Have you ever wondered how we achieve such flawless, mirror-like finishes on metal and glass surfaces? This article unveils the fascinating world of lapping—a precision machining process that delivers unmatched surface smoothness and accuracy. You’ll learn about its unique characteristics, the materials it can handle, and the principles behind its incredible results. Get ready to explore the secrets of achieving perfection in machining!

Lapping has the following characteristics:

(1) The workpiece’s surface roughness can reach Ra = 0.006 to 0.1 μm, and micro-cutting with Ra = 0.1 μm can be achieved.

(2) It can result in a very precise fit between mating surfaces.

(3) Lapping is performed at low speed and low pressure, generating minimal heat.

The workpiece’s surface does not have a metamorphic layer, resulting in improved quality.

(4) The grinding device and machine have a relatively simple structure, making it suitable for both manual single-piece production and mechanical batch production.

The accuracy of manual grinding depends on the accuracy of the lapping tool and the worker’s operation skills, while the accuracy of mechanical grinding also depends on the precision of the lapping tool, the correct trajectory, and proper operation methods.

(5) During the grinding process, hard abrasive particles can easily embed into the workpiece’s soft surface, impacting its service life and optical properties.

(6) Lapping efficiency is low.

The lapping tool material is typically soft and prone to wear, so it should be maintained regularly to ensure its accuracy.

Grinding can process a variety of metal materials, including steel (including quenched steel), cast iron, copper, and cemented carbide, as well as non-metal materials such as ceramics, gems, semiconductors, glass, and plastics.

The workpiece surface shape includes inner and outer cylindrical surfaces, conical surfaces, planes, convex and concave surfaces, inner and outer spherical surfaces, screw threads, gears, and more.

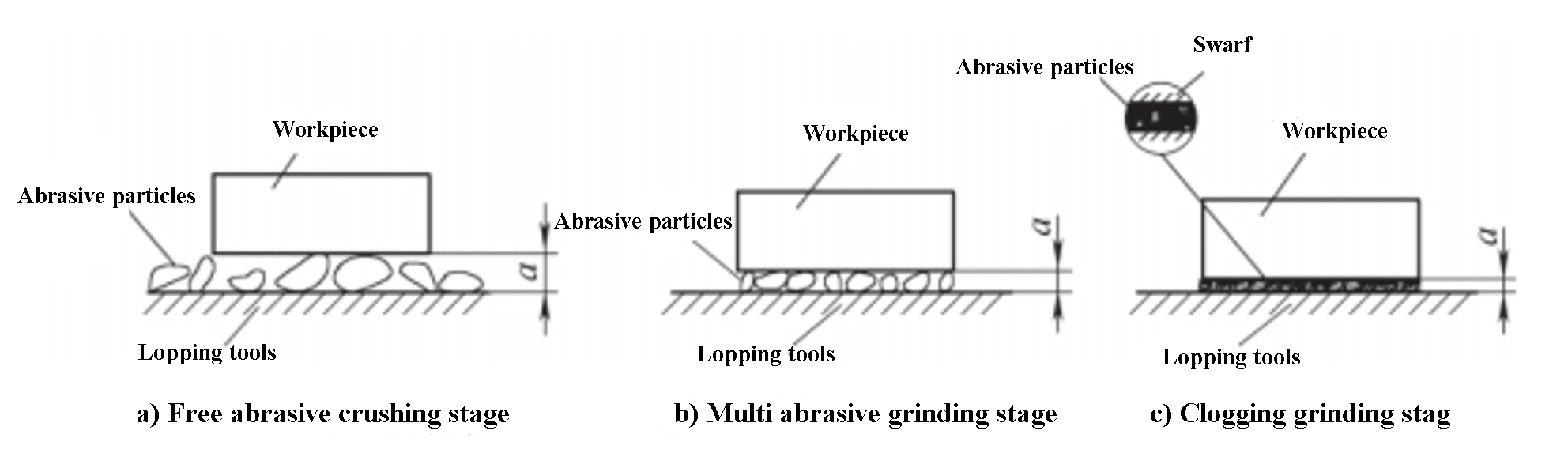

In lapping, the appropriate amount of abrasive is placed between the lapping tool and the workpiece surface.

The combination of reciprocating motion and rotation or rotation and planetary motion is then carried out under a specific pressure.

The abrasive particles in the abrasive are made to slide or roll between the lapping tool and the workpiece surface, resulting in micro-cutting.

Due to the fine nature of the abrasive particles, only a very thin layer of material can be cut.

This results in a very small net movement track on the workpiece’s surface, leading to exceptional surface quality and machining accuracy.

Abrasives can be divided into wet lapping (sanding lapping, as shown in Figure 1), dry lapping (sanding lapping), and semi-dry lapping (paste lapping) based on their use conditions.

Fig. 1 Wet lapping process

Lapping builds upon good pre-processing by performing micro-cutting with a surface roughness of Ra = 0.01 to 0.1 μm and micro-feed.

This level of precision and surface quality is difficult to achieve through other machining methods and can be several times higher than the results from alternative methods.

The precision can reach 0.025 μm and the surface roughness can reach Ra = 0.006 μm.

While other machining methods may follow a “copy processing” approach, lapping is a “creation processing” throughout.

During this process, both the precision of the lapping tool and the workpiece are improved, surpassing the original precision of the lapping tool.

The abrasive consists of abrasive particles, grinding fluid, and an auxiliary filler.

Based on the grinding method and workpiece material, liquid abrasives, grinding paste, and solid abrasives can be prepared.

Abrasive particles are the essential component of the abrasive, and their performance and proper selection significantly impact the grinding efficiency and quality.

1) Abrasives

The commonly used abrasives are corundum, silicon carbide, boron carbide, diamond, and cubic boron nitride.

Soft abrasives, such as iron oxide, chromium oxide, and cerium oxide, can also be used to further reduce the workpiece’s surface roughness.

Corundum abrasive is used to grind general steel parts, while silicon carbide or boron carbide abrasives are used for grinding hard and brittle materials such as cast iron, hard alloys, gems, and ceramics.

Diamond abrasive is appropriate for grinding cemented carbide, ceramics, gemstones, and optical glass, and cubic boron nitride abrasive should be used for grinding high-speed steel and die steel.

The choice of abrasive size and grinding efficiency are directly linked to the workpiece’s surface roughness.

A coarse particle size results in high efficiency but a high surface roughness value (Ra), while a smaller particle size leads to lower efficiency but a lower surface roughness value.

The grain size ranges from W0.5 to W40, and the surface roughness can range from 0.006 to 0.4 μm.

2) Lapping fluid

The lapping fluid serves the purpose of cooling and lubrication during the process and helps distribute the abrasive particles evenly on the surface of the lapping tool.

For rough grinding, N15 full-loss system oil is used, while for finishing grinding, a mixture of one part N15 full-loss system oil, three parts kerosene, a small amount of turbine oil or spindle oil, and light mineral oil or transformer oil is used.

Kerosene is used for grinding cast iron, while animal oil and a small amount of spindle oil or vegetable oil is used for grinding copper. Vegetable oil, turbine oil, or emulsion is used for grinding quenched steel and stainless steel.

Olive oil, roundness oil, or distilled water is used for grinding diamonds, gasoline for grinding cemented carbide, alcohol for grinding gold, silver, and platinum, and water for grinding glass and crystal.

3) Auxiliary fillers

In the lapping process, auxiliary fillers serve the purpose of adsorption and improving the processing efficiency.

Commonly used auxiliary fillers are composed of stearic acid or oleic acid, fatty acid, and industrial glycerin as the main components in varying proportions.

4) Preparation of abrasive

In wet lapping, liquid abrasives are made up of kerosene, mixed grease, and abrasive powder with a concentration (mass fraction) of approximately 30% to 40%. The concentration decreases if the powder is fine and supplied automatically by the machine.

In dry lapping, a mixture of 15g of abrasive powder, 8g of mixed fat, 200ml of aviation gasoline, and 35g of kerosene are used after soaking for one week. The grinding paste contains 20% to 50% abrasive powder, 25% to 30% oleic acid, 18% to 30% mixed grease, and in some cases, about 15% Vaseline is added for very fine powder.

Solid abrasive, or abrasive soap, is used to improve the surface gloss of the workpiece. Its composition includes 57% chromium oxide, 21.5% paraffin, 21.5% beeswax, 11% stearic acid mixed grease, and 7% kerosene.

1) Functions of lapping tools

The lapping tool serves as the mold for lapping, imparting its own geometric accuracy onto the workpiece to a certain degree. It is responsible for carrying the abrasives for coating and embedding. During its relative motion with the workpiece, the workpiece is processed to achieve the desired machining accuracy and surface quality.

The lapping tool must have grooves to hold abrasives and prevent the buildup of excess abrasives. It must also have proper geometric accuracy, sufficient stiffness, a compact material free of impurities, and uniform hardness.

2) Materials of lapping tools

Cast iron is suitable for grinding a variety of materials; mild steel is suitable for grinding small diameter threads and small holes; brass and red copper are suitable for rough grinding and grinding gems; hardwood is suitable for grinding copper and soft metals; tin and lead are suitable for improving the surface quality of workpieces as they are too soft to alter the shape of the workpieces.

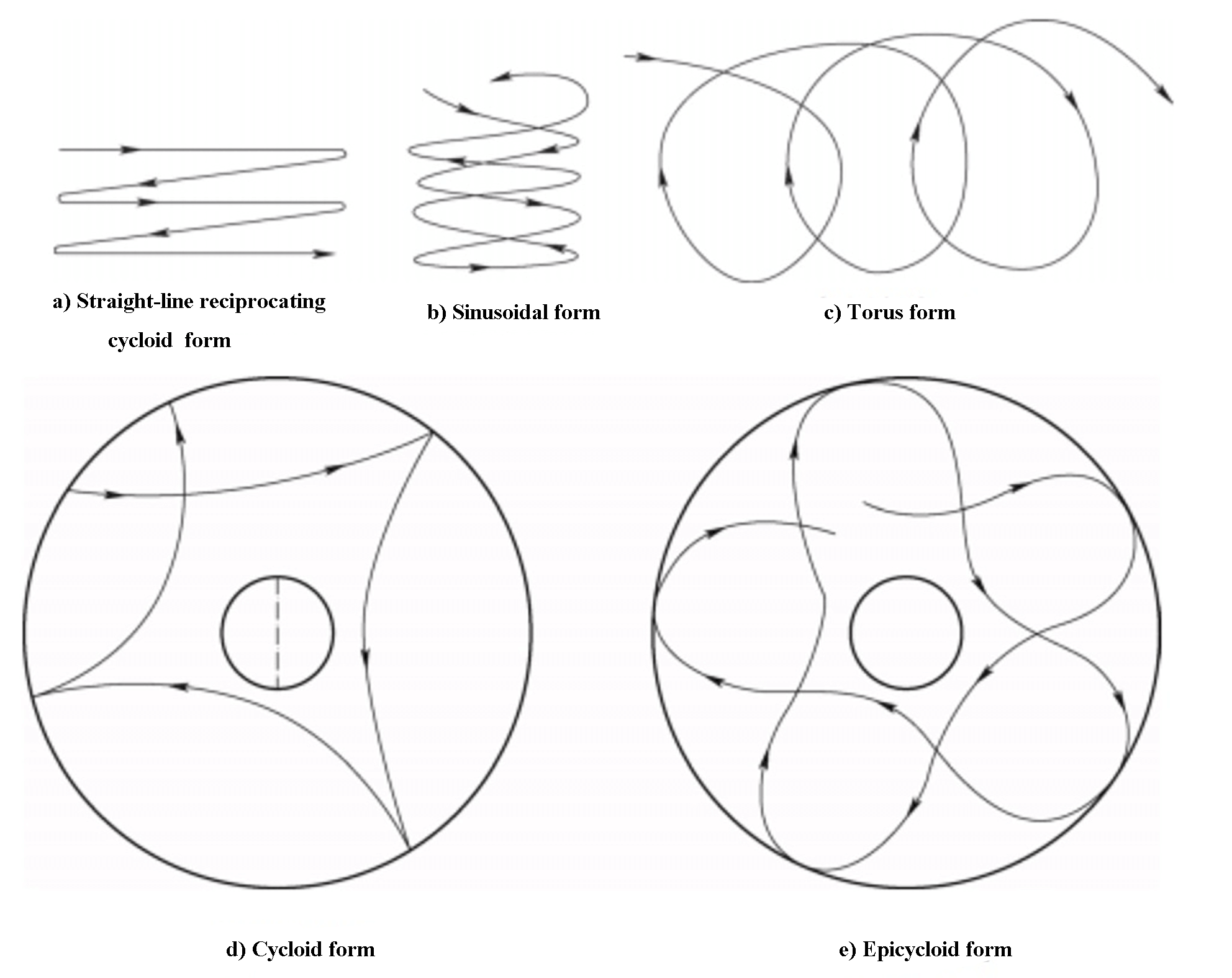

1) The lapping trajectory is shown in Fig. 2, and it has different forms such as straight-line reciprocating cycloid.

Fig. 2 The lapping trajectory

2) Lapping pressure

In wet lapping, the pressure ranges from 10 to 25 MPa, while in dry lapping, the pressure ranges from 1 to 15 MPa. For fine lapping, the pressure value is lower.

3) Lapping speed

The lapping efficiency is directly proportional to the lapping speed. The lapping speed of wet lapping is 20 to 100 m/min, and that of dry lapping is 10 to 20 m/min. If the accuracy of the workpiece is high and the material of the workpiece is soft, a smaller value should be taken.

4) Lapping allowance

The inner hole is 0.01-0.03 mm (diameter allowance), the outer circle is 0.005-0.01 mm, and the plane is 0.005-0.01 mm.

5) Problems needing attention

The abrasives must be stored properly to prevent contamination from dust; when switching to abrasives with a different particle size, the existing abrasives on the workpiece and lapping tool must be cleaned with kerosene to prevent scratches on the surface of the workpiece; the lapping environment should be free of dust.

Lapping is a precision and ultra-precision processing technology that achieves very low surface roughness values. With the advancement of technology, the demands for product quality are increasing. In local finishing, lapping has unmatched advantages over other cutting methods, making it significant in processing workpieces with high precision and surface quality.