Why is laser cutting galvanized steel sheets so challenging yet crucial in modern manufacturing? This article explores the difficulties faced when laser cutting galvanized steel and examines the solutions involving various auxiliary gases—air, oxygen, and nitrogen. You’ll learn the pros and cons of each method, helping you make informed decisions for efficient and high-quality cutting processes. Dive in to discover how to optimize your laser cutting operations and enhance your manufacturing outcomes.

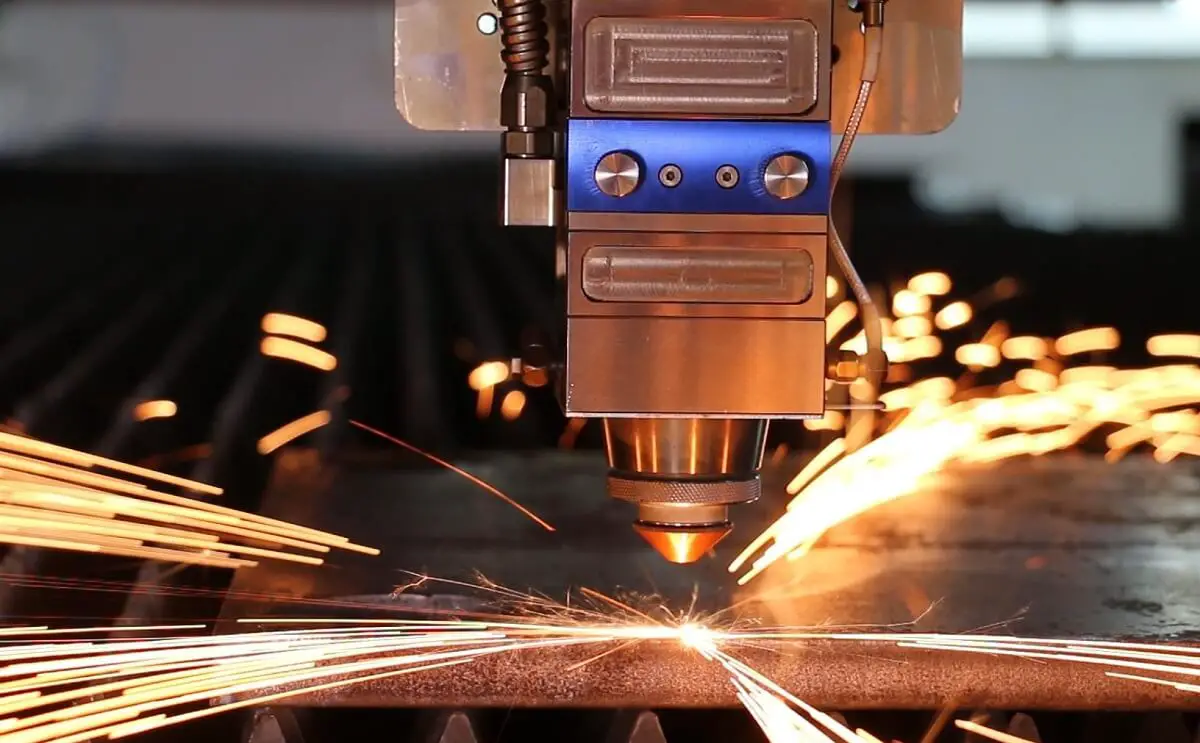

Nowadays, the utilization of laser cutting technology has become ubiquitous in sheet metal fabrication industries.

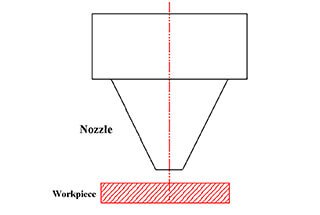

One of the primary advantages of laser cutting is its non-contact nature, which preserves the integrity of the plate surface and produces cut sections free from burrs. This characteristic significantly reduces the need for post-processing operations, enhancing overall production efficiency.

However, laser cutting technology is not without its challenges, particularly when processing certain materials. This article will focus on the specific difficulties encountered when cutting galvanized steel plates—a material widely used in various industries—and explore effective solutions to these challenges.

Galvanized steel plates are designed to protect the underlying carbon steel substrate with a protective zinc coating, effectively preventing corrosion over time. While these plates are initially more expensive than standard carbon steel, they offer cost-effectiveness in the long run by eliminating the need for additional rust prevention treatments.

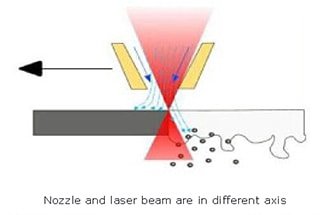

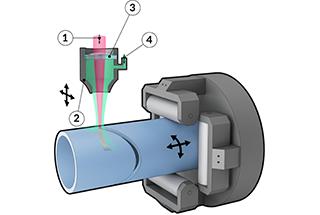

The complexities arise during laser processing of galvanized steel. The choice of assist gas plays a crucial role in the cutting process, with three primary methods available: air cutting, oxygen cutting, and nitrogen cutting.

Let’s examine the advantages and disadvantages of these three cutting processes in detail:

Air cutting in laser processing offers significant cost advantages due to its minimal operational requirements. This method utilizes only electricity for the laser and air compressor, eliminating the need for expensive assist gases like nitrogen or oxygen. For thin plates (typically <3mm), air cutting can achieve cutting speeds comparable to nitrogen cutting, making it an economically viable and efficient option for many applications.

However, air cutting presents several technical challenges that must be considered. The process often produces bottom burrs along the cut edges, necessitating secondary deburring operations. These additional steps can negatively impact overall production cycle times and efficiency. Moreover, the high-temperature oxidation reaction during air cutting frequently results in darkened or blackened cut edges, which may compromise the aesthetic quality and surface finish of the final product.

The limitations of air cutting are particularly pronounced when processing galvanized steel plates. The zinc coating on these materials can vaporize during cutting, potentially contaminating the laser optics and affecting cut quality. Additionally, the oxidation and edge quality issues inherent to air cutting often negate the primary advantages of laser processing, such as precision, clean cuts, and reduced post-processing requirements.

Consequently, many manufacturers, especially those prioritizing high-quality finishes or working with coated materials, opt for alternative cutting methods. Nitrogen or oxygen assist gas cutting, while more expensive in terms of consumables, often proves more cost-effective in the long run by minimizing secondary operations and maintaining superior edge quality. For applications where air cutting is suitable, implementing proper process parameters, such as optimized cutting speed, laser power, and focal position, can help mitigate some of its drawbacks.

Oxygen cutting, also known as oxy-fuel cutting or flame cutting, remains one of the most traditional and widely used thermal cutting methods in metal fabrication. Its primary advantage lies in its cost-effectiveness, particularly for processing carbon steel sheets. The low cost of fuel gases (typically acetylene or propane) and oxygen, combined with simplified factory management due to the elimination of frequent auxiliary gas changes, makes it an attractive option for many manufacturers.

This process excels in cutting thick carbon steel plates (up to 300mm or more) and offers good portability for on-site cutting operations. The method relies on a chemical reaction between oxygen and the base metal, which generates heat to sustain the cutting process.

However, oxygen cutting has notable limitations. The most significant drawback is the formation of an oxide layer on the cut surface, known as kerf. This oxide skin can negatively impact subsequent processes, particularly welding. If components with this oxide layer are welded directly, the oxide may lead to inclusions and porosity in the weld, potentially compromising the joint’s integrity. Over time, this can result in the oxide skin peeling off, reducing the overall quality and longevity of the fabricated product.

Interestingly, the presence of this oxide layer can be beneficial in certain applications, such as when working with galvanized sheets. The oxide skin contributes to improved solderability of these materials, as it can act as a flux and promote better wetting of the solder.

To mitigate the negative effects of the oxide layer in most applications, post-cutting surface preparation is often necessary. This may include mechanical cleaning methods like grinding or shot blasting, or chemical treatments to remove the oxide before welding or other joining processes.

In modern fabrication environments, oxygen cutting is increasingly being supplemented or replaced by more precise methods like laser or plasma cutting, especially for thinner materials or when higher accuracy is required. However, it remains a valuable technique in the metal fabrication toolkit, particularly for thick plate cutting and in scenarios where its specific advantages outweigh its limitations.

Nitrogen is extensively employed in high-speed precision cutting processes, particularly for materials sensitive to oxidation. Unlike oxygen, which promotes combustion and can lead to unwanted chemical reactions, nitrogen acts as an inert shielding gas during the cutting operation. This protective function prevents the formation of oxide layers on the cut edges, resulting in a clean, high-quality finish. Consequently, nitrogen cutting has become the preferred method for processing galvanized steel plates in many industrial applications.

The use of nitrogen offers several advantages:

However, nitrogen cutting also presents certain challenges:

To maximize the benefits of nitrogen cutting for galvanized steel, manufacturers often implement integrated solutions, such as in-line edge coating systems or controlled environment storage, to mitigate the corrosion risk while maintaining production efficiency.