How can laser cutting achieve perfection in every cut? This article reveals the secrets to optimizing laser cutter parameters. From adjusting laser power and focal length to selecting the right assist gas, you’ll learn how each setting impacts cutting precision and efficiency. Discover how to fine-tune your machine for different materials and thicknesses, ensuring top-notch results every time.

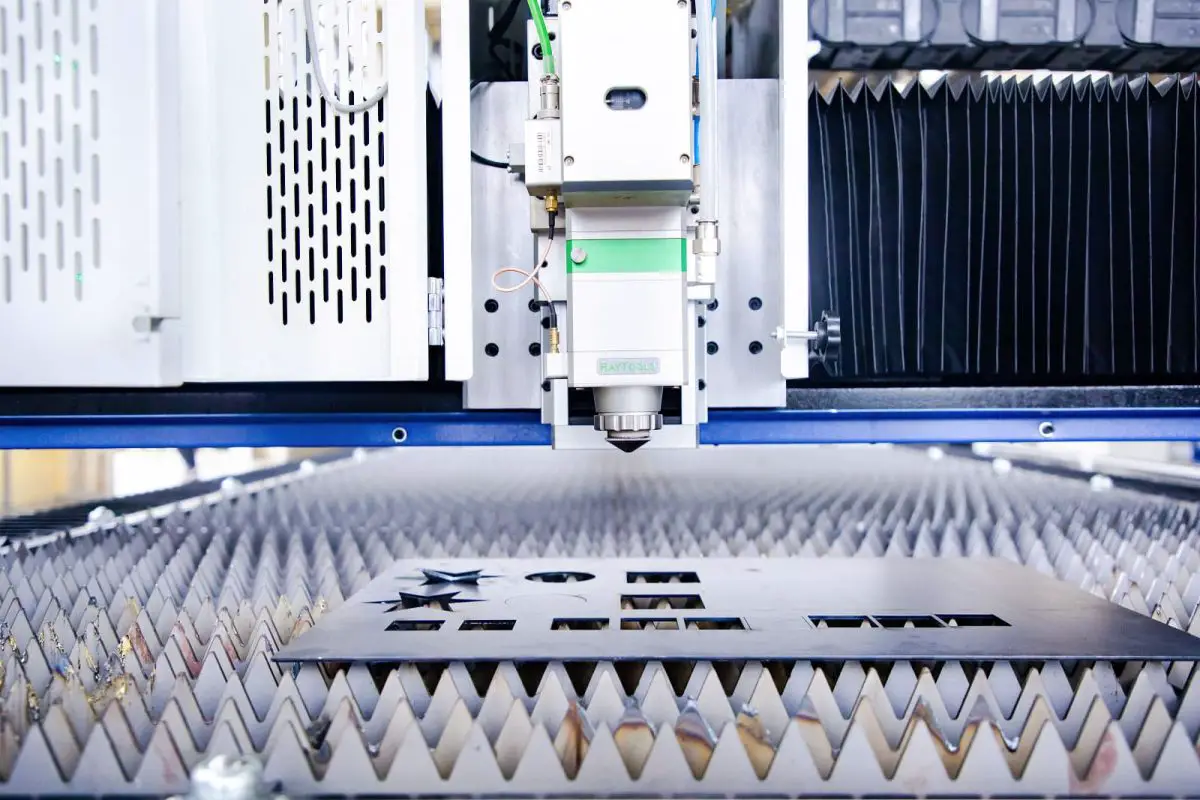

All laser cutting machines essentially consist of a laser, a light guiding system, a numerical control motion system, an auto-adjusting cutting head, a work platform, and high-pressure gas blowing systems.

Many parameters can affect the laser cutting process, with some depending on the technical performance of the laser and machine tools, while others need to be adjusted based on specific needs.

Key Adjustments for Laser Cutters:

Beam mode

The fundamental mode, also known as Gaussian mode, is the most ideal for cutting and is mainly found in low-power laser cutting machines with power under 1 kW. Multimode is a combination of higher-order modes, which has poorer focusing and cutting capabilities compared to single-mode lasers.

The required laser power for a cutting machine depends on the cutting material, material thickness, and cutting speed requirements. Laser power has a significant impact on cutting thickness, cutting speed, and kerf width. Generally, as laser power increases, the cutting capacity for thicker materials also increases, resulting in faster cutting speeds and wider kerfs.

Focal point position

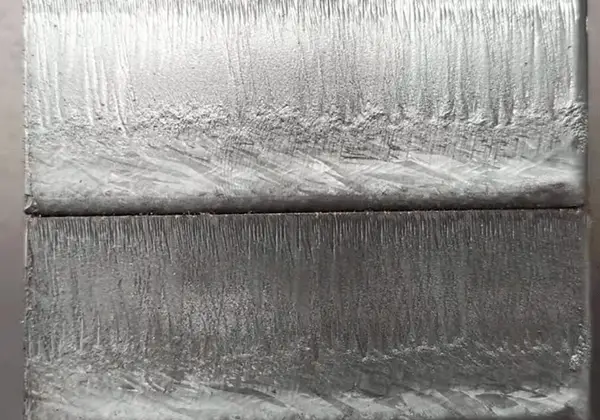

The focal point position greatly affects the kerf width. Generally, positioning the focal point about 1/3 of the material thickness below the surface results in the deepest cut and narrowest kerf width.

Focal length

When cutting thick steel plates, a longer focal length beam should be used to achieve a vertical cutting surface with good quality. A larger focal depth increases the beam spot diameter, reducing power density and cutting speed. To maintain a certain cutting speed, laser power must be increased.

For cutting thin plates, a beam with a shorter focal length is preferred, as it results in a smaller beam spot diameter, higher power density, and faster cutting speeds.

Assist gas

Oxygen is commonly used as the cutting gas for low-carbon steel to promote the iron-oxygen combustion reaction heat during the cutting process, which results in faster cutting speeds and better cut quality, producing slag-free kerfs.

Increased pressure leads to higher kinetic energy and improved slag removal capability. The cutting gas pressure should be determined based on material, thickness, cutting speed, and surface quality factors.

Nozzle structure

The structure and size of the laser cutting machine’s nozzle also affect cutting quality and efficiency. Different nozzles should be used for different cutting requirements. Common nozzle shapes include cylindrical and conical shapes.

Coaxial gas blowing (where the gas flow is concentric with the optical axis) is generally used for laser cutting. If the gas flow is off-axis, excessive spattering may occur during cutting.

To ensure cutting process stability, the distance between the nozzle end and the workpiece surface should be controlled, typically between 0.5 to 2.0 mm, for smooth cutting.