Bayangkan sebuah dunia di mana material dapat melengkung sesuai dengan keinginan kita, di mana kekuatan dan ketahanan berada di ujung jari kita. Dalam artikel blog yang memikat ini, kami menyelami dunia perbandingan kekerasan logam yang menarik. Temukan rahasia di balik skala Vickers, Brinell, dan Rockwell, saat insinyur mekanik ahli kami memandu Anda melalui seluk-beluk topik penting ini. Bersiaplah untuk memperluas pengetahuan Anda dan kuasai seni pemilihan material.

Pengujian kekerasan adalah metode yang paling sederhana dan paling mudah di antara pengujian properti mekanis. Untuk mengganti uji properti mekanis tertentu dengan uji kekerasan, hubungan konversi yang relatif akurat antara kekerasan dan kekuatan dibutuhkan dalam produksi.

Pengalaman telah menunjukkan bahwa ada perkiraan hubungan yang sesuai antara berbagai nilai kekerasan bahan logam, dan antara nilai kekerasan dan nilai kekuatan. Hal ini karena nilai kekerasan ditentukan oleh ketahanan deformasi plastis awal dan ketahanan deformasi plastis lanjutan. Semakin tinggi kekuatan material, semakin tinggi ketahanan deformasi plastisnya, dan dengan demikian, semakin tinggi pula nilai kekerasannya.

| Kekuatan tarik N / mm2 | Kekerasan Vickers | Kekerasan Brinell | Kekerasan Rockwell |

| Rm | HV | HB | HRC |

| 250 | 80 | 76 | |

| 270 | 85 | 80.7 | |

| 285 | 90 | 85.2 | |

| 305 | 95 | 90.2 | |

| 320 | 100 | 95 | |

| 335 | 105 | 99.8 | |

| 350 | 110 | 105 | |

| 370 | 115 | 109 | |

| 380 | 120 | 114 | |

| 400 | 125 | 119 | |

| 415 | 130 | 124 | |

| 430 | 135 | 128 | |

| 450 | 140 | 133 | |

| 465 | 145 | 138 | |

| 480 | 150 | 143 | |

| 490 | 155 | 147 | |

| 510 | 160 | 152 | |

| 530 | 165 | 156 | |

| 545 | 170 | 162 | |

| 560 | 175 | 166 | |

| 575 | 180 | 171 | |

| 595 | 185 | 176 | |

| 610 | 190 | 181 | |

| 625 | 195 | 185 | |

| 640 | 200 | 190 | |

| 660 | 205 | 195 | |

| 675 | 210 | 199 | |

| 690 | 215 | 204 | |

| 705 | 220 | 209 | |

| 720 | 225 | 214 | |

| 740 | 230 | 219 | |

| 755 | 235 | 223 | |

| 770 | 240 | 228 | 20.3 |

| 785 | 245 | 233 | 21.3 |

| 800 | 250 | 238 | 22.2 |

| 820 | 255 | 242 | 23.1 |

| 835 | 260 | 247 | 24 |

| 850 | 265 | 252 | 24.8 |

| 865 | 270 | 257 | 25.6 |

| 880 | 275 | 261 | 26.4 |

| 900 | 280 | 266 | 27.1 |

| 915 | 285 | 271 | 27.8 |

| 930 | 290 | 276 | 28.5 |

| 950 | 295 | 280 | 29.2 |

| 965 | 300 | 285 | 29.8 |

| 995 | 310 | 295 | 31 |

| 1030 | 320 | 304 | 32.2 |

| 1060 | 330 | 314 | 33.3 |

| 1095 | 340 | 323 | 34.4 |

| 1125 | 350 | 333 | 35.5 |

| 1115 | 360 | 342 | 36.6 |

| 1190 | 370 | 352 | 37.7 |

| 1220 | 380 | 361 | 38.8 |

| 1255 | 390 | 371 | 39.8 |

| 1290 | 400 | 380 | 40.8 |

| 1320 | 410 | 390 | 41.8 |

| 1350 | 420 | 399 | 42.7 |

| 1385 | 430 | 409 | 43.6 |

| 1420 | 440 | 418 | 44.5 |

| 1455 | 450 | 428 | 45.3 |

| 1485 | 460 | 437 | 46.1 |

| 1520 | 470 | 447 | 46.9 |

| 1557 | 480 | 456 | 47 |

| 1595 | 490 | 466 | 48.4 |

| 1630 | 500 | 475 | 49.1 |

| 1665 | 510 | 485 | 49.8 |

| 1700 | 520 | 494 | 50.5 |

| 1740 | 530 | 504 | 51.1 |

| 1775 | 540 | 513 | 51.7 |

| 1810 | 550 | 523 | 52.3 |

| 1845 | 560 | 532 | 53 |

| 1880 | 570 | 542 | 53.6 |

| 1920 | 580 | 551 | 54.1 |

| 1955 | 590 | 561 | 54.7 |

| 1995 | 600 | 570 | 55.2 |

| 2030 | 610 | 580 | 55.7 |

| 2070 | 620 | 589 | 56.3 |

| 2105 | 630 | 599 | 56.8 |

| 2145 | 640 | 608 | 57.3 |

| 2180 | 650 | 618 | 57.8 |

| 660 | 58.3 | ||

| 670 | 58.8 | ||

| 680 | 59.2 | ||

| 690 | 59.7 | ||

| 700 | 60.1 | ||

| 720 | 61 | ||

| 740 | 61.8 | ||

| 760 | 62.5 | ||

| 780 | 63.3 | ||

| 800 | 64 | ||

| 820 | 64.7 | ||

| 840 | 65.3 | ||

| 860 | 65.9 | ||

| 880 | 66.4 | ||

| 900 | 67 | ||

| 920 | 67.5 | ||

| 940 |

| Rockwell | Rockwell | Vickers | Brinell | Kekuatan tarik |

| HRC | HRA | HV | HB | N / mm2 |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | - | 1815 |

| 52 | 76.9 | 543 | - | 1850 |

| 52.5 | 77.1 | 551 | - | 1885 |

| 53 | 77.4 | 561 | - | 1920 |

| 53.5 | 77.7 | 570 | - | 1955 |

| 54 | 77.9 | 579 | - | 1995 |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

| Kekerasan Rockwell | Kekerasan Rockwell permukaan | Vickers | Brinell | Pantai | |||||

| HRA | HRB | HRC | HRD | 15N | 30N | 45N | HV | HB | HS |

| 60kgf | 100kgf | 150kgf | 100kgf | 15kgf | 30kgf | 45kgf | 50kgf | 3000kgf | JIS |

| 85.6 | 68 | 76.9 | 93.2 | 84.4 | 75.4 | 940 | 97.6 | ||

| 85.3 | 67.5 | 76.5 | 93 | 84 | 74.3 | 920 | 96.4 | ||

| 85 | 67 | 76.1 | 92.9 | 83.6 | 74.2 | 900 | 95.2 | ||

| 84.7 | 66.5 | 75.7 | 92.7 | 83.1 | 73.6 | 880 | 94 | ||

| 84.4 | 65.9 | 75.3 | 92.5 | 82.7 | 73.1 | 860 | 92.8 | ||

| 84.1 | 65.3 | 74.8 | 92.3 | 82.2 | 72.2 | 840 | 91.5 | ||

| 83.8 | 64.7 | 74.3 | 92.1 | 81.7 | 71.8 | 820 | 90.2 | ||

| 83.4 | 64 | 73.8 | 91.8 | 81.1 | 71 | 800 | 88.9 | ||

| 83 | 63.3 | 73.3 | 91.5 | 80.4 | 70.2 | 780 | 87.5 | ||

| 82.6 | 62.5 | 72.6 | 91.2 | 79.7 | 69.4 | 760 | 86.2 | ||

| 82.2 | 61.8 | 72.1 | 91 | 79.1 | 68.6 | 740 | 84.8 | ||

| 81.8 | 61 | 71.5 | 90.7 | 78.4 | 67.7 | 720 | 83.3 | ||

| 81.3 | 60.1 | 70.8 | 90.3 | 77.6 | 66.7 | 700 | 81.8 | ||

| 81.1 | 59.7 | 70.5 | 90.1 | 77.2 | 66.2 | 690 | 81.1 | ||

| 80.8 | 59.2 | 70.1 | 89.8 | 76.8 | 65.7 | 680 | 80.3 | ||

| 80.6 | 58.8 | 69.8 | 89.7 | 76.4 | 65.3 | 670 | 79.6 | ||

| 80.3 | 58.3 | 69.4 | 89.5 | 75.9 | 64.7 | 660 | 78.8 | ||

| 80 | 57.8 | 69 | 89.2 | 75.5 | 64.1 | 650 | 78 | ||

| 79.8 | 57.3 | 68.7 | 89 | 75.1 | 63.5 | 640 | 77.2 | ||

| 79.5 | 56.8 | 68.3 | 88.8 | 74.6 | 63 | 630 | 76.4 | ||

| 79.2 | 56.3 | 67.9 | 88.5 | 74.2 | 62.4 | 620 | 75.6 | ||

| 78.9 | 55.7 | 67.5 | 88.2 | 73.6 | 61.7 | 610 | 74.7 | ||

| 78.6 | 55.2 | 67 | 88 | 73.2 | 61.2 | 600 | 73.9 | ||

| 78.4 | 54.7 | 66.7 | 87.8 | 72.7 | 60.5 | 590 | 73.1 | ||

| 78 | 54.1 | 66.2 | 87.5 | 72.1 | 59.9 | 580 | 72.2 | ||

| 77.8 | 53.6 | 65.8 | 87.2 | 71.7 | 59.3 | 570 | 71.3 | ||

| 77.4 | 53 | 65.4 | 86.9 | 71.2 | 58.6 | 560 | 70.4 | ||

| 77 | 52.3 | 64.8 | 86.6 | 70.5 | 57.8 | 550 | 505 | 69.6 | |

| 76.7 | 51.7 | 64.4 | 86.3 | 70 | 57 | 540 | 496 | 68.7 | |

| 76.4 | 51.1 | 63.9 | 86 | 69.5 | 56.2 | 530 | 488 | 67.7 | |

| 76.1 | 50.5 | 63.5 | 85.7 | 69 | 55.6 | 520 | 480 | 66.8 | |

| 75.7 | 49.8 | 62.9 | 85.4 | 68.3 | 54.7 | 510 | 473 | 65.9 | |

| 75.3 | 49.1 | 62.2 | 85 | 67.7 | 53.9 | 500 | 465 | 64.9 | |

| 74.9 | 48.4 | 61.6 | 84.7 | 67.1 | 53.1 | 490 | 456 | 64 | |

| 74.5 | 47.7 | 61.3 | 84.3 | 66.4 | 52.2 | 480 | 448 | 63 | |

| 74.1 | 46.9 | 60.7 | 83.9 | 65.7 | 51.3 | 470 | 441 | 62 | |

| 73.6 | 46.1 | 60.1 | 83.6 | 64.9 | 50.4 | 460 | 433 | 61 | |

| 73.3 | 45.3 | 59.4 | 83.2 | 64.3 | 49.4 | 450 | 425 | 60 | |

| 72.8 | 44.5 | 58.8 | 82.8 | 63.5 | 48.4 | 440 | 415 | 59 | |

| 72.3 | 43.6 | 58.2 | 82.3 | 62.7 | 47.4 | 430 | 405 | 58 | |

| 71.8 | 42.7 | 57.5 | 81.8 | 61.9 | 46.4 | 420 | 397 | 56.9 | |

| 71.4 | 41.8 | 56.8 | 81.4 | 61.1 | 45.3 | 410 | 388 | 55.9 | |

| 70.8 | 40.8 | 65 | 81 | 60.2 | 44.1 | 400 | 379 | 54.8 | |

| 70.3 | 39.8 | 55.2 | 80.3 | 59.3 | 42.9 | 390 | 369 | 53.7 | |

| 69.8 | 110 | 38.8 | 54.4 | 79.8 | 58.4 | 41.7 | 380 | 360 | 52.6 |

| 69.2 | 37.7 | 53.6 | 79.2 | 57.4 | 40.4 | 370 | 350 | 51.5 | |

| 68.7 | 109 | 36.6 | 52.8 | 78.6 | 56.4 | 39.1 | 360 | 341 | 50.4 |

| 68.1 | 35.5 | 51.9 | 78 | 55.4 | 37.8 | 350 | 331 | 49.3 | |

| 67.6 | 108 | 34.4 | 51.1 | 77.4 | 54.4 | 36.5 | 340 | 322 | 48.1 |

| 67 | 33.3 | 50.2 | 76.8 | 53.6 | 35.2 | 330 | 313 | 47 | |

| 66.4 | 107 | 32.2 | 49.4 | 76.2 | 52.3 | 33.9 | 320 | 303 | 45.8 |

| 65.8 | 31.6 | 48.4 | 75.8 | 51.8 | 32.8 | 310 | 294 | 44.6 | |

| 65.2 | 105.5 | 29.8 | 47.5 | 74.9 | 50.2 | 31.1 | 300 | 284 | 43.4 |

| 64.8 | 29.2 | 47.1 | 74.6 | 49.7 | 30.4 | 295 | 280 | 42.8 | |

| 64.5 | 104.5 | 28.5 | 46.5 | 74.2 | 49 | 29.5 | 290 | 275 | 42.2 |

| 64.2 | 27.8 | 46 | 73.8 | 48.4 | 28.7 | 285 | 270 | 41.6 | |

| 63.8 | 103.5 | 27.1 | 45.3 | 73.4 | 47.8 | 27.9 | 280 | 265 | 40.9 |

| 63.5 | 26.4 | 44.9 | 73 | 47.2 | 27.1 | 275 | 261 | 40.3 | |

| 63.1 | 102 | 25.6 | 44.3 | 72.6 | 46.4 | 26.2 | 270 | 256 | 39.7 |

| 62.7 | 24.8 | 43.7 | 72.1 | 45.7 | 25.2 | 265 | 252 | 39 | |

| 62.4 | 101 | 24 | 43.1 | 71.6 | 45 | 24.3 | 260 | 247 | 38.4 |

| 62 | 23.1 | 42.2 | 71.1 | 44.2 | 23.2 | 255 | 243 | 37.8 | |

| 61.6 | 99.5 | 22.2 | 41.7 | 70.6 | 43.4 | 22.2 | 250 | 238 | 37.2 |

| 61.2 | 21.3 | 41.1 | 70.1 | 42.5 | 21.1 | 245 | 233 | 36.5 | |

| 60.7 | 98.1 | 20.3 | 40.3 | 69.6 | 41.7 | 19.9 | 240 | 228 | 35.9 |

| 96.7 | 18 | 230 | 219 | 34.1 | |||||

| 95 | 15.7 | 220 | 209 | 33.2 | |||||

| 93.4 | 13.4 | 210 | 200 | 31.8 | |||||

| 91.5 | 11 | 200 | 190 | 30.4 | |||||

| 89.5 | 8.5 | 190 | 181 | 29 | |||||

| 87.1 | 6 | 180 | 171 | 27.7 | |||||

| 85 | 3 | 170 | 162 | 26.5 | |||||

| 81.7 | 0 | 160 | 152 | 25 | |||||

| 78.7 | 150 | 143 | 23.7 | ||||||

| 78 | 140 | 133 | 22.1 | ||||||

| 71.2 | 130 | 124 | 20.6 | ||||||

| 66.7 | 120 | 114 | 19.1 | ||||||

| 62.3 | 110 | 105 | 17.6 | ||||||

| 56.2 | 100 | 95 | 16.1 | ||||||

| Kekerasan Rockwell | Kekerasan Rockwell permukaan | Kekerasan Vickers | |||

| HRB | HRF | 15T | 30T | 45T | HV |

| 100kgf | 60kgf | 15kgf | 30kgf | 45kgf | 50kgf |

| 93.5 | 110 | 90 | 77.5 | 66 | 196 |

| 109.5 | 65.5 | 194 | |||

| 93 | 77 | 65 | 192 | ||

| 92.5 | 109 | 76.5 | 64.5 | 190 | |

| 92 | 89.5 | 64 | 188 | ||

| 91.5 | 108.5 | 76 | 63.5 | 186 | |

| 91 | 75.5 | 63 | 184 | ||

| 90.5 | 108 | 89 | 62.5 | 182 | |

| 90 | 107.5 | 75 | 62 | 180 | |

| 89 | 74.5 | 61.5 | 178 | ||

| 88.5 | 107 | 61 | 176 | ||

| 88 | 88.5 | 74 | 60.5 | 174 | |

| 87.5 | 106.5 | 73.5 | 60 | 172 | |

| 87 | 59.5 | 170 | |||

| 86 | 106 | 88 | 73 | 59 | 168 |

| 85.5 | 72.5 | 58.5 | 166 | ||

| 85 | 105.5 | 72 | 58 | 164 | |

| 84 | 105 | 87.5 | 57.5 | 162 | |

| 83.5 | 71.5 | 56.7 | 160 | ||

| 83 | 104.5 | 71 | 56 | 158 | |

| 82 | 104 | 87 | 70.5 | 55.5 | 156 |

| 81.5 | 103.5 | 70 | 54.5 | 154 | |

| 80.5 | 103 | 54 | 152 | ||

| 80 | 86.5 | 69.5 | 53.5 | 150 | |

| 79 | 102.5 | 69 | 53 | 148 | |

| 78 | 102 | 68.5 | 52.5 | 146 | |

| 77.5 | 101.5 | 86 | 68 | 51.5 | 144 |

| 77 | 101 | 67.5 | 51 | 142 | |

| 76 | 100.5 | 85.5 | 67 | 50 | 140 |

| 75 | 100 | 66.5 | 49 | 138 | |

| 74.5 | 99.5 | 85 | 66 | 48 | 136 |

| 73.5 | 99 | 65.5 | 47.5 | 134 | |

| 73 | 98.5 | 84.5 | 65 | 46.5 | 132 |

| 72 | 98 | 84 | 64.5 | 45.5 | 130 |

| 71 | 97.5 | 63.5 | 45 | 128 | |

| 70 | 97 | 83.5 | 63 | 44 | 126 |

| 69 | 96.5 | 62.5 | 43 | 124 | |

| 68 | 96 | 83 | 62 | 42 | 122 |

| 67 | 95.5 | 61 | 41 | 120 | |

| 66 | 95 | 82.5 | 60.5 | 40 | 118 |

| 65 | 94.5 | 82 | 60 | 39 | 116 |

| 64 | 94 | 81.5 | 59.5 | 38 | 114 |

| 63 | 93 | 81 | 58.5 | 37 | 112 |

| 62 | 92.6 | 80.5 | 58 | 35.5 | 110 |

| 61 | 92 | 57 | 34.5 | 108 | |

| 59.5 | 91.2 | 80 | 56 | 33 | 106 |

| 58 | 90.5 | 79.5 | 55 | 32 | 104 |

| 57 | 89.8 | 79 | 54.5 | 30.5 | 102 |

| 56 | 89 | 78.5 | 53.5 | 29.5 | 100 |

| 54 | 88 | 78 | 52.5 | 28 | 98 |

| 53 | 87.2 | 77.5 | 51.5 | 26.5 | 96 |

| 61.6 | 86.6 | 77 | 50.5 | 24.5 | 94 |

| 49.5 | 85.4 | 76.5 | 49 | 23 | 92 |

| 47.5 | 84.4 | 75.5 | 48 | 21 | 90 |

| 46 | 83.5 | 75 | 47 | 19 | 88 |

| 44 | 82.3 | 74.5 | 45.5 | 17 | 86 |

| 42 | 81.2 | 73.5 | 44 | 14.5 | 84 |

| 40 | 80 | 73 | 43 | 12.5 | 82 |

| 37.5 | 78.6 | 72 | 41 | 10 | 80 |

| 35 | 77.4 | 71.5 | 39.5 | 7.5 | 78 |

| 32.5 | 76 | 70.5 | 38 | 4.5 | 76 |

| 30 | 74.8 | 70 | 36 | 1 | 74 |

| 27.5 | 73.2 | 69 | 34 | 72 | |

| 24.5 | 71.6 | 68 | 32 | 70 | |

| 21.5 | 70 | 67 | 30 | 68 | |

| 18.5 | 68.5 | 66 | 28 | 66 | |

| 15.5 | 66.8 | 65 | 25.5 | 64 | |

| 12.5 | 65 | 63.5 | 23 | 62 | |

| 10 | 63 | 62.5 | 20.5 | 60 | |

| 61 | 61 | 18 | 58 | ||

| 58.8 | 60 | 15 | 56 | ||

| 56.5 | 58.5 | 12 | 54 | ||

| 53.5 | 57 | 52 | |||

| 50.5 | 55.5 | 50 | |||

| 49 | 54.5 | 49 | |||

| 47 | 53.5 | 48 | |||

| 45 | 47 | ||||

| 43 | 46 | ||||

| 40 | 45 | ||||

Catatan: Apabila mempertimbangkan proses pemotongan, konversi umum 1HRC ≈ 10HB berlaku (kekerasan bahan benda kerja mungkin sedikit berbeda).

Uji kekerasan lekukan yang paling umum digunakan untuk bahan logam adalah uji kekerasan Brinell, Rockwell, dan Vickers.

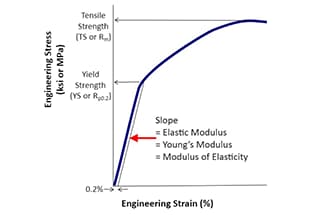

Nilai kekerasan menunjukkan kemampuan material untuk menahan deformasi plastis yang disebabkan oleh intrusi benda lain.

Apabila mengukur kekerasan menggunakan metode pantulan, nilai kekerasan mewakili tingkat fungsi deformasi elastis logam.

Kekerasan adalah metrik yang mengukur ketahanan material terhadap deformasi lokal, seperti deformasi plastis, lekukan, atau goresan.

Ini adalah faktor krusial dalam menentukan kekerasan suatu bahan.

Menurut metode pengujian yang berbeda-beda, ada tiga jenis kekerasan.

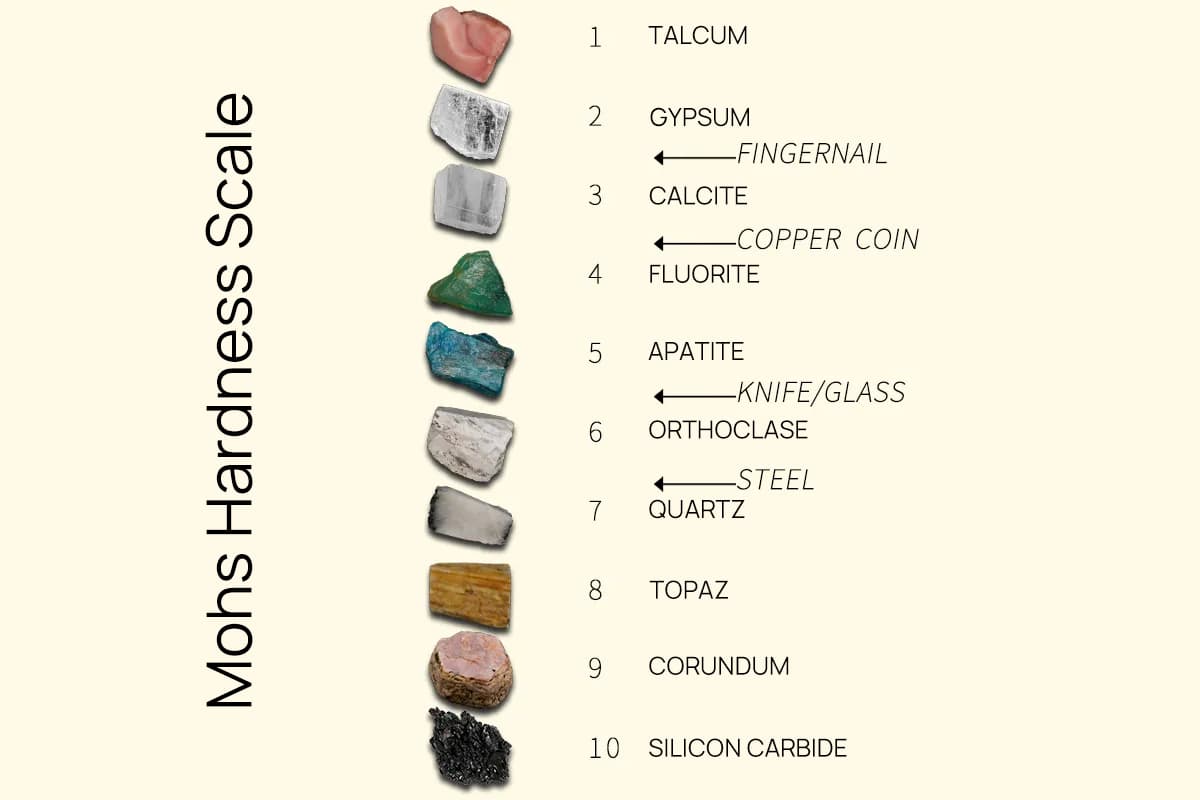

(1) Kekerasan goresan

Kekerasan terutama digunakan untuk membandingkan ketahanan terhadap deformasi lokal berbagai mineral.

Prosesnya melibatkan penggunaan batang dengan ujung yang keras dan lunak untuk menguji bahan dengan menggesernya di sepanjang batang.

Kelembutan atau kekerasan bahan ditentukan berdasarkan panjang goresan yang ditinggalkannya pada batang.

Biasanya, goresan yang dibuat oleh bahan yang lebih keras akan lebih panjang dan goresan yang dibuat oleh bahan yang lebih lunak akan lebih pendek.

② Kekerasan lekukan

Pengujian kekerasan lekukan terutama digunakan untuk mengevaluasi bahan logam. Pengujian ini melibatkan penerapan indentor tertentu pada permukaan material yang diuji dengan beban tertentu.

Kekerasan material ditentukan dengan membandingkan jumlah deformasi plastis lokal pada permukaan material.

Ada beberapa jenis uji kekerasan lekukan, termasuk Kekerasan Brinellkekerasan Rockwell, kekerasan Vickers, dan kekerasan mikro, yang berbeda dalam hal indentor yang digunakan, beban yang diterapkan, dan durasi beban.

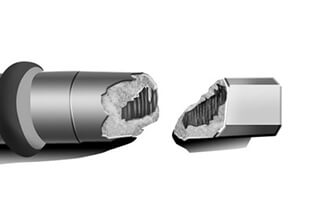

③ Kekerasan pantulan

Pengujian kekerasan pantul terutama digunakan untuk material logam. Metode ini melibatkan penggunaan palu kecil khusus yang dijatuhkan dari ketinggian tertentu untuk menumbuk sampel material yang sedang diuji.

Kekerasan material ditentukan oleh jumlah energi regangan yang tersimpan di dalam dan kemudian dilepaskan dari sampel selama tumbukan, yang diukur dengan tinggi pantulan palu.