Imagine being able to cut through metal with the precision of a surgeon and the speed of a lightning bolt. This is the reality of modern laser processing technology. From welding and cutting to intricate microfabrication, lasers are revolutionizing manufacturing with unparalleled accuracy and efficiency. In this article, you’ll discover how these advancements are reshaping industries, making production faster, more cost-effective, and incredibly precise. Get ready to explore the cutting-edge world of laser technology and see how it’s transforming the future of manufacturing.

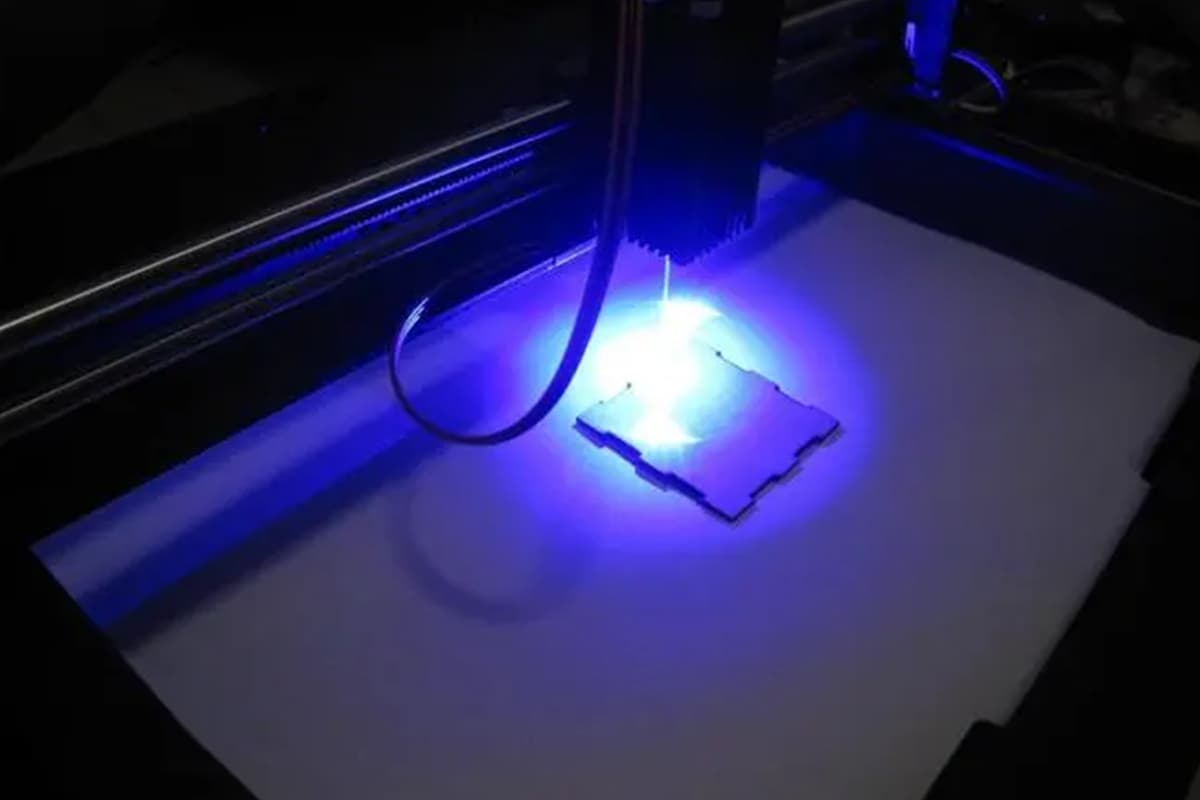

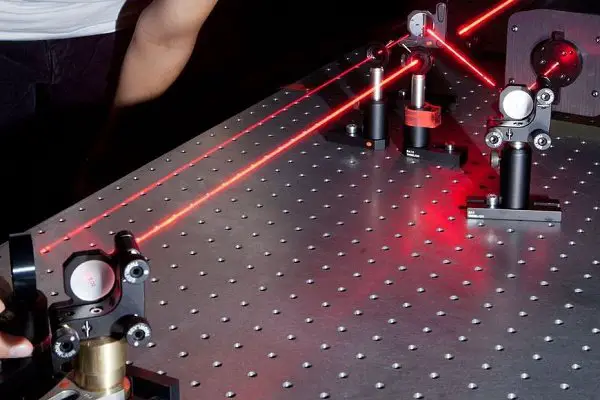

Laser processing involves using a laser beam to alter the surface of a material through thermal effects, including laser welding, laser cutting, surface modification, laser marking, laser drilling, and microprocessing.

The laser beam can be used to perform various tasks, such as punching, cutting, scribing, welding, and heat treatment, on different materials.

The laser is capable of processing any material, and it plays an indispensable role in precision and specialized processing and manufacturing, especially in special circumstances and with special materials.

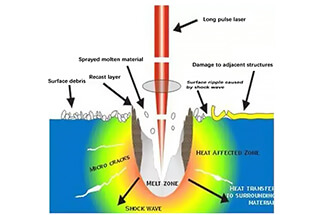

Laser processing involves using a laser beam to alter the surface of a workpiece through high energy irradiation. This results in removal of material, melting, or modification of surface properties. The process is non-contact, meaning the tool does not generate resistance by grinding against the workpiece surface, making it a fast and efficient method.

Additionally, the energy and speed of the laser beam can be adjusted, allowing for versatile applications to various levels and ranges.

The unique characteristics of laser processing determine its advantages in the field of processing:

(1) As it is non-contact processing, and the energy of the high-energy laser beam and its moving speed are adjustable, it can be used for a variety of processing purposes.

(2) It can process a variety of metal and non-metallic materials, especially those with high hardness, brittleness, and melting point.

(3) Laser processing does not cause wear on the “tool,” and does not generate cutting forces on the workpiece.

(4) The laser beam energy density is very high during processing, making it fast and highly localized, with minimal impact on areas not exposed to laser irradiation.

This results in a small heat-affected zone, minimal thermal deformation of the workpiece, and reduced need for subsequent processing.

(5) It can be used for processing within a sealed container through a transparent medium to the workpiece.

(6) The laser beam is easy to guide and focus, allowing for the transformation of direction and making it easy to work with CNC systems for complex part processing.

(7) Laser processing is highly efficient, produces reliable quality, and has good economic returns.

For example

(1) The US General Electric Company uses slab laser processing to cut the shaped slots on aircraft engines, completing the task with high quality in less than 4 hours, while the original EDM processing method took more than 9 hours. This alone saves $50,000 on the cost of each engine.

(2) The efficiency of cutting steel with lasers can increase 8-20 times, leading to a 15-30% reduction in material costs. This results in significant cost savings, while also providing high-precision machining and ensuring stable and reliable product quality.

While laser processing has many advantages, its limitations are also apparent.

Laser processing involves using a laser beam to perform various processes such as punching, cutting, scribing, welding, and heat treatment.

Laser processing has many advantages:

① High laser power density allows for the rapid rise in temperature and melting or vaporization of the workpiece, even for materials with high melting points, high hardness, and brittleness (such as ceramics and diamonds);

② The laser head does not come into direct contact with the workpiece, eliminating the issue of wear during processing;

③ The workpiece is free from forces and is not easily contaminated;

④ The workpiece can be processed while in motion or inside a sealed glass shell;

⑤ The divergence angle of the laser beam can be less than 1 millionth of an arc, with a spot diameter as small as a few microns and an action time of nanoseconds to picoseconds. Meanwhile, high-power laser continuous output power can reach kilowatts to ten kilowatts, making the laser suitable for both precision microprocessing and large-scale material processing;

⑥ The laser beam is easy to control and can be paired with precision machinery, precision measurement technology, and electronic computers for high automation and accuracy in processing;

⑦ Robots can be used for laser processing in harsh environments or in places where it is difficult for humans to work.

Pulsed laser is used for drilling, with a pulse width of 0.1 to 1 millisecond. It is especially suitable for creating holes and shaped holes with an aperture of approximately 0.005 to 1 mm. Laser drilling has been widely adopted in the production of parts such as watches and clocks, gemstone bearings, diamond drawing dies, and chemical fiber spinnerets.

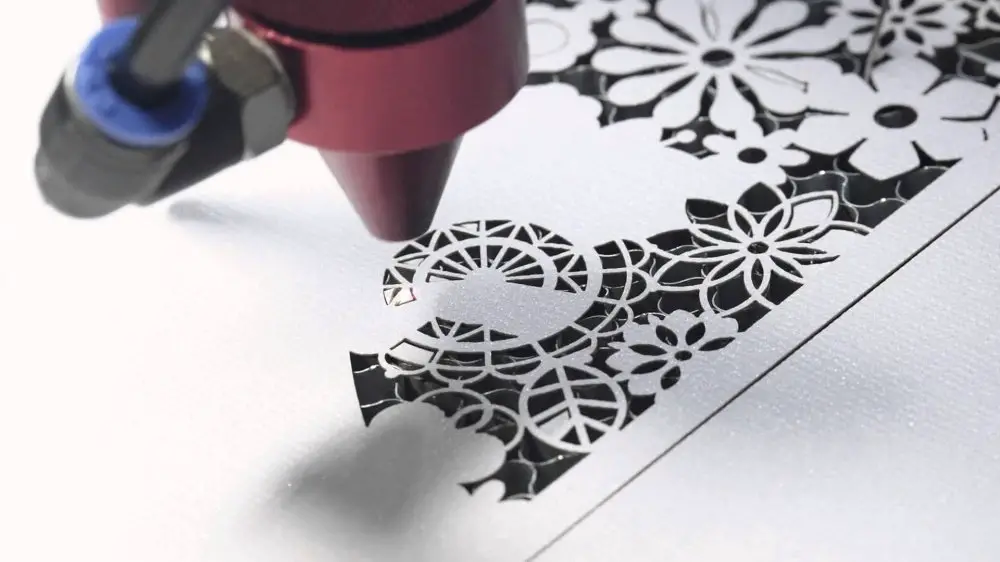

The shipbuilding and automobile manufacturing industries often use continuous CO2 lasers with hundreds of kilowatts to millions of watts to cut large parts, ensuring accurate shape of the curved space while also providing higher processing efficiency.

Medium and small power solid-state lasers or CO2 lasers are commonly used for cutting small workpieces. In microelectronics, lasers are commonly used to cut silicon or make slits, which is fast and has a small heat-affected area.

The laser can be used for workpiece lettering or marking on the assembly line without affecting the speed of the assembly line, and the carved characters can be permanently maintained.

The use of medium and low power lasers is applied to remove parts of the electronic components on the material to alter electrical parameters such as resistance, capacitance, and resonant frequency.

Laser fine-tuning boasts high precision, speed, and is suitable for large-scale production.

Similar principles can be used to repair defective integrated circuit masks, improve the yield of integrated circuit memory, and perform precise dynamic balance adjustments on gyroscopes.

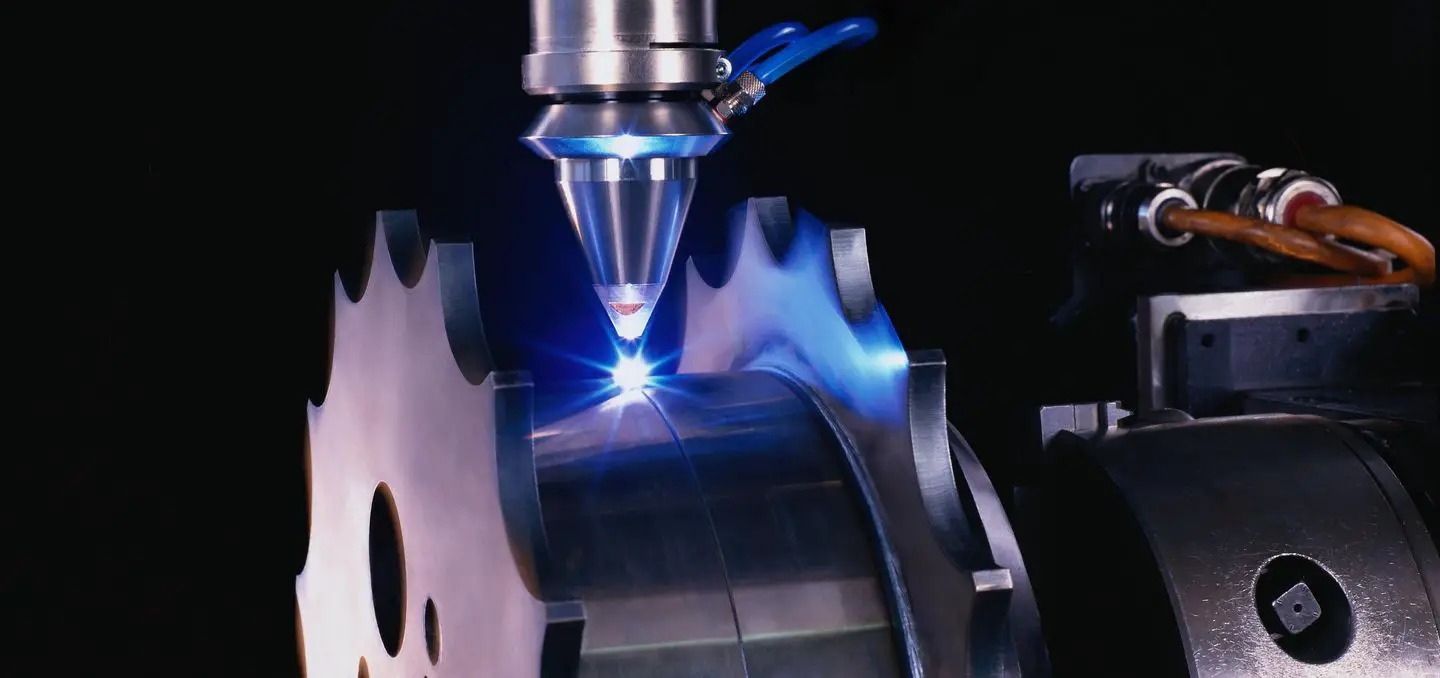

Laser welding is characterized by its high strength, minimal thermal deformation, effective sealing, consistent welding size and nature, and ability to weld materials with high melting points (such as ceramics) and those that are prone to oxidation.

Laser welding is particularly useful for pacemakers, which are sealed effectively and have a long lifespan, as well as a small size.

With the laser irradiation of material, the appropriate wavelength, control of the irradiation time and power density can be selected to cause the surface of the material to melt and recrystallize, achieving the goal of quenching or annealing.

Laser heat treatment has the advantage of being able to precisely control the depth of heat treatment and select the specific area to be treated.

The workpiece deformation is minimal, and it can effectively handle complex and intricate shapes, as well as process blind and deep holes in inner walls.

For instance, laser heat treatment can extend the life of a cylinder piston and restore damage caused by ion bombardment in silicon materials.

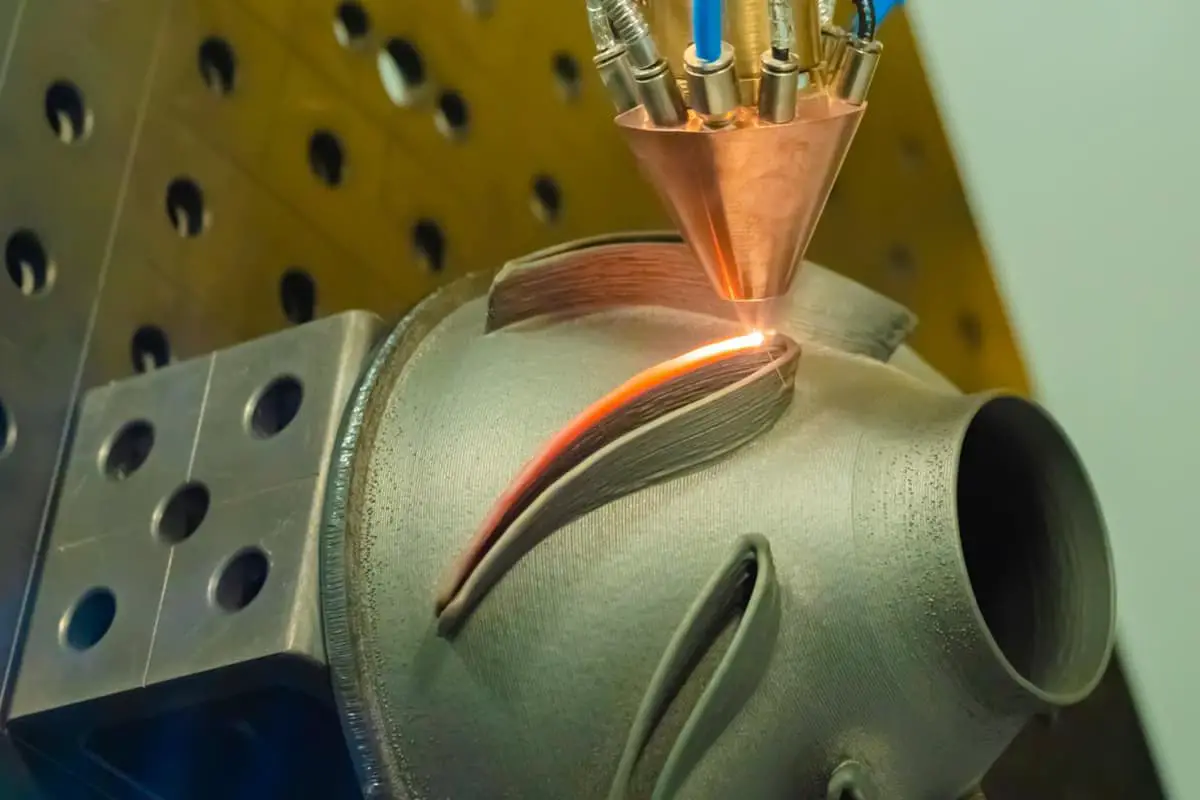

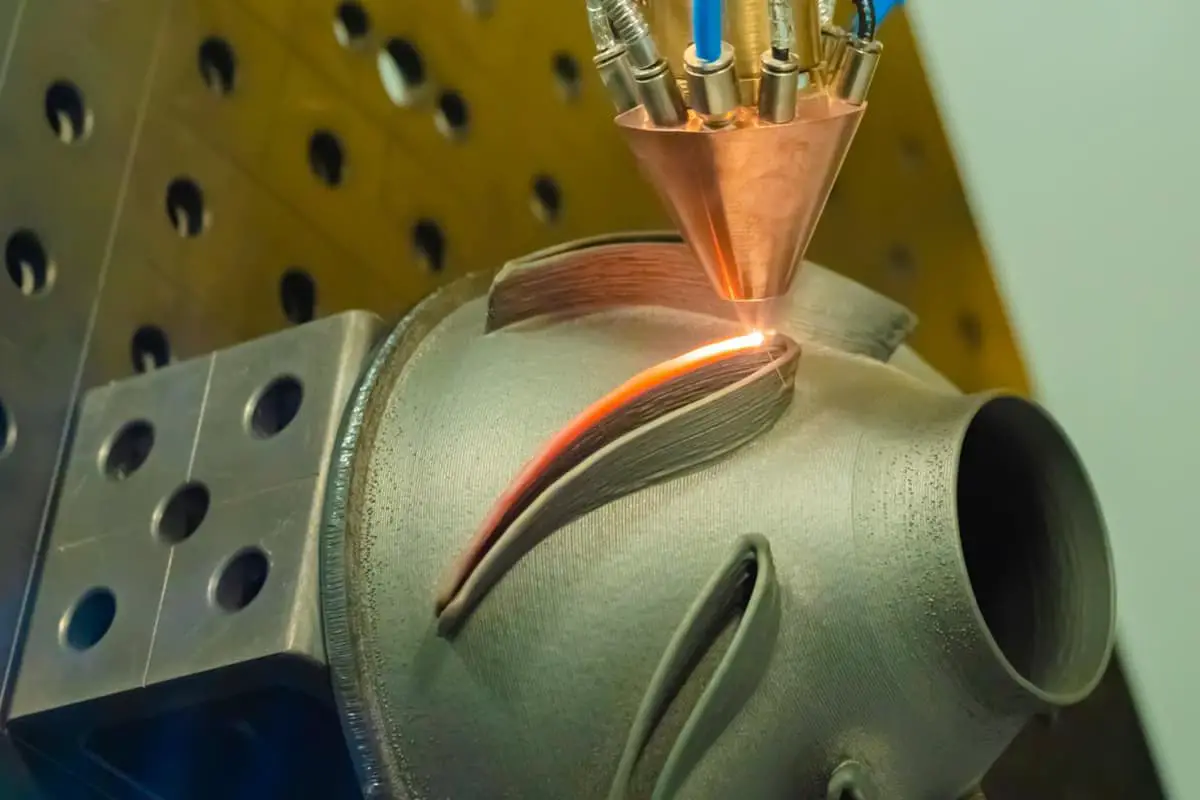

Laser Surface Strengthening Technology utilizes a high-energy density laser beam to heat and rapidly self-cool the workpiece.

In metal surface laser reinforcement, when the laser beam energy density is low, it can be used for metal surface transformation. At high beam density, the workpiece surface acts similarly to a moving crucible, enabling a range of metallurgical processes, such as surface remelting, surface carbonation, surface alloying, and surface cladding.

These functions have the potential to bring significant economic benefits to the manufacturing industry through material substitution technology.

In tool material modification, melting treatment is the primary application. It involves melting the metal material surface under laser beam irradiation, then quickly solidifying to form a new surface layer.

The material surface changes can be categorized into various types, including alloying, dissolving, remelting refinement, glazing, and surface composite.

Laser fusing involves using laser parameters to rapidly melt and condense the material surface, resulting in a more refined and homogeneous organization with improved surface properties. This is a surface modification technology.

The advantages of laser surface melting include:

The beam can be directed through an optical path, allowing for the processing of parts with special positions and complex shapes.

Combining the benefits of technology with the limitations of widely used techniques, the application of laser technology for surface strengthening of tool materials enhances the wear resistance and lifespan of the tool, particularly for ceramics and carbide cutting tools with high hardness and heat resistance.

This improves processing efficiency and accuracy and enables the processing of materials like hardened steel under challenging conditions.

Despite their high hardness and heat resistance, ceramics and carbide cutting tools have limited application due to their relatively low strength and poor toughness. The application of laser surface hardening technology to these materials is therefore a subject of significant research and has a wide range of potential applications.

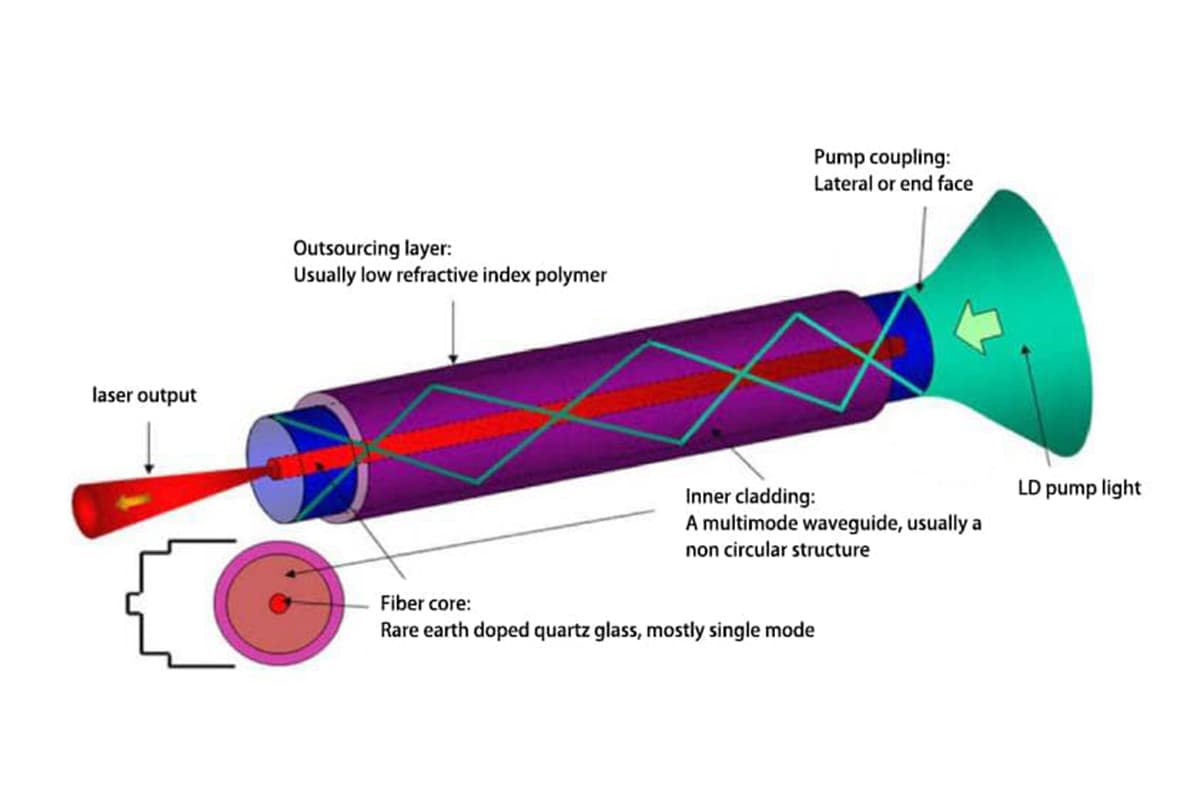

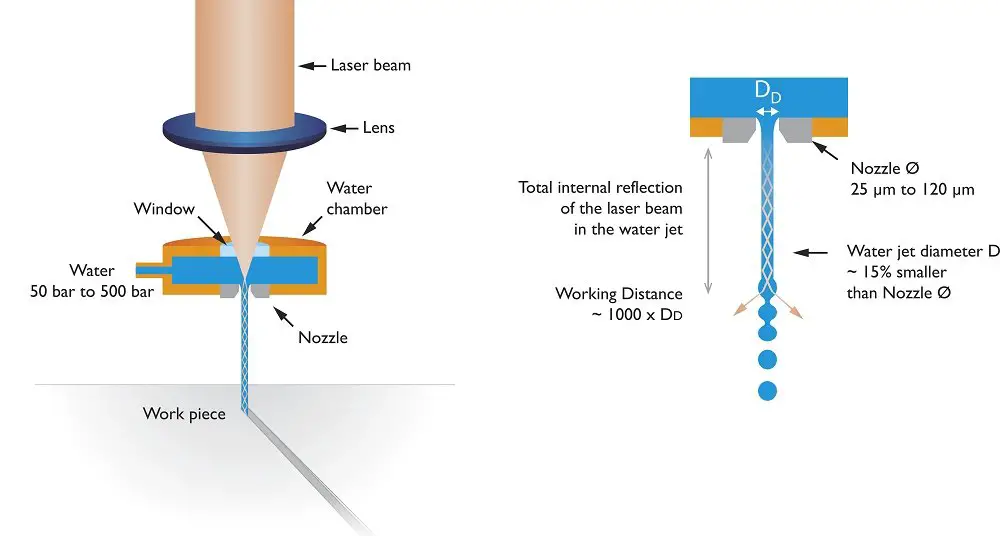

By selecting the appropriate laser wavelength and utilizing various optimization techniques and approximating the diffraction limit of the focusing system, a high-quality, stable light beam with a micro-sized focal spot can be obtained.

Its sharp and precise “light knife” characteristics are utilized for engraving high-density micro-marks and directly writing high-density information.

It can also leverage its optical trap “force” effect to manipulate tiny transparent objects, such as through high-precision grating engraving.

With the aid of CAD/CAM software to simulate and control patterns or text, high-fidelity marking can be achieved.

Additionally, its optical trap “binding force” can be used for the manipulation of biological cells, known as biological light tweezers.

The Fine Machining Process

Most of the fine cuts on the convex (outer) surface are made using single crystal diamond tools or cutters. The tip radius is approximately 100 μm, and the diamond blade has a 45° conical cutting surface when rotated.

The minimum machinable size of the concave (inner) surface is limited by the size of the tool. For example, a twist drill can be used to machine a 50 μm hole, but for smaller holes, a flat drill must be used as twist drill products are not available.

A key challenge in microfabrication is ensuring that the tool installation posture and its coaxial alignment with the spindle axis are consistent with the coordinate system. Otherwise, it can be difficult to achieve a small amount of cut. To address this issue, the same machine tool can be used for both tool production and microprocessing, thus avoiding clamping errors caused by using different working conditions.

A wire discharge grinding machine can be used on the machine tool to produce a 50 μm wide slot.

Fine Electric Processing Technology

The machining of micro-shafts and profiled section bars can be achieved through wire discharge grinding (WEDG). Its unique discharge circuit allows for only 1/100th of the ordinary EDM. To achieve a smoother surface, WECG can be used after WEDG processing, which removes a thin surface layer using deionized water at a low current.

Micro-EDM machines, such as the MG-ED71 from Japan’s Matsushita Electric Industrial Co., Ltd., can be used for this process. These machines have a positioning control resolution of 0.1 μm and the smallest processing aperture of 5 μm, resulting in a surface roughness of 0.1 μm.

For example, a 9-tooth stainless steel gear with a diameter of 300 μm and a thickness of 100 μm can be machined. The rough contour is first punched with a φ24 μm electrode, and the contour is then scanned with a φ31 mm electrode according to the tooth profile, resulting in a precision of ± 3 μm.

This technology can also be used to process a miniature step shaft with a minimum diameter of 30 μm and a processed keyway section of 10 μm x 10 μm. Electrodes for machining small parts should be made on the same machine tool, otherwise, it may be difficult to process holes smaller than 100 μm in diameter due to electrode connection and mounting errors.

For example, micro-EDM machine tooling electrodes or ultrasonic processing tools can be used to process 5 to 10 μm micro-holes. Compared to micro-machining and fine machining, the material removal rates are low, but the processing size can be smaller, and the hole diameter ratio can be as high as 5 to 10. This makes it particularly superior for the fine and complex concave cavity processing.

With the development of the laser industry and changes in downstream industry demands, medium and high-power laser equipment has become a market focus. Particularly, the emergence of 20kW, or even higher power, fiber laser cutting machines have propelled the maturation of laser technology, constantly pushing the boundaries of cutting thickness.

As we look to the future, with the upgrading of laser cutting equipment, high-power, high-speed laser cutting machines will replace traditional machining equipment due to their outstanding efficiency and precision advantages, significantly improving industrial processing efficiency and quality.

In the digital economy era, the advancement of digital technology has greatly enhanced production and innovation efficiency. The effective integration of laser technology with numerical control technology will give laser cutting equipment the ability to analyze, judge, infer, and make decisions about the cutting process, thereby realizing automation and intelligentization of all parts of the manufacturing equipment.

At the same time, the rising labor costs in the laser industry and the upgrading and iteration of industrial technology also drive the need for laser cutting equipment to evolve towards higher levels of automation and intelligence.

As we can foresee, with the rapid advancement of intelligent manufacturing strategies, digitization and intelligentization in laser cutting field will become an inevitable trend. Highly intelligent multi-functional laser cutting equipment will continue to emerge, greatly enhancing industrial processing efficiency, and achieving efficient production management.

In the era of intelligent manufacturing, downstream user processing scenarios are becoming more diverse and complex, increasing the demand for personalized laser processing equipment. This requires laser cutting companies to be more flexible in their product applications to suit different processing scenarios and meet diverse customer needs.

Therefore, the use of modular design to improve equipment integration, adaptability, and functionality, and to achieve consumer-oriented flexible production, will become an important development direction for the future laser cutting equipment industry.