Have you ever wondered how modern industries shape and cut metal with such precision? Enter the ironworker machine, a powerhouse of efficiency and versatility. This article will reveal how these machines transform metalworking, making complex tasks like punching, shearing, and bending seem effortless. Prepare to uncover the secrets behind their incredible performance!

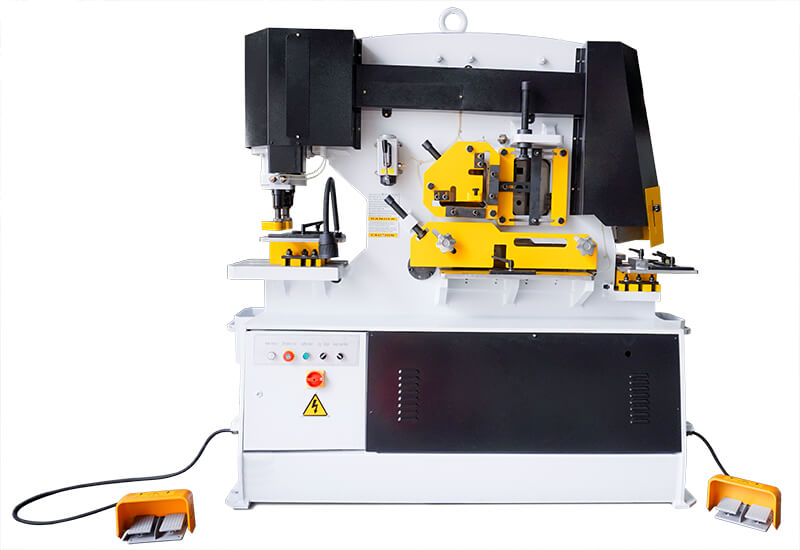

Ironworker machine is a machine tool that integrates multiple functions such as metal shearing, punching, plate cutting, and bending.

The ironworker machine has the advantages of being simple to operate, having low energy consumption, and having low maintenance costs.

It is a preferred equipment for metal processing in modern manufacturing industries, such as metallurgy, bridge construction, communication, electric power, military industry, and more.

The ironworker machine comes in two forms: hydraulic and mechanical.

Compared to hydraulic punching machines, the ironworker machine is significantly more powerful.

Not only can the ironworker machine punch various types of holes, including square holes, but it can also punch flat section steel, I-beams, channel steel, and angle steel.

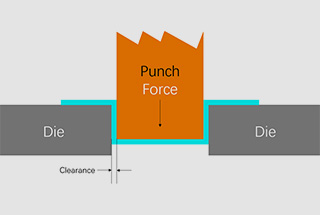

(1) The ironworker machine works by using a sliding plate with a cutting edge, which is driven up and down through a two-stage lever and sliding block. The cutting and punching of metal materials is performed by a fixed edge that is installed on the frame.

(2) The machine is powered by electricity and is controlled by a foot switch, allowing for up to 30 punching and shearing actions per minute.

(3) The ironworker machine can punch and shear various types of common steels, such as angle steel, channel steel, steel plates, square steel, and I-beams. It can also shear, cut angles, die-shear, and punch these materials.

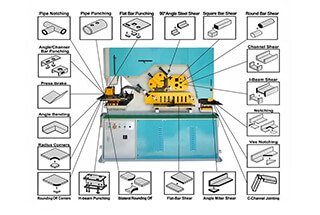

(4) The ironworker machine has multiple working stations, including a punching station, an angle steel cutting station, a bar cutting station, a plate cutting station, a corner cutting station, and more. The machine is multi-purpose and easy to operate.

(5) The ironworker machine’s structure consists of a motor, a shield, a foot switch, a frame, and multiple ironworker components.

The ironworker machine uses hydraulic transmission and has a reasonable structure, is lightweight, operates quietly, is reliable, and has good performance in the face of overloads.

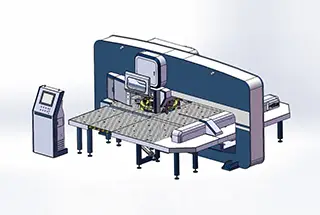

The machine is equipped with a punching station, a channel steel and angle steel cutting station, a thick plate cutting station, a round steel and square steel cutting station, and a corner cutting station. You can use it for punching large holes, plate bending, channel steel punching, louver cutting, and pipe corner cutting, among other things.

The machine comes with five stations and dual hydraulic workstations as standard and can work independently at the same time. No horizontal debugging is required, and the machine can be used right after being placed in position. An optional CNC control system is available to increase automatic punching and shearing efficiency.

The machine uses European top-level processing technology, and its frame is fully welded. After undergoing high-temperature quenching, the frame has high rigidity and strength. The tools are treated with a special vacuum and high temperature to extend their lifespan.

The pipe cutting die can also cut and groove pipes, resulting in high efficiency, cost savings, and a beautiful cut section.

The ironworker machine uses mechanical transmission, driven by the motor and reducer to operate various parts.

It is designed with functions for shearing angles, punching, cutting, and cutting. Different functions can be used to perform different punching and shearing processes on metal profiles.

Let’s take a closer look at the structure and function of each part so that we can become familiar with its operation during everyday use.

The ironworker machine is suitable for cutting angle steel, channel steel, round steel, and iron plates.

It has the function of electric single cutting and is convenient to operate, with high cutting precision and a smooth incision.

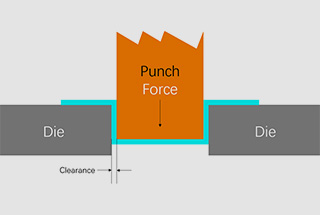

The ironworker machine is suitable for punching flat steel and angle steel, and round holes or long holes can be customized to meet specific requirements.

The ironworker machine is applicable for square cutting of angle steel, V-shaped cutting of angle steel, butt cutting, and cutting of metal profiles, such as the butt cutting of angle steel, V-shaped cutting openings, and square cutting of angle steel.

These punching and shearing functions are performed with the assistance of a foot switch, which allows for up to 30 punching and shearing actions per minute.

Additionally, the key components are made from high-hardness materials and undergo quenching, improving their strength and resistance to wear.

The ironworker machine is used for shearing, punching, and die-shearing of metal profiles, and has the advantages of being easy to operate, having multiple functions in one machine, and being time- and labor-saving.

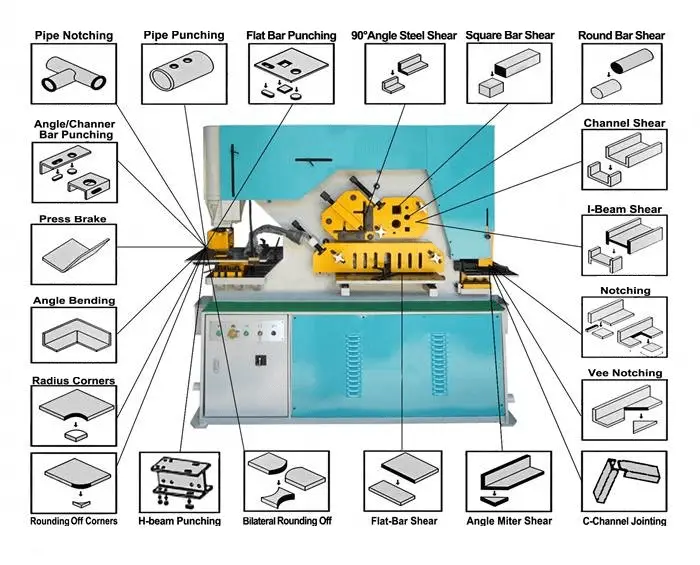

Structure and function diagram of ironworker machine:

The ironworker machines are widely used in:

| Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 | |

|---|---|---|---|---|---|---|---|

| Plate cutting | Cutting force (Kn) | 600 | 900 | 1200 | 1600 | 2000 | 2500 |

| One stroke shearable flat steelthick × wide (mm) | 16×250 | 20×330 | 25×330 | 30×355 | 35×380 | 40×400 | |

| Maximum shear size(mm) | 8×400 | 10×480 | 16×600 | 20×600 | 25×700 | 30×750 | |

| Blade length(mm) | 410 | 485 | 620 | 610 | 710 | 760 | |

| Blade angle(mm) | 7 | 8 | 8 | 8 | 8 | 8 | |

| Section cutting | Side length of square steel(mm) | 40 | 45 | 50 | 55 | 60 | 65 |

| Round steel diameter(mm) | 45 | 50 | 60 | 65 | 75 | 80 | |

| Channel (mm) | 120 | 160 | 200 | 280 | 300 | 320 | |

| I beam(mm) | 120 | 160 | 200 | 280 | 280 | 320 | |

| Equilateral angle steel 90 ° shear(mm) | 100×10 | 140×12 | 160×14 | 180×16 | 200×16 | 200×20 | |

| Die cut | Thickness (mm) | 8 | 10 | 12 | 16 | 16 | 18 |

| Width(mm) | 57 | 80 | 80 | 60 | 100 | 120 | |

| Depth(mm) | 100 | 100 | 100 | 100 | 105 | 120 | |

| Punch hole | Punch force(Kn) | 600 | 900 | 1200 | 1600 | 2000 | 2500 |

| Thickness(mm) | 16 | 20 | 25 | 30 | 35 | 35 | |

| Max dia.(mm) | 25 | 30 | 35 | 35 | 40 | 45 | |

| Throat depth(mm) | 300 | 355 | 400 | 600 | 550 | 550 | |

| Max stroke(mm) | 80 | 80 | 80 | 80 | 80 | 100 | |

| Stroke times() | 8 | 8 | 8 | 8 | 8-24 | 8-24 | |

| Material strength (Mpa) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | |

| Motor | Model | Y112M2-4 | Y132M2 | Y132M4 | Y160M-4 | HYY2160L-4 | HYY2160L-4 |

| Power(KW) | 4/5.5 | 5.5/7.5 | 7.5/11 | 11/15 | 15/18.5 | 18.5/22 | |

| Rotation rate(r/min) | 1440 | 1440 | 1440 | 1460 | 1440 | 1460 | |

| Size | Length(mm) | 1650 | 1950 | 2350 | 2680 | 2800 | 3000 |

| Width(mm) | 800 | 900 | 980 | 1060 | 1160 | 1440 | |

| Height(mm) | 1780 | 1930 | 2100 | 2380 | 2400 | 2450 | |

| Weight (kg) | 1800 | 2600 | 4800 | 6800 | 9200 | 12800 | |

Before starting up the ironworker machine, it is important to check that all transmission parts, connecting screws, and pin shafts are securely fastened and that electrical grounding is intact.

Before beginning work, lubricate all parts and perform a test run for two to three minutes. Only start working if there are no issues.

Avoid overloading the machine, and never punch or shear quenched steel.

Wear gloves and protective clothing while working, and avoid wearing sandals or slippers.

During punching and shearing, continuously lubricate the punching tools to prevent the upper and lower punching tools from misalignment.

Take care to protect your fingers during feeding, especially when the sheet metal cannot be held in place by the last presser foot. Do not punch or shear under these conditions.

It is strictly prohibited to disassemble, modify, or calibrate the cutting edge and die while the machine is in operation. Do not strike the die, shear blade, or other parts.

The thickness range of sheet metal must be carefully controlled, and punching and shearing should not be done if it exceeds the specified range.

Do not stack other materials or large amounts of debris in the workspace, and stop the machine during adjustments and cleaning.

After finishing work, turn off and disconnect the power promptly, and clean the site.

The operator must follow the standard safety procedures for operating an ironworker machine. They must be familiar with the machine’s structure and performance, strictly adhere to the equipment operation procedures, and only be allowed to work after receiving training and passing an examination.

The operator must wear the necessary protective clothing before operating the ironworker machine.

Before starting the machine, the power supply and voltage must be checked and confirmed to meet the required specifications.

Before daily operation, the lubrication system, hydraulic system, and compressed air system must be checked, and the oil level, oil pressure, and air pressure must meet the required standards.

Before beginning work, check that the photoelectric protection device is functioning properly. If it is not, the machine cannot be started. The operator must ensure that no one is in the machine’s working range when starting it.

For programs that are being used for the second time, perform a dry run without loading the workpiece first. Load the workpiece for processing only after confirming that there are no errors.

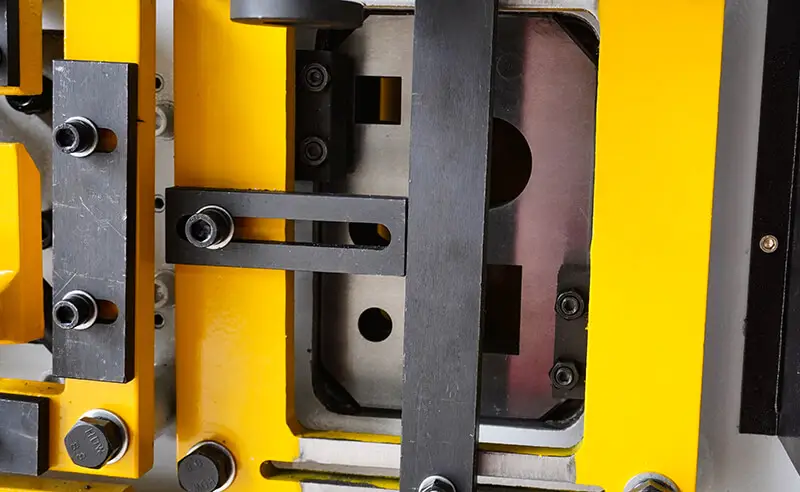

Before starting, check the discharge ports of the upper and lower molds to make sure there is no scrap metal. Ensure that the tool holder assembly, stripper, tool, intermediate ring, and adjusting ring are intact, that the shear tool and punching die are not cracked, that the gap between the punch and the die hole wall is uniform, and that the cutting edge of the shear tool is sharp.

When the ironworker is started, the operator must remain at the console and not allow anyone else to operate it. When leaving, the machine should be stopped or the power switch turned off.

When approaching the machine, adjust the speed to zero and press the stop key.

After work, turn off the power to the ironworker, including disconnecting the air switch in the power box and the power supply to the air compressor. Put each handle in the working position and lock each cabinet door.

The operator must keep the site and machine clean, maintain the ambient temperature between 10-40°C, and keep the hydraulic oil temperature of the machine between 20-60°C.

Strictly follow the above operating procedures.

If there is any abnormal noise, impact, vibration, or high temperature during operation, immediately press the emergency stop button and shut down the machine for maintenance. Operating the machine while it is malfunctioning is strictly prohibited.

Preparation before starting

Before starting, check that all fasteners are securely fastened, the upper and lower die holes are aligned, there are no small iron blocks or debris on exposed gears and transmission parts, the clamping plate operates normally, and the pressure of each part is within normal range.

The feeding mechanism can only be started if there is no vibration, abnormal noise, or obstacles during a dry run.

When cutting large materials, a designated person must be in charge to oversee, focus, and coordinate the operation.

The loading and unloading of tools, setting of tools, unloading of molds, calibration of dies, and feeding of screws for the punch must be performed after shutting down the machine.

All machined parts must fall within the specified range of the machine.

When loading and unloading workpieces and molds, be cautious and keep your feet away from the foot switch. Outsiders are strictly prohibited from being near the foot switch.

When adjusting the upper and lower die molds, they must be rotated by hand, and the machine can only be started if there are no obstacles.

Precautions during operation

When cutting a narrow steel plate, a special wrench should be inserted at the edge of the plate, and the plate should be pressed with the appropriate pressure to prevent damage to the machine due to the plate warping upwards. The cut steel plate should be promptly pushed out of the mouth with a stick to avoid excessive accumulation and cracking at the mouth.

When punching a hole in an angle steel, the angle steel must be supported flat and firmly clamped with a special wrench to prevent rebound injury or damage to the punch.

The punch and stripper can only be replaced after the punch handle is in a neutral position.

It is prohibited to punch and shear beyond the length and thickness of the shearing machine. It is also prohibited to shear and punch high carbon steel, high alloy steel, quenched steel, cast iron, and other materials that fall outside the capabilities of the ironworker machine. Overloading the machine with excessive punching and shearing is not allowed.

When the punch is running, it is forbidden to reach into the mold to retrieve or adjust the position of the workpiece. Take care to prevent injury from sliding, and use pliers, hooks, or other tools to clean after the clutch is disengaged.

The cutting and punching must be performed correctly, and overload operation is not allowed.

Shutdown precautions

The iron rod used for turning must be removed promptly.

Before changing the mold and scissors, turn off the power supply.

Once the punching and shearing work is completed, hands and feet should be removed from the buttons or pedals promptly to prevent accidental operation.

If the machine is operating abnormally, shut it down immediately for maintenance.

In the event of any abnormality, the ironworker machine must be immediately shut down and the situation reported to the maintenance team. During maintenance, the power supply must be turned off and a “Do Not Start During Repair” warning sign must be posted at the switch. If necessary, the switch box should be locked or monitored.

Strictly follow the operating procedures.

Before starting up each time, regularly and quantitatively add lubricating oil at specified intervals according to the lubrication chart requirements. The oil must be clean and free of impurities.

Ensure that the plate shears are always kept clean, and that the unpainted parts are protected with anti-rust grease.

Regularly replace and refill the lubricating oil in the motor bearings, and regularly check the electrical components for normal operation, safety, and reliability.

Frequently inspect the triangular belt, handle, knob, and key of the plate shear for damage. If they are severely worn, replace them promptly and report to the spare parts department for replenishment.

Regularly inspect and repair switches, fuses, and handles to ensure they function reliably.

Lubricate and clean the machine tool 10 minutes before starting work each day.

The blades of the ironworker machine are typically made of materials such as T10, 9CrSi, 6CrW2Si, 12CrMoV, H13, and alloy steel.

The ironworker machine blade includes components such as the punch head, die, and knife plate. It is a versatile tool suitable for modern manufacturing industries such as metallurgy, bridge construction, communication, electric power, and more.

As market competition continues to increase, there are more and more manufacturers and trading companies producing ironworker machines, leading many buyers to have more questions when choosing which one to purchase, and they may not know which product offers better value for the cost.

Then, it should be helpful for us to put forward some precautions for all purchasers:

Select several excellent suppliers.

There are several methods to choose suppliers.

You can search for keywords such as “ironworker machine” or “steelworker machine” and find many reputable suppliers, such as Geka.

You can also ask friends or colleagues if they have worked with a reliable ironworker machine supplier.

Good use of these options often leads to finding good suppliers.

Communicate in many ways to identify manufacturers or trading companies.

It’s not to say that all trading companies are bad, as they typically cannot offer a competitive price advantage. However, their after-sales service may not be as reliable. While it’s important to note that not all trading companies are poor, there are still many reputable ones.

Determine the purchase money and make field observations.

An ironworker machine can cost tens of thousands of dollars.

As a buyer, it is important to visit the manufacturer before making a purchase in order to gain insight into their scale, team, production equipment, and other relevant information. This will help you make an informed decision.

Pay attention to details.

Due to the varied nature of their business, the construction of ironworker machines can vary.

It is important to communicate with the manufacturer to ensure that there are no discrepancies between the machine and your expectations after production.

Don’t buy with price alone.

If the price is significantly lower than the market average, the quality of the product may be questionable.

For instance, while our company’s products may be slightly more expensive than others with the same functions, they are reliable and have no problems after being used for over a year.

Therefore, buyers should not base their decision solely on the price.

A hydraulic ironworker machine is a machine that performs punching and shearing operations using hydraulic transmission as its power source.

Why does this machine use hydraulic transmission?

Hydraulic transmission is a method of transmitting power and control using liquid as the working medium.

It is a novel technology that leverages the principle of hydrostatic pressure transmission.

It is widely used in industrial and agricultural production, and is commonly employed in large machinery such as hydraulic ironworker machines and multi-functional ironworker machines, as well as in standalone applications.

The basic principle of hydraulic transmission:

The hydraulic system in a hydraulic ironworker machine converts the mechanical energy from the prime mover into liquid pressure energy through the use of a hydraulic pump. This force is transmitted through changes in liquid pressure energy.

By utilizing control valves and pipelines, the hydraulic pressure energy is converted back into mechanical energy with the help of a hydraulic actuator (such as a hydraulic cylinder or motor), which drives the working mechanism and creates linear reciprocating and rotary motion.

The liquid used as the working medium is typically mineral oil, serving a similar function to transmission elements like belts, chains, and gears in mechanical transmission.

Due to these advantages, hydraulic transmission is the preferred choice for hydraulic ironworker machines. With hydraulic pressure, the machine is stronger, operates more stably, is lighter in weight, operates quietly, is highly efficient, cost-effective, and produces a smooth and attractive cutting surface.

As a result, hydraulic ironworker machines have become a popular choice in the industrial manufacturing sector.

The following are six well-known ironworker machine manufacturers.

Which one is the best for you?

It is important to conduct some research to determine the best fit for you.

Keep in mind that our suggestions will be based on your budget and specific needs.

The following price of the ironworker machine can be your reference.

| Model | Price |

|---|---|

| Q35Y-12 | $2,769 |

| Q35Y-16 | $4,431 |

| Q35Y-20 | $5,400 |

| Q35Y-25 | $7,615 |

| Q35Y-30 | $11,354 |

| Q35Y-40 | $12,600 |

| Q35Y-50 | $18,831 |