Imagine a cleaning method that’s both powerful and precise, capable of removing contaminants from surfaces without damaging them. Laser cleaning machines achieve this by using focused laser beams to vaporize unwanted particles. This blog explores the principles behind dry and wet laser cleaning, highlighting how laser wavelength, power density, and pulse width impact cleaning efficiency. Dive in to understand the intricate balance of parameters that make laser cleaning an innovative solution for industries seeking efficiency and precision.

Laser cleaning is an effective method to remove dirty particles and films of different materials and sizes from a solid surface.

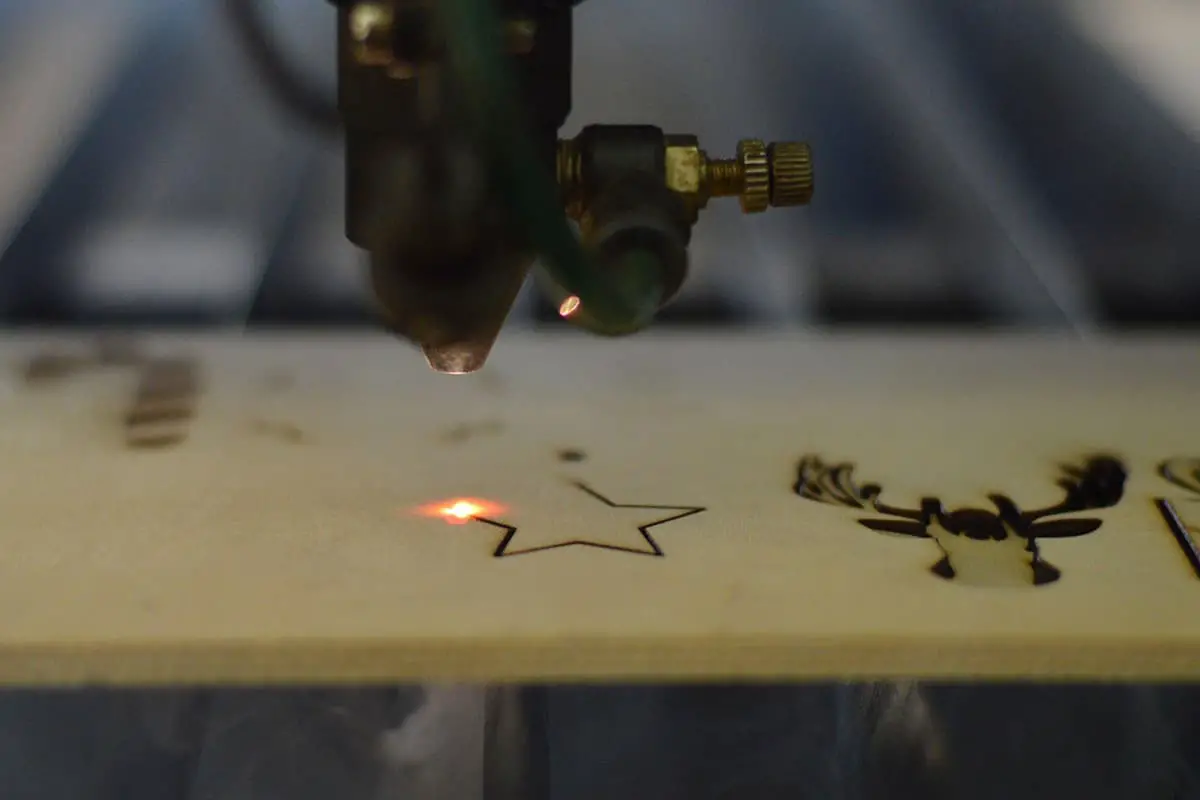

By using a high-brightness and well-directed continuous or pulsed laser, a laser beam with a specific spot shape and energy distribution is formed after optical focusing and spot shaping. The laser beam is then irradiated onto the surface of the contaminated material that needs to be cleaned.

After the contaminant material attached on the surface absorbs laser energy, it will undergo a series of complex physical and chemical processes such as vibration, melting, combustion, and even vaporization, ultimately causing the pollutant to detach from the material surface.

Even if the laser is applied to the cleaned surface, the majority of it will be reflected without causing damage to the substrate, thus achieving the cleaning effect.

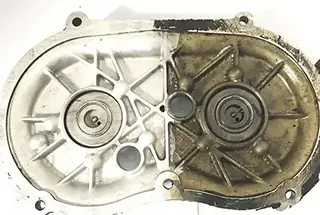

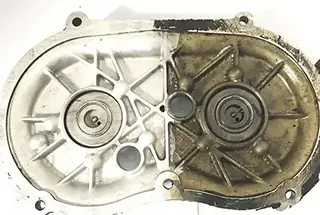

See the following figure for an example of cleaning aluminum alloy with red paint on its surface.

Laser cleaning can be classified according to different criteria. For example, it can be divided into dry laser cleaning and wet laser cleaning based on whether a liquid film is applied to the substrate surface during the laser cleaning process.

The former involves directly irradiating the pollutant surface with laser beams, while the latter requires the application of moisture or liquid film to the surface being cleaned. Wet laser cleaning is efficient but requires manual coating of the liquid film, which must not alter the properties of the substrate material.

Therefore, compared with dry laser cleaning technology, the application scope of wet laser cleaning is somewhat limited.

Dry laser cleaning is currently the most widely used laser cleaning method, in which laser beams are used to directly irradiate the surface of the workpiece to remove particles and films.

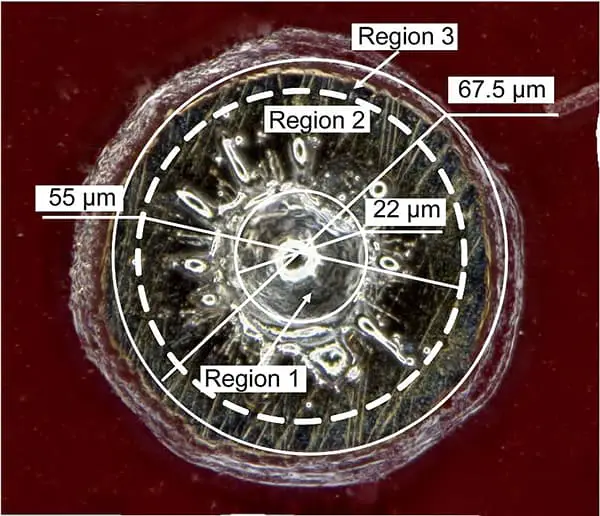

The basic principle of dry laser cleaning is that when particles and substrate are irradiated by laser beams, the absorbed light energy is converted into heat energy in an instant. This causes instantaneous thermal expansion of the particles, substrate or both, generating an acceleration between them.

The force produced by this acceleration overcomes the adhesion force between the particles and substrate, causing the particles to detach from the substrate surface.

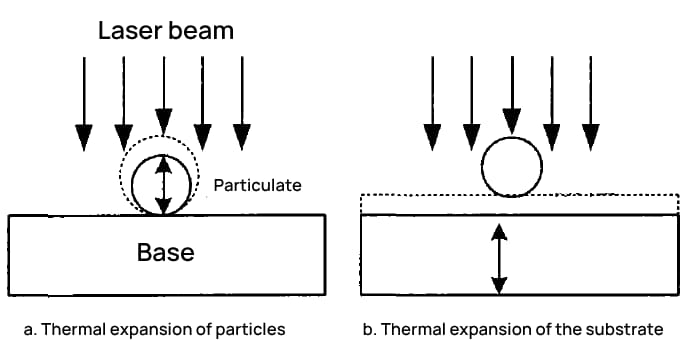

(1) Dry laser cleaning can be divided into two main forms according to different absorption mechanisms:

For dust particles with melting points higher than that of the matrix (or with significantly different laser absorption rates):

The absorption of particles under laser irradiation is stronger (a) or weaker (b) than that of the substrate. In this case, the absorbed laser energy is converted into thermal energy, causing thermal expansion of the particles.

Although the amount of thermal expansion is very small, it occurs within an extremely short period of time, resulting in a huge instantaneous acceleration acting on the substrate between particles and substrate.

Meanwhile, the substrate also acts on the particles, overcoming the adhesion force between them and causing the particles to detach from the substrate, as shown in Figure 1.

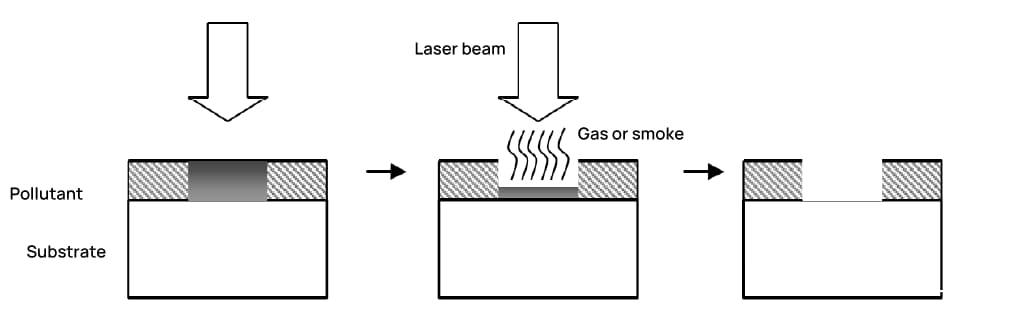

(2) For dirt with lower boiling points:

The surface dirt directly absorbs laser energy, causing instantaneous high-temperature boiling and evaporation, which removes the dirt by direct vaporization. The principle is shown in Figure 2.

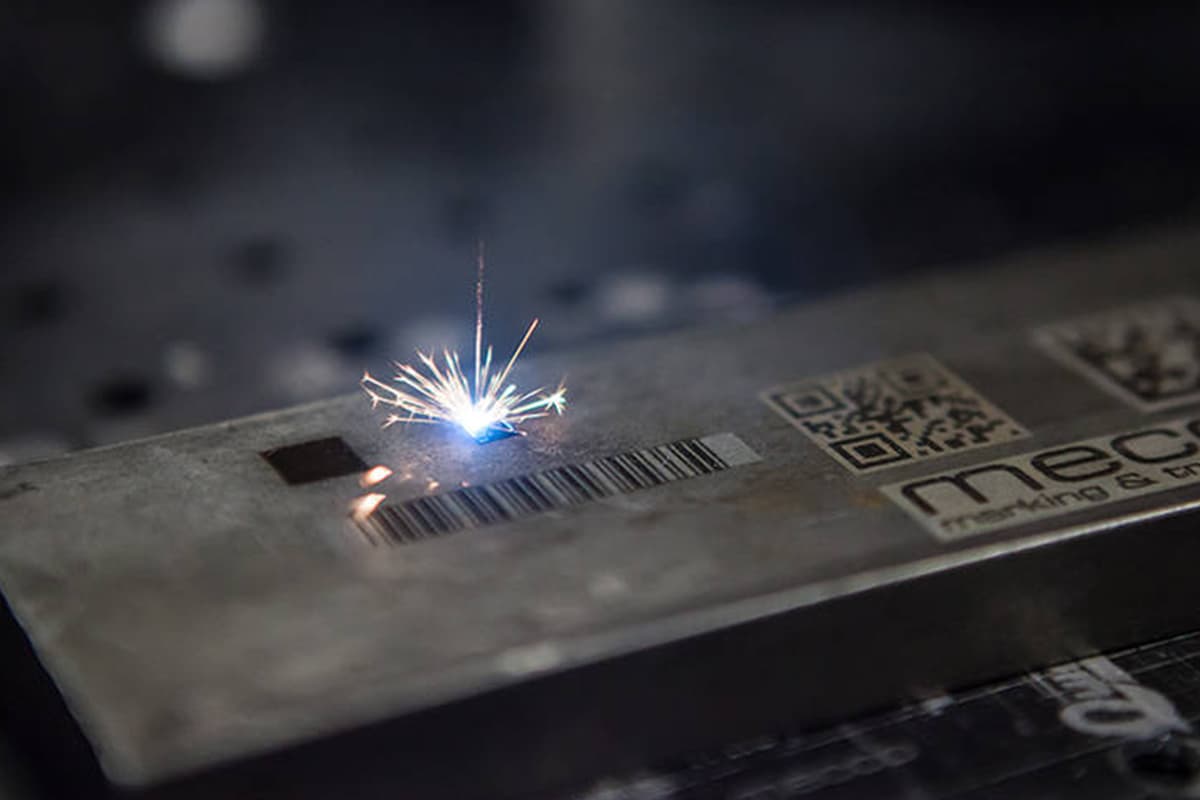

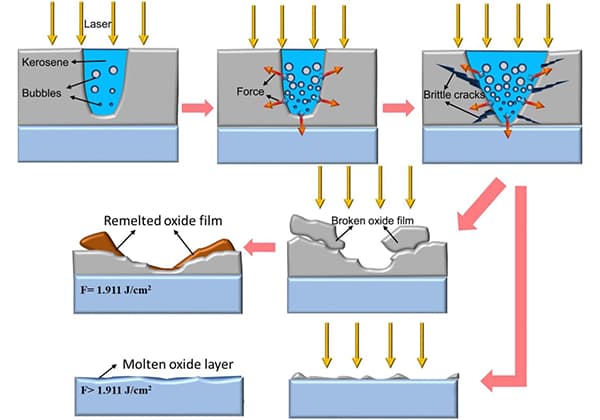

Laser wet cleaning, also known as laser vapor cleaning, is a method of laser cleaning in which there is a thin liquid film or medium film of several micrometers on the surface of the cleaned object.

Compared with dry cleaning, wet cleaning involves the presence of such a film, which, when irradiated by the laser beam, undergoes an instantaneous temperature rise and generates a large number of bubbles that produce gasification reactions.

The impact force generated by the gasification explosion overcomes the adhesion force between particles and substrate.

Depending on the different absorption coefficients of laser wavelength by particles, liquid films, and substrates, laser wet cleaning can be divided into three types.

(1) When the substrate absorbs laser energy strongly:

When the laser is irradiated onto the substrate and liquid film, the absorption of the substrate to the laser is much greater than that of the liquid film.

Therefore, an explosive vaporization phenomenon occurs at the junction between the substrate and the liquid film, as shown in the figure below. In theory, the narrower the pulse time, the easier it is to produce overheating at the junction, resulting in greater explosive impact force.

(2) When the liquid film absorbs laser energy strongly:

This cleaning principle involves the liquid film absorbing most of the laser energy and undergoing explosive vaporization at its surface, as shown in the figure below.

In this case, the efficiency of laser cleaning is not as good as when the substrate absorbs the laser, because the explosive impact force occurs only at the surface of the liquid film.

When the substrate absorbs the laser, bubbles and explosions occur at the junction between the substrate and the liquid film, and the explosive impact force is more likely to push the particles away from the substrate surface. Therefore, the cleaning effect of substrate absorption is better.

(3) When both the substrate and liquid film absorb laser energy:

In this case, the cleaning efficiency is low. After the laser is irradiated onto the liquid film, part of the laser energy is absorbed, and the energy is dispersed throughout the entire liquid film.

The liquid film boils to produce bubbles, and the remaining laser energy is absorbed by the substrate after passing through the liquid film, as shown in the figure. This method requires more laser energy to generate boiling bubbles and explosions. Therefore, the efficiency of this method is very low.

When using substrate absorption for laser wet cleaning, most of the laser energy is absorbed by the substrate, causing overheating at the junction between the liquid film and the substrate, producing bubbles at the interface.

Compared with dry cleaning, wet cleaning utilizes the explosive impact force generated by the bubble explosion at the interface to achieve laser cleaning.

At the same time, a certain amount of chemical substances can be added to the liquid film to react with pollutant particles and reduce the adhesion force between particles and substrate materials, thus lowering the threshold for laser cleaning.

Therefore, wet cleaning can improve the cleaning efficiency to some extent, but it also has certain difficulties. The introduction of a liquid film may lead to new pollution, and the thickness of the liquid film is difficult to control.

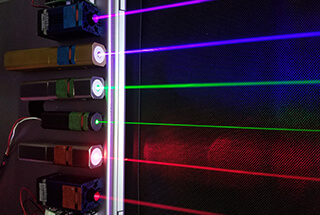

Influence of laser wavelength:

The premise of laser cleaning is laser absorption, so when selecting a laser source, it is necessary to combine the light absorption characteristics of the cleaned object to choose a laser that is suitable for the band as the laser source.

In addition, experimental research by foreign scientists has shown that for cleaning particles with the same characteristics, the shorter the wavelength, the stronger the cleaning ability of the laser and the lower the cleaning threshold.

Therefore, under the premise of meeting the material’s light absorption characteristics, in order to improve the cleaning effect and efficiency, lasers with shorter wavelengths should be selected as cleaning light sources.

Influence of power density:

When conducting laser cleaning, there is an upper limit damage threshold and a lower limit cleaning threshold for the laser power density. Within this range, the larger the laser power density during laser cleaning, the greater the cleaning ability and the more significant the cleaning effect.

Therefore, the laser power density should be increased as much as possible without damaging the substrate material.

Influence of pulse width:

The laser source for laser cleaning can be continuous or pulsed light. Pulsed lasers can provide very high peak power, making it easy to meet the threshold requirements.

In addition, research has found that pulsed lasers have a smaller impact on thermal effects on substrates during cleaning, while continuous lasers have a larger thermal effect area.

Influence of scanning speed and frequency:

Obviously, in the process of laser cleaning, the faster the laser scanning speed and the fewer the number of times, the higher the cleaning efficiency, but this may result in a decrease in cleaning effectiveness.

Therefore, in practical cleaning applications, appropriate scanning speed and frequency should be selected according to the material characteristics of the cleaned object and the degree of contamination. The overlap rate during scanning will also affect the cleaning effect.

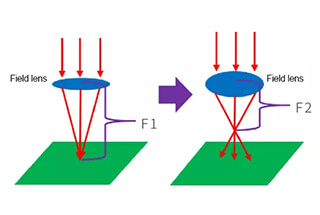

Influence of defocus amount:

Before laser cleaning, the laser is usually focused through a certain combination of focusing lenses. During the actual laser cleaning process, it is generally performed in a defocused state.

The greater the defocus amount, the larger the light spot on the material, the larger the scanning area, and the higher the efficiency. When the total power is constant, the smaller the defocus amount, the higher the laser power density and the stronger the cleaning ability.