Ever wondered how to boost your laser cutting efficiency and save on costs? This article reveals four essential strategies, from optimizing cutting paths to improving material usage. Discover practical tips to enhance your production speed and maximize material utilization, ensuring your laser cutting process is both efficient and economical. Dive in to learn how you can transform your operations and achieve better results with minimal waste.

Laser cutting machines have revolutionized sheet metal product processing, offering high precision, superior surface quality, reduced noise, and minimal equipment vibration. These advantages have contributed to their increasing popularity in the industry.

However, laser cutting technology also presents certain limitations. While it excels in precision, it can be slower in processing speed compared to traditional methods. Additionally, material utilization rates may be lower, and the overall processing cost can be higher due to equipment and operational expenses.

One of the key strengths of laser cutting lies in its flexibility. Operating on a non-contact principle and requiring no specialized tooling, laser cutting surpasses the limitations of conventional multi-station punch processing. This allows for the production of complex shapes and intricate designs directly from CAD files, making it ideal for prototyping, single-run production, and small batch manufacturing. This flexibility enables rapid fulfillment of customized product requirements, a significant advantage in today’s market-driven by personalization.

The advantages of laser cutting become particularly evident in thick plate processing. Modern laser cutting systems can effectively cut steel plates exceeding 20mm in thickness, far surpassing the 3mm to 8mm range typical of multi-station presses. The laser cutting process employs a moving cutting head, which allows for a longer stroke and greater working envelope. However, this increased range comes at the cost of slower processing speeds and longer cycle times, especially when compared to punching operations. The use of assist gases in laser cutting, while necessary for the process, also contributes to higher operational costs.

To enhance the efficiency and economic viability of laser cutting operations, focus must be placed on optimizing several key areas. Reducing laser cutting time is crucial, but it’s not the only factor. Attention must also be given to minimizing non-productive time, such as piercing delays, cutting pauses, and head positioning movements. Additionally, improving material utilization through advanced nesting algorithms can significantly impact overall cost-effectiveness. By addressing these aspects holistically, manufacturers can maximize the benefits of laser cutting technology while mitigating its limitations.

The laser cutting process can be divided into two parts: the cutting path and the material removal or separation process path.

The cutting path is the effective working path, and the time consumed is considered the effective cutting time. On the other hand, the empty stroke is the invalid path, and the time consumed is considered the invalid working time.

For a single CNC laser cutting machine, when using the maximum power for processing parts, the effective cutting speed is fixed when quality is guaranteed.

Improving cutting efficiency and reducing the time spent on invalid cutting is achieved mainly by reducing the cutting path length. Additionally, adjusting the cutting process parameters and choosing different perforation methods can also reduce the time spent on cutting processing.

For instance, when punching holes, adjustments such as the external light path, beam gathering, and vertical adjustment belong to process adjustment pauses.

The plate laser cutting process is divided into two parts: the components and the residual materials.

The workpieces that are cut to the design specifications are the usable parts, while the rest is irregular and is usually considered waste.

Therefore, the effective utilization rate of laser cutting material is calculated as follows: (the area of useful parts / total area of the sheet) * 100%.

To improve the utilization rate of the plate, it is necessary to reduce the residual material after laser cutting.

Nowadays, laser cutting equipment can be equipped with an optimization function for nesting, which is the primary method for reducing the cutting spacing and edge distance of various parts.

One can also choose smaller size raw material plates according to the workpiece size or make non-standard size plates based on the actual size of the part, to improve the actual utilization of the plate.

The offline programming software of the laser cutting machine is utilized to optimize the sheet material and process settings, resulting in improved utilization rate and cutting efficiency.

The following measures are mainly adopted:

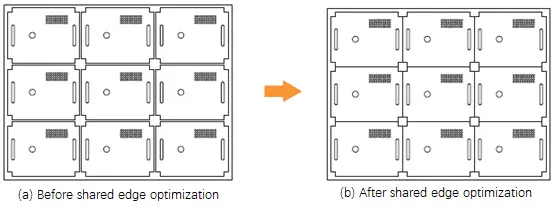

Parts with regular shapes use the borrowing edge and common edge when nesting.

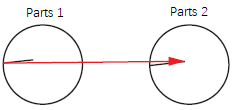

When cutting (refer to Figure 1), one edge of the two parts is used as a shared edge, greatly shortening the cutting path and reducing the cutting time.

Fig.1 Shared edge cutting cases

It is not possible to have all parts share one edge on a single sheet metal. It is generally recommended to use 2 to 4 parts as a group to share the edge.

If all parts share the edge, it can cause instability on the workbench. Additionally, processing on the edge of the finished product parts during the cutting process can interfere with and damage the cutting head, as the finished parts will be turned up.

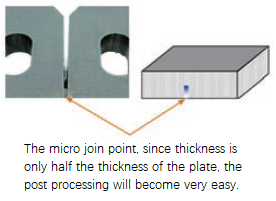

To improve the precision of the final part, the bridge method can be used when cutting with a shared edge. This involves making precise, micro connections between parts in the nesting (refer to Figure 2), with the distance being equal to the diameter of the laser spot.

Fig.2 The micro connection

Statistics show that by adopting shared edge cutting, the actual cutting path can be reduced by 30% and the material utilization rate can be increased by 8%.

Typically, the machine will lift to a certain height after cutting an outline and then move to the next contour’s cutting position for piercing and cutting.

This is done to prevent collisions between the cutting head and the cut piece when moving from the current profile to the next cutting profile.

However, if the cutting path of the cutting head is optimized or the micro-connection contour is used, the lifting motion of the cutting head can be eliminated, thereby improving the efficiency of the laser cutter.

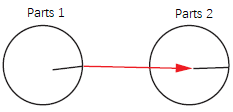

Fig.3 Before and after the cutting head lifting motion optimization (the dotted line is the cutting head movement path)

Figure 3a illustrates the lifting action of the cutting head.

Figure 3b shows that after optimization and setting in the programming software, the cutting head does not lift and moves directly to the next contour’s cutting position.

It is important to note that after using this optimization method, one must pay attention to the movement path of the cutting head, as it cannot pass over the finished contour, as shown in Figure 3.

Fig.4 Traditional laser cutting path

Fig.5 Optimized laser head cutting path

Before laser hole cutting, a hole must be made in the plate first.

Once the material is exposed to a continuous laser, a pit forms in the center and the molten material is removed by the working airflow along with the laser beam, resulting in a hole.

This hole is similar to a threaded hole created through thread cutting.

The laser beam is used for contour cutting at the start of the processing.

Typically, the laser beam’s flight path direction is perpendicular to the tangent direction of the processed part’s cut contour.

Many factors impact the quality of laser drilling, and optimizing the processing technology requires understanding and analyzing the drilling parameters based on the principle and characteristics of drilling.

Different puncture and processing technologies should be used for different part contours.

The piercing mode of the laser cutting machine mainly consists of the following three types:

(1) No piercing (for thin plates under 1mm)

(2) Regular piercing, which is the pulse mode piercing, utilizes high peak power pulsed laser to melt or vaporize a small amount of material. Each pulse of light results in only small particles of spray, which are gradually deepened over time, so it takes several seconds to pierce a thick plate.

The advantage is that the piercing quality is high and the cutting quality is ensured.

The disadvantage is that it takes a long time, requires some debugging experience, and the piercing time increases with the plate’s thickness.

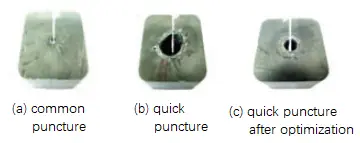

(3) Rapid piercing, also known as blasting perforation.

The material forms a pit in the center after continuous laser exposure.

The advantage is that the piercing time is short.

The disadvantage is that the piercing is large and if the position setting is not correct, it can affect the contour and, in turn, the cutting quality.

The piercing time is within 1 second.

For thick plate cutting, especially large contour cutting such as a carbon steel plate above 4mm with a diameter of more than 10mm, it is recommended to use rapid piercing instead of regular piercing.

However, before setting the rapid piercing, the length of the cut line must be properly adjusted (Rapid piercing holes have large apertures and rough surfaces, requiring longer lead-in lines to ensure proper cutting quality).

Fig.6 Perforation way

Because of the requirements of the process, some parts are usually left unprocessed in the nesting area, such as the space between the parts or the distance from the outer contour of the plate. To optimize the utilization of the plate, reducing the spacing or using a shared edge can be effective.

In this blog post, four methods for shortening laser cutting time and improving plate utilization rate have been summarized. These methods include using shared edge cutting, optimizing sheet material, reducing cutting head lift motion, and selecting the appropriate piercing method. The comprehensive application of these methods can lead to improved work efficiency, reduced waste, and better economic outcomes, as verified through practical experience.