Why do certain iron castings excel in vibration absorption while others boast superior strength and wear resistance? Iron castings, integral to machinery and structural components, come in various types, each with unique properties. From gray iron’s excellent vibration damping to ductile iron’s impressive toughness, understanding these differences is crucial. In this article, explore the characteristics, benefits, and applications of the seven main types of iron castings, enhancing your knowledge and helping you choose the right material for your needs.

Iron castings are articles made by casting molten iron. However, due to various factors, such as impurities, defects like pores, pinholes, slag inclusions, cracks, and pits are common occurrences.

Iron castings possess good fluidity during the casting process, and exhibit small volume shrinkage and linear shrinkage. However, their overall mechanical properties are relatively low, with compressive strength about 3-4 times higher than tensile strength.

Iron castings also exhibit good vibration absorption due to their low elastic modulus. These castings are suitable for complex shapes and asymmetric structures.

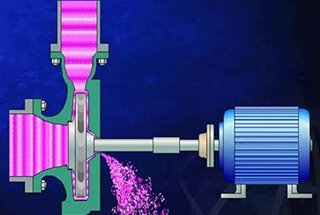

For instance, iron castings are commonly used in engine cylinder blocks, cylinder sleeves, various machine beds, bases, flat plates, platforms, and other similar applications.

The fluidity of this material is similar to that of gray cast iron. However, its body shrinkage is larger and linear shrinkage is smaller, which makes it susceptible to shrinkage cavities and porosity formation.

Despite this, the material exhibits higher comprehensive mechanical properties and elastic modulus when compared to gray cast iron. It also boasts excellent abrasion resistance, impact toughness, and fatigue strength.

However, its vibration damping capacity is lower than that of gray cast iron.

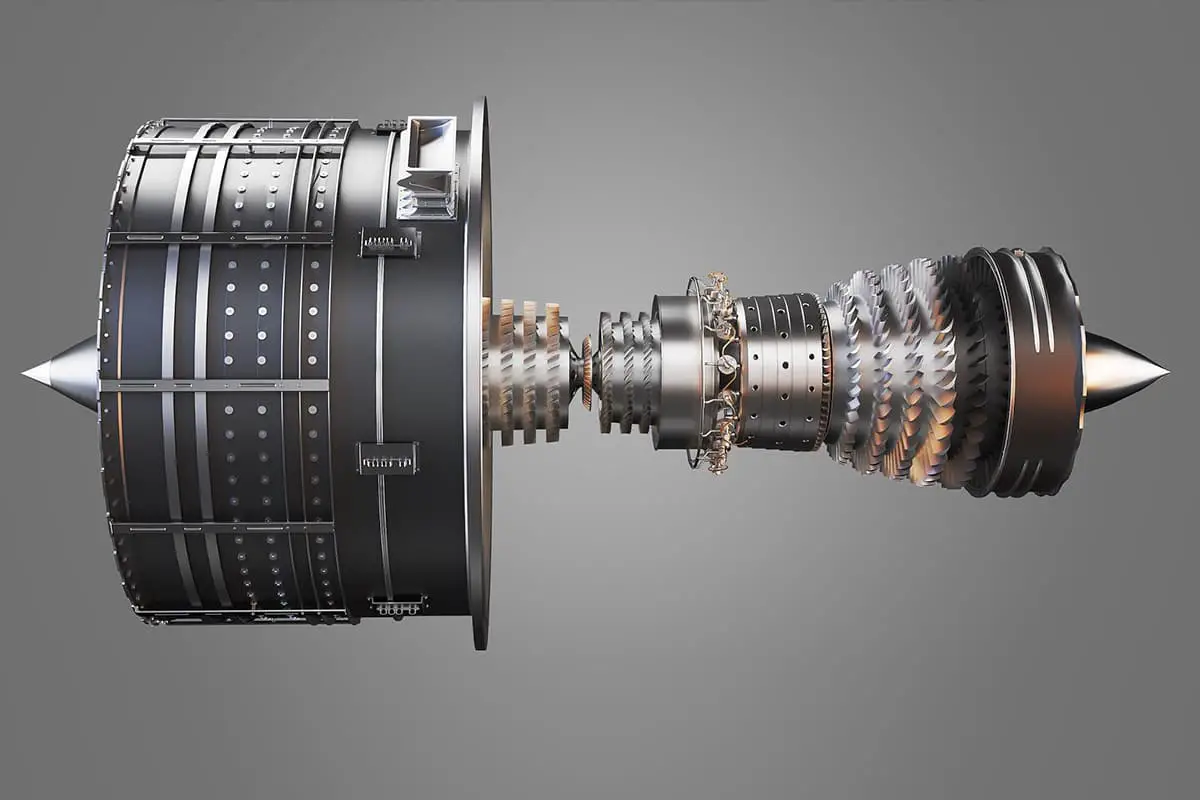

In terms of application, it is generally recommended to design parts with uniform wall thickness. For thick and large section parts, a hollow structure can be adopted, such as the nodular cast iron crankshaft journal.

The fluidity of this material is worse than that of gray cast iron. The bulk shrinkage is also significant, resulting in a very small final linear shrinkage after annealing. Furthermore, before annealing, the material is very brittle, making it easy to damage the blank.

While the comprehensive mechanical properties are slightly lower than that of nodular cast iron, its impact toughness is 3-4 times higher than that of gray cast iron.

This material is typically used for thin-walled, uniform parts with a common thickness of 5-16mm. The requirement for white mouth as cast means that the cross-sectional shape is often I-shaped, T-shaped, or box-shaped to avoid cross-section. Protruding parts of the component should be reinforced with ribs to increase its rigidity.

The fluidity of the material is poor, and it is highly sensitive to volume shrinkage, linear shrinkage, and cracking.

It possesses high comprehensive mechanical properties, with compressive strength almost equal to tensile strength.

However, it has poor vibration absorption.

For application, the structure should have minimal thermal nodes and provide conditions for sequential solidification. The connection and transition of adjacent walls should be smoother. The casting section should adopt box shapes, groove shapes, or other approximate closed structures. Some horizontal walls can be changed into inclined walls or wavy shapes.

To reduce the possibility of cracks, the integral wall should be changed to a wall with a window. The preferred shapes of the window are oval or circular, with the edges made into bosses.

The casting performance of this material is similar to that of gray cast iron. However, there are some drawbacks. Firstly, the crystallization range is large, which means that shrinkage cavity is more likely to occur. Secondly, it has poor liquidity.

Additionally, it performs poorly at high temperatures and tends to become brittle. Lastly, the strength of the material decreases significantly as the cross-section increases. On the bright side, it has good wear resistance.

In terms of application, it is important to note that the wall thickness should not be too large. If there are protruding parts in the parts, they should be reinforced with thin reinforcing ribs to avoid hot cracking. Moreover, it is advisable to avoid overly complicated shapes.

This material exhibits significant shrinkage, a narrow crystallization range, and is prone to producing concentrated shrinkage holes. However, it has good liquidity and demonstrates excellent wear and corrosion resistance.

This material can be applied in a manner similar to steel castings.

The casting property is similar to that of cast steel, but the strength decreases more significantly with an increase in wall thickness. Therefore, it is recommended that the wall thickness should not be too large. Additionally, this applies to other similar steel castings as well.

1. The design process of cast iron.

During the design process, it’s essential to determine the geometry and size of the cast iron based on working conditions and the properties of the metal materials. However, it’s also important to consider the rationality of the design from the perspective of casting alloy and casting process characteristics. This includes taking into account the obvious size effect, solidification, shrinkage, stress, and other potential issues to avoid or minimize the occurrence of composition segregation, deformation, cracking, and other defects in the cast iron.

2. There should be a reasonable casting process.

According to the structure, weight, and size of the cast iron, as well as the characteristics of the casting alloy and the production conditions, it is important to select the appropriate parting surface, molding and core-making method. Additionally, setting the casting ribs, cold iron, riser, and gating system in a reasonable manner is crucial to ensuring the quality of the final product.

3. The quality of raw materials for casting.

The use of low-quality materials, including metal charge, refractory, fuel, flux, modifier, casting sand, molding sand binder, coating, and other materials, can result in defects such as porosity, pinholes, slag inclusions, and sand sticking in the cast iron. These defects not only affect the appearance but also the internal quality of the cast iron. In severe cases, the cast iron may need to be scrapped.

4. Process operation.

It is essential to develop appropriate procedures for process operations, enhance the technical proficiency of workers, and guarantee the accurate execution of these procedures.