When it comes to cutting metals, choosing the right method can be a game-changer. Have you ever wondered how laser, waterjet, plasma, and wire cutting differ? This article dives into the unique capabilities, advantages, and limitations of each cutting technique. From cutting precision and speed to material suitability and cost, discover what makes each method distinct and which might be the best fit for your needs. Gain insights into the practical applications and performance of these cutting technologies.

The choice of cutting method depends on the specific situation. In addition to laser cutting, there are other methods such as water cutting, plasma cutting, and wire cutting. When are they used?

According to an engineer in the cutting field:

We will be analyzing these various cutting techniques in more detail.

Laser cutting is a process in which a focused high power density laser beam is directed onto the workpiece, causing the material to melt, vaporize, ablate, or reach ignition. The molten material is then removed by a high-speed airstream that is coaxial with the light beam, resulting in the cutting of the workpiece.

Currently, CO2 pulsed lasers and fiber lasers are the most commonly used types of lasers for cutting. Laser cutting is considered to be one of the thermal cutting methods.

Waterjet cutting, also referred to as water knife, is a cutting machine that uses high-pressure water flow to cut materials. Under computer control, it has the ability to carve the workpiece as desired, with minimal impact on the material’s quality.

Water cutting is further divided into two methods: sand-free cutting and sand cutting.

See also:

Plasma arc cutting is a process that uses the heat generated by a high-temperature plasma arc to melt and vaporize the metal at the cutting edge of the workpiece. The momentum of the high-speed plasma is then used to eliminate the molten metal and form a cut.

Wire Electrical Discharge Machining (WEDM), also known as Wire Cut Electrical Discharge Machining, is a type of electrical processing. It can be divided into fast wire cutting, medium wire cutting, and slow wire cutting. Fast WEDM wire cutting has a wire traveling speed of 6 to 12 m/s, and the wire moves back and forth at high speed with relatively low cutting accuracy.

Medium WEDM wire cutting is a newer technique that offers multiple frequency cutting functions based on fast WEDM wire cutting. Slow WEDM wire cutting has a wire traveling speed of 0.2 m/s. The electrode wire moves in a low-speed, unidirectional manner, resulting in very high cutting precision.

In the following sections, we will make a detailed comparison of these cutting methods.

Laser cutting machines have a broad range of applications and can cut both metal and non-metal materials. For example, non-metal materials such as cloth and leather can be cut using a CO2 laser cutter. When it comes to cutting metal, a fiber laser cutting machine is preferred due to its ability to produce minimal plate deformation.

Water cutting is considered a cold cutting method and does not result in hot deformation. It produces a high-quality cutting surface and eliminates the need for secondary machining. Additionally, it is easy to reprocess if necessary. Water cutting can efficiently cut any material with a fast cutting speed and flexible processing size.

Plasma cutting machines are capable of cutting stainless steel, aluminum, copper, cast iron, carbon steel, and other metal materials. However, plasma cutting has a noticeable thermal effect and low precision, making it difficult to reprocess the cutting surface.

Wire cutting can only be used to cut conductive materials and requires a cutting coolant during the process. As a result, non-conductive materials such as paper and leather, or materials that are sensitive to water or cutting coolant pollution, cannot be cut using this method.

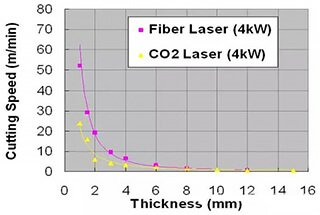

The use of laser cutting for carbon steel in industry is typically limited to thicknesses under 20mm, with a cutting capacity generally below 40mm.

For cutting stainless steel, the typical limit is below 16mm, and the cutting capacity is generally below 25mm. As the thickness of the workpiece increases, the cutting speed decreases significantly.

Waterjet cutting has the capability to cut materials with thicknesses ranging from 0.8mm to 100mm, and in some cases, even thicker materials.

The cutting thickness range for plasma cutters is from 0mm to 120mm. Plasma cutters that can cut metal with a thickness of 20mm are considered to have the best cost performance.

Wire cutting typically has a thickness range of 40mm to 60mm, with the ability to reach up to 600mm for the thickest cuts.

If a 2mm thick mild steel plate is cut with a laser power of 1200W, the cutting speed can reach up to 600cm/min. For a 5mm thick polypropylene resin plate, the cutting speed can be as fast as 1200cm/min. This highlights the speed advantage of laser cutting for mass production.

The efficiency of EDM wire cutting is generally 20mm2 to 60mm2 per minute, with a maximum of 300mm2 per minute. In comparison, laser cutting is faster and more suitable for mass production.

Water cutting speed is relatively slow, making it less suitable for mass production.

Plasma cutting has a slow cutting speed and relatively low precision, making it best suited for cutting thick plates. However, the end face will have a slope.

For metal processing, wire cutting offers higher precision, but it has a slow cutting speed. In some cases, other methods such as perforating and thread cutting may be necessary, but they have limited cutting capabilities.

The laser cutting incision is narrow, with parallel and perpendicular sides to the surface. The size accuracy of the cut part can reach ±0.2mm.

Plasma cutting has a precision of less than 1mm.

Water cutting does not produce thermal deformation and has a precision of ±0.1mm. If a dynamic water cutting machine is used, the cutting precision can be improved to as high as 0.02mm, and the cutting slope will be eliminated.

Wire cutting generally has a precision of ±0.01mm to ±0.02mm, with a maximum precision of ±0.004mm.

Laser cutting is more precise than plasma cutting, with small slits of approximately 0.5mm.

The cutting slots of plasma cutting are larger than those of laser cutting, typically 1-2mm.

Water cutting results in slits that are about 10% larger than the diameter of the cutter tube, typically 0.8mm to 1.2mm. As the diameter of the sand cutter tube increases, the size of the incision will also increase.

Wire cutting has the smallest slit width, typically around 0.1mm to 0.2mm.

The surface precision roughness of laser cutting is not as good as that of water cutting, and this becomes more pronounced as the material thickness increases.

Water cutting does not alter the texture of the material surrounding the cut joint. This is because laser cutting is a thermal cutting method which changes the texture around the cutting area.

(1) Laser cutters vary in price depending on their intended use. A cheaper option, such as a CO2 laser cutter, can cost around $4,000, while a more expensive option, such as a 1000W fiber laser cutter, can cost over $50,000. Laser cutting has no consumables, but it has the highest equipment investment cost and maintenance costs among all cutting methods.

(2) Plasma cutters are much cheaper than laser cutters and prices vary based on factors such as the plasma cutting machine’s power and brand. Plasma cutting has a high use cost, as it can cut any material that conducts electricity.

(3) Waterjet cutting equipment is second in cost only to laser cutting, with high energy consumption and maintenance costs. It has a slower cutting speed compared to plasma cutting. Additionally, all abrasives used are disposable and can contribute to environmental pollution.

(4) Wire cutting typically costs several thousands of dollars. However, it has consumables, such as molybdenum wire, cutting coolant, etc. There are two commonly used wires: one is molybdenum wire, which is expensive but can be reused many times and is used for rapid wire moving equipment; the other is copper wire, which is used for slow wire moving equipment but can only be used once. Additionally, fast WEDM machines are 5-6 times cheaper than slow WEDM machines.