Imagine a welding method so precise and powerful that it can join materials with minimal distortion and unparalleled strength. This is the promise of laser deep penetration welding. In this article, you’ll explore how this advanced technique works, the principles behind it, and its applications in various industries. From enhancing manufacturing efficiency to ensuring high-quality welds, you’ll discover the transformative potential of this cutting-edge technology. Dive in to understand the process parameters, benefits, and the future of welding with lasers.

The process of laser welding, primarily for sheet metal welding, can be divided into two categories: fiber continuous laser welding and YAG pulse laser welding.

Based on the laser welding principle, it can be further divided into heat conduction welding and laser deep penetration welding. When the power density is less than 104 to 105 W/cm², it is considered heat conduction welding. This results in shallow penetration and a slower welding speed.

On the other hand, when the power density is greater than 105 to 107 W/cm², the metal surface will form “holes” due to heating and result in laser deep penetration welding. This method is characterized by its fast welding speed and large depth-to-width ratio.

The principle of heat conduction laser welding involves heating the surface to be processed through laser radiation, guiding the surface heat through transfer and internal diffusion, and melting the workpiece to form a specific molten pool by controlling laser parameters such as pulse width, energy, peak power, and repetition frequency. This method is suitable for thin plate welding.

Laser deep penetration welding is mainly used for gear welding and metallurgical sheet welding, and the focus of this article is on the principle of laser deep penetration welding.

Aluminum shell lithium battery top cover welding – fiber continuous laser (new energy vehicle cell, mostly 3-Series aluminum)

Laser deep penetration welding utilizes a high-power density continuous laser beam, typically delivered through an optical fiber, to join materials. This advanced welding technique shares similarities with electron beam welding, both employing a “keyhole” mechanism for material fusion.

When the focused laser beam impinges on the workpiece surface, it rapidly heats the material beyond its vaporization point, creating a narrow, vapor-filled cavity known as the keyhole. This keyhole acts as a near-perfect blackbody, efficiently absorbing subsequent laser energy and facilitating deep penetration into the material.

The temperature within the keyhole can exceed 2500°C, significantly above the melting point of most metals. Heat transfer occurs from the keyhole walls to the surrounding material, creating a melt pool that envelops the keyhole. This melt pool consists of a thin layer of liquid metal surrounded by solid material.

The keyhole is sustained by a dynamic equilibrium between several forces:

As the laser beam traverses the workpiece, the keyhole and associated melt pool move in tandem. The leading edge of the keyhole continues to vaporize material, while the trailing edge allows molten metal to flow back, filling the void. This molten metal then rapidly solidifies, forming the weld seam.

In contrast to conventional welding methods and laser conduction welding, where energy is deposited on the surface and transferred inward via thermal conduction, laser deep penetration welding allows for direct energy coupling deep within the material. This results in:

The high energy density and efficient coupling mechanism enable welding speeds of several meters per minute, significantly outpacing traditional welding techniques. Additionally, the process’s rapid heating and cooling cycles can lead to unique microstructures in the weld zone, often resulting in superior mechanical properties.

Laser deep penetration welding’s ability to produce deep, narrow welds with minimal heat input makes it particularly suitable for joining thick sections, dissimilar materials, and heat-sensitive components in industries such as automotive, aerospace, and advanced manufacturing.

6 series aluminum fiber CW laser welding (this is the high-speed rail floor)

There is a threshold for laser energy density in laser welding. If the laser energy density is below this value, the penetration is shallow. However, if it reaches or exceeds this value, the penetration is greatly improved.

The generation of plasma, which signifies the progress of stable deep penetration welding, occurs only when the laser power density on the workpiece exceeds the threshold, which is dependent on the material.

When the laser power density is below the threshold, only surface melting of the workpiece takes place, resulting in stable heat conduction welding.

If the laser power density is near the critical condition for keyhole formation, the welding process becomes unstable, with alternating deep penetration welding and conduction welding, resulting in significant fluctuations in penetration depth.

During laser deep penetration welding, the laser power simultaneously controls the penetration depth and welding speed. The penetration depth is directly related to the beam power density and is a function of the incident beam power and beam focal spot.

In general, for a given diameter laser beam, the penetration increases as the beam power increases.

Kettle horse – YAG pulse laser welding (can directly make the appearance surface)

The beam spot size is a critical variable in laser welding as it determines the power density. However, measuring the spot size for high-power lasers is a challenging task, despite the availability of various indirect measurement technologies.

The limit of the beam focus diffraction spot size can be calculated using light diffraction theory, but the actual spot size is larger due to the presence of focusing lens aberrations.

The simplest method of measurement is the equal temperature profile method, which involves measuring the focal spot and perforation diameter after burning thick paper and penetrating a polypropylene plate.

This method requires the mastery of laser power and the action time of the beam, which can be achieved through practice and measurement.

The laser absorption of materials is dependent on several important properties of the material, such as absorptivity, reflectivity, thermal conductivity, melting temperature, evaporation temperature, and so on.

There are two factors that affect the absorptivity of materials to the laser beam:

First, the resistance coefficient of the material. After measuring the absorptivity of the polished surface of the material, it has been found that the absorptivity of the material is directly proportional to the square root of the resistance coefficient, which changes with temperature.

Second, the surface state or finish of the material, which has a significant impact on the beam absorptivity and thus the welding effect.

Materials with high purity and general conductivity, such as stainless steel and nickel, are the best to weld.

On the other hand, high-conductivity materials like copper and aluminum are difficult to weld. Welding of 6 series aluminum and above is prone to cracks and pores.

The welding of copper generally depends on the application requirements, and it can be done with YAG pulse laser and fiber continuous laser.

In the jewelry industry, gold and silver are generally spot welded. However, there are few industrial applications for welding these materials. The focus here is on industrial applications.

The output wavelength of CO2 lasers is typically 10.6 μm. At room temperature, the absorption rate of non-metallic materials, such as ceramics, glass, rubber, and plastics, is very high, whereas the absorption rate of metal materials is poor.

However, once the material is melted or even vaporized, its absorption increases dramatically.

The method of surface coating or forming an oxide film on the surface is highly effective in improving the absorption of light beams.

The welding speed has a significant impact on the penetration depth. Increasing the speed will result in shallower penetration, but a speed that is too low will cause excessive melting of the material and result in too much penetration of the workpiece.

Therefore, there is a suitable range of welding speeds for a specific material with a certain laser power and thickness, and the maximum penetration can be achieved at the corresponding speed value.

Stainless steel YGA pulse laser wire filling welding (it can overcome the problem of large butt joint and appearance surface treatment in the later stage)

Inert gas is often used in laser welding to protect the molten pool. In some cases, protection may not be necessary if the material can be welded without surface oxidation.

However, most applications utilize helium, argon, nitrogen, or other gases to protect the workpiece from oxidation during welding.

Helium is an effective shielding gas due to its high ionization energy, which allows the laser beam to pass smoothly and reach the workpiece surface without any impediments. However, it is relatively expensive.

Argon is relatively cheap and has high density, providing good protection. But, it is prone to ionization by high-temperature metal plasma, which reduces the effective laser power and welding speed, as well as the penetration.

The surface of the weldment protected by argon is smoother compared to the surface protected by helium.

Nitrogen is the cheapest shielding gas, but it is not suitable for some types of stainless steel welding due to metallurgical problems, such as absorption, which can sometimes lead to pores in the lap area.

The second purpose of using shielding gas is to protect the focusing lens from metal vapor pollution and liquid droplet sputtering, which is especially important in high-power laser welding where the ejecta becomes more powerful.

The third function of the shielding gas is to disperse the plasma shielding produced by high-power laser welding. The metal vapor absorbs the laser beam, ionizing it into a plasma cloud, and the shielding gas around the metal vapor also ionizes due to heating.

If there is too much plasma, it will consume the laser beam to some extent. The plasma on the working surface acts as a second energy source, making the penetration shallower and the surface of the welding pool wider.

The recombination rate of electrons can be increased by increasing the collision of electrons with ions and neutral atoms, reducing the electron density in the plasma.

The lighter the neutral atom, the higher the collision frequency and the higher the recombination rate.

On the other hand, only shielding gas with high ionization energy will not increase the electron density due to its own ionization.

Atomic (molecular) weight and ionization energy of common gases and metals

| Material | He | Ar | N | Al | Mg | Fe |

| Atomic (molecular) weight | 4 | 40 | 28 | 27 | 24 | 56 |

| Ionization energy (eV) | 24.46 | 15.68 | 14.5 | 5.96 | 7.61 | 7.83 |

As shown in the table, the size of the plasma cloud depends on the type of shielding gas used. Helium produces the smallest plasma cloud, nitrogen produces the second smallest, and argon produces the largest. The larger the plasma size, the shallower the penetration depth.

This difference is not only due to the different levels of gas molecule ionization, but also to the difference in metal vapor diffusion caused by the different densities of the shielding gas.

Helium has the lowest ionization and density, and it can quickly clear the rising metal vapor from the metal molten pool.

As a result, using helium as a shielding gas can effectively inhibit plasma and increase penetration and welding speed. Additionally, it is light and unlikely to cause pores.

However, in actual welding, using argon as a shield provides good results. The effect of plasma cloud on penetration is most noticeable at low welding speeds, and as the welding speed increases, its impact decreases.

The shielding gas is released onto the workpiece surface through a nozzle at a certain pressure. The shape of the nozzle and the outlet diameter are critical, as the nozzle must be large enough to cover the welding surface with the shielding gas, but it must also be limited in size to effectively protect the lens and prevent metal vapor pollution or metal splatter from damaging the lens.

The flow rate must also be controlled, otherwise, the laminar flow of the protective gas will become turbulent and air will be drawn into the molten pool, forming pores.

To improve the protective effect, lateral blowing can also be used, where the shielding gas is injected into the small hole of deep penetration welding at a certain angle through a small diameter nozzle.

This not only reduces the plasma cloud on the workpiece surface, but also affects the plasma in the hole and the formation of small holes, resulting in increased penetration depth and an ideal weld with a high depth-width ratio.

However, this method requires precise control of the size and direction of the gas flow, as turbulence and damage to the molten pool can easily occur, making it difficult to stabilize the welding process.

The laser beam is usually focused during welding and a lens with a focal length of 63mm to 254mm (2.5″ to 10″) is typically selected. The spot size of the focus is directly proportional to the focal length; a shorter focal length results in a smaller spot.

However, the focal length also affects the focal depth, which increases with the focal length. This means that a short focal length improves the power density but requires accurate maintenance of the distance between the lens and the workpiece for proper penetration.

In actual welding, the shortest focal depth used is usually 126mm (5″). When a larger joint or increased welding is needed, a lens with a focal length of 254mm (10″) can be selected, but this requires a higher laser output power for the desired deep penetration keyhole effect.

For laser powers exceeding 2kW, especially for 10.6μm CO2 lasers, the reflection focusing method is often used, with polished copper mirrors as the mirrors, to avoid the risk of optical damage to the focusing lens.

Copper mirrors are often recommended for high-power laser beam focusing due to effective cooling.

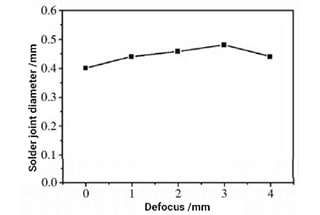

In laser welding, the position of the focus is crucial to ensure adequate power density. The variation in the relative position between the focus and the workpiece surface significantly impacts the depth and width of the weld.

In most laser welding applications, the focus is usually set about a quarter of the required penetration below the surface of the workpiece.

The final quality of the weld when laser welding different materials is largely controlled by the laser beam position, with butt joints being more sensitive than lap joints.

For instance, when welding a quenched steel gear to a low-carbon steel drum, proper control of the laser beam position will result in a weld mainly composed of low-carbon components, which possess excellent crack resistance.

In certain situations, the geometry of the workpiece being welded necessitates a deflection angle for the laser beam. When the angle of deflection between the beam axis and the joint plane is less than 100 degrees, the absorption of laser energy by the workpiece remains unaffected.

In laser deep penetration welding, small holes are present regardless of the depth of the weld. When the welding process is completed and the power switch is turned off, pits will appear at the end of the weld.

Furthermore, if the new laser welding layer covers the previous weld, excessive absorption of the laser beam may occur, leading to overheating or porosity in the weldment.

To prevent these issues, the power start and end points can be programmed to allow for adjustable start and end times. This is accomplished by electronically increasing the starting power from zero to the set power value quickly and adjusting the welding time.

Finally, the power is gradually decreased from the set value to zero at the end of welding.

Stainless steel optical fiber continuous laser welding (suitable for butt welding of small plates with a thickness of 0.2-3mm)

1. High Aspect Ratio Welding

Laser deep penetration welding is distinguished by its ability to produce deep, narrow welds with high aspect ratios. This process utilizes a focused laser beam to create a cylindrical keyhole of vaporized metal that penetrates deep into the workpiece. As the keyhole advances, molten metal flows around it, solidifying to form a weld with exceptional depth-to-width ratio, often exceeding 10:1.

2. Minimized Heat Input

The process achieves fusion with remarkably low heat input due to the concentrated energy within the keyhole. This localized heating results in rapid melting and solidification, minimizing overall heat transfer to the workpiece. Consequently, thermal distortion is significantly reduced, and the heat-affected zone (HAZ) is notably smaller compared to conventional welding methods, preserving the mechanical properties of the base material.

3. High-Density Welds

The high-temperature vapor within the keyhole induces vigorous stirring of the molten pool, promoting the escape of trapped gases and impurities. This mechanism, coupled with the rapid solidification rate, produces exceptionally dense welds with minimal porosity. The fine-grained microstructure resulting from fast cooling further enhances the weld’s mechanical properties and resistance to defects.

4. Superior Weld Strength

Laser deep penetration welding eliminates the need for filler materials or electrodes, reducing the introduction of impurities into the weld pool. The intense, localized heating alters the size and distribution of inclusions, often leading to their refinement or elimination. As a result, the weld metal frequently exhibits strength and toughness equal to or surpassing that of the base material, with improved fatigue resistance and ductility.

5. Precise Control and Flexibility

The highly focused laser beam, typically with a spot diameter of 0.2-0.6 mm, enables exceptional precision in weld positioning and geometry control. The instantaneous on/off capability of the laser source, combined with advanced beam manipulation technologies, allows for intricate weld patterns and seamless integration with CNC systems. This precision makes laser welding ideal for complex geometries and automated production environments.

6. Non-Contact Atmospheric Processing

As a non-contact process, laser welding eliminates tool wear and workpiece distortion associated with mechanical contact. The energy transfer via photons is unaffected by magnetic fields or atmospheric conditions, allowing welding in various environments, including vacuum or controlled atmospheres. This characteristic facilitates the welding of sensitive materials and enables unique joint configurations that are challenging for traditional methods.

1. High Welding Speed and Minimal Distortion

Laser deep penetration welding utilizes a highly focused beam with power densities exceeding 106 W/cm2, enabling welding speeds up to 10 m/min for thin materials. This concentrated energy input results in a narrow heat-affected zone (HAZ), typically 10-30% smaller than traditional arc welding methods. Consequently, thermal distortion is significantly reduced, often by 50-70%, making it ideal for precision welding of heat-sensitive materials like titanium alloys and advanced high-strength steels (AHSS).

2. Efficient and Low Maintenance

The precision-controlled laser beam can be transmitted over long distances using fiber optics and manipulated with high-speed galvanometer scanners, eliminating the need for complex mechanical systems. Unlike electron beam welding, laser welding requires no vacuum chamber, reducing setup time by up to 80%. The non-contact nature of the process results in minimal wear on equipment, with typical maintenance intervals 3-5 times longer than conventional welding systems, significantly enhancing production uptime and overall equipment effectiveness (OEE).

3. Superior Weld Quality and Mechanical Properties

The rapid heating and cooling rates (103-105 °C/s) inherent to laser welding promote fine-grained microstructures and reduce elemental segregation. This results in welds with tensile strengths often 5-15% higher than the base material, and improved fatigue resistance. The process’s ability to maintain precise control over heat input also allows for welding of dissimilar materials, expanding design possibilities in industries like aerospace and automotive.

4. Cost-Effective

Laser welding’s high precision (typically ±0.1 mm) and minimal distortion can reduce or eliminate post-weld machining in many applications, potentially cutting finishing costs by 30-50%. The process’s energy efficiency, often 2-3 times higher than traditional arc welding, coupled with reduced material waste due to narrow weld seams, contributes to lower operational costs. In high-volume production scenarios, these factors can lead to overall cost savings of 15-25% compared to conventional welding methods.

5. Enhanced Automation and Integration

The non-contact nature of laser welding, combined with its compatibility with real-time process monitoring systems (e.g., spectroscopic analysis, high-speed imaging), facilitates seamless integration into Industry 4.0 environments. Advanced robotic systems can manipulate the laser beam with six degrees of freedom, enabling complex 3D welding paths. This flexibility, coupled with the ability to rapidly switch between welding parameters, allows for efficient multi-material and multi-thickness welding in a single setup, significantly reducing production cycle times in automated manufacturing lines.

1. Limited Welding Depth

While laser deep penetration welding offers significant advantages in many applications, it does have limitations in terms of achievable weld depth. Typically, the maximum penetration depth is around 25-30 mm for high-power (>10 kW) continuous wave lasers in steel. This depth constraint is primarily due to the physics of keyhole formation and plasma shielding effects at greater depths. For thicker materials, alternative welding techniques such as electron beam welding or hybrid laser-arc welding may be more suitable.

2. Stringent Requirements for Workpiece Assembly

Laser deep penetration welding demands precise workpiece fit-up and positioning. The narrow beam focus necessitates tight gap tolerances, typically less than 10% of the material thickness or a maximum of 0.2-0.3 mm. This precision requirement can increase preparation time and costs, especially for large or complex assemblies. Advanced fixturing systems, real-time seam tracking, and adaptive control technologies can help mitigate these challenges but add to the overall system complexity.

3. Significant Initial Investment in Laser System

The acquisition and setup of a laser deep penetration welding system represent a substantial capital investment. High-power lasers, precision beam delivery optics, robust motion systems, and specialized shielding enclosures contribute to the high initial costs. Additionally, the need for skilled operators and maintenance personnel adds to the operational expenses. However, it’s important to consider the long-term benefits such as increased productivity, reduced post-weld processing, and improved weld quality when evaluating the return on investment.