Have you ever struggled with the precise installation of synchronous belt pulleys and shafts? This article provides clear, step-by-step methods to ensure accurate and secure assembly. You’ll discover common installation techniques, from set screws to tensioning sleeves, along with practical tips for each method. By the end, you’ll have the knowledge to choose the best approach for your application, ensuring efficiency and reliability in your mechanical systems.

It consists of a circular belt with equidistant teeth on its inner circumference and corresponding teeth on the pulleys. During operation, the teeth of the belt mesh with the grooves of the pulley to transmit motion and power. It is a new type of belt transmission that combines the advantages of belt, chain, and gear transmissions.

Today we will only discuss the design and assembly methods of synchronous belt pulleys.

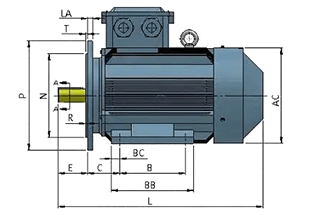

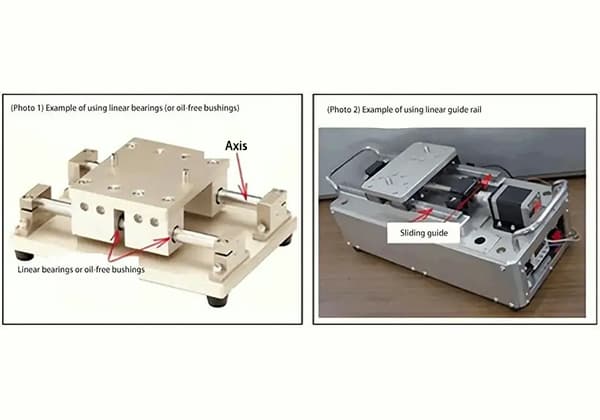

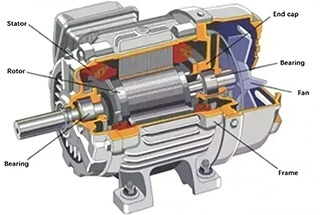

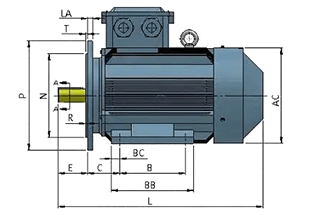

We will summarize and share several common methods of installation, which are generally used for the installation of the output shaft (power shaft) of the motor and the synchronous belt pulley.

They are provided as a reference for everyone. If anyone has a better structure, you can leave a message.

There are several ways to install the synchronous belt pulley on the motor shaft (output shaft) or driven shaft. Let’s discuss some of the conventional methods.

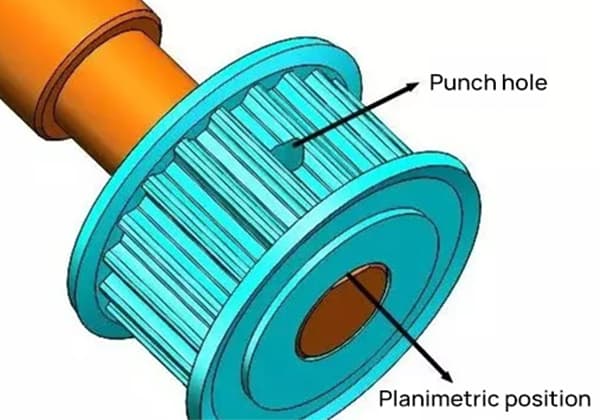

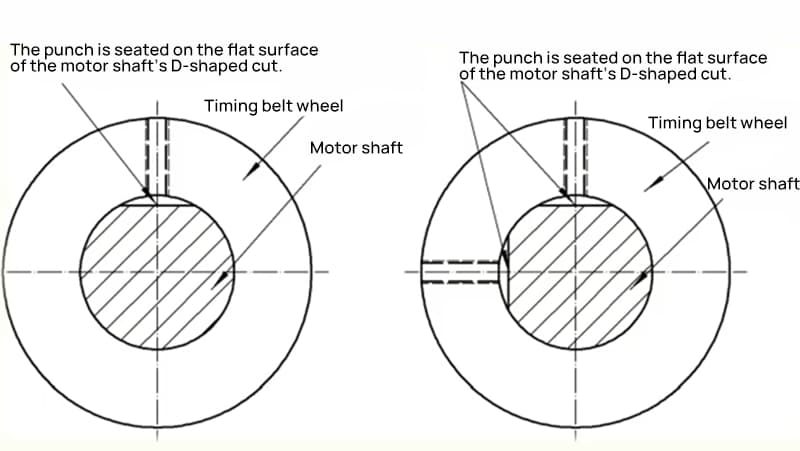

This is the most common method, which I believe everyone has seen and used before.

It involves using a radial set screw on the synchronous belt pulley to clamp onto the flat end of the motor shaft.

(1) Remove burrs at the interface between the motor shaft and synchronous belt pulley.

(2) Install the synchronous belt pulley onto the motor shaft (for pulleys with shaft shoulders, install them all the way to the end of the shaft), adjust the distance, and then tighten the set screw.

Note: For this type of installation method, the matching surface of the shaft needs to be machined to have a flat cut surface.

Characteristics:

This method uses a set screw to position and transmit the driving torque, and is suitable for light loads.

Explanation:

This method involves securing the synchronous belt pulley with a tensioning sleeve, and securing it parallel to the axial direction of the motor shaft using screws.

This method is suitable for compact spaces where installation can only be done axially at a higher cost.

I like this method as it reduces your design workload.

This installation method is also simple and easy, but the only downside is that it is slightly more expensive and cannot be used in situations where high torque transmission is required.

Installation precautions:

(1) When installing, clean the surface of the motor shaft and apply a thin layer of lubricating oil or grease.

(2) Before installation, wipe the contact surface between the synchronous belt pulley and the bushing, and apply lubricating oil and grease. (The threaded surface and supporting surface of the fastening bolts should also be coated.)

(3) Temporarily assemble the synchronous belt pulley and bushing, and then insert it into the motor shaft. (It is not allowed to directly fasten the bushing with bolts without inserting it into the shaft.)

(4) After positioning is completed, gradually tighten the screws on the bushing in diagonal order, then lock them and mark different lines.

Characteristics:

The absence of a keyway does not reduce the strength of the shaft, and it is easy to position.

Concentricity can be easily ensured, but the price is relatively higher.

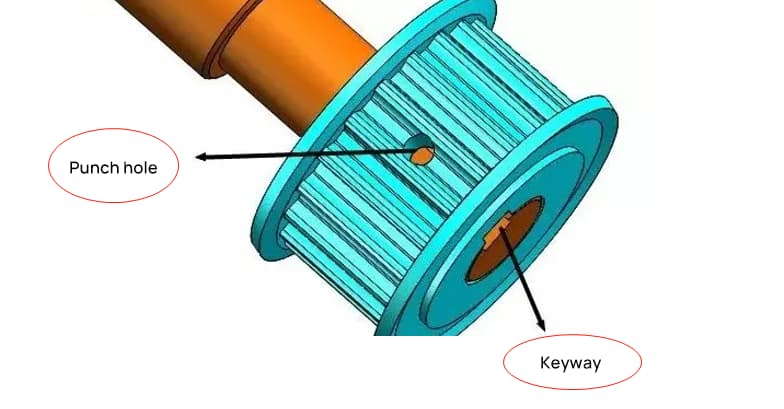

This method involves connecting the synchronous belt pulley to the shaft using a flat key and a set screw. This method is suitable for high torque applications.

(1) Remove burrs from the flat key and the shaft to ensure part cleanliness.

(2)Install the synchronous belt pulley onto the shaft, adjust the distance or tighten the shaft shoulder according to the design dimension, and then tighten the set screw.

Characteristics:

This method uses a keyway to transmit greater torque and is suitable for medium to heavy loads.

(This is the optimal and most commonly used method.)

This method involves directly gripping the synchronous belt pulley with a stepped design onto the shaft, and screwing it onto the motor shaft in the radial direction. This is the most widely used method and is suitable for low torque applications. It is not commonly used when transmitting higher torques.

These are the four common methods for designing and installing synchronous belt pulleys. You can choose from them based on your specific application scenarios, cost considerations, and maintenance needs.