How do lasers transform solid metals into precise shapes and intricate designs? This article delves into the fundamentals of laser drilling and cutting, explaining the physical mechanisms, influencing factors, and practical applications of these advanced techniques. From understanding pulse energy to mastering cutting speed, readers will gain insights into how lasers achieve high precision in various industries. Explore how laser technology can enhance your manufacturing processes and unlock new possibilities in metalworking.

When a metal material is radiated by a laser with a power density of 106-109W/cm2, due to the high laser power density, the temperature of the material surface will exceed the boiling point, resulting in melting or vaporization, and the oxidized split mixture on the surface will be ejected.

At the end of the laser pulse, the laser power density decreases and the split jet weakens.

With the injection of the fission products, the vaporization takes place at a certain speed.

The degree moves towards the inside of the material, the material is vaporized and removed, and the hole is gradually deepened.

With the increase of the hole diameter and depth, the fission products are removed successively by steam pressure, and finally a deep hole is formed.

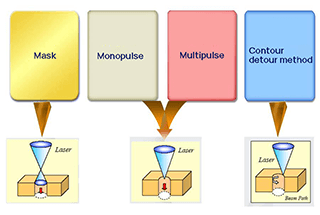

Classification of laser drilling

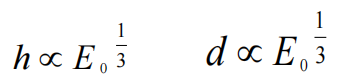

(1) Pulse energy

Primary gasification depth:

Lm and Lv are the latent heat of melting and vaporization of materials respectively.

At this time, the material removal mass is πa02d’ρ.

C: Specific heat capacity

Tb: Melting point temperature

T0: Room temperature

E0: Pulse energy

Ignore heat conduction and surface emission.

(2) Pulse width

| Energy/J | Pulse width/ms | Hole depth/mm | Aperture/mm | Depth diameter ratio |

| 5.4 5.1 5.9 5.7 5.4 5.0 | 0.25 0.35 0.55 0.75 0.85 1.15 | 1.2 1.3 1.5 1.6 1.8 1.6 | 0.42 0.39 0.38 0.36 0.30 0.26 | 2.9 3.3 3.9 4.4 6.0 6.1 |

The selection of pulse width depends on the requirements of the hole:

With the increase of pulse width, more heat is used for non-destructive heating of materials, resulting in large deformation of materials, large thermal stress and easy cracks.

Generally, 0.3-0.7ms pulse width is used.

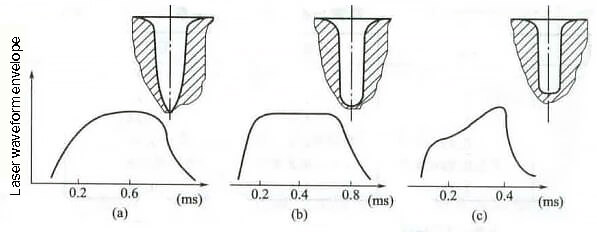

(3) Pulse waveform

The waveform with steep front and back edges and gradually increased laser light intensity shall be selected as far as possible.

Generally, the front edge of the laser shall be controlled at 8~10us to obtain a better entrance, and the back edge shorter than 8us can obtain a high inner wall quality.

Especially for the small hole less than 50us, the gradient of the back edge is increased to prevent the hole from being blocked by liquid substances.

(4) Laser mode

The divergence angle of laser mainly affects the aperture difference and taper at the inlet and outlet.

Generally, with the increase of divergence angle, the taper of the hole increases, and the diameter of the focused spot of the laser beam also increases.

Approximate formula of focusing radius:

Approximate formula of focusing depth:

The lower the mode is, the smaller the divergence angle is.

The divergence angle of the base die is the smallest.

The drilling taper of the base die should be small.

(5) Focusing conditions (focusing, defocusing amount)

The influence of defocusing amount △∫ on the shape of hole wall

(6) Material characteristics (physical characteristics, overall dimensions)

When the laser power density F is low, the thermal diffusion loss of aluminum is higher than that of iron, and the hole depth of aluminum is shallower than that of iron.

With the increase of F, the material will quickly reach the boiling point and the heating speed is fast.

At this time, the heat conduction loss can be ignored.

Because aluminum has latent heat of vaporization, the amount of vaporization removal of aluminum is larger than that of iron, so the hole depth of aluminum is deeper than that of iron.

The laser pulse with high power density should be used for drilling.

(7) Multi pulse drilling

The hole depth of single pulse drilling is limited, only 3~4 times of the hole diameter, and the accuracy and repeatability are difficult to control.

Generally, multi pulse drilling is used.

Multi pulse drilling can control unstable factors such as hole shape distortion, expansion of heat affected zone, and surface cracking.

(8) Auxiliary technology of laser drilling

Improve hole shape:

(a) The liquid film with low surface tension is coated to reduce the deposit and the taper of the hole.

(b) Cover the shielding layer so that the taper of laser drilling is on the shielding layer.

(c) Blow in compressed air to improve surface quality.

(d) A reflector is installed under the workpiece.

(e) Multi pulse drilling, periodically focusing the laser beam to a certain position at the bottom of the hole.

(f) After laser drilling, auxiliary correction.

| Quality advantage | Technical characteristics | Practical application |

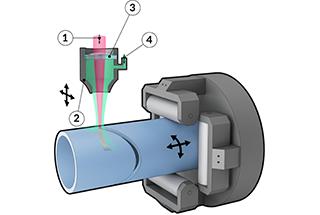

| 1. Laser can drill small deep holes | Laser focusing diameter can reach 0.3mm | Special nozzles and cooling channels |

| 2. Punch oblique holes and special-shaped holes on the inclined plane | Laser air transmission | Turbine engine blade drilling |

| 3. Punch extremely hard ceramic parts | No technical difficulty in laser drilling ceramic holes | High temperature resistant flame nozzle for steel industry |

| 4. High punching accuracy and reliable performance | No tool wear during laser drilling | Gas engine nozzle drilling |

| 5. Laser drilling high-density small holes | Laser can be used for drilling with high-speed flight method | Precision chemical industry, pharmaceutical sieve plate |

Application examples of laser drilling:

Ceramics· Φ 0.5mm hole

Engine blade· Φ 0.5mm small hole

Laser drilling of aircraft components:

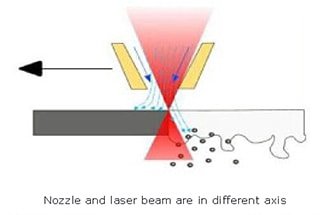

Laser cutting is to irradiate the workpiece with a focused high-power density laser beam.

On the premise of laser power density exceeding the laser threshold, the energy of the laser beam and the chemical reaction heat energy added in the active gas assisted cutting process are all absorbed by the material, which causes the temperature of the laser operating point to rise sharply.

After reaching the boiling point, the material begins to vaporize and forms holes.

With the relative movement of the beam and the workpiece, the material finally forms a slit, and the slag at the slit is blown off by a certain amount of auxiliary gas.

Laser cutting can be divided into vaporization cutting, melting cutting and oxygen combustion supporting cutting.

Oxygen combustion supporting cutting is the most widely used.

From cutting different materials, it can be divided into metal laser cutting and nonmetal laser cutting.

Related reading: Laser Cutting Basics

(1) Vaporization cutting

Vaporization cutting refers to the laser beam heating the workpiece to the temperature above the boiling point.

Some materials escape in the form of steam, and some materials are blown away from the cutting bottom as jets.

The required laser cutting energy is 10 times that of melting cutting.

The mechanism is as follows:

① The laser heats the material, partially reflecting and partially absorbing, and the reflectivity of the material decreases with the increase of temperature.

② The temperature rise in the laser action zone is fast enough to avoid melting caused by heat conduction.

③ Steam escapes rapidly from the surface of the workpiece at approximate sound speed.

Vaporization cutting is only applied to materials such as wood, plastic and carbon that cannot be melted.

Femtosecond laser cutting belongs to gasification cutting.

(2) Melting cutting

Melting cutting is that when the laser beam power density exceeds a certain value, the inner part of the workpiece evaporates to form a hole, and then blows auxiliary inert gas with the optical axis to drive away the molten materials around the hole.

The mechanism of melting and cutting is:

① When the laser beam irradiates the workpiece, the rest of the energy, except for reflection, heats the material and evaporates into holes.

② Once the hole is formed, it absorbs all the light energy with a black body, and the hole is surrounded by a molten metal wall. The molten wall is kept relatively stable by high-speed steam flow.

③ The melting isotherm runs through the workpiece, and the melted material is blown away by auxiliary blowing.

④ With the movement of the workpiece, the small hole moves horizontally by a slit.

(3) Oxygen combustion supporting cutting

The mechanism of oxygen assisted melting and cutting is:

① Under the laser irradiation, the material reaches the Tm temperature, and then contacts with oxygen, which causes violent combustion reaction and emits a lot of heat.

Under the combined action of laser and this heat, a small hole filled with steam is formed in the material, and the surrounding of the hole is surrounded by molten gas;

② The steam flow makes the surrounding molten metal wall move forward, and heat and material transfer occurs;

③ The combustion speed of oxygen and metal is limited by the conversion of combustion materials into slag.

The speed of oxygen diffusion through the slag to the ignition front. The higher the oxygen flow rate, the faster the chemical reaction of combustion;

④ In the area not reaching the combustion temperature, the oxygen flow acts as cooling to narrow the cutting heat affected zone.

⑤ There are two heat sources, laser radiation and chemical reaction heat, in oxygen assisted cutting.

Related reading: Types of Laser Cutting Methods

SUMMARY OF PROCESSING CAPABILITY

(2) Laser mode

(a) Gaussian mode (b) Low order mode (c) Multimodal

(3) Laser power and cutting speed

Relationship between cutting speed and laser power, plate thickness

For a certain plate thickness, the laser cutting speed usually increases linearly with the laser power.

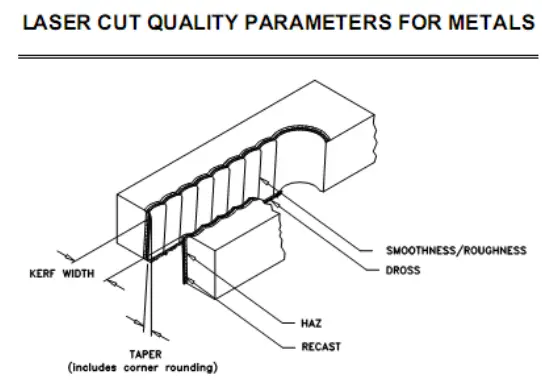

(4) Notch and roughness

Relationship between notch roughness and cutting thickness

For the incision roughness of metal laser cutting, the upper half is generally the best, the middle section is the second, and the lower section is poor.

The roughness of the notch is related to the cut notch.

(5) Focus position

The ratio a0 of the distance from the workpiece to the focusing lens to the focal length is 0.988<a0<1.003.

For example, when laser cutting 2.3 mm low-carbon steel plate, it is better to use negative defocusing of 0.3 to 0.7 mm.

(6) Focusing mirror

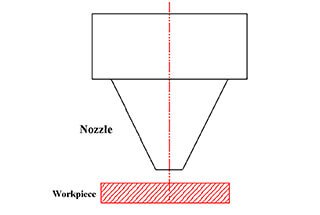

(7) Nozzle diameter

The oxygen flow should be supersonic convergent air flow to avoid the expansion of the lower section of the incision.

There is an optimal nozzle diameter for a specific laser cutting. In the figure, 1.5mm is the best nozzle diameter.

(8) Oxygen blowing pressure

Relationship between oxygen blowing pressure and cutting speed

In different laser power and different thickness, there is an optimal value of oxygen blowing pressure.

(9) Laser polarization

The state of the incision obtained by different polarized light

(a) Linear polarized light;

(b) Linear polarized light;

(c) Linear polarized light;

(d) Circularly polarized light.

As can be seen from the figure, circular polarized light is used, and the incision is straight, independent of the cutting direction.

The cutting system is generally equipped with a circular polarizer with 45 degree reflection.

Related reading: Factors Affecting Laser Cutting Quality

| Quality advantage | Technical characteristics | Practical application |

| 1. The heat affected zone at the edge of the cutting joint is small | Less total energy required for laser cutting | Cutting of silicon steel core for large motor |

| 2. The slit of laser cutting is narrow | High concentration of energy in laser cutting | Cutting of filter joint of oil pipe |

| 3. High cutting accuracy and small workpiece deformation | The diameter of laser focus spot is small | Cutting and forming of cylinder gasket |

| 4. Good cutting repeatability and small error | CNC precision cutting | Cutting complex shaped parts |

| 5. The laser cutting surface is clean without slag | Perfection of physical metallurgical process of cutting | Cutting with diamond saw blade for decoration |