some of the key sectors include:

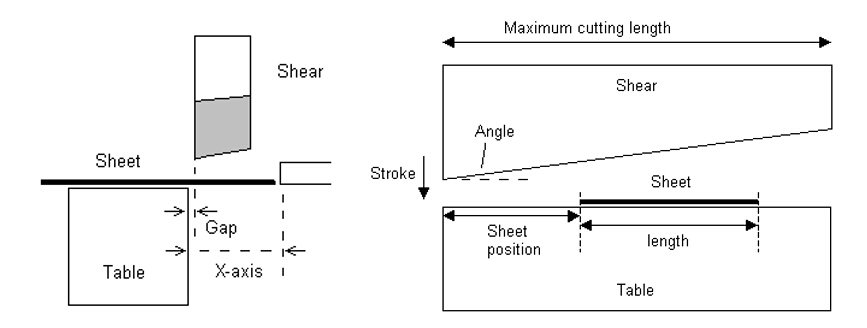

The hydraulic shearing machine operates on the principle of shear cutting, where sheet metal is cut by the relative motion of two blades. The process is driven by a hydraulic system that provides the necessary force and controlled movement. Here’s a more detailed explanation of the working principle:

This hydraulic-driven process enables the shearing machine to deliver high cutting forces with precise control, making it suitable for a wide range of sheet metal thicknesses and materials.

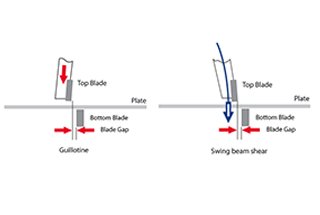

Shearing machines are essential tools in the metalworking industry, used to cut sheet metal and other materials. They can be broadly classified into two main types: hydraulic shears and mechanical shears. Hydraulic shearing machines are more commonly used due to their lower energy consumption and reduced noise compared to mechanical shears.

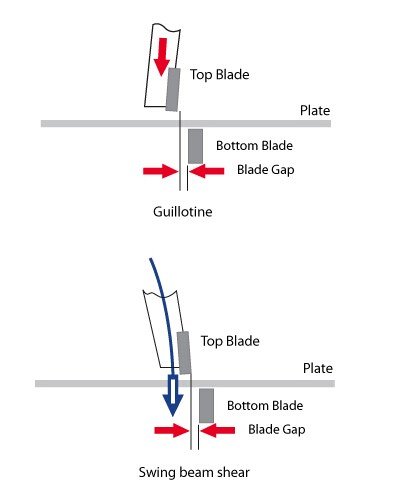

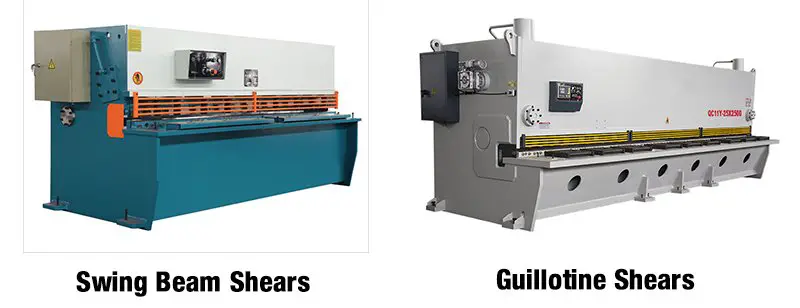

Hydraulic shearing machines can be further categorized based on the movement of the blade carrier:

Here is a detailed list of various types of shearing machines, along with their specific characteristics:

Hydraulic shearing machines offer a range of options to suit various industrial needs, from simple manual operations to complex, multi-functional machines. Understanding the specific types and their applications can help in selecting the right machine for a given task, ensuring efficiency and precision in metalworking operations.

Hydraulic shearing machines offer several advantages over traditional plate shears, making them a preferred choice in modern industrial applications. Here are some key benefits:

Numerical Control (NC): One of the most significant advantages of hydraulic shearing machines is their ability to be controlled by numerical codes. These codes are generated through various combinations of characters based on specific work requirements. This numerical control allows for precise management of the machine’s orientation, speed, and cutting force.

Accurate Positioning: Hydraulic shearing machines excel in positioning accuracy. The adjusting rod can rotate continuously around the central axis without dead angles, ensuring precise cuts. This feature is particularly beneficial for complex and repetitive tasks.

Quiet Operation: Unlike traditional mechanical shears, hydraulic shearing machines operate quietly. This reduces noise pollution in the workplace, contributing to a more pleasant and healthier environment for operators.

Ease of Use: The operation of hydraulic shearing machines is straightforward and easy to learn. Operators primarily need basic computer skills to manage the machine, thanks to its user-friendly interface and automated controls.

Material Quality: These machines are typically constructed from durable stainless steel, which offers strong corrosion resistance and stability. This makes them suitable for environments with high vibration amplitudes and harsh conditions.

Robust Design: The robust construction of hydraulic shearing machines ensures long-term reliability and minimal maintenance requirements, further enhancing their operational efficiency.

Self-Defense Fence: Safety is a critical consideration in industrial machinery. Hydraulic shearing machines are equipped with sturdy self-defense fences that protect operators. In the event of a machine failure, the fence acts as a barrier, preventing direct contact between the operator and the machine.

Enhanced Visibility: The adjustment of lighting in hydraulic shearing machines improves visibility, allowing operators to quickly and accurately position the material. This feature adds convenience and safety to the production process.

Sleek Appearance: In addition to their functional benefits, hydraulic shearing machines often feature a sleek and modern design. This not only enhances the aesthetic appeal of the workspace but also reflects the advanced technology and precision engineering behind the machine.

Versatility: Hydraulic shearing machines are highly versatile, capable of handling a wide range of materials and thicknesses. This makes them suitable for various industrial applications, from automotive to aerospace manufacturing.

Hydraulic shearing machines represent a significant advancement over traditional plate shears, offering precision, efficiency, durability, safety, and aesthetic appeal. Their ability to be controlled through numerical codes, combined with their robust construction and user-friendly operation, makes them an invaluable asset in modern manufacturing environments.

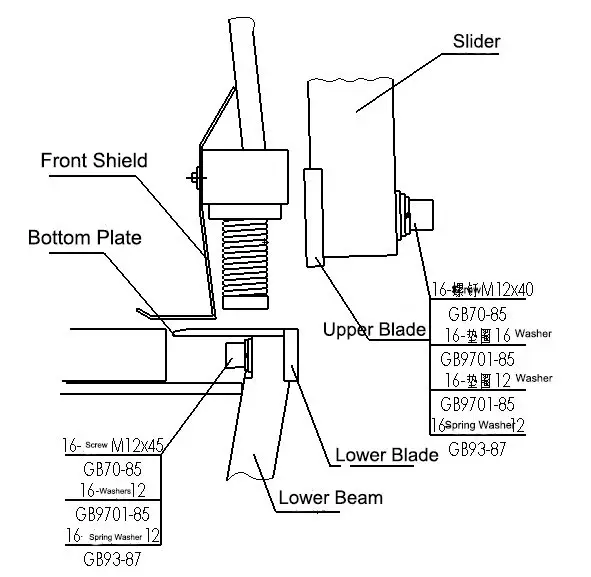

Hydraulic shearing machines are essential in the metalworking industry for cutting sheet metal with precision and efficiency. Understanding the various components and their functions is crucial for optimal operation and maintenance. Below is a detailed overview of the main parts and functions of a hydraulic shearing machine.

The frame of the shearing machine is a robust structure constructed from steel plates, ensuring stability and durability. It includes several key components:

Additionally, hydraulic cylinders and sliding block guide supports are installed on both sides of the frame. These components act as a push-up mechanism to control the clearance of the blades, ensuring precise cuts.

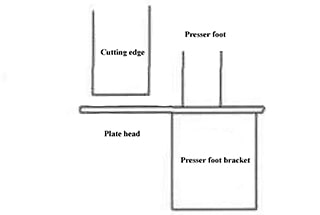

The blade holder is a critical component that houses the upper blade. It is connected to the hydraulic cylinder, allowing for vertical movement to transmit shear force and perform cutting. The blade holder also includes the backgauge mechanism, which accurately positions the size of the sheared plate.

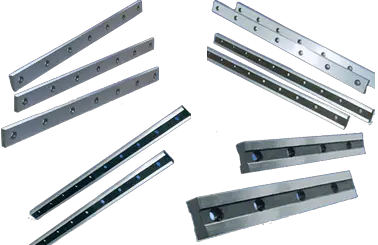

The shear blades are made from high-standard steel and are designed to cut various types of steel sheets, from low carbon to stainless steel. Both the upper and lower blades feature four interchangeable cutting edges, which can be rotated to extend the lifespan of the blades.

The backgauge mechanism is essential for precise cut-to-length operations. It includes:

The fuel tank is mounted on the oil tank base behind the shearing machine. It houses:

An oil gauge on the left side of the tank indicates the hydraulic oil level, which should be maintained at the middle level for optimal performance.

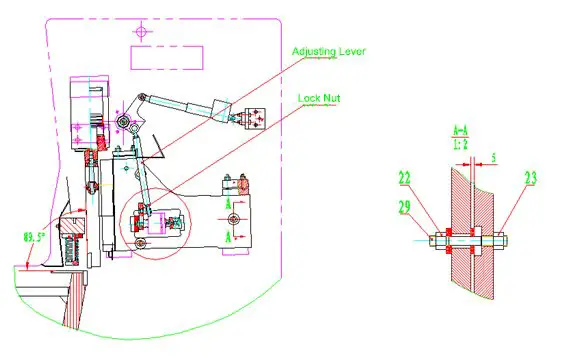

This device allows for the adjustment of the gap between the upper and lower blades to match the thickness of the material being cut. Proper clearance adjustment is crucial for optimizing shear force, extending blade lifespan, and ensuring high-quality cuts. The general rule is to set the gap to 10% of the material thickness.

The front supporter includes a side retaining device attached to the worktable, ensuring that the sheared plate remains perpendicular on both sides, which is essential for accurate and straight cuts.

Safety is paramount in operating a shearing machine. The finger protection plate is installed on the machine clamp holder to maintain a safe distance between the operator’s fingers and the cutting blades. This plate must meet mechanical safety standards to prevent accidents.

Understanding the parts and functions of a hydraulic shearing machine is vital for its efficient and safe operation. Each component plays a specific role in ensuring precise cuts, maintaining blade longevity, and protecting the operator. Regular maintenance and proper adjustment of these components will enhance the machine’s performance and extend its service life.

Safe distance for fingers protection

| Shears | max.A | min.B |

|---|---|---|

| 8/6.5/3000 | 12 | 80 |

| 8/6/4000 | 12 | 80 |

| 10/3000/4000 | 20 | 120 |

| 13/3000 | 23 | 200 |

Note: These dimensions comply with mechanical safety standards.

When positioning the plate in the backstop block, it is crucial to avoid placing your fingers between the plate and the shearing machine table. Failure to do so could result in the plate pressing against your fingers during the pressing process, leading to severe injuries.

Additionally, if the backgauge block is not in position, do not push the plate through the finger protection plate. This precaution helps prevent potential finger injuries.

Hold down Cylinder

The hold-down cylinder is essential for preventing plate movement during the cutting process. It firmly presses the plate to ensure stability and accuracy, thereby enhancing the quality of the cut and maintaining operator safety.

Electrical System of the Shearing Machine

The electrical system of a shearing machine is designed to perform several critical functions:

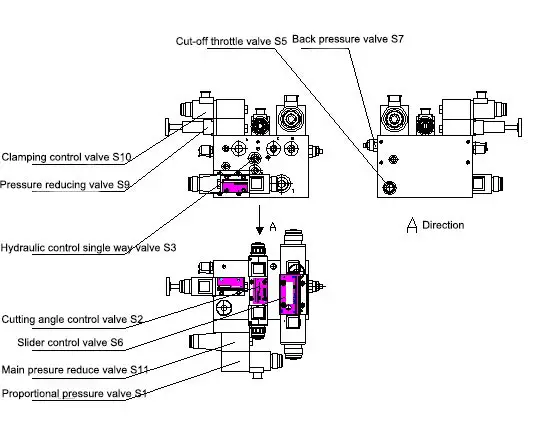

Hydraulic System of the Shearing Machine

The hydraulic system is a complex assembly of various components that work together to perform the cutting operation. It includes:

The hydraulic system’s precise control of pressure and flow direction is critical for the efficient and accurate operation of the shearing machine. These revisions ensure that the article is not only accurate and professional but also provides clear and detailed information that can be easily understood by readers, enhancing its overall quality and value.

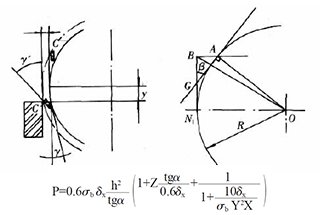

The maximum thickness that a hydraulic shearing machine can shear is primarily determined by the strength of the shearing mechanism and the shear force it can generate. Several factors influence the shear force, including:

Typically, hydraulic shearing machines can handle shear thicknesses up to 32mm. Beyond this thickness, the process becomes less cost-effective and efficient.

The shear sheet width refers to the maximum width of the metal sheet that can be cut in one pass by the shearing mechanism. This width is determined by the length of the cutting edge and the manufacturer’s specifications.

As long as the strip width is less than the throat depth of the shearing mechanism, there are no significant limitations on the size. With technological advancements, hydraulic shearing machines now offer plate cutting widths up to 6000mm, with some foreign models reaching up to 10,000mm.

To minimize bending and distortion in the sheared sheet metal, a smaller shear angle is generally preferred. While this increases the shear force required, it enhances the quality of the cut. However, the increased shear force can impact the strength and stiffness of the shearing mechanism’s stressed components.

The throat depth is crucial for longitudinal cutting methods. A smaller throat depth improves the stiffness of the frame but may reduce the overall quality of the machine. The trend in modern hydraulic shearing machines is to optimize throat depth to balance stiffness and cutting quality.

By understanding these specifications, users can select the appropriate hydraulic shearing machine for their specific needs, ensuring efficient and high-quality metal cutting operations.

Hydraulic shearing machines are versatile tools extensively utilized across various industries due to their precision, efficiency, and ability to handle a wide range of materials. Below are some of the key applications of hydraulic shearing machines in different sectors:

In the decoration industry, hydraulic shearing machines are often used in tandem with bending machines to create stainless steel doors and windows. These machines help in cutting metal sheets to precise dimensions, which are then bent and shaped to form decorative elements for special places, enhancing both functionality and aesthetic appeal.

Hydraulic shearing machines play a crucial role in the electrical and electric power industries. They are employed to cut metal plates into specific sizes, which are then further processed using bending machines. This process is essential in the manufacturing of electrical cabinets, refrigerator panels, and air conditioning shells. The precision cutting ensures that the components fit together seamlessly, maintaining the integrity and safety of the electrical appliances.

In the automobile and shipbuilding industries, large hydraulic shearing machines are indispensable for plate shearing tasks. These machines cut large metal sheets that are subsequently subjected to secondary processes such as welding and bending. The ability to handle thick and large plates makes hydraulic shearing machines ideal for producing car bodies, ship hulls, and other large structural components.

The aerospace industry demands high precision and accuracy, which is why CNC hydraulic shearing machines and electro-hydraulic synchronous CNC bending machines are preferred. These advanced machines offer superior accuracy and efficiency, essential for producing high-quality aerospace components. The precise cutting ensures that the parts meet stringent industry standards and can withstand the demanding conditions of aerospace applications.

Beyond the aforementioned sectors, hydraulic shearing machines and bending machines are also vital in various other industries. They are used in the production of machinery, construction materials, and even in the fabrication of everyday consumer goods. The versatility and efficiency of hydraulic shearing machines make them a valuable asset in any industry that requires precise metal cutting and shaping.

In summary, hydraulic shearing machines are essential tools in numerous industries, contributing to the production of high-quality components and products. Their ability to cut and shape metal with precision and efficiency makes them indispensable in modern manufacturing processes.

Pre-operation Preparation

Using a hydraulic shearing machine involves several critical steps to ensure safety, precision, and efficiency. Below is a detailed guide on how to operate the machine correctly:

By following these steps, you can operate a hydraulic shearing machine safely and efficiently, ensuring high-quality cuts and prolonging the machine’s lifespan.

By adhering to these guidelines, operators can ensure the safe and efficient use of hydraulic shearing machines, minimizing the risk of accidents and equipment damage.

Operating a hydraulic shearing machine requires careful attention to detail and adherence to safety protocols to ensure optimal performance and prevent accidents. Here are key considerations to keep in mind:

Regularly check the blade clearance and adjust it according to the thickness of the different materials being cut. Proper blade clearance is crucial for achieving clean cuts and prolonging the lifespan of the blades.

Ensure that the blade is sharp and that the cut surface is free of scars, gas cuts, and protruding burrs. Dull blades can lead to poor cut quality and increased wear on the machine.

When making adjustments to the machine, it must be turned off to prevent personal injury and machine damage. Always follow the manufacturer’s guidelines for making adjustments safely.

If abnormal noise or overheating of the oil tank is detected during operation, stop the shearing machine immediately to investigate the issue. The highest temperature of the oil tank should not exceed 60℃. Overheating can indicate potential issues with the hydraulic system that need to be addressed promptly.

Do not attempt to cut strips, as this can damage the machine. The minimum width of the material being cut should not be less than 40mm. Cutting narrow strips can place undue stress on the blades and the machine’s frame.

The cutting capacity of the hydraulic shearing machine depends on the strength of the material being cut. For example:

Understanding the material properties and adjusting the machine settings accordingly is essential for maintaining the machine’s integrity and ensuring precise cuts.

By following these guidelines, operators can ensure safe and efficient operation of hydraulic shearing machines, leading to high-quality output and extended machine life.

The blades of hydraulic shearing machines are critical components that determine the quality and efficiency of the cutting process. These blades are typically made from high-quality tool steels, which are chosen for their hardness, toughness, and wear resistance. The most commonly used materials for shearing machine blades include:

The hardness of shearing machine blades is a crucial factor that affects their cutting performance and durability. The standard hardness for these blades varies depending on the thickness of the material they are designed to cut. Here are the typical hardness values for blades used in hydraulic shearing machines:

These hardness levels ensure that the blades can effectively cut through standard cold-rolled plates and most stainless steel plates.

Standard blade hardness table

| 6.5/10mm | HRC | 58/59 |

|---|---|---|

| 13/16mm | HRC | 56/57 |

When cutting large quantities of stainless steel or other hard materials, rough edges may occur during the cutting process. This can be due to the increased wear and tear on the blades, which may not maintain their sharpness and precision over extended use. To address this issue, an optional blade with a slightly lower hardness (HRC 56/57) for 6.5/10mm shears is available. This blade is designed to provide a balance between hardness and toughness, reducing the occurrence of rough edges and improving the overall quality of the cut.

For more detailed information on the materials used for hydraulic shear blades, you can refer to the guide on “8 Commonly Used Materials of Hydraulic Shears Blade.” This resource provides an in-depth look at the properties and applications of different blade materials, helping you choose the right blade for your specific cutting needs.By understanding the material composition and hardness of shearing machine blades, you can make informed decisions to optimize the performance and longevity of your hydraulic shearing machine.

In the operation of shearing machines, the adjustment of the blade angle and clearance is crucial for achieving optimal cutting results. These adjustments are highly dependent on the material being processed, as different materials have varying properties such as thickness, hardness, and tensile strength.

The blade angle, often referred to as the “rake angle” or “tilt angle,” plays a significant role in the shearing process. Adjusting this angle can have various effects on the quality of the cut and the overall efficiency of the shearing machine.

The clearance between the blades is another vital parameter that needs careful adjustment. Proper clearance ensures a clean cut and prolongs the life of the blades.

Modern shearing machines often come equipped with advanced control systems that allow for real-time adjustments and monitoring of blade angle and clearance.

The adjustment of blade angle and clearance in shearing machines is a critical aspect of achieving high-quality cuts and efficient operation. By understanding the effects of these adjustments and making precise changes based on the material properties, operators can enhance the performance of their shearing machines and produce superior results. Regular monitoring and adjustments, facilitated by advanced control systems, further ensure consistent and reliable shearing operations.

When using a hydraulic shearing machine, the minimum cutting width is a critical factor to consider to ensure the quality and precision of the cut. The guidelines for minimum cutting width vary depending on whether the shearing is precise or not.

For non-precise shearing, the width of the sheared strip should not be less than three times the thickness of the plate. This guideline helps to prevent excessive deformation and ensures a more stable cutting process. For example, if the plate thickness is 5 mm, the minimum width of the sheared strip should be at least 15 mm.

For precision shearing, the requirements are more stringent. The width of the sheared material should be at least six times the thickness of the plate. This higher ratio is necessary to avoid distortion or bending of the material, which can compromise the precision and quality of the cut. For instance, if the plate thickness is 5 mm, the minimum width of the sheared strip should be at least 30 mm.

When evaluating the quality of shearing performed by a hydraulic cutting machine, several key parameters need to be considered, especially for a 2mm ordinary cold-rolled plate. These parameters ensure the precision and consistency of the shearing process, which is critical for maintaining the quality of the final product. Below are the detailed criteria for assessing shearing accuracy:

By adhering to these parameters, the shearing accuracy of a hydraulic cutting machine can be effectively evaluated and maintained. Ensuring parallelism, straightness, and repeat positioning accuracy within the specified tolerances guarantees high-quality shearing results, which are essential for the subsequent manufacturing processes and the overall quality of the final product.

By following these detailed instructions, you can ensure the proper installation and optimal performance of the blades on your hydraulic shearing machine.

Blade clearance is a critical factor in the operation of shearing machines, directly impacting the quality of the sheared surface and the lifespan of the blade. Proper adjustment ensures efficient and safe operation. Here’s a detailed guide on adjusting blade clearance:

Typically, the standard clearance between the upper and lower blades is around 0.02mm, which is roughly the thickness of a standard A4 paper. A common method for adjusting blade clearance during installation is to use the shearing machine to cut paper.

This is a common mistake made by non-professionals during blade installation. To prevent the blades from striking each other, they often increase the gap unnecessarily, which is incorrect.

Regular adjustment of the blade clearance is necessary after prolonged use of the shears. It is recommended to set the blade clearance at around 10% of the metal sheet thickness. The lower blade is fixed on the hydraulic shearing machine, and the blade clearance can only be adjusted by changing the position of the upper blade. The minimum clearance should be between 0.05-0.1mm.

Proper blade clearance adjustment is vital for maintaining the quality of the sheared surface and extending the lifespan of the blades. Regular checks and adjustments, especially after prolonged use, ensure the shearing machine operates efficiently and safely.

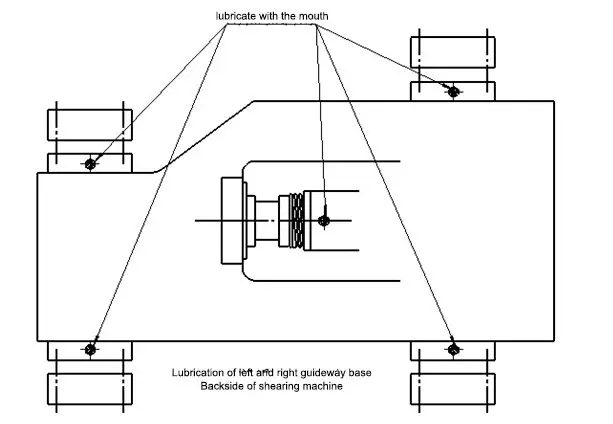

Proper maintenance of a hydraulic shearing machine is crucial for ensuring its longevity, reliability, and safety. This guide outlines the essential maintenance tasks, including daily lubrication, cleaning, and specific safety instructions.

When conducting any maintenance on the shearing machine, it is imperative to prioritize safety. Follow these steps to ensure a safe working environment:

Lubrication is essential for the smooth operation of the shearing machine. Follow these guidelines:

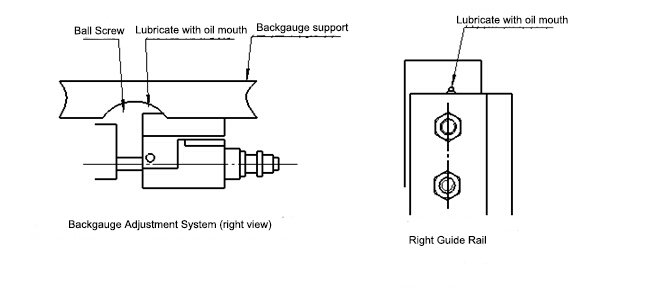

The lubrication points are shown below:

| No. | Lubrication point | Grease |

|---|---|---|

| 1 | Ball screw, nut and screw end bearing | Calcium base grease |

| 2 | Guide rail and slide guide base | Calcium base grease |

| 3 | Sliding block guide rail | Calcium base grease |

| 4 | Guide rail and clearance adjustment screw and nut | Calcium base grease |

For optimal performance, use the following hydraulic oils:

| Manufacturer | Hydraulic Oil |

|---|---|

| ESSO | NUTO H46 |

| SHELL | TELLUS 46 |

| GULF | HARMONY 46 AW |

| BP | HLP46 |

| TBXACO | RANDO OIL 46 |

| MOBIL OIL | MOBIL DTE 25 |

Regular replacement of hydraulic oil is crucial for maintaining the shearing machine’s performance. Follow these steps:

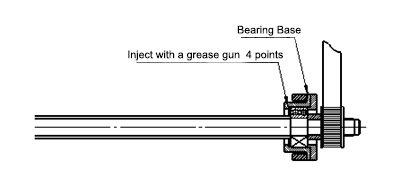

To ensure reliable operation, adhere to the following maintenance procedures, which are based on a 5-day workweek with 8 hours of work per day:

By following these maintenance guidelines, you can ensure the efficient and safe operation of your hydraulic shearing machine, ultimately extending its service life and maintaining its performance.

| Item | The attention points | Period |

|---|---|---|

| Whole body | Brush the dust and dirt on the machine, gently oil the blade | weekly |

| Slider | Gun lubrication | weekly |

| Backgauge support bearing | Gun lubrication | weekly |

| Backgauge ball screw | Gun lubrication | weekly |

| Slider guide rail | Check the derrick adjustment | 3 month |

| Check backgauge positioning | If the position error of the backstop blocks exceeds + 0.1mm, please reset | 3 month |

| Hydraulic parts and systems | Check the tank oil level. If you need to replace the new oil, change the filter to 20um | weekly |

| Drain the old oil and add the new oil | 12 months for the 1st time | |

| Check all valves, hydraulic system, tubing and connectors to prevent leakage, blockage and replacement when necessary. | 3 month | |

| Check the cleanness of the import and export filters | 3 month | |

| Footswitch | Check foot switch pedal, in case of deformation, breakage, etc | monthly |

| Electrical control equipment | Check the limit switches in the electric cabinet, and the wear and burn must be replaced in time | 3 month |

| Shears | Observe wear and abnormality of air metal shears | 3 month |

| Finger protector | Check the sheet shears protection device to prevent the finger from entering the dangerous area | monthly |

You can click the below link to view both the instruction manual for swing beam shears as well as guillotine shears.

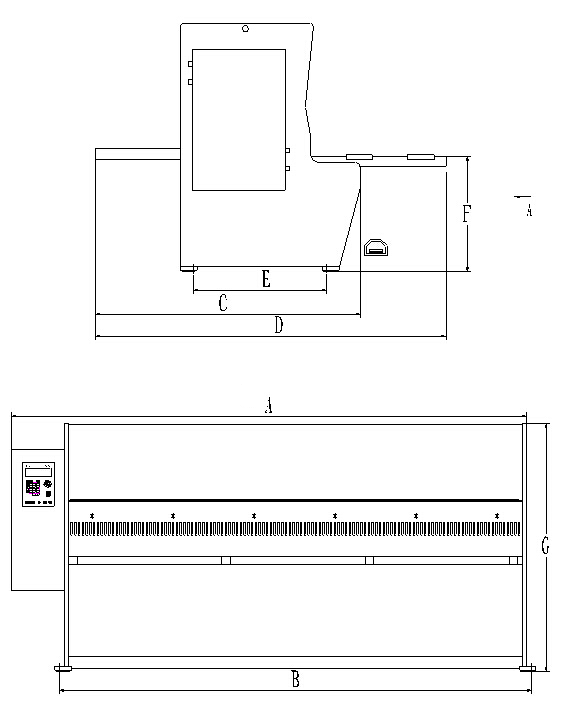

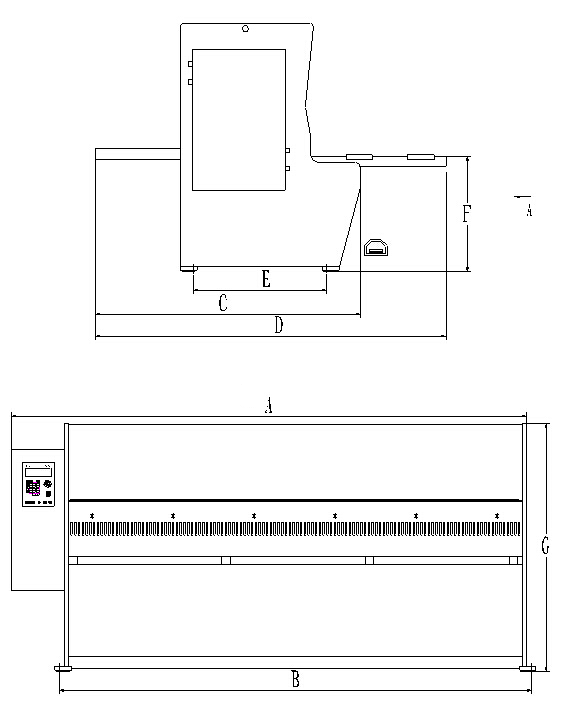

Here are the drawings:

Here are the drawings:

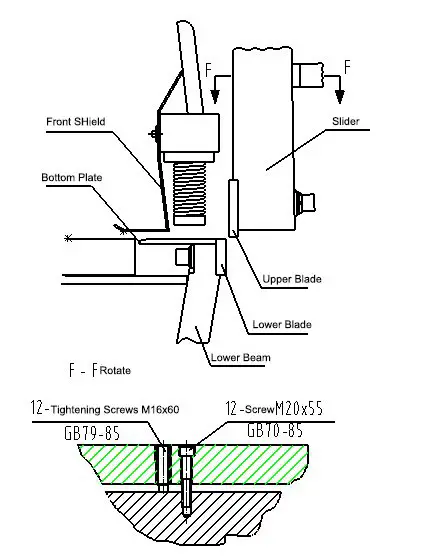

1. Slider Movement Up and Down

When the oil from the main oil line is directed into the three-position four-way directional control valve S6, S6Y1A gets energized. The oil then enters S6B through S6P, opens the one-way valve S8, and flows into the lower chamber of the right cylinder (the left and right cylinders are connected in series), causing the oil to flow from the right tank into the lower chamber of the left cylinder.

The oil in the upper chamber of the left cylinder enters S6A and then S6T, causing the slider to move up.

If S6Y1 is energized, the oil will enter S6A through S6, then into the upper chamber of the left cylinder, and then into the upper chamber of the right cylinder.

The oil will overcome the pressure of the back pressure valve S7 and enter S6T through S6B, then return to the oil tank, causing the slider to move down.

2. Adjusting the Shear Angle

If there is no set value for the shear angle of the shearing machine, the slider block cannot move up and down. Therefore, the shear angle must be set through the controller.

The shear angle adjustment is as follows:

When the oil is directed into the three-position four-way directional control valve S2, and Y2A is energized, the oil will enter S2B through S2P, open the hydraulic control single-way valve S3, and flow into the lower chamber of the left cylinder and the upper chamber of the right cylinder, causing the upper chamber of the left oil cylinder to not form a circuit and not move.

When the oil in the lower chamber of the right cylinder returns to the oil tank through S6T, the back pressure valve S7, and the S6B valve, the cutting angle becomes smaller.

Conversely, if Y2B is energized, the oil will enter S2A through S2P, open the single-way valve S4, and flow into the lower chamber of the right oil cylinder.

The oil in the upper chamber of the right cylinder can only enter the hydraulic control single-way valve S3 (at this point, the S3 valve is open), and the oil will enter S2T through S2B, causing the shearing angle to become larger.

The relationship between shear angle and shear force:

| Mild Steel (mm) | 6 | 8 | 10 | 13 | 13 | 13 | 13 | 16 | 16 | 20 |

|---|---|---|---|---|---|---|---|---|---|---|

| Stainless Steel (mm) | 3 | 4 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 12 |

| Shear Force (KN) | 132 | 220 | 430 | 730 | 620 | 620 | 650 | 730 | 850 | 1270 |

| Shear Angle Adjustment (°) | 0.5-2.5 | 0.5-2.5 | 0.5-2 | 0.5-2 | 0.5-2.5 | 0.5-2.5 | 0.5-2 | 0.5-3 | 0.5-2.5 | 0.5-3 |

3. The work of the hold-down cylinder

When the oil enters the directional control valve S9 through the clamping proportional control valve S10 (the proportional pressure of which is controlled by an electrical arc pressure adjustment switch), upon activation of S9, the oil will enter S9A through S9P and then enter the upper chamber of the clamping device, causing the clamping piston to move downward and create compression.

When S9 loses electricity, the clamping piston will be pushed upward by the internal spring of the clamp, forcing the oil in the upper chamber of the clamping cylinder to enter S9T through the S9 valve, resetting the clamping device.

| No. | Item | Amount | Price (RMB) |

|---|---|---|---|

| 1 | Timing belt | 1 | 150 |

| 2 | O ring | 1 | 10 |

| 3 | O ring | 1 | 12 |

| 4 | Sealing ring | 4 | 174 |

| 5 | Dustproof ring | 2 | 302 |

Under the guidance of the sheet metal workshop director, the hydraulic shearing machine operator must:

By adhering to these responsibilities and procedures, the hydraulic shearing machine operator ensures safe, efficient, and high-quality operations within the sheet metal workshop.

Hydraulic shearing machines are essential tools in the metal fabrication industry, primarily used to cut steel plates. These machines come in various configurations, with the most common being designed to handle steel plates with a thickness of 4-8mm and a width of 2.5-3.2m.

Understanding the differences and price points of these machines can help in making an informed decision based on the specific requirements of the cutting tasks at hand.

The detailed difference between swing beam shear and guillotine shear can be checked here.

Selecting the appropriate hydraulic shearing machine for your needs involves several critical steps. This guide will help you navigate the process to ensure you make an informed decision that aligns with your specific requirements and budget.

Below are answers to some frequently asked questions:

Hydraulic shearing machines are highly versatile and can cut a wide range of metal materials with varying thicknesses and properties. These machines can efficiently cut carbon steel plates, stainless steel sheets and plates (both hot-rolled and cold-rolled varieties), and aluminum sheets and plates, which are commonly used in the aerospace, automotive, and electronics industries. Additionally, hydraulic shears can handle other metals such as brass, copper, and various alloys.

The machines are capable of cutting metal sheets and plates with thicknesses ranging from very thin to typically up to 40mm or more, depending on the machine’s capacity. The adjustable shearing angle and blade clearance in hydraulic shearing machines allow for effective cutting of materials with different thicknesses, ensuring minimal distortion and high accuracy.

In specific applications, hydraulic shears are used in the aerospace industry to cut high-strength steel plates for aircraft parts, in the automotive industry to cut steel and aluminum plates for vehicle components like bodies and doors, and in the production of household appliances and electronics for cutting stainless steel and aluminum plates for products like refrigerators, air conditioners, and electronic device shells. Overall, hydraulic shearing machines are essential tools in various industrial sectors due to their ability to handle a diverse range of metal materials.

When deciding between a manual mechanical shearing machine and a CNC-controlled hydraulic shearing machine, several factors must be considered: precision, speed, control, maintenance, and specific shop requirements.

CNC-controlled hydraulic shearing machines excel in precision and accuracy, offering tolerance levels of ±0.1 mm and producing high-quality cuts with minimal material distortion. In contrast, manual mechanical shearing machines, while accurate, cannot match the precision needed for critical applications.

In terms of speed, mechanical shearing machines can achieve 60-100 cuts per minute, making them ideal for high-volume production. However, they require periodic rest and blade gap adjustments. Hydraulic shearing machines operate at a slower speed of 20-30 cuts per minute, suitable for precise but lower-volume cutting due to the fluid dynamics involved.

Control and automation are significant advantages of CNC-controlled hydraulic machines. They feature automated adjustments, digital displays, and precise control over various cutting parameters, reducing human error. Manual mechanical machines lack these automation features, leading to potential inconsistencies in the cutting process.

Maintenance and costs also differ. Hydraulic shearing machines require regular maintenance of the hydraulic system, potentially increasing costs. Mechanical shearing machines are simpler and easier to maintain, with no need for hydraulic oil, making them more environmentally friendly. However, they pose more safety concerns and require periodic adjustments.

Safety is another consideration. Hydraulic machines typically have built-in overload protection and are safer to operate. Mechanical machines, with their rapid mechanical movements and manual operation, present more safety risks.

In summary, if your shop requires high-volume production with less emphasis on precision, a mechanical shearing machine might be more suitable. For precise, lower-volume cutting with automated control, a CNC-controlled hydraulic shearing machine is preferable. Consider maintenance costs and safety features as well, with hydraulic machines offering better safety and automation at the cost of higher maintenance, while mechanical machines are simpler and more environmentally friendly.

When buying a hydraulic shearing machine, several key specifications and factors need to be considered to ensure the machine meets your specific application needs and operates efficiently.

First, consider the material type and thickness you intend to cut. The machine must have the appropriate maximum cutting capacity and tonnage to handle your material, as insufficient tonnage can lead to poor cut quality and reduced efficiency.

Next, determine the desired cutting length. The machine should have a cutting length sufficient to handle your material in a single cut to avoid inefficiencies and increased production time.

Blade quality and type are also crucial. The blades should be made from durable materials like alloy steel and should be suitable for the material you are cutting to ensure high-quality shearing. Regular adjustments or replacements may be necessary.

The control system of the machine affects its precision and efficiency. Options range from manual to automatic control systems, with advanced CNC systems like those from Cybelec or Delem offering enhanced automation and precision.

Safety features are paramount. Look for machines with guards, emergency stop buttons, and safety interlocks to prevent accidents and injuries.

The machine’s structure and configuration, including the body, tool rests, hydraulic system, and blade gap adjustment mechanism, should be robust and reliable. Ensure that the machine has good strength and rigidity and that the hydraulic system is easy to maintain.

Blade gap adjustment is essential for accommodating different material thicknesses. Proper adjustment prevents blade damage and ensures clean cuts.

The shear angle, typically between 0.5° and 3.5°, affects material deformation. A smaller shear angle can improve cut quality but may require more force.

Budget and return on investment (ROI) are also important considerations. Ensure the machine fits within your budget and provides a satisfactory ROI to avoid financial strain.

Maintenance and service are crucial for the machine’s longevity and efficiency. Regular maintenance tasks like blade sharpening, oil changes, and electrical inspections are necessary to keep the machine in optimal condition.

Finally, consider your future production needs. The machine should be versatile enough to handle potential expansion and any special requirements that may arise.

By evaluating these factors, you can select a hydraulic shearing machine that meets your specific needs, enhances efficiency, and provides a good return on investment.

To maintain your hydraulic shearing machine for optimal performance, adhere to the following practices:

Operate the machine strictly according to the manufacturer’s guidelines. Regularly clean the machine to remove dust, metal shavings, and debris, using a brush or compressed air, particularly around the cutting area, backgauge system, and guide rails. Lubricate moving parts and assemblies as per the manufacturer’s instructions, ensuring the lubricating oil is clean and free from precipitation.

Replace the lubricating grease in the motor bearing regularly and lubricate all designated points daily, especially in machines with decentralized lubrication systems. Regularly inspect critical and moving parts for wear, damage, or misalignment. Check the blade for chipping or dulling and grind or replace it as necessary. Inspect the V-belt, handle, knob, and buttons for damage or severe wear and replace them promptly.

Check the hydraulic oil level regularly, maintaining it at the recommended level. Inspect and replace hydraulic filters according to the manufacturer’s guidelines, and check the hydraulic system for leaks or hose damage, addressing any issues immediately. Regularly inspect electrical connections for wear, damage, or looseness, ensuring all connections are secure. Keep the control panel clean and protected from water, dust, or excessive heat, and update software and firmware as recommended.

Implement lockout/tagout procedures before any maintenance or inspection to prevent accidental machine activation. Ensure that only designated personnel operate the machine and that it is stopped when unattended. Thoroughly clean the machine weekly and lubricate guide rail surfaces, sliding surfaces, balls, and screws. Daily, lubricate and clean the machine tools, and check and tighten tool fixing screws, transmission mechanisms, handwheel, table support screws, and jack lines.

Check the oil and nitrogen levels in each lubricating oil tank, refueling as per regulations, and ensure the oil window is bright and the oil tank is sediment-free. Inspect the transmission parts for looseness and the meshing of gears and racks, adjusting or replacing as necessary. Clean old grease from the ball screw and replace it with new grease. Clean various valves and filters, and change the oil as required. Inspect the motor commutator surface, removing burrs, cleaning carbon powder, and replacing worn carbon brushes.

Avoid cutting materials that are too long and thick, such as high-speed steel, tool steel, or cast iron, and do not cut beyond the specified material surface to prevent machine damage. Monitor the fuel tank temperature, shutting down the machine if it rises above 60 degrees, and be attentive to any abnormal failures of clamping mechanisms, clutches, and brakes, stopping the machine immediately if issues are detected.

By following these comprehensive maintenance steps, you can ensure your hydraulic shearing machine operates optimally and has a prolonged service life.