How can we ensure the safety of laser products in our daily lives? This article dives into the classification of laser safety levels, explaining the International Electrotechnical Commission standards. From understanding the harmless Class 1 to the hazardous Class 4, readers will learn how to identify the danger levels of various laser products and the necessary precautions to prevent injuries. Whether you’re a consumer or a professional, this guide will equip you with the knowledge to safely handle laser devices.

With the rapid development and wide application of laser technology, various laser products can be seen everywhere in our life and work environment.

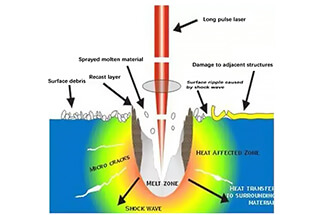

While some laser products can be safely used, improper use of others can cause severe injuries to our eyes and skin, and even lead to fire, electric shock, burns, and other serious hazards.

So, how can we know whether a laser product is safe or not?

To enable users to easily identify the danger level of laser products, we can classify them according to their harmful mechanisms to human tissue and the degree of injury caused.

The wavelength and power of a laser product determine its impact on different human tissues. The wavelength determines the absorption characteristics of different human tissues for the laser and the mechanism of injury. Power and energy determine the degree of laser damage.

According to the International Electrotechnical Commission standard, laser products are classified into several safety levels based on their wavelength, maximum output power or energy.

These levels are like business cards for laser products, representing the degree of harm they may cause and the precautions that users need to take.

Therefore, whether you are an ordinary consumer or a professional operator, it is important to understand the level of a laser product and the degree of harm it represents, as well as the precautions that should be taken, in order to avoid many incidents of laser injury.

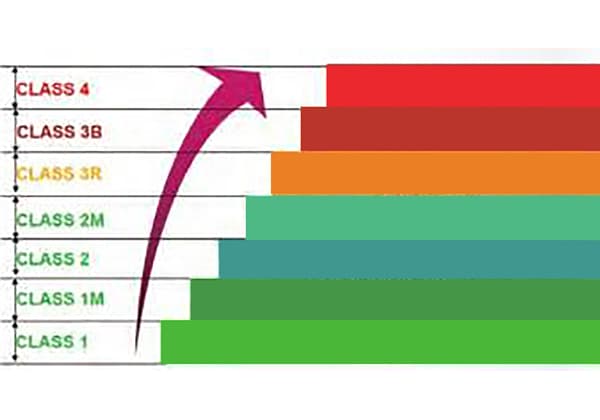

According to the International Electrotechnical Commission standard (IEC 60625-1), laser products are classified into seven levels – 1, 1M, 2, 2M, 3R, 3B, and 4 – based on their wavelength and maximum output power.

Levels 1M and 2M represent the same level of safety as levels 1 and 2, respectively, but when optical instruments such as telescopes are used, the degree of harm may be amplified beyond that of levels 1 and 2. Level 3 is further divided into two sub-levels, 3R and 3B.

The specific classification and degree of harm represented by each category can be understood through Figure 1 and Table 1.

Table 1: Detailed description of hazards represented by laser level classification

| Laser Levels | Description of Laser Hazards | Examples |

| Class 1 | Based on current medical knowledge, it is considered safe. Under any circumstances, the eyes will not be exposed to harmful optical radiation. Or although the product contains harmful lasers, they are placed in corresponding sealed products, and no harmful radiation can escape the enclosure. | Ophthalmic laser keratometer, DVD player |

| Class IM | Large diameter or high divergence beams. There’s no harm under normal usage, but when optical devices such as telescopes are used, there could be hazards exceeding Class 1 limits. | Low power fiber optic communication lasers |

| Class 2 | Low power, visible lasers (400-700nm), belong to low risk lasers. The human eye’s natural aversion response usually protects the eye, and eye damage can only occur if one intentionally keeps staring at it. | Laser scanners, laser pointers |

| Class 2M | Low power, visible lasers (400-700nm), large diameter or high divergence beams. It falls under Class 2 during normal usage, but when optical devices such as telescopes are used, hazards can exceed Class 2. | Laser level instruments |

| Class 3R | No harm under normal use, but looking directly at the beam is hazardous. | Laser rangefinders |

| Class 3B | Direct exposure or viewing secondary beams can cause harm, while scattered beams are not hazardous. | Demonstration lasers |

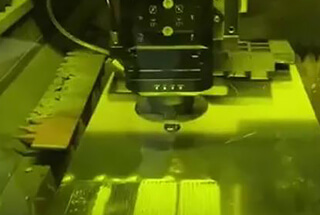

| Class4 | Direct, reflected, or scattered beams can all cause harm to the eyes or skin. | Laser welding, laser marking machines |

Now that we understand the significance of laser hazard levels, let’s take a look at how we can determine the safety level of a laser product.

In fact, laser products that have undergone strict testing and certification all have a clearly visible laser safety level mark in a location that is easily visible to users, as shown in the following Table 2:

Table 2. Laser Safety Level Labels and Warnings

| Laser Level | Laser Warning Label | Warning Text | Personal Protective Equipment |

| Class I | Class 1 Laser Product | Not Required | |

| Class 1M | Laser Radiation Do Not View Beam with Optical Instruments Class 1M Laser Product | Not Required | |

| Class 1C | Laser Radiation Refer to User Instructions Class 1C Laser Product | Refer to User Instructions | |

| Class 2 | Laser Radiation Do Not Stare Into Beam Class 2 Laser Product | Not Required | |

| Class 2M | Laser Radiation Do Not Stare Into Beam or View with Optical Instruments Class 2M Laser Product | Not Required | |

| Class 3R | Laser Radiation Avoid Eye Exposure to Direct Beam Class 3R Laser Product | Not Required | |

| Class 3B | Warning – Laser Radiation Avoid Exposure to Beam Class 3B Laser Product | Protective goggles, protective gloves, protective clothing, etc. | |

| Class 4 |  | Danger – Laser Radiation Avoid Eye or Skin Exposure to Direct or Scattered Radiation Class 4 Laser Product | Protective goggles, protective gloves, protective clothing, etc. |

According to the classification criteria for laser safety levels, different levels represent different degrees of harm and usage restrictions. Therefore, not all products can be sold on the market with any laser level.

In the following, we will discuss a few questions related to laser levels in order to draw attention to them:

When laser technology is used in toys, whether visible or invisible, special attention should be given to the fact that children may continue to stare at the laser surface in a very dangerous way out of curiosity and without understanding the meaning of warning signs, thus causing serious eye injuries.

Currently, especially in China, many children can easily obtain laser pens or toy laser projectors, some of which have laser power far exceeding the limit of Class 1, posing great safety hazards.

Therefore, all countries require that laser products for children’s toys must meet the Class 1 level.

Some Class 1 lasers are inherently very low in emission power and therefore do not pose a risk to humans.

However, not all lasers are like this. Many lasers classified as Class 1 may internally use Class 3B or 4 lasers. If we use them improperly, such as opening the laser protective shell or intentionally changing the optical path, it may result in higher-level laser beam leakage, causing personal injury.

Laser pointers, laser measurement devices, and tool equipment with laser indicators that ordinary consumers can access or use should generally not have a level higher than Class 3R.

In some markets, such as Europe and Australia, it is required that indication lasers, such as laser pointers, must comply with Class 2 or lower requirements to be sold.

During the research and development or debugging process, we may sometimes be unable to determine the laser level of a particular part inside a product. In this case, we should not simply assume that its level is the same as that of the laser source or a very low level just because it is troublesome.

Instead, we should assume that its level is at least Class 3B or even Class 4 and take sufficient safety measures, such as wearing laser protective goggles and gloves, to avoid accidents.