Imagine harnessing a beam of light powerful enough to cut through steel or perform delicate surgeries. This article delves into the fascinating world of laser technology, exploring the core components and principles that make lasers possible. From the active medium to the optical resonator, each element plays a crucial role in generating and amplifying laser light. Readers will gain a comprehensive understanding of how lasers work and the science behind this revolutionary technology. Prepare to uncover the secrets of these extraordinary beams of light!

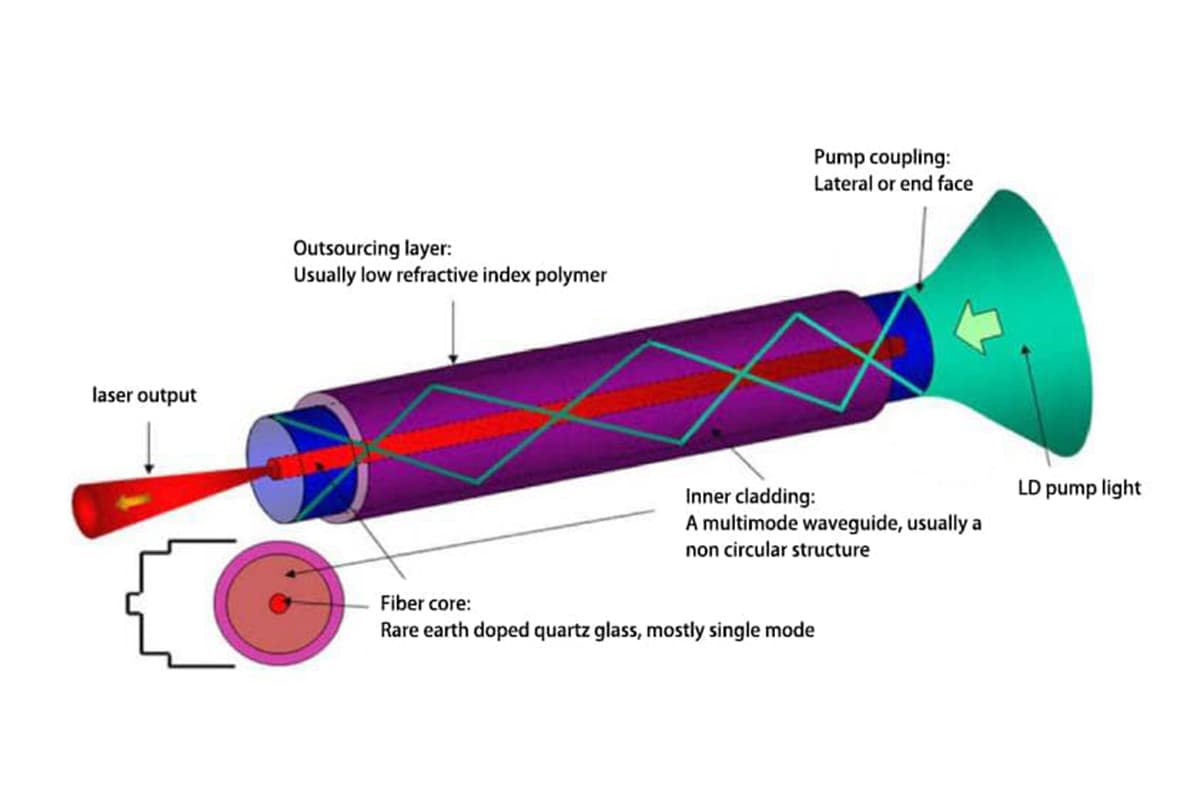

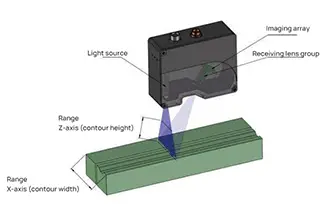

The basic structure of the laser is illustrated in Figure 1 and consists of the following components:

The production of laser light requires a suitable active medium, which can be a gas, liquid, solid, or semiconductor. In this medium, population inversion can be achieved to create the necessary conditions for generating laser light. The existence of metastable energy levels greatly facilitates population inversion.

There are nearly a thousand types of active media available, capable of producing laser wavelengths ranging from ultraviolet to far-infrared, covering a broad spectrum.

As the heart of the laser, the active medium consists of activator particles (typically metals) and a matrix. The energy level structure of the activator particles determines the spectral characteristics and fluorescence lifetime of the laser, while the matrix mainly determines the physical and chemical properties of the active medium.

Lasers can be divided into three-level systems (such as ruby lasers) and four-level systems (such as Nd:YAG lasers) based on the energy level structure of the activator particles. Commonly used shapes for the active medium are cylindrical (most widely used), planar, disc, and tubular.

To achieve population inversion in the active medium, atoms must be excited in a certain way to increase the number of particles at higher energy levels. Continuous laser output requires constant “pumping” to maintain a higher population of particles at the upper energy level than at the lower one, thus the external pumping source is also referred to as the pump source.

The pump source provides energy to reverse the population between the high and low energy levels, with optical pumping being the primary method used today. The pump source must meet two basic conditions: it must have a high luminous efficiency and its spectral characteristics must match the absorption spectrum of the active medium. Common pump sources include inert gas discharge lamps, solar energy, and diode lasers.

Inert gas discharge lamps are the most commonly used pump sources. Solar energy pumping is often used for low-power devices, especially small lasers in space applications that can use solar energy as a permanent power source. Diode pumping represents the future direction of solid-state lasers, combining many advantages and becoming one of the fastest-developing lasers.

Diode pumping methods can be divided into two types: transverse pumping (end-face pumping with coaxial incidence) and longitudinal pumping (side pumping with vertical incidence).

Diode-pumped solid-state lasers have numerous advantages, including long life, good frequency stability, and minimal thermal optical distortion, with the most prominent advantage being high pumping efficiency due to the precise match between the pump light wavelength and the absorption spectrum of the active medium.

The focusing cavity serves two functions: it effectively couples the pump source with the active medium and determines the distribution of the pump light density on the active medium, thus affecting the uniformity, divergence, and optical distortion of the output beam.

Since both the active medium and the pump source are installed within the focusing cavity, its quality directly impacts the efficiency and performance of the pump. Elliptical cylinder focusing cavities are most commonly used in small solid-state lasers.

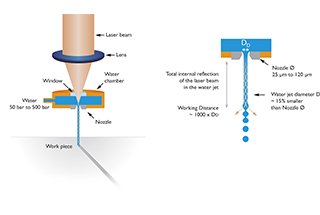

The optical resonator is essentially two highly reflective mirrors placed face to face at the ends of the laser. One mirror is fully reflective while the other is partially reflective, allowing most of the light to be reflected back while a small amount is transmitted out, producing laser light. The light reflected back into the active medium continues to induce new stimulated emissions, amplifying the light.

The light oscillates back and forth within the resonator, causing a chain reaction and avalanche-like amplification, resulting in intense laser light being emitted from the partially reflective mirror end.

The optical resonator not only provides optical feedback to sustain continuous laser oscillation and stimulated emission but also restricts the direction and frequency of the oscillating light beam to ensure the high monochromaticity and high directivity of the output laser. The simplest and most commonly used optical resonator for solid-state lasers consists of two flat (or spherical) mirrors facing each other.

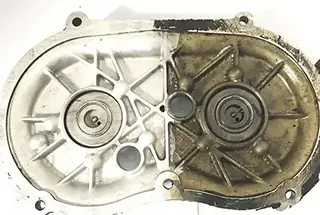

The cooling and filtering systems are indispensable auxiliary devices for a laser. Lasers generate significant heat when operating, thus necessitating cooling measures. The cooling system primarily cools the laser-active medium, the pumping source, and the focusing cavity to ensure the laser’s normal operation and protect the equipment.

The methods of cooling include liquid, gas, and conduction, with liquid cooling being the most widely used. Additionally, to obtain a laser beam with high monochromaticity, it is necessary to filter the output. The filtering system can remove most of the pump light and other interfering light, resulting in an output laser beam of high monochromatic quality.

Let’s take the ruby laser as an example to explain the working principle of a laser. The active medium is a ruby rod. Ruby is an aluminum oxide crystal doped with a small amount of trivalent chromium ions, typically a chromium oxide mass ratio of about 0.05%. Since chromium ions absorb green and blue light from white light, the gem appears pink.

The ruby used by Maiman in the first invented laser in 1960 was a cylindrical rod with a diameter of 0.8 cm and a length of about 8 cm. Its ends are a pair of parallel plane mirrors, one coated with a fully reflective film and the other with a 10% transmission rate, allowing the laser to pass through.

In the ruby laser, a high-pressure xenon lamp is used as the “pump” to excite chromium ions to the excited state E3. Electrons pumped to E3 quickly transition (in about 10-8 seconds) to E2 without radiation. E2 is a metastable energy level where the probability of spontaneous emission to E1 is very low, with a lifespan of up to 10-3 seconds, allowing particles to stay for an extended period.

Consequently, particles accumulate at E2, achieving a population inversion between energy levels E2 and E1. The stimulated emission of light from E2 to E1 is a red laser with a wavelength of 694.3 nm. The pulse laser obtained from the pulsed xenon lamp lasts less than 1 ms per light pulse, with each pulse energy exceeding 10 J and the power of each pulse laser capable of exceeding 10 kW.

The process of chromium ions being excited and emitting laser light involves three energy levels, hence it is called a three-level system. In a three-level system, since the lower energy level E1 is the ground state and typically accumulates a large number of atoms, achieving population inversion requires a substantial amount of excitation.