Have you ever wondered about the impressive strength and versatility of I-beams in construction? In this blog post, we’ll dive into the world of these essential structural components. As an experienced mechanical engineer, I’ll share insights on the types, specifications, and weight calculations of I-beams. Get ready to discover how these seemingly simple beams play a crucial role in creating sturdy and reliable structures.

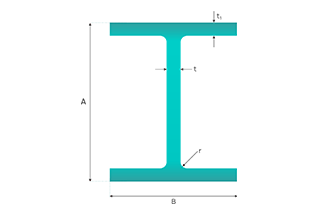

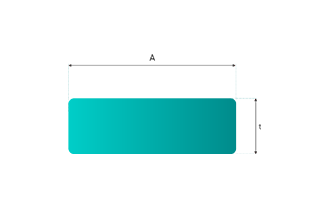

Calculating the weight of an I-beam is a fundamental task in structural engineering and construction projects. Accurate weight calculation ensures the safety, stability, and cost-effectiveness of structures. An I-beam, also known as a universal beam, has a distinctive I-shaped cross-section that includes two horizontal flanges connected by a vertical web. Understanding the geometry and material properties of the I-beam is crucial for determining its weight.

Hot-rolled I-beams, as specified in GB/T 706-2008 for structural steel sections, typically come in lengths ranging from 5 to 19 meters. This standard outlines crucial parameters including dimensional tolerances, cross-sectional geometry, weight specifications, and allowable deviations.

In the steel fabrication industry, I-beams are commonly supplied based on either actual weight or theoretical weight. The industry-standard tolerance for weight deviation between the theoretical and actual weight of an I-beam is tightly controlled, typically falling within a range of -5% to +3%. This tolerance accounts for minor variations in steel density, rolling precision, and other manufacturing factors.

To accurately determine the weight of an I-beam for design, procurement, or logistics purposes, engineers and steel fabricators utilize specialized I-beam weight calculators. These tools incorporate precise dimensional data, material density, and shape factors to provide reliable weight estimations. The calculator below offers a quick and accurate method for determining I-beam weights based on standard profiles and custom dimensions:

When using this calculator, it’s important to consider factors such as:

For critical applications, it’s advisable to consult manufacturer-specific data sheets or perform physical measurements to ensure the most accurate weight determination.

Related Tool: Steel Weight Calculator

To simplify weight calculations, engineers and contractors often refer to standardized I-beam weight charts. These charts typically provide the weight per foot or meter for various beam sizes and profiles.

Here’s a sample I Beam Steel Weight Chart for common sizes (in imperial units):

Weight table of hot rolled ordinary I-beam

| Model | Size(mm) | Sectional area | Weight | ||||

| h | b | d | t | r1 | cm² | kg/m | |

| 10 | 100 | 68 | 4.5 | 7.6 | 3.3 | 14.3 | 11.2 |

| 12.6 | 126 | 74 | 5 | 8.4 | 3.5 | 18.1 | 14.2 |

| 14 | 140 | 80 | 5.5 | 9.1 | 3.8 | 21.5 | 16.9 |

| 16 | 160 | 88 | 6 | 9.9 | 4 | 26.1 | 20.5 |

| 18 | 180 | 94 | 6.5 | 10.7 | 4.3 | 30.6 | 24.1 |

| 20a | 200 | 100 | 7 | 11.4 | 4.5 | 35.5 | 27.9 |

| 20b | 200 | 102 | 9 | 11.4 | 4.5 | 39.5 | 31.1 |

| 22a | 220 | 110 | 7.5 | 12.3 | 4.8 | 42 | 33 |

| 22b | 220 | 112 | 9.5 | 12.3 | 4.8 | 46.4 | 36.4 |

| 25a | 250 | 116 | 8 | 13 | 5 | 48.5 | 38.1 |

| 25b | 250 | 118 | 10 | 13 | 5 | 53.5 | 42 |

| 28a | 280 | 122 | 8.5 | 13.7 | 5.3 | 55.45 | 43.4 |

| 28b | 280 | 124 | 10.5 | 13.7 | 5.3 | 61.05 | 47.9 |

| 32a | 320 | 130 | 9.5 | 15 | 5.8 | 67.05 | 52.7 |

| 32b | 320 | 132 | 11.5 | 15 | 5.8 | 73.45 | 57.7 |

| 32c | 320 | 134 | 13.5 | 15 | 5.8 | 79.95 | 62.8 |

| 36a | 360 | 136 | 10 | 15.8 | 6 | 76.3 | 59.9 |

| 36b | 360 | 138 | 12 | 15.8 | 6 | 83.5 | 65.6 |

| 36c | 360 | 140 | 14 | 15.8 | 6 | 90.7 | 71.2 |

| 40a | 400 | 142 | 10.5 | 16.5 | 6.3 | 86.1 | 67.6 |

| 40b | 400 | 144 | 12.5 | 16.5 | 6.3 | 94.1 | 73.8 |

| 40c | 400 | 146 | 14.5 | 16.5 | 6.3 | 102 | 80.1 |

| 45a | 450 | 150 | 11.5 | 18 | 6.8 | 102 | 80.4 |

| 45b | 450 | 152 | 13.5 | 18 | 6.8 | 111 | 87.4 |

| 45c | 450 | 154 | 15.5 | 18 | 6.8 | 120 | 94.5 |

| 50a | 500 | 158 | 12 | 20 | 7 | 119 | 93.6 |

| 50b | 500 | 160 | 14 | 20 | 7 | 129 | 101 |

| 50c | 500 | 162 | 16 | 20 | 7 | 139 | 109 |

| 56a | 560 | 166 | 12.5 | 21 | 7.3 | 135.25 | 106.2 |

| 56b | 560 | 168 | 14.5 | 21 | 7.3 | 146.45 | 115 |

| 56c | 560 | 170 | 16.5 | 21 | 7.3 | 157.85 | 123.9 |

| 63a | 630 | 176 | 13 | 22 | 7.5 | 154.9 | 121.6 |

| 63b | 630 | 178 | 15 | 22 | 7.5 | 167.5 | 131.5 |

| 63c | 630 | 180 | 17 | 22 | 7.5 | 180.1 | 141 |

Weight table of hot rolled light I-beam

| Model | Size(mm) | Sectional area | Weight | ||||

| h | b | d | t | r1 | cm² | kg/m | |

| 10 | 100 | 68 | 4.5 | 7.6 | 3.3 | 14.3 | 11.2 |

| 12.6 | 126 | 74 | 5 | 8.4 | 3.5 | 18.1 | 14.2 |

| 14 | 140 | 80 | 5.5 | 9.1 | 3.8 | 21.5 | 16.9 |

| 16 | 160 | 88 | 6 | 9.9 | 4 | 26.1 | 20.5 |

| 18 | 180 | 94 | 6.5 | 10.7 | 4.3 | 30.6 | 24.1 |

| 20a | 200 | 100 | 7 | 11.4 | 4.5 | 35.5 | 27.9 |

| 20b | 200 | 102 | 9 | 11.4 | 4.5 | 39.5 | 31.1 |

| 22a | 220 | 110 | 7.5 | 12.3 | 4.8 | 42 | 33 |

| 22b | 220 | 112 | 9.5 | 12.3 | 4.8 | 46.4 | 36.4 |

| 25a | 250 | 116 | 8 | 13 | 5 | 48.5 | 38.1 |

| 25b | 250 | 118 | 10 | 13 | 5 | 53.5 | 42 |

| 28a | 280 | 122 | 8.5 | 13.7 | 5.3 | 55.45 | 43.4 |

| 28b | 280 | 124 | 10.5 | 13.7 | 5.3 | 61.05 | 47.9 |

| 32a | 320 | 130 | 9.5 | 15 | 5.8 | 67.05 | 52.7 |

| 32b | 320 | 132 | 11.5 | 15 | 5.8 | 73.45 | 57.7 |

| 32c | 320 | 134 | 13.5 | 15 | 5.8 | 79.95 | 62.8 |

| 36a | 360 | 136 | 10 | 15.8 | 6 | 76.3 | 59.9 |

| 36b | 360 | 138 | 12 | 15.8 | 6 | 83.5 | 65.6 |

| 36c | 360 | 140 | 14 | 15.8 | 6 | 90.7 | 71.2 |

| 40a | 400 | 142 | 10.5 | 16.5 | 6.3 | 86.1 | 67.6 |

| 40b | 400 | 144 | 12.5 | 16.5 | 6.3 | 94.1 | 73.8 |

| 40c | 400 | 146 | 14.5 | 16.5 | 6.3 | 102 | 80.1 |

| 45a | 450 | 150 | 11.5 | 18 | 6.8 | 102 | 80.4 |

| 45b | 450 | 152 | 13.5 | 18 | 6.8 | 111 | 87.4 |

| 45c | 450 | 154 | 15.5 | 18 | 6.8 | 120 | 94.5 |

| 50a | 500 | 158 | 12 | 20 | 7 | 119 | 93.6 |

| 50b | 500 | 160 | 14 | 20 | 7 | 129 | 101 |

| 50c | 500 | 162 | 16 | 20 | 7 | 139 | 109 |

| 56a | 560 | 166 | 12.5 | 21 | 7.3 | 135.25 | 106.2 |

| 56b | 560 | 168 | 14.5 | 21 | 7.3 | 146.45 | 115 |

| 56c | 560 | 170 | 16.5 | 21 | 7.3 | 157.85 | 123.9 |

| 63a | 630 | 176 | 13 | 22 | 7.5 | 154.9 | 121.6 |

| 63b | 630 | 178 | 15 | 22 | 7.5 | 167.5 | 131.5 |

| 63c | 630 | 180 | 17 | 22 | 7.5 | 180.1 | 141 |

When using these charts, it’s important to consider:

For precise calculations, especially in critical structural applications, it’s advisable to consult the manufacturer’s specifications or use specialized structural engineering software.

Understanding and accurately calculating I-beam weights is crucial for:

By utilizing I Beam Steel Weight Charts, professionals can streamline their design and construction processes, ensuring efficiency and accuracy in structural steel projects.

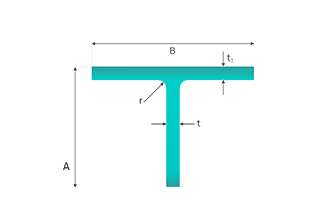

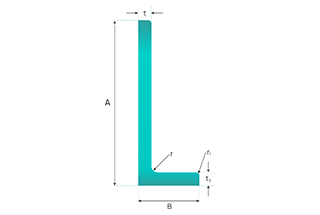

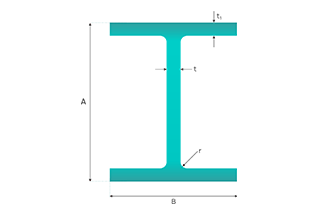

I-beams, also known as H-beams or wide flange beams, are structural steel members characterized by their distinctive I-shaped cross-section. This profile consists of two horizontal elements called flanges, connected by a vertical component known as the web. I-beams are widely used in construction and engineering due to their excellent strength-to-weight ratio and versatile load-bearing capabilities.

These beams are typically manufactured through hot rolling, a process that ensures uniform material properties and precise dimensional control. I-beams are available in various sizes and grades, with two main categories:

I-beams excel in resisting bending moments and shear forces, making them ideal for use as primary support members in buildings, bridges, and industrial structures. Their design allows for efficient material distribution, with the flanges primarily resisting bending stresses and the web handling shear forces.

The selection of an appropriate I-beam depends on factors such as required load capacity, span length, and specific project requirements. Engineers often refer to standardized tables and design codes to determine the optimal I-beam size and grade for a given application, ensuring structural integrity and cost-effectiveness.

I-beams are classified into three primary categories: standard I-beams, light I-beams, and wide flange I-beams. This classification is based on the geometric properties and manufacturing processes of the beams.

The categorization of I-beams is further refined based on the ratio of flange width to web height, resulting in four distinct profiles: wide, medium, narrow, and wide flange I-beams. This ratio significantly influences the beam’s load-bearing capacity, torsional resistance, and overall structural performance.

Standard and light I-beams are typically manufactured in heights ranging from 100 mm to 600 mm (10 to 60 centimeters). This range accommodates various structural requirements in construction and engineering applications.

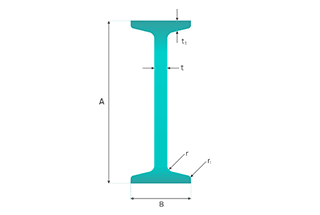

Light I-beams are characterized by their narrow flanges and thin webs, resulting in a lower weight-to-height ratio compared to standard I-beams of equivalent height. This design optimizes material usage while maintaining adequate strength for specific load conditions.

Wide flange I-beams, often referred to as H-beams due to their shape, feature parallel flanges without taper. These beams are renowned for their cost-effectiveness and efficient load distribution. They are produced using a four-high universal rolling mill, which gives rise to their alternative designation as “universal beams” or “universal columns.”

National and international standards, such as ASTM A6/A6M and EN 10365, have been established to regulate the dimensions, tolerances, and mechanical properties of standard and light I-beams. These standards ensure consistency in manufacturing and facilitate the integration of I-beams into structural designs across various industries.

Below are answers to some frequently asked questions:

To use an I beam weight calculator, you need to input several specific dimensions and parameters related to the I beam. The key dimensions include:

By inputting these dimensions, the calculator can accurately determine the weight of the I beam by calculating the cross-sectional area, volume, and then applying the density to find the weight.

The weight of an I beam is calculated by determining the volume of the beam and then multiplying that volume by the density of the material from which the beam is made, typically steel. This process involves several steps:

First, you need to gather the necessary dimensions of the I beam, which include the length (L), the width of the flange (Wf), the thickness of the flange (Tf), the thickness of the web (Tw), and the total height (H) of the beam.

Next, calculate the cross-sectional areas. For the flanges, the area is found by multiplying the width of the flange by the thickness of the flange and then doubling this value since there are two flanges. For the web, the area is calculated by subtracting twice the thickness of the flange from the total height and then multiplying by the thickness of the web.

After calculating the individual areas, add them together to get the total cross-sectional area of the I beam.

To find the volume of the I beam, multiply the total cross-sectional area by the length of the beam.

Finally, calculate the weight by multiplying the volume by the density of the material. For steel, the density is typically 7850 kg/m³.

Using these steps, or an online I beam weight calculator that automates these calculations, you can accurately determine the weight of an I beam for various applications in construction and engineering projects.

Yes, you can use an I beam weight calculator for different types of steel. These calculators are designed to accommodate a wide range of steel types, including carbon steel, stainless steel, alloy steel, and mild steel, among others. The key to their versatility lies in the ability to input specific material properties, such as density, which can vary depending on the type of steel used. For instance, while the standard density of steel is typically around 7850 kg/m³, this value can be adjusted in the calculator to reflect the particular steel grade you are working with.

Additionally, these calculators often support custom dimensions and various measurement units, allowing for precise and tailored weight calculations for different project requirements. They may also integrate material pricing databases and adhere to different design standards, making them highly useful tools for engineers, architects, and metalworkers involved in diverse construction and engineering projects.

Complying with engineering standards in I beam calculations is critical for several reasons. Firstly, these standards ensure the structural integrity and safety of the construction project by guaranteeing that the I beam can support the intended loads without risk of deformation or failure. Overloading an I beam beyond its capacity can lead to dangerous consequences, including structural collapse, which poses serious risks to both people and property.

Secondly, adherence to building codes and regulations is mandatory for legal and regulatory compliance. These codes specify minimum requirements for load-bearing capacities, material properties, and safety margins, which must be met to obtain building approvals and avoid legal complications.

Accurate load capacity calculations are another vital aspect. Standards such as those from the American Institute of Steel Construction (AISC) provide guidelines for calculating bending, shear, axial, and tension strengths, ensuring that the selected I beam can handle the specified loads. This accuracy is crucial in preventing structural failures.

Material and design considerations also play a significant role. Compliance with standards involves selecting the appropriate material and ensuring the beam’s geometry, such as width, height, and web thickness, meets the required specifications for load-bearing. This ensures the beam can resist stresses like bending and vibration effectively.

Furthermore, engineering standards often incorporate safety factors to account for uncertainties in load estimations and material properties. These factors provide an additional layer of safety, ensuring the actual load capacity exceeds the expected load, thus enhancing reliability.

Lastly, compliance with standards aids in selecting the most efficient and cost-effective I beam for the project. By evaluating the costs and capabilities of different beams based on these standards, structural engineers can ensure that the chosen beam meets all necessary safety and performance criteria without unnecessary excess, optimizing both structural integrity and cost efficiency.

In summary, adhering to engineering standards in I beam calculations is essential for ensuring safety, structural integrity, regulatory compliance, and cost-effectiveness in construction projects.

To ensure the accuracy of your I beam weight calculations, follow these steps and consider the following factors:

By following these steps and using the correct formulas and data, you can ensure the accuracy of your I beam weight calculations.