Have you ever wondered why your laser cutting machine fails to cut through metal cleanly? This article explores the common causes behind this issue and offers practical solutions to enhance your machine’s performance. Learn how to maintain your equipment for precise and efficient metal cutting.

.jpg)

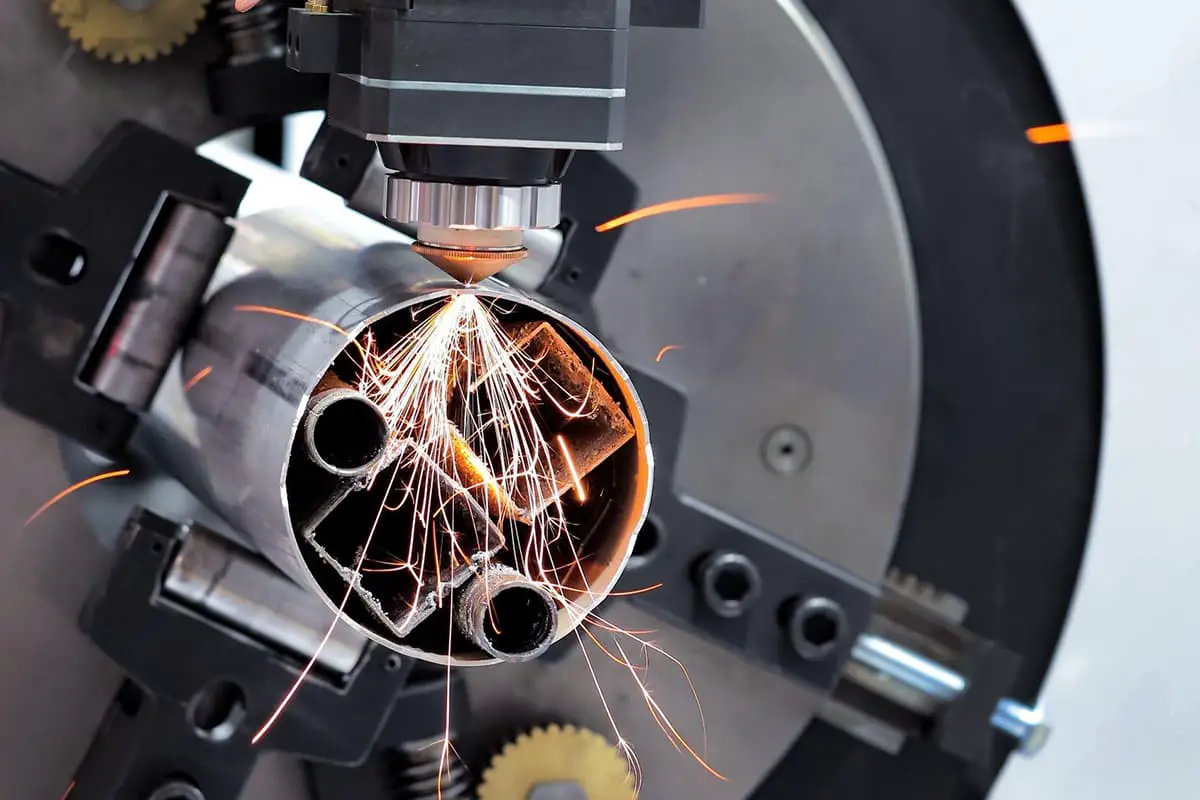

Metal laser cutting machines are a critical asset in the mechanical metal processing and manufacturing industry, often superseding traditional cutting equipment due to their precision and efficiency. However, these sophisticated systems can encounter operational issues if not properly maintained or operated, potentially compromising their performance and output quality.

One prevalent challenge in laser cutting operations is the phenomenon of incomplete penetration, commonly referred to as “not cutting through.” This issue can significantly impact production efficiency and product quality, making it essential to identify its root causes and implement effective solutions.

To effectively address incomplete penetration in laser cutting, it’s crucial to understand the underlying factors contributing to this problem and develop targeted strategies for resolution. These factors may include laser power inconsistencies, focusing errors, material variations, or machine-specific issues.

In the following sections, we will explore in detail the primary causes of incomplete penetration in laser cutting processes and present practical, industry-tested solutions. By understanding these aspects, operators and engineers can optimize their laser cutting operations, enhance cut quality, and improve overall manufacturing productivity.

Laser cutting, a precision manufacturing process, can sometimes result in incomplete cuts or rough incisions due to various factors. Understanding these causes is crucial for maintaining optimal cutting performance and product quality.

One primary reason for ineffective cutting is reduced laser power, often stemming from an aging laser source or degraded optical components. This leads to insufficient beam energy to fully penetrate the material. Similarly, operating at excessive cutting speeds can prevent the laser from delivering adequate energy to complete the cut.

Optical system issues, such as damaged focusing lenses, improper focal point adjustment, or misaligned beam paths, can significantly impair cutting efficiency. These factors directly affect the laser beam’s intensity and focus at the cutting point.

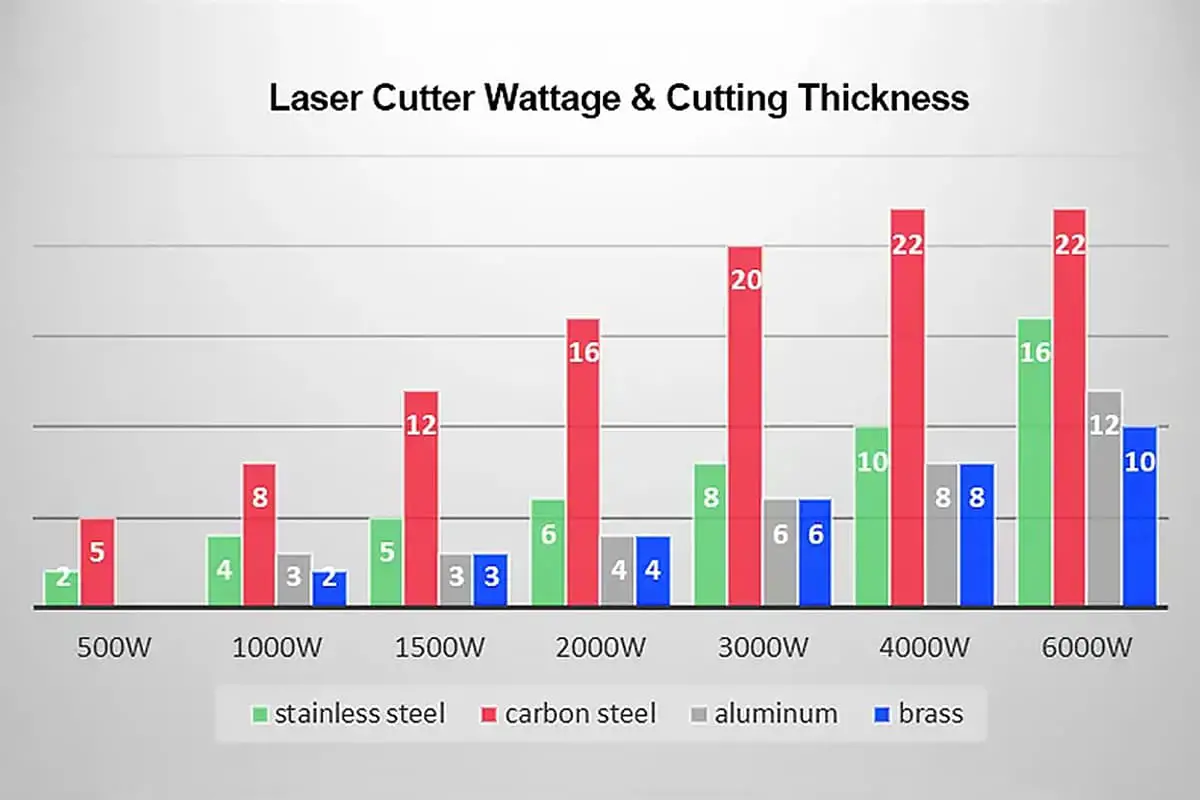

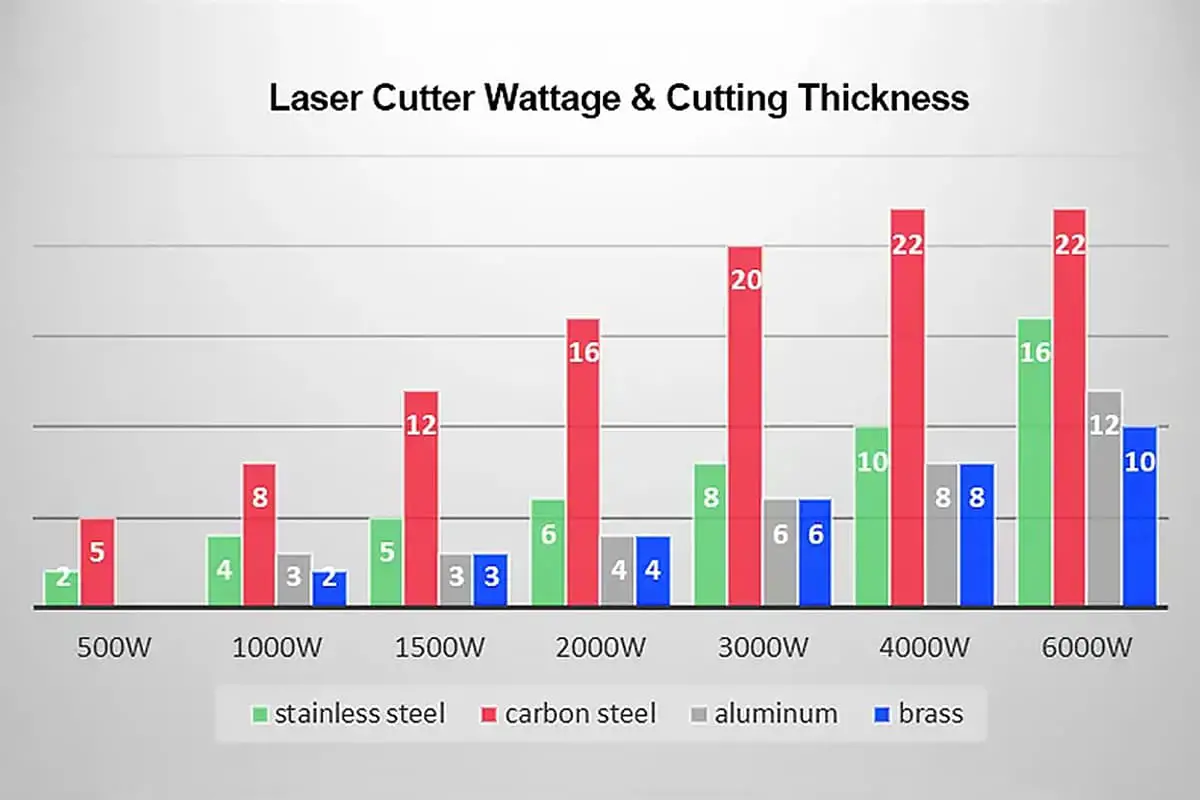

Material-specific challenges also play a role. Variations in thickness, composition, or surface condition can impact the laser’s ability to cut consistently. For instance, highly reflective materials may require higher power settings or specialized techniques.

Auxiliary systems are equally important. Insufficient assist gas pressure fails to effectively remove molten material from the kerf, leading to incomplete cuts. A compromised cooling system, either due to contaminated coolant or poor circulation, can cause thermal instability in the laser source, affecting beam quality and consistency.

Environmental factors, such as unstable input voltage or inadequate heat dissipation in the work area, can introduce variability into the cutting process, potentially resulting in inconsistent cut quality.

To ensure high-quality laser cutting and maximize production efficiency, it’s essential to systematically identify and address these potential issues. Regular maintenance, proper system calibration, and continuous monitoring of cutting parameters are key to maintaining optimal performance in laser cutting operations.

The following is a list of six reasons for a laser cutting failure.

To address the issue of incomplete laser cutting, several key factors and solutions should be considered:

By systematically addressing these factors, most incomplete cutting issues can be resolved. However, if problems persist after implementing these solutions, it is crucial to contact your laser system supplier promptly. Their specialized after-sales support team can conduct comprehensive diagnostics, perform advanced maintenance, and provide tailored solutions to ensure optimal cutting performance.

Perform weekly cleaning using a vacuum cleaner to remove dust and debris from the machine, ensuring all electrical cabinets remain sealed to prevent particulate infiltration. This routine maintenance is crucial for optimal performance and longevity of the equipment.

Conduct regular inspections of the steel belt tension on the fiber laser cutting machine. Proper tension is critical for operational efficiency and safety. Even minor belt looseness can lead to significant performance issues and potential hazards, emphasizing the importance of maintaining optimal belt tension.

Bi-annually, assess the straightness of the laser cutting machine’s track and verify the machine’s verticality. Prompt maintenance and calibration should be performed if any deviations are detected. Neglecting these crucial checks can result in compromised cutting quality and increased error rates, ultimately affecting the overall precision and efficiency of the cutting process.

Pay special attention to the double focal length laser cutting head, as it is a critical component susceptible to wear over extended periods of use. Regular inspection and timely replacement of this component are essential to maintain cutting accuracy and quality.

Implement a consistent cleaning regimen for the guide rails of the optical fiber laser cutting machine to ensure smooth operation. Regularly wipe down the rack and apply appropriate lubricating oil to prevent debris accumulation. Thorough cleaning and lubrication of the guide rail and motor components are vital for enhancing the machine’s movement precision and cutting accuracy, directly contributing to improved product quality.

To further optimize maintenance: