What makes laser cutting so versatile? This article explores four key laser cutting methods: fusion cutting, vaporization cutting, fracture-controlled cutting, and oxidation melting cutting. By understanding each method’s unique advantages and applications, readers can determine the best approach for their specific material and cutting requirements. Dive in to learn how these techniques transform raw materials with precision and efficiency.

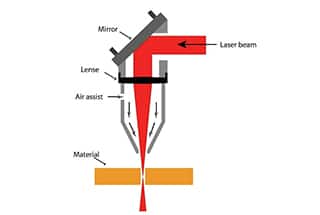

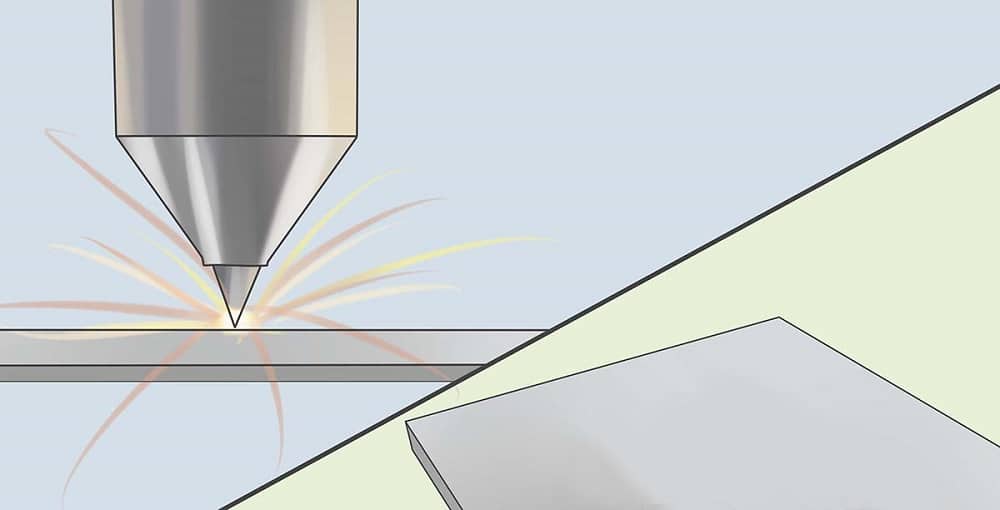

Laser cutting is a precision non-contact machining method that offers exceptional energy concentration and density control. This advanced technique employs a highly focused laser beam to create an intense, high-energy-density light spot capable of vaporizing, melting, or burning away material with remarkable accuracy.

The laser cutting process offers numerous advantages in metal fabrication, including:

Laser cutting technology primarily utilizes four distinct cutting methods to address diverse material and application requirements:

Each method offers unique benefits and is selected based on factors such as material type, thickness, desired edge quality, and production requirements. The versatility of these cutting methods enables laser technology to effectively handle a wide range of metalworking challenges in modern manufacturing environments.

Laser fusion cutting is a precision thermal process that utilizes a focused laser beam to partially melt the workpiece material. The molten material is then ejected from the kerf using a high-pressure inert gas stream. This process is distinguished by material removal occurring exclusively in the liquid state, hence the term “fusion cutting.”

The laser beam works in conjunction with a high-purity inert cutting gas, typically nitrogen or argon. This gas serves two primary functions: it expels the molten material from the cut zone and provides a protective atmosphere to prevent oxidation. Importantly, the gas does not participate in the cutting reaction itself.

Compared to laser vaporization cutting, fusion cutting achieves higher cutting speeds. This efficiency stems from the lower energy requirement for melting versus vaporization. However, it’s worth noting that in fusion cutting, only a portion of the laser energy is absorbed by the material, with some reflection occurring at the melt surface.

The cutting speed in fusion cutting is influenced by several factors:

When operating below certain power thresholds, the limiting factors shift to:

Laser fusion cutting is particularly advantageous for creating non-oxidized cuts in reactive metals such as steel and titanium. This is achieved by using inert gases and operating at power densities below the vaporization threshold. For steel, the typical power density range for fusion cutting is between 104 W/cm² and 105 W/cm².

Understanding these parameters allows for optimization of the cutting process, balancing speed, quality, and material constraints in industrial applications.

In laser vaporization cutting, the material’s surface temperature rapidly escalates to its boiling point, bypassing the melting phase typically induced by heat conduction. This process results in partial material vaporization, while the remaining material is expelled by the high-velocity auxiliary gas flow directed through the kerf. This technique demands exceptionally high laser power densities, typically exceeding 108 W/cm2, with the exact requirement varying based on the material properties, cutting depth, and focal position of the beam.

To maintain process efficiency and prevent vapor recondensation on the kerf walls, the material thickness must not surpass the laser beam diameter. This constraint limits the application of vaporization cutting to relatively thin materials or scenarios where precision cutting without a melt phase is crucial.

Vaporization cutting finds niche applications in industries requiring the avoidance of molten material, particularly for small-scale, high-precision cuts in ferrous alloys. However, its use is limited for materials like wood and certain ceramics that lack a distinct molten phase. Ironically, these materials are less prone to vapor recondensation issues but often require wider kerfs, making them less suitable for this technique.

The optimization of beam focusing in laser vaporization cutting is a complex interplay between material thickness and beam quality. While laser power and the material’s heat of vaporization influence the process, their effect on the optimal focal position is secondary. For plate thicknesses below a critical value, the maximum cutting speed exhibits an inverse relationship with the material’s vaporization temperature. This relationship underscores the importance of material selection and laser parameters in process optimization.

It’s worth noting that for certain thin plates, the maximum achievable cutting speed becomes limited by the velocity of the assisting gas jet rather than the laser’s vaporization capacity. This phenomenon highlights the multifaceted nature of the process, where both laser parameters and auxiliary systems play crucial roles in determining cutting performance.

Fracture-controlled cutting through laser beam heating is a sophisticated, high-speed, and precisely controllable cutting method specifically designed for brittle materials that are susceptible to heat damage. This advanced technique leverages the unique properties of laser energy to achieve clean, accurate cuts without compromising material integrity.

The process fundamentally relies on the strategic application of thermal stress. A high-power laser beam is focused to heat a localized area of the brittle material, typically measuring just a few micrometers in diameter. This intense, concentrated heat creates a steep thermal gradient between the heated zone and the surrounding cooler material. The resulting differential thermal expansion induces significant mechanical stress in the region, ultimately leading to controlled material fracture.

The key to this method’s effectiveness lies in maintaining a carefully balanced heating gradient. By precisely controlling laser parameters such as power density, pulse duration, and beam profile, operators can manipulate the stress field to guide crack propagation along predetermined paths. This level of control allows for cutting in virtually any desired direction, including complex curved patterns that would be challenging or impossible with conventional cutting methods.

One of the primary advantages of fracture-controlled cutting is its ability to process heat-sensitive materials with minimal thermal damage to the surrounding areas. This makes it particularly valuable for cutting advanced ceramics, glass, semiconductors, and other brittle materials used in electronics, optics, and aerospace industries. Additionally, the non-contact nature of the process eliminates tool wear and can result in exceptionally smooth cut edges, often eliminating the need for post-processing.

Oxidation melting cutting, also known as laser flame cutting, is a variant of laser cutting that utilizes a reactive gas, typically oxygen, instead of an inert gas. In this process, the material is ignited under laser beam irradiation, initiating a chemical reaction with oxygen. This exothermic reaction generates an additional heat source, further elevating the material temperature and enhancing the cutting efficiency.

Compared to fusion cutting, oxidation melting cutting achieves higher cutting speeds for equivalent thicknesses of structural steel. However, this increased speed comes at the cost of reduced cut quality. The process typically results in:

Due to these characteristics, laser flame cutting is not ideal for fabricating precision components or machining sharp corners, as there is a significant risk of thermal damage and corner burning. To mitigate these effects, pulsed laser modes can be employed to limit heat input. The cutting speed is primarily determined by the laser power, with higher powers generally allowing for faster processing.

For a given laser power, the process is limited by two key factors:

To optimize laser flame cutting, careful consideration must be given to material properties, desired cut quality, and production requirements. Advanced process control systems and real-time monitoring can help maintain consistent cut quality while maximizing cutting speeds.

Laser cutting technology has revolutionized metal fabrication, offering precision, speed, and versatility across various materials and thicknesses. The four primary methods – fusion cutting, flame cutting, remote cutting, and sublimation cutting – each present unique advantages and applications in modern manufacturing. When selecting the optimal cutting approach, fabricators must carefully consider multiple factors, including:

By matching the cutting method to specific project requirements, manufacturers can maximize efficiency, minimize material waste, and achieve superior results. As laser technology continues to advance, we can expect further innovations in cutting speeds, precision, and the ability to process increasingly complex materials and geometries. Staying informed about these developments and their practical applications is crucial for maintaining a competitive edge in the metal fabrication industry.