Imagine the catastrophic consequences of neglecting laser cutting machine maintenance. Don’t let your business fall victim to costly downtime and repairs! In this blog post, we’ll dive into the essential daily, weekly, and irregular maintenance tasks that will keep your laser cutter running smoothly. Our expert mechanical engineer will guide you through the critical steps to ensure optimal performance and longevity. Get ready to master the art of laser cutting machine maintenance!

Before starting the machine each day, carefully check the working gas and cutting gas pressure of the laser. If the gas pressure is inadequate, it must be replaced promptly.

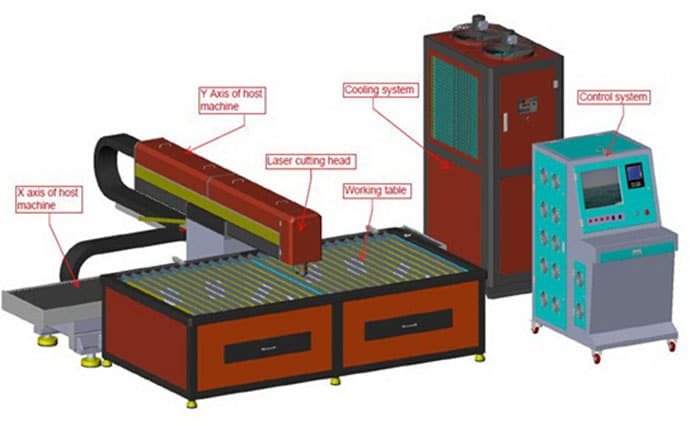

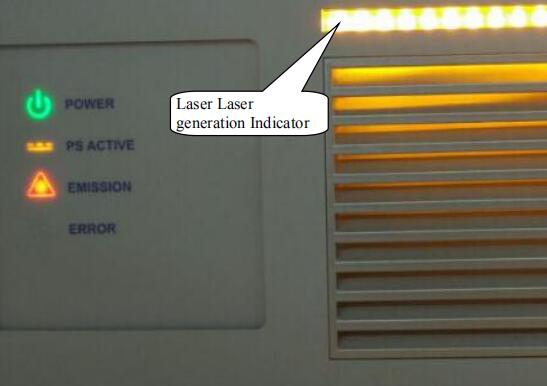

Check the X-axis zero point, Y-axis zero point, Z-axis zero point, laser readiness status, and other buttons for damage (verify the indicator light).

Verify that the mounting screws for the X-axis, Y-axis, and Z-axis zero points, limit switch, and mounting blocks are tightened and that the limit switches for each axis are responsive.

Ensure that the circulating water level in the chiller is adequate. If the water level is insufficient, add water promptly.

Check the external optical path’s circulating waterway for leaks, and promptly address any leaks; otherwise, the optical lens’s lifespan may be affected.

After each day of cutting, inspect the focus lens for damage.

Inspect the external light path’s telescopic skin cavity for burns or damage.

After completing daily work, promptly clean up the cutting waste, clear the work area, and keep it tidy. Also, ensure that all equipment parts are clean and free of dirt, and avoid placing debris on any equipment part.

After daily work is done, open the air compressor’s drain valve at the bottom of the air tank to drain the water. Close the drain valve once the waste water has drained.

After completing daily work, follow the shutdown procedure, and turn off the main power supply of the entire machine.

It is essential to regularly clean the debris from the air outlet to ensure proper ventilation.

Check the filters in the gas path regularly to promptly remove any water and debris.

Ensure that the screws of the travel switch bracket and the bumper bracket are not loose by checking them regularly.

To facilitate the heat dissipation of internal electrical components, clean the dust from the filter screen of the electric control cabinet ventilation fan in a timely manner.

Cleaning the protective skin cavity of the guide rail on time is necessary to prevent damage to the guide rail, thereby extending its service life.

After installing the machine tool and using it for a period, it is vital to readjust the level of the machine tool to ensure its cutting accuracy.

Check the lubrication filling of the X, Y, Z axis guides, and lead screws every other week to keep the moving parts lubricated. This can extend the service life of X, Y, Z axis guides and their lead screws.

Depending on the environment of the workshop, it is important to irregularly (at least once a month) check the pollution on the surface of the reflector and focusing lens and clean the optical lens in time to ensure its service life.

Avoid touching the surface of the optical lens (reflector, focusing lens, etc.) directly with your hands, as this can easily cause scratches on the mirror. If there are oil stains or dust on the mirror surface, clean it promptly to avoid affecting the lens’ performance.

Under no circumstances should the optical lens be cleaned with water and detergent as the lens’ surface is plated with a special film. Using water and detergent to clean the lens can damage its surface.

Keep the lens away from dark and humid environments as this can cause the lens surface to age.

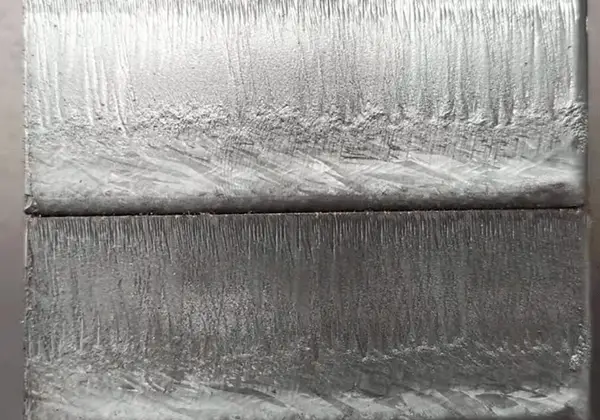

Dust, dirt, or water vapor on the lens surface can easily absorb laser light and damage the lens coating, which can significantly affect the quality of the laser beam, and in severe cases, there would be no laser beam at all.

If the lens is damaged, contact the laser after-sales service department immediately to repair it. Avoid using the damaged lens, as this can accelerate the damage of the repairable lens.

When installing or replacing the reflector or focusing lens, avoid using excessive pressure, as it can cause deformation of the lens and affect the quality of the beam.

Please pay attention before installing optical lenses:

(1) Please wear clean clothes, wash your hands with soap or detergent, and wear clean and light-colored gloves;

(2) Do not touch the lens with any part of your hands;

(3) When removing the lens, please wear gloves and hold it from the side of the lens. Do not touch the lens coating surface directly.

When assembling the lens, avoid blowing air against the lens with your mouth. Instead, place the lens on a clean desktop with a few sheets of lens paper underneath. Take care when removing the lens to prevent it from getting scratched or falling, and do not apply any force on the coated surface of the lens. Ensure that the lens holder on which the lens is installed is clean, and remove any dust or dirt in the holder with a clean air spray gun. Then, gently place the lens in the holder.

When mounting the lens to the holder, do not use excessive force to fix the lens, as this may cause deformation and affect the quality of the beam.

Precautions to take when replacing optical lenses:

Different lenses require different cleaning methods. For flat mirror surfaces without a lens holder, use lens paper to clean, such as when cleaning a reflector. However, for curved mirror surfaces or those with a lens holder, it is best to use a cotton swab, such as when cleaning a focusing lens.

Steps for cleaning a lens with lens paper:

(1) Use a blower to blow off any dust on the lens surface.

(2) Clean the lens surface with alcohol or lens paper. Do not use dry lens paper to directly drag it across the mirror surface. Instead, place the lens paper on the surface of the lens, add 2-3 drops of high-purity alcohol or high-purity acetone, and slowly pull the lens paper out towards the operator. Repeat this process several times until the mirror surface is clean.

(3) If the mirror surface is very dirty, fold the lens paper in half 2 to 3 times and repeat the above steps until the mirror surface is clean.

Steps to Clean a Lens with a Cotton Swab:

Before switching on the laser, it is important to perform daily maintenance checks to ensure optimal performance.

Regular maintenance is essential for the chiller to ensure it operates efficiently. In case of any malfunction, it is imperative to seek the assistance of a professional technician for repair. It is strictly prohibited to disassemble the machine by oneself.

Here are some important aspects to consider during daily maintenance of the chiller:

Regular cleaning and inspection are fundamental to maintaining the efficiency and longevity of your laser cutting machine. After each use:

Performing system checks before starting the machine is crucial:

Maintaining the cooling system is vital for preventing overheating:

Ensuring the safety and proper functioning of electrical components helps prevent equipment damage:

Some additional checks can further safeguard your machine’s performance:

Maintain a safe and clean work environment to enhance operational efficiency:

Maintaining a clean laser cutting machine is essential for optimal performance and longevity. Regular cleaning tasks include:

Regular mechanical inspections help prevent performance issues and extend the machine’s lifespan:

Proper lubrication is crucial for the longevity of moving components:

A well-maintained cooling system is vital for preventing overheating and ensuring efficient operation:

Proper airflow is essential for maintaining operational efficiency and preventing overheating:

Maintaining the integrity of electrical components is crucial for safety and performance:

By diligently performing these weekly maintenance tasks, you can significantly enhance the operational reliability and efficiency of your laser cutting machine. Neglecting these tasks can lead to decreased performance, increased wear and tear, and potential machine failure, highlighting the importance of regular upkeep.

Regular monthly maintenance of your laser cutting machine is crucial to ensure its longevity, efficiency, and precision. This chapter outlines essential tasks and their significance, providing detailed explanations to enhance understanding and execution.

Maintaining the cooling system and chiller is essential for preventing overheating and ensuring efficient operation.

Ensuring the integrity of electrical components helps prevent equipment damage and enhances safety.

Maintaining proper alignment and focus is essential for precision cutting.

Proper airflow and ventilation are critical for maintaining cutting quality and preventing overheating.

Lubricating moving parts reduces friction and ensures smooth operation.

Replacing worn or damaged consumables and filters is essential for maintaining optimal performance.

Ensuring the functionality of safety features is crucial for safe operation.

Monitoring machine logs and performance helps identify potential issues before they become significant problems.

By performing these monthly maintenance tasks, you can ensure your laser cutting machine operates optimally, reduce downtime, and extend its lifespan.

To ensure the cooling system and chiller function optimally:

Maintaining the integrity of electrical and high-voltage components is crucial:

Proper maintenance of the gas supply system is essential for consistent cutting performance:

Regular inspection and replacement of mechanical components help maintain precision and efficiency:

Maintaining precise alignment and calibration is critical for accurate cutting:

Proper ventilation and filtration are essential for maintaining air quality and preventing dust buildup:

Ensuring proper grounding and safety measures are crucial for safe operation:

Keeping detailed records and scheduling professional check-ups help track maintenance history and identify potential issues:

Conduct regular inspections to identify any signs of wear, rust, or damage on both exterior and interior components. Early detection of potential issues allows for timely interventions, preventing more significant problems and costly repairs. For instance, checking for loose electrical connections can prevent short circuits, while inspecting moving parts ensures smooth operation. Regular maintenance tasks, such as lubricating moving parts and checking coolant levels, help maintain the machine’s efficiency and longevity.

Attempting to repair a laser cutting machine without proper knowledge and expertise can lead to severe damage and potential safety hazards. Always seek professional help for repairs and maintenance. Qualified technicians have the necessary skills and tools to diagnose and fix issues correctly, ensuring the machine’s optimal performance and safety. For example, improper handling of laser components can result in misalignment or damage, which may be costly to rectify.

Ensure the laser cutting machine is situated away from direct sunlight, vents, air ducts, and other potential heat sources. Excessive heat can affect the machine’s components, leading to malfunctions and reduced efficiency. For instance, prolonged exposure to sunlight can cause the machine’s casing to warp, affecting its structural integrity. Maintaining a stable, cool environment helps prolong the life of the machine and ensures consistent cutting performance.

Regularly verify that all safety interlocks and guards are functioning correctly. Safety interlocks prevent accidental exposure to the laser beam and other hazards, ensuring user safety. Periodic checks help identify any faults or issues that could compromise safety, allowing for timely repairs and adjustments. For example, a malfunctioning interlock could fail to shut off the laser when the machine’s door is opened, posing a serious risk to operators.

Keeping the machine’s software up-to-date is crucial for preventing malfunctions and bugs. Regular software updates often include performance enhancements, new features, and security patches that improve the machine’s efficiency and reliability. Check for updates periodically and install them as recommended by the manufacturer. Updated software can also provide better compatibility with new materials and cutting techniques, enhancing the machine’s versatility.

Proper grounding of the laser cutting machine is essential to prevent static electricity buildup, which can damage electronic components and pose safety risks. Regularly check the grounding connections to ensure they are secure and functioning correctly. This step helps maintain a stable electrical environment and reduces the risk of electrical faults. For example, improper grounding can lead to erratic machine behavior or even electrical fires.

Ensure the machine’s control parameters, such as laser power, cutting speed, and focus position, are correctly set. Regularly check and adjust the alignment and focus of the laser beam to maintain cutting precision. Proper calibration and alignment are crucial for achieving high-quality cuts and maximizing the machine’s efficiency. Misaligned lasers can result in uneven cuts, wasting materials and time.

Regularly clean the exhaust system to prevent fires and ensure proper ventilation. Check the fan unit and extraction hoses for dust and debris buildup. A well-maintained exhaust system helps maintain a clean operating environment, reducing the risk of respiratory issues and ensuring the machine functions efficiently. For example, clogged filters can lead to poor air quality and overheating, which can damage the machine.

Maintaining detailed records of all maintenance tasks and repairs is essential for tracking the machine’s maintenance history. These records help identify patterns or recurring issues, allowing for proactive measures to prevent major problems. Detailed logs also assist technicians during professional inspections and repairs, ensuring a comprehensive understanding of the machine’s condition. For example, tracking the frequency of laser tube replacements can help predict when the next replacement might be needed.

Book annual services with qualified technicians to perform thorough inspections, replace worn parts, and calibrate the machine for optimal performance. Professional maintenance ensures comprehensive care and addresses any issues that may not be apparent during regular checks. This step is vital for extending the machine’s lifespan and maintaining its operational efficiency. For instance, professional technicians can use specialized tools to measure and adjust laser alignment more precisely than routine checks.

Below are answers to some frequently asked questions:

To ensure the optimal performance and safety of a laser cutting machine, several daily checks are crucial. Here are the key daily maintenance tasks:

Inspect and clean the lens of the laser cutter daily, especially before and after each use, to maintain optimal performance and prevent damage. Check and clean mirrors to ensure they are properly aligned, maintaining the focus and intensity of the laser beam. Inspect the machine for any damage or wear, including loose bolts, screws, or electrical connections, and ensure all safety enclosures are secure. Verify that emergency stop buttons, interlocks, and safety guards are functioning correctly.

Check the working pressure of auxiliary and cutting gases, and inspect the coolant levels to ensure the cooling water system is functioning properly. Verify that all electrical components, including switches, buttons, and lights, are working correctly, and check the wiring for any signs of wear or damage. Jog each axis through its full range of motion to ensure smooth movement and verify there is no backlash or excessive play.

Regularly clean the machine, including the honeycomb bed, panels, and other components. Empty all slag drawers and bins, and remove debris and scraps from the work surface. Ensure the air assist nozzle is clean and functioning properly to prevent debris buildup and maintain airflow. Verify that the water circuit, air circuit, and oil level in the laser vacuum pump are normal.

Ensure the zero points of the X, Y, Z axes are normal, and the limit switches and lock mounting screws are firm. Check that the cooling water pressure is maintained at the required level and the cooling water temperature is as specified by the manufacturer. By performing these daily checks, you can ensure the laser cutting machine operates safely and efficiently, maintaining its precision and longevity.

The cooling system of a laser cutting machine should be inspected on a weekly or monthly basis, depending on the machine’s usage and operating environment. Regular inspections are crucial to maintaining optimal performance and preventing potential damage due to overheating. During these inspections, check the coolant lines, connections, and reservoirs for leaks, corrosion, or damage. Additionally, ensure the coolant level is adequate and top it up with the recommended coolant as needed. Cleaning the cooling system periodically to remove debris and contaminants is also essential. By adhering to these maintenance practices, you can ensure the efficiency and longevity of your laser cutting machine.

Regular cleaning of a laser cutting machine is vital for several reasons that significantly enhance its performance, efficiency, and longevity. Firstly, it prevents performance degradation by eliminating the buildup of dust, debris, and contaminants that can adversely affect the machine’s cutting precision and quality. When lenses, mirrors, and nozzles are kept clean, they can focus and direct the laser beam effectively, ensuring high-quality cuts.

Moreover, routine cleaning plays a crucial role in reducing downtime and preventing unexpected breakdowns. By identifying and addressing minor issues during cleaning, operators can avoid more significant problems that could lead to production delays. This proactive maintenance strategy keeps the machine running smoothly and efficiently.

Additionally, regular cleaning extends the lifespan of the laser cutting machine. Contaminants can cause overheating and wear on critical components, leading to premature failures. Keeping the machine clean helps prevent unnecessary wear and tear, allowing it to function optimally for a longer period.

Safety is another important aspect of regular cleaning. A clean machine minimizes the risk of accidents by ensuring that all components are functioning correctly and are free from obstructions. Furthermore, a well-maintained machine operates more efficiently, contributing to better productivity and output quality.

In summary, the importance of regular cleaning lies in its ability to maintain cutting quality, reduce downtime, prolong machine life, and enhance safety and efficiency, making it an essential part of a comprehensive maintenance checklist for laser cutting machines.

To ensure the safety of your laser cutting machine, it is essential to implement a combination of personal protective measures, routine maintenance, safety features, and operator training. Start by equipping all operators with appropriate personal protective equipment (PPE), such as laser safety glasses, masks to filter fumes, and heat-resistant gloves. Regular machine maintenance is crucial; routinely inspect cooling systems to prevent overheating and ensure all components are functioning properly.

Implement safety features such as fully enclosing the machine to contain the laser beam and using safety interlocks that prevent operation when safety barriers are not engaged. Ensure that an efficient fume exhaust system is in place to manage harmful emissions.

Material safety is also paramount; only use materials that are safe for laser cutting and keep the work area free from combustibles. Establish a standard operating procedure (SOP) that details safe operation and emergency protocols, and provide thorough training for all operators on these guidelines and potential hazards. Regular inspections of the equipment and maintenance of filters will help keep the machine in optimal working condition. By following these practices, you can significantly enhance the safety of your laser cutting operations.

Record-keeping is crucial for laser cutting machine maintenance for several important reasons. First, it allows operators to track the maintenance history of the machine, documenting tasks completed, parts replaced, and the dates of service. This information helps identify patterns and potential causes of issues, facilitating more effective troubleshooting and preventive maintenance.

Additionally, maintaining thorough records ensures compliance with the manufacturer’s recommended maintenance schedules. Consistent adherence to these schedules is vital for maximizing machine performance and longevity. By keeping accurate records, operators can also reduce downtime and associated repair costs by addressing potential issues before they result in breakdowns, thus minimizing the need for expensive repairs.

Moreover, detailed maintenance logs assist in optimizing maintenance schedules. By reviewing past maintenance activities, operators can determine the frequency and necessity of each task, ensuring efficient and effective upkeep. Record-keeping also plays a significant role in enhancing safety; accurate records of inspections and repairs confirm that the machine is in safe working condition, reducing the risk of accidents.

Finally, proper documentation helps maintain the machine’s value over time. A well-maintained laser cutting machine with detailed maintenance records is more reliable and retains a higher residual value, benefiting both current operators and future buyers. In summary, diligent record-keeping is essential for ensuring the optimal performance, longevity, and safety of laser cutting machines while also reducing downtime and maintenance costs.

The steps for daily inspection and cleaning of a laser cutting machine include the following aspects:

Daily maintenance of the laser:

Before starting each day, maintenance of the laser is required, including checking the cylinders of the laser working gas and cutting gas, ensuring the cooling water pressure is maintained between 3.5 to 5 bar, verifying the temperature of the cooling water meets the requirements of the selected laser, inspecting the oil level in the laser vacuum pump, and checking for leaks in the laser’s oil, water, and gas lines, as well as in the vacuum pump, the pneumatic components of the resonator, and the pipe joints.

Cleaning of the lenses:

For the lenses of the laser cutting machine, particularly the focusing lens and the reflective lens, it is recommended to clean the focusing lens after each day’s use, and to clean the reflective lens and the laser beam combiner lens at least once a week.

The correct cleaning method includes blowing off surface particulates from the original parts with a blower balloon, gently cleaning the lens with analytically pure acetone, and if the acetone cannot remove all dirt, vinegar can be used for cleaning. When contaminants and lens damage cannot be cleared and removed, replacing the lens is the only way to restore optimal performance.

Inspection of other parts of the machine:

Before starting the machine, it is also necessary to carefully inspect the entire bed, check the cleanliness of the lenses, perform coaxial debugging of the laser cutting machine, and check the status of the chiller.

Additionally, after the completion of daily work, the drain valve at the bottom of the air compressor’s gas storage tank should be opened for drainage, the drain valve should be closed after wastewater is discharged, and the machine should be shut down following the shutdown procedure, then the total power of the entire machine should be turned off.

Cleaning of the guide rails and linear axes:

It is recommended to clean the guide rails and linear axes once every half month, which should be done when the machine is turned off.

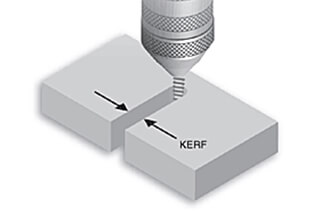

To properly maintain the tracks and guide rails of a laser cutting machine and ensure their straightness and verticality, the following steps and precautions should be followed:

Regular inspection:

First, it’s essential to regularly check whether the X, Y, and Z axes of the machine tool can return to the origin, and whether the steel belt remains under tension. This helps to identify and resolve any issues that may cause deviations in straightness and verticality promptly.

Use of professional tools:

For straightness error detection of guide rails, an optical collimator can be used to detect the straightness error of the guide rail in the vertical and horizontal planes. Although this method is highly accurate, it is complex to set up and adjust, so it’s advisable to have a professional measurement personnel operate it.

In addition, tools such as adjustment screws, magnetic adjusters, and laser measuring instruments can be used to adjust parameters such as the installation position, parallelism, and verticality of the guide rail.

Calibration process:

When adjusting the angle of the linear guide rail, the adjusted guide rail should be based on the guide rail that has been rectified to minimize the least squares error between the adjusted guide rail and the base guide rail.

During the calibration process, actual parameters of the guide rail should be measured and recorded for subsequent precise adjustments.

Maintenance and debugging:

If any abnormality is found in the straightness of the track or the verticality of the machine during the inspection process, timely maintenance and debugging should be carried out.

Comprehensive use of multiple measurement methods:

To obtain a comprehensive straightness characteristic, equipment with high measurement resolution, such as the Swiss RAYTEC laser collimator, can be used. It can capture the offsets in both the X and Y directions simultaneously.

The best practices for managing the cooling system and water tank of a laser cutting machine include the following points:

Regularly clean the water tank and replace the circulating water:

To maintain the normal operation of the laser cutting machine and extend its service life, it is necessary to regularly clean the water tank and replace the circulating water.

Specific operations include turning off the power, unplugging the water inlet pipe, letting the water in the laser tube automatically flow into the water tank, then opening the water tank to take out the water pump, removing the dirt on the water pump, and replacing the circulating water after cleaning the water tank.

Use a closed-loop cooling system with a dual temperature control system:

To maintain the optimal performance of the fiber laser cutting machine, a closed-loop cooling system with a dual temperature control system can be adopted, which performs excellently in keeping the fiber laser cutting machine cool.

Pay attention to the ion exchange column in the cooling system:

During long-term use, you should always observe the state of the ion exchange column in the cooling system to ensure the effective operation of the cooling system.

Winter maintenance:

In the event of a strong cold wave or long-term non-use of the laser cutting machine, attention should be paid to the overcurrent components in the cooling system to ensure that the equipment can perform optimally even in harsh cold environments.

Empty the cooling water:

Before shutting down the laser cutting machine, you should actively empty the cooling water with the water chiller to avoid problems caused by the freezing of water.

The methods and cycles for maintaining the laser head and lens of the laser cutting machine mainly include the following points:

Installation method of the fiber head:

It should be operated in a clean environment, and the fiber head should be installed horizontally into the cutting head and locked to avoid dust rising. The correct installation method can slow down lens aging and minimize lens wear.

Check before daily use:

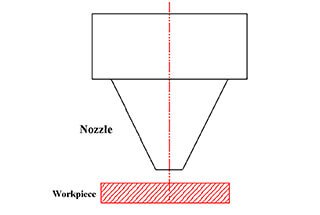

Check whether the laser is emitted from the center of the nozzle to ensure the normal output and cutting accuracy of the laser.

Maintenance cycle:

The lens should be cleaned daily to maintain the cleanliness and good working condition of the optical lens.

In addition, for the replacement of cooling water and the cleaning of the water tank, it is recommended to do it once every six months or before replacing equipment that has not been used for a long time.

The special maintenance measures for the laser cutting machine in special seasons like summer mainly include the following points:

Check and maintain the cooling system:

Due to the increase in temperature in summer, the working pressure of the cooling system of the laser cutting machine increases. It is recommended to check the internal pressure of the cooler before the heat arrives and consult the equipment manufacturer for specific parameters.

In addition, the chiller should be checked and maintained regularly to prevent the laser from condensing in the summer.

Use regular distilled water or pure water:

In summer, due to the higher temperature, the deterioration speed of the cooling water will also accelerate, so it is recommended to use regular distilled water or pure water, and clean the scale regularly to avoid laser power being affected by the scale attached inside the laser and the pipeline.

Replace and clean the cooling water:

It is recommended that customers clean the water tank scale, replace the water and filter regularly, especially in summer, to keep the cooling system clean and efficient.

Prevent the laser from condensing:

In order to prevent the core component of the laser cutting machine – the laser from condensing, the water temperature of the chiller can be set to 28℃, and ensure the independent space environment where the laser is placed is below 35℃, and the environment humidity is below 60℃.