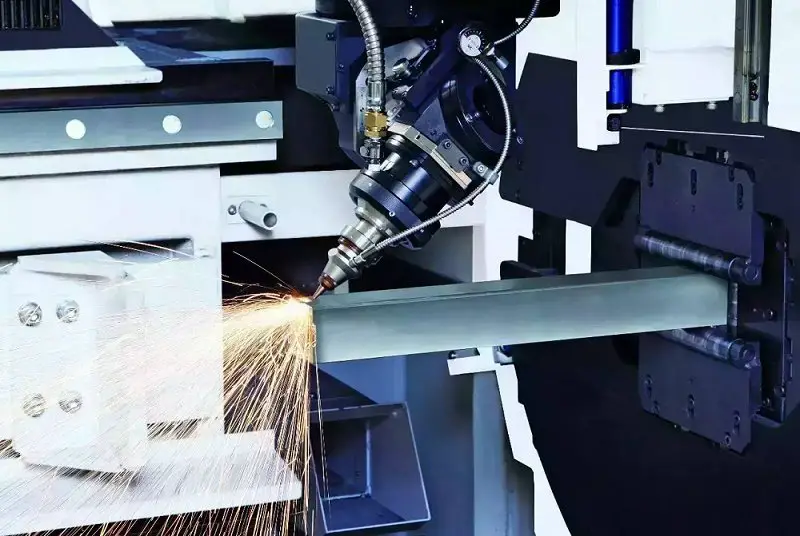

Have you ever wondered about the potential dangers lurking in advanced technology? Laser cutting machines, essential in many industries, emit radiation that can pose significant risks to human health. This article explores the different levels of laser radiation, their effects on the human body, and the safety standards set by regulatory bodies. By understanding these risks, you can better protect yourself and your team when working with laser equipment.

The laser cutter’s laser is a special type of energy source. It emits radiation to a certain extent, and how harmful is this radiation?

Depending on the laser irradiation, CDRH and IEC divide the harm of laser and laser products into four grades, based on the processable radiation limit AEL (which refers to the allowable maximum radiation of the laser at each level and for laser products).

AEL has a relationship with the wavelength and time of exposure to radiation.

1st Level:

In normal operating conditions, there is no radiation that is harmful to humans.

2nd Level:

The range of its radiation is in the visible spectrum region, and its AEL value is equivalent to the value of 0.25 seconds in radiation exposure to the first-stage product.

The product requires additional warning marks for safety testing.

3rd Level:

It is divided into 3a and 3b levels.

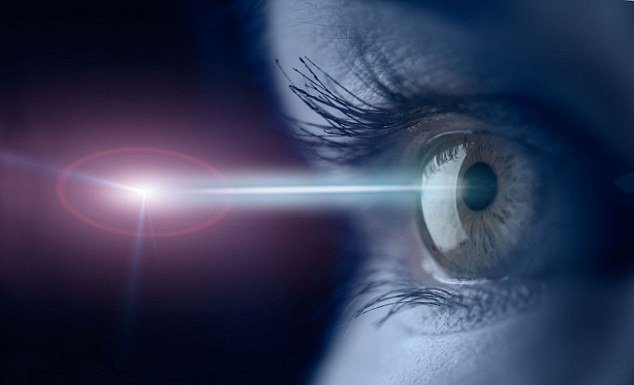

For people who have a normal avoidance response to the hard light, the 3a level will not cause harm to the naked eye, but in the case of observation through the use of lens instruments, it will cause harm to people’s eyes.

The 3b level includes radiation from 200nm to 1000000nm, which can cause accidental damage when viewed with the naked eye.

Management and control of this level is stricter than the second level.

4th Level:

Above the third level, not only does it hurt the human eyes when looked at directly, but it can also cause injury in other situations, such as on the skin, or even cause fire.

Strict management and control of this kind of product should be carried out.

According to the CDRH standard, the output power of the first-level product should be below 8.5mW for the laser device and the single-mode optical fiber communication system which uses a 1550nm laser.

If the power is higher than 500mW, then it belongs to the 4th level.

According to the IEC standard, the output power of the first-stage product should be below 10mW for the laser device and single-mode optical fiber communication system using a 1550nm laser.

If the power is less than 50mW, it belongs to the 3rd level. If it is greater than 500mW, it is the 4th level.

After the introduction of optical fiber amplifiers in an optical communication system, radiation safety received a lot of attention because the output power of the optical fiber amplifier is greater than that of general semiconductor lasers.

When the International Telecommunications Union (ITU-T) creates standards for the optical communication system, especially for the use of optical fiber amplifier systems (such as WDM), they take into consideration the safe use of lasers.

In some recommendations such as G. 691, G. 692, G. 664, G. 957, etc., IEC 825-related definitions and descriptions are introduced.

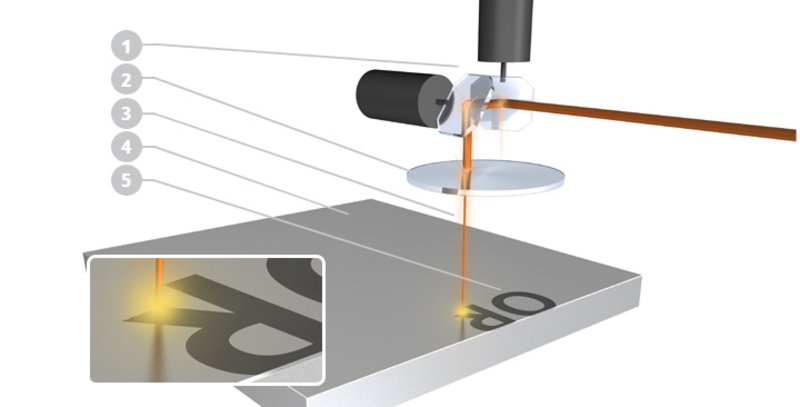

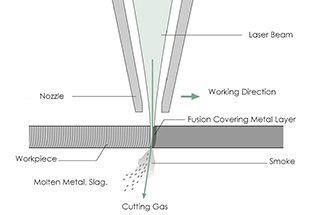

The light of a laser cutting machine is different from other ordinary light.

The laser generated by the laser source is monochromatic, coherent, collimated, and has high-density energy.

Therefore, it can achieve the effect of energy concentration and cause harm to human organs (especially the eyes).

For lasers in the infrared spectrum region, the damage to the human body is mainly due to the thermal effect, while lasers in the blue and ultraviolet spectrum region mainly cause photochemical damage.

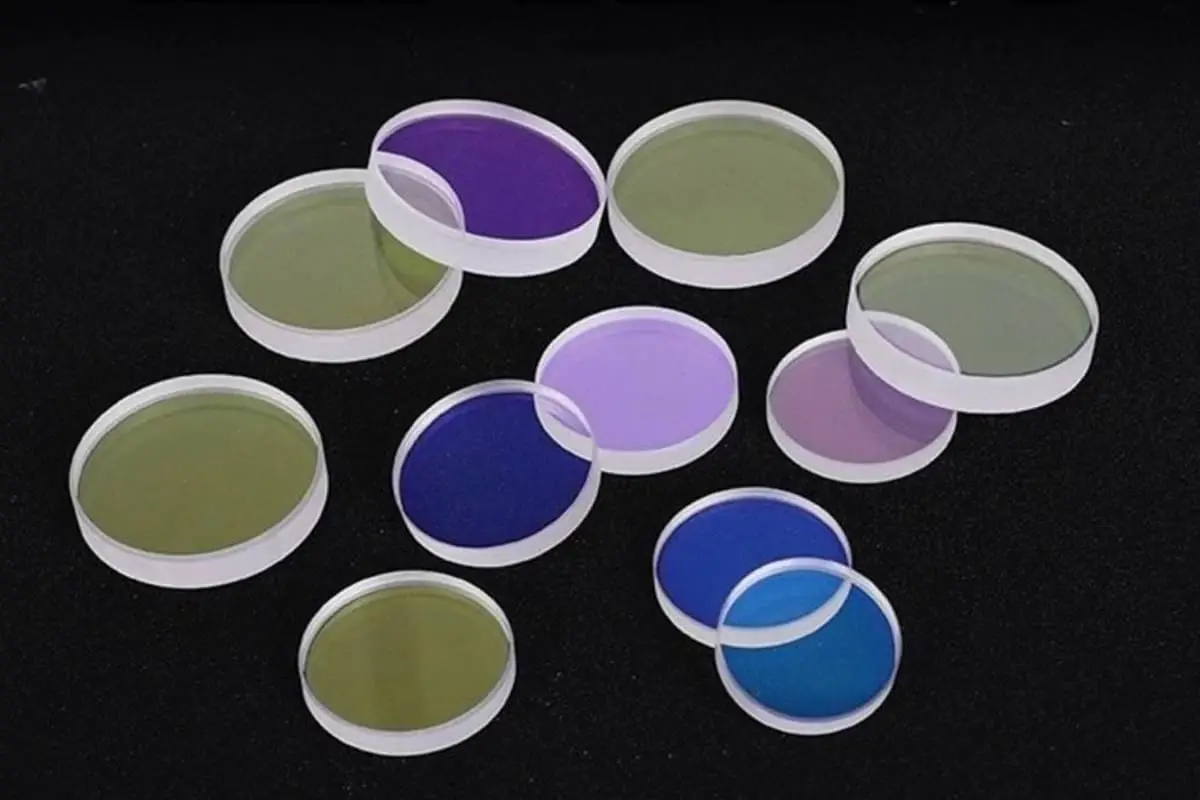

Therefore, when the human eye is directly exposed to a laser from a laser source or optical fiber connector, it can cause damage to the eye.

If it is an ultraviolet laser, it can lead to inflammation of the cornea and cataract.

For the current laser sources using a 1550nm laser, the light source of the laser marking machine is in the far infrared band, which mainly causes damage to the cornea and lens of the eye.