회주철의 내구성과 가공성을 높이는 방법에 대해 궁금한 적이 있나요? 이 문서에서는 어닐링, 정규화, 담금질 등 회주철을 열처리하는 복잡한 과정을 살펴봅니다. 재료의 강도와 안정성을 향상시키는 특정 온도와 기술에 대해 알아보세요. 이 가이드는 제조 업계 종사자나 호기심 많은 사용자 모두에게 회주철의 특성을 최적화하는 데 유용한 인사이트를 제공합니다. 이러한 방법을 통해 프로젝트와 제품을 개선할 수 있는 방법을 알아보세요.

제거하려면 잔류 스트레스 주물에서 기하학적 크기를 안정화하고 절단 후 왜곡을 줄이거나 제거하려면 주물에 응력 제거 어닐링을 수행해야 합니다.

참조하세요:

응력 제거 어닐링 공정을 결정할 때는 주철의 조성을 고려해야 합니다.

회주철의 온도가 550 ℃를 초과하면 일부 시멘타이트의 흑연화 및 과립화가 발생하여 다음과 같은 감소를 유발할 수 있습니다. 강도 및 경도.

다음의 존재 합금 원소 는 시멘타이트가 분해되기 시작하는 온도를 약 650℃까지 높일 수 있습니다.

일반적으로 회주철의 응력 제거 어닐링 온도는 550℃이며, 저합금 회주철은 600℃에서, 고합금 회주철은 650℃에서 어닐링할 수 있습니다. 가열 속도는 일반적으로 시간당 60 ~ 120 ℃입니다.

유지 시간은 어닐링 온도, 주물의 크기와 복잡성, 응력 완화 요구 사항 등의 요인에 따라 결정됩니다.

다음 그림은 홀딩 시간과 잔류 스트레스 다른 어닐링 온도에서.

그림 2 어닐링 온도와 시간 및 잔류물의 관계 내부 스트레스

a) 조성(질량 분율) (%): C 3.18, Si 2.13, Mn 0.70, S 0.125, P 0.73, Ni 1.03, Cr 2.33, Mo 0.65;

b) 조성(질량 분율) (%): C 3.12, Si 1.76, Mn 0.78, S 0.097, P 0.075, Ni 1.02, Cr 0.41, Mo 0.58;

c) 조성(질량 분율) (%): C 2.78, Si 1.77, Mn 0.55, S 0.135, P 0.069, Ni 0.36, Cr 0.10, Mo 0.33, Cu 0.46, V 0.04.

주물의 응력 제거 어닐링 중 냉각 속도는 이차 응력의 발생을 방지하기 위해 느려야 합니다. 냉각 속도는 일반적으로 시간당 20~40℃의 속도로 제어되며, 공기 냉각을 허용하기 전에 온도를 150~200℃ 이하로 냉각해야 합니다.

다음 표는 일부 회색에 대한 응력 완화 어닐링 사양을 보여줍니다. 철 주물:

표 3 그레이 캐스트에 대한 응력 완화 어닐링 사양 철 주물

| 캐스팅 유형 | 주조 질량 / kg | 주조 벽 두께 / mm | 충전 온도 / ° C | 온도 상승률 / (C / h) | 난방 온도 / C | 보유 시간 / h/ | 느린 냉각 속도(C/h) | 방전 온도 / C | |

| 일반 주철 | 저합금 주철 | ||||||||

| 일반 캐스팅 | <200 | ≤200 | ≤100 | 500~550 | 550-570 | 4-6 | 30 | ≤200 | |

| 200-2500 | ≤200 | ≤80 | 500~550 | 550~570 | 6-8 | 30 | ≤200 | ||

| >2500 | ≤200 | ≤60 | 500-550 | 550-570 | 8 | 30 | ≤200 | ||

| 정밀 주조 | <200 | ≤200 | ≤100 | 500-550 | 550-570 | 4-6 | 20 | ≤200 | |

| 200~3500 | ≤200 | ≤80 | 500-550 | 550-570 | 6-8 | 20 | ≤200 | ||

| 단순 또는 원통형 주물, 일반 정밀 주물 | <300 | 10-40 | 100-300 | 100-150 | 500~600 | 2-3 | 40-50 | <200 | |

| 100-1000 | 15-60 | 100-200 | <75 | 500 | 8-10 | 40 | <200 | ||

| 복잡한 구조와 고정밀 주조 | 1500 | <40 | <150 | <60 | 420~450 | 5~6 | 30~40 | <200 | |

| 1500 | 40-70 | <200 | <70 | 500-550 | 9-10 | 20-30 | <200 | ||

| 1500 | >70 | <200 | <75 | 500-550 | 1.5 | 30-40 | 150 | ||

| 섬유 기계 소형 주조 공작 기계 소형 주조 공작 기계 대형 주조 | <50 | <15 | <150 | 50-70 | 500-550 | 3~5 | 20~301 | 50-200 | |

| <1000 | <60 | ≤200 | <100 | 500-550 | 3-5 | 20-30 | 150-200 | ||

| >2000 | 20-80 | <150 | 30-60 | 500-550 | 8-10 | 30-40 | 150-200 | ||

회주철 주물의 흑연화 어닐링의 목적은 경도를 낮추고 기계 가공성을 높이며 가소성과 인성을 높이는 것입니다. 주물에 공융 시멘타이트가 포함되어 있지 않거나 소량만 포함되어 있는 경우 저온 흑연화 어닐링을 수행할 수 있습니다. 그러나 공융 시멘타이트의 양이 많은 경우에는 고온 흑연화 어닐링이 필요합니다.

(1) 저온 흑연화 어닐링.

회주철에서 유텍토이드 시멘타이트의 흑연화 및 과립화 과정은 재료가 저온에서 어닐링될 때 발생합니다. 이 과정을 통해 경도가 감소하고 가소성이 증가합니다.

회주철의 저온 흑연화 어닐링은 주물을 A의 하한보다 약간 낮은 온도로 가열하는 것을 포함합니다.C1를 사용하여 이 온도에서 일정 시간 동안 유지하여 유텍토이드 시멘타이트가 분해되도록 한 다음 용광로에서 냉각합니다.

프로세스 곡선은 다음과 같습니다:

그림 4 회주철의 저온 흑연화 어닐링 공정 곡선

(2) 고온 흑연화 어닐링.

회주철의 고온 흑연화 어닐링 공정은 재료를 A의 상한 온도 이상으로 가열하는 과정을 포함합니다.C1. 이 과정은 주철의 유리 시멘타이트가 다음과 같이 분해됩니다. 오스테나이트 및 흑연으로 구성됩니다. 그런 다음 재료를 이 온도에서 지정된 시간 동안 유지하고 원하는 매트릭스 구조에 따라 특정 방식으로 냉각합니다.

가소성과 인성이 높은 페라이트 매트릭스를 원하는 경우 공정 사양 및 냉각 방법은 다음과 같습니다:

그림 5 페라이트 매트릭스의 고온 흑연화 어닐링 공정

강도가 높고 내마모성이 우수한 펄라이트 매트릭스 구조를 원하는 경우, 공정 사양 및 냉각 방법은 그림 6과 같이 진행할 수 있습니다:

그림 6 펄라이트 매트릭스의 고온 흑연화 어닐링 공정

회주철을 정상화하는 목적은 강도, 경도 및 내마모성을 개선하거나 표면 담금질을 위한 예비 열처리 및 매트릭스 구조를 개선하기 위한 것입니다.

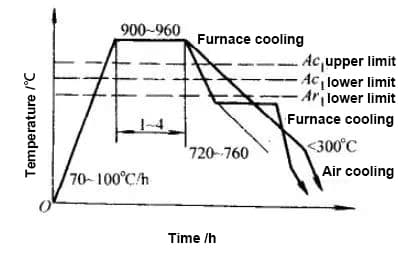

의 사양은 정규화 프로세스 회색 주철의 비율은 아래 그림에 나와 있습니다:

일반적으로 주물은 A의 상한까지 가열됩니다.C130°C에서 50°C 사이입니다. 이로 인해 원래 구조가 오스테나이트로 변형됩니다.

일정 시간 동안 유지한 후 주물은 공기에 의해 냉각됩니다(아래 그림 a 참조).

복잡하거나 중요한 모양의 주물의 경우, 내부 응력을 제거하기 위해 정규화 후 어닐링이 필요합니다.

주철의 원래 구조에 과도한 유리 시멘타이트가 있는 경우 A의 상한까지 가열해야 합니다.C1를 50°C에서 100°C 사이로 가열하여 고온 흑연화를 통해 유리 시멘타이트(그림 b 참조)를 제거합니다.

아래 그림은 가열 온도가 정규화 후 주철의 경도에 미치는 영향을 보여줍니다.

정상화 온도 범위 내에서 주철의 경도는 온도가 증가함에 따라 증가합니다.

따라서 정규화된 주철에서 높은 경도와 내마모성을 달성하기 위해 정규화 온도 범위 내에서 더 높은 가열 온도를 선택할 수 있습니다.

그림 8 회주철의 경도에 대한 온도 정규화의 영향

참고: 그림의 원소 함량은 질량 분율(%)로 표시되어 있습니다.

정규화 후 냉각 속도는 침전된 페라이트의 양과 경도에 영향을 미칩니다.

냉각 속도가 높을수록 침전되는 페라이트의 양이 줄어들어 경도가 높아집니다.

따라서 냉각 속도를 제어(예: 공랭식, 수냉식 또는 미스트 냉각)하여 원하는 주철 경도를 조정할 수 있습니다.

주철의 담금질 공정은 주물을 AC1 상한 온도에 30~50℃를 더한 온도(일반적으로 850℃~900℃)로 가열하여 구조를 오스테나이트로 변환하는 과정을 포함합니다. 그런 다음 주물을 이 온도에서 유지하여 오스테나이트의 탄소 용해도를 높인 다음 담금질합니다. 오일 담금질 이 프로세스에 일반적으로 사용됩니다.

참조하세요:

수정된 버전은 다음과 같습니다:

캐스팅 복잡한 모양 또는 큰 사이즈는 고르지 않은 가열로 인한 균열을 방지하기 위해 천천히 가열해야 합니다. 필요한 경우 500~650℃로 예열하면 균열을 방지하는 데 도움이 될 수 있습니다.

표 8.1은 담금질 가열 온도가 주철의 경도에 미치는 영향을 보여줍니다. 위 표에 나열된 주철의 화학 성분은 표 8.2에서 확인할 수 있습니다.

오스테나이트화 온도를 높이면 담금질 후 경도가 높아집니다. 그러나 오스테나이트화 온도가 높을수록 주철의 변형 및 균열 위험이 높아질 뿐만 아니라 더 많은 유지된 오스테나이트를 사용하여 경도를 낮춥니다.

그림 9는 유지 시간이 경도에 미치는 영향을 보여줍니다.

표 8.1 오스테나이트화 온도가 화재 후 회주철의 경도에 미치는 영향(오일 가려움증)

| 회색 주철 | 출연자 | HBW | |||

| 790°C | 815C | 845°C | 870°C | ||

| A | 217 | 159 | 269 | 450 | 477 |

| B | 255 | 207 | 450 | 514 | 601 529 |

| C | 223 | 311 | 477 | 486 | |

| D | 241 | 355 208 | 469 487 | 486 520 | 460 |

| E | 235 | 512 | |||

| F | 235 | 370 | 477 | 480 | 465 |

표 8.2 여러 주철의 화학적 조성(질량 분율)(%)

| 주철 | TC | CC | Si | P | S | Mn | Cr | Ni | Mo |

| A | 3.19 | 0.69 | 1.70 | 0.216 | 0.097 | 0.76 | 0.03 | – | 0.013 |

| B | 3.10 | 0.70 | 2.05 | – | – | 0.80 | 0.27 | 0.37 | 0.45 |

| C | 3.20 | 0.58 | 1.76 | 0.187 | 0.054 | 0.64 | 0.005 | 추적 | 0.48 |

| D | 3.22 | 0.53 | 2.02 | 0.114 | 0.067 | 0.66 | 0.02 | 1.21 | 0.52 |

| E | 3.21 | 0.60 | 2.24 | 0.114 | 0.071 | 0.67 | 0.50 | 0.06 | 0.52 |

| F | 3.36 | 0.61 | 1.96 | 0.158 | 0.070 | 0.74 | 0.35 | 0.52 | 0.47 |

그림 9 주철 금속 매트릭스의 원래 구조가 840°C에서 다양한 유지 시간에 대한 담금질 후 경도에 미치는 영향

이 회주철의 화학 성분(질량 분율)은 다음과 같습니다: 3.34% C, 2.22% Si, 0.7% Mn, 0.11% P 및 0.1% S.

회주철의 경화성은 흑연 크기, 모양, 분포, 화학 성분 및 오스테나이트 입자 크기 등의 요인에 의해 영향을 받습니다.

주철의 흑연은 열전도율을 감소시켜 경화성을 감소시킵니다. 굵은 흑연의 양이 많을수록 이 효과는 더욱 두드러집니다.

템퍼링 온도가 주철의 기계적 특성에 미치는 영향은 아래 그림 10에서 확인할 수 있습니다.

흑연화를 방지하기 위해 템퍼링 온도는 일반적으로 550℃ 이하로 유지해야 하며, 템퍼링 유지 시간은 t = [주조 두께(mm)/25] + 1(h)로 계산해야 합니다.

그림 10 템퍼링 온도가 다음 사항에 미치는 영향 경도 및 강도 담금질 주철의