Curious about the future of manufacturing? Laser welding is revolutionizing the industry with its precision, versatility, and efficiency. In this blog post, we’ll dive into the world of laser welding, exploring its key features, classifications, and working principles. Join us as we uncover the secrets behind this cutting-edge technology and discover how it’s transforming the way we create and build. Get ready to be amazed by the power of light!

Laser welding is an advanced fusion welding process that utilizes a high-energy laser beam as the primary heat source to melt and join materials at the weld interface. This technique employs concentrated photon energy to create a narrow, deep weld with minimal heat-affected zone (HAZ).

In this non-contact welding method, the focused laser beam generates localized heating without applying mechanical pressure. To protect the molten pool from atmospheric contamination and ensure weld quality, an inert shielding gas—typically argon or helium—is used. For specific applications, filler metals may be introduced to enhance joint properties or compensate for fit-up gaps.

One of the paramount advantages of laser welding is its exceptional precision in energy delivery and control. The ability to manipulate parameters such as power density, pulse duration, and focal spot size allows for unparalleled accuracy in heat input. This makes laser welding particularly suitable for joining intricate micro-components and thin-walled structures in industries like electronics, medical devices, and aerospace.

Furthermore, laser welding demonstrates remarkable versatility in material compatibility. It can effectively join a wide spectrum of metals and alloys, including those traditionally considered challenging or dissimilar. This capability extends to high-strength steels, aluminum alloys, titanium, and even some exotic materials. The process’s flexibility, combined with its potential for high-speed automation, makes it increasingly valuable in modern manufacturing environments where efficiency and quality are paramount.

Laser welding technology has revolutionized joining processes across industries, driven by advancements in high-power laser research and development. Its distinctive characteristics include:

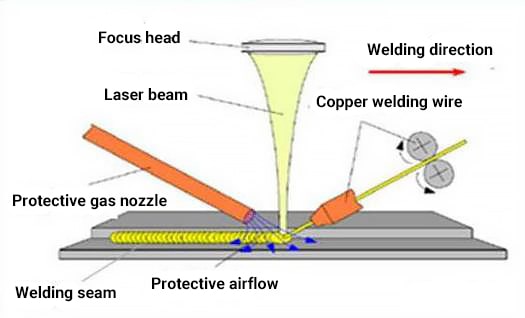

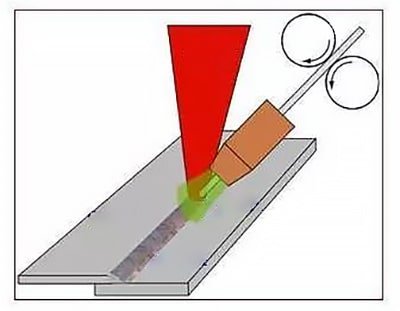

The principle of laser brazing welding is as follows:

The laser beam is used as the heat source, and the focused beam is directed onto the surface of the filler wire. The wire is continuously heated by the beam energy, causing it to melt and form a high-temperature liquid metal.

This liquid metal infiltrates into the joint of the parts to be welded, and with appropriate external conditions, a good metallurgical bond is formed between the workpiece and the filler wire.

The application of laser brazing to welding not only enhances the appearance of the product and improves sealing, but it also greatly improves the strength of the welded area and the overall safety performance of the vehicle.

It is important to note that the bond between the workpieces is achieved through brazing the melted metal, and the base material should not undergo severe laser fusion.

Advantages of laser brazing include:

Disadvantages include:

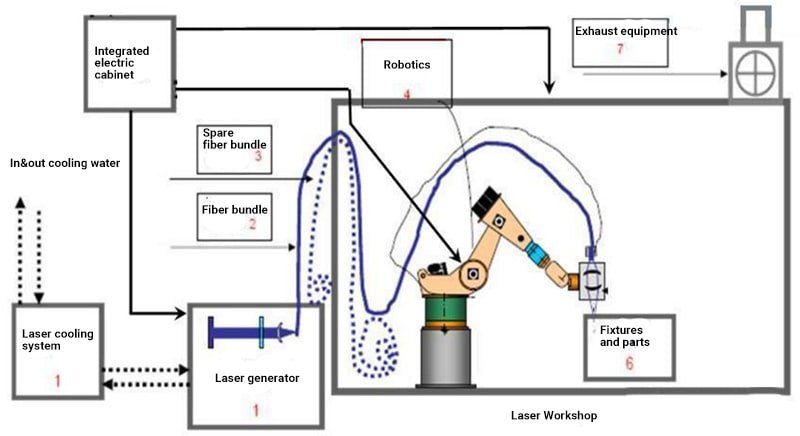

The laser brazing system consists of components such as the laser generator and cooling system, laser brazing head, wire feeding mechanism, robot, fixture, dust removal system, control system, etc.

The Laser Generator and Cooling System

The laser generator is the device that generates laser light and is the primary source of energy in the laser brazing system.

The Laser Brazing Head

It mainly consists of several components, including a collimation module, control module, focus module, weld seam tracking module, air curtain module, and others.

Wire Feeding System

The wire feeding system is responsible for maintaining a stable wire feed during welding.

A push-pull wire feeding mechanism is utilized to ensure proper wire alignment and consistent wire feeding speed. If preheating is necessary, a hot wire power source is added.

Robotics

The motion system, which facilitates the movement of the welding trajectory, also holds the laser brazing head and accompanying devices, as well as water and gas circuits.

The robot is responsible for executing the welding process and communicating with the automation system to access the welding process parameters stored in the system.

Control System

The autonomous process cabinet controls the timing of the robot, laser, brazing head, wire feeder, and preheating system through the industrial bus to complete the welding process. The main production line PLC exchanges signals with the robot through the industrial bus.

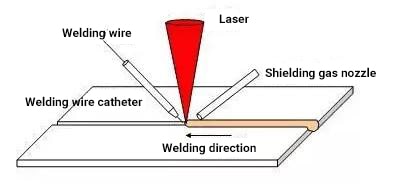

Laser fusion welding is a welding technique that uses a laser beam as a heat source to melt the base material at the corner of two plate parts, and the welding wire is melted to fill the corner, resulting in a liquid metal. After cooling, a strong bond is established. The process is depicted in Figure 2.

Laser fusion welding can be divided into several types, including laser penetration welding, laser fusion welding without wire filling, and laser fusion wire filling welding. These methods are commonly used in welding automobile roofs and floors.

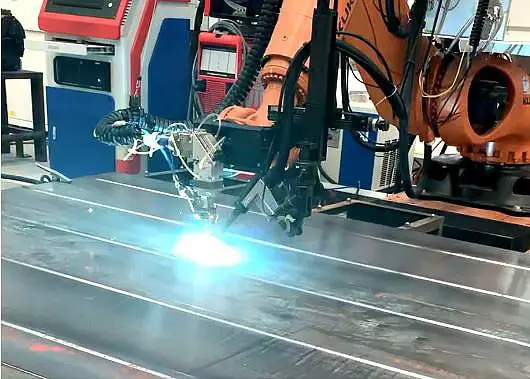

Laser remote welding involves the use of an oscillating mirror scanning head on the sixth axis of the robot to achieve movement of the laser beam through reflection of the lens, without the need for the robot arm to follow.

This makes the system highly flexible and efficient, with the capability of replacing 6 to 9 sets of ordinary robotic spot welding machines.

One of the key benefits of laser remote welding is increased productivity. The fast movement of the scanning head lens results in a drastic reduction in positioning time for the robot, thus significantly reducing manufacturing time.

Compared to an average speed of 0.5 joints per second for resistance spot welding, the laser remote welding speed is 3 to 4 joints per second, enabling full utilization of the laser beam.

In mass production tests, laser remote welding has been found to reduce the time by 80% compared to conventional resistance welding.

Another advantage of laser remote welding is its versatility. The scanning lens provides high flexibility, allowing for a range of weld shapes.

In particular, a C-shaped weld seam has a much higher welding speed compared to a linear weld seam.

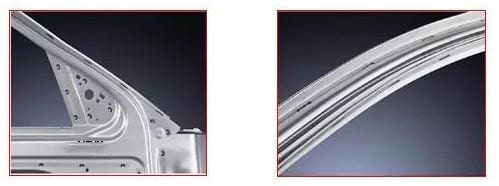

Laser remote welding is primarily used in the automotive industry for body-in-white sub-assemblies. Figure 3 shows an example of actual laser remote welding.

The distance between the laser head and the workpiece is over 500mm, which extends the lifespan of the lens protection glass.

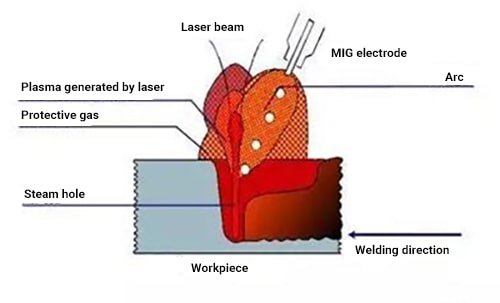

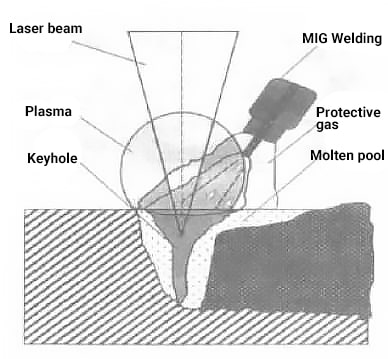

Laser composite welding mainly refers to the combination of laser and MIG arc welding. The laser and arc work together in this process, as shown in Figure 4.

Laser composite welding, which refers to the combination of laser and MIG arc welding, is more economical compared to laser welding alone.

The use of a laser beam and an electric arc in tandem results in a high welding speed, a stable welding process, and high thermal efficiency, while also allowing for larger welding gaps.

The smaller melt pool of laser-MIG composite welding leads to lower heat input, a small heat-affected zone, and reduced workpiece distortion, resulting in less correction work required after welding. The bonding effect of laser composite welding is shown in the figure below.

Laser welding can be achieved using either a continuous or pulsed laser beam, and the principle of laser welding can be divided into heat conduction welding and laser deep fusion welding.

For heat conduction welding, the power density is less than 104 to 105 W/cm2, resulting in a shallow melt depth and slow welding speed.

For laser deep fusion welding, the power density is greater than 105 to 107 W/cm2, causing the metal surface to form a “hole” and leading to deep fusion welding. This method is characterized by its fast welding speed and large depth-to-width ratio.

The principle of heat conduction type laser welding involves the laser radiation heating the surface to be processed, and the surface heat diffuses internally through heat conduction.

The laser parameters, such as the width, energy, peak power, and repetition frequency of the laser pulse, are controlled to form a specific melt pool and cause the workpiece to melt.

Laser deep fusion welding is mainly used in laser welding machines for gear welding and metallurgical sheet welding. The principles of laser deep fusion welding will be highlighted below.

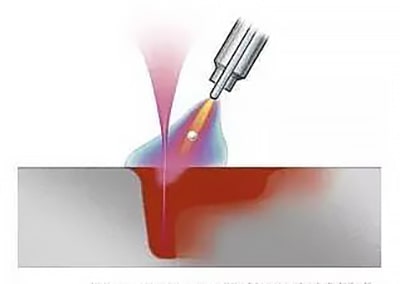

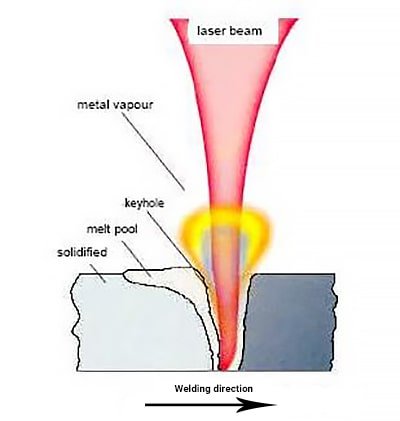

Laser Deep Fusion Welding utilizes a high-power continuous laser beam to join materials through a process analogous to Electron Beam Welding. The core of this technique revolves around the formation and maintenance of a “keyhole” structure, which facilitates efficient energy transfer and material fusion.

When the high-intensity laser beam impinges on the workpiece, it rapidly heats the material beyond its vaporization point, creating a narrow, vapor-filled cavity known as the keyhole. This keyhole behaves as a near-perfect blackbody absorber, capturing approximately 95% of the incident laser energy. The temperature within the keyhole can exceed 25,000°C, far surpassing the melting point of most metals.

Heat dissipation from the keyhole walls induces melting in the surrounding metal, forming a melt pool. The keyhole is sustained by a delicate balance between vapor pressure, surface tension, and hydrostatic forces. The continuous vaporization of material at the keyhole front, coupled with the flow of molten metal around it, creates a dynamic equilibrium.

Unlike conventional welding methods or laser conduction welding, where heat transfer primarily occurs through surface absorption and conduction, the keyhole mechanism allows for direct energy deposition deep within the material. This results in a characteristic narrow and deep weld profile, with aspect ratios (depth-to-width) often exceeding 10:1.

As the laser beam traverses the workpiece, the keyhole and surrounding melt pool move in tandem. The molten material flows around the keyhole, filling the void left in its wake. Rapid solidification of this melt pool forms the weld seam. The high energy density and efficient coupling allow for welding speeds of several meters per minute, with some advanced systems achieving speeds up to 10 m/min for thin materials.

The keyhole dynamics significantly influence weld quality and defect formation. Proper control of laser parameters (power, focus, and travel speed) and shielding gas flow is crucial to maintain keyhole stability and prevent issues such as porosity, spatter, or incomplete fusion.

Recent advancements in laser technology, including the development of high-brightness fiber and disk lasers, have further enhanced the capabilities of laser deep fusion welding, enabling deeper penetration, higher speeds, and improved weld quality across a wide range of materials and thicknesses.

(1) Laser Power

In laser welding, there is a threshold energy density below which the depth of the melt is shallow, and above it, the depth of the melt increases dramatically.

For a stable deep fusion weld, plasma must be generated, and this occurs only when the laser power density on the workpiece exceeds the threshold value, which is dependent on the material.

If the laser power is below this threshold, only surface melting of the workpiece occurs and the welding process is stable heat transfer type.

However, if the laser power density is near the threshold for small hole formation, both deep fusion welding and conduction welding become unstable, alternating and causing large fluctuations in the melt depth.

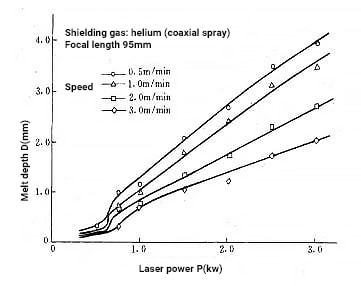

In laser deep fusion welding, the laser power determines both the penetration depth and the welding speed.

The depth of the melt is directly proportional to the beam power density and is dependent on the incident beam power and the focal spot of the beam.

For a fixed laser beam diameter, the depth of fusion increases as the beam power increases.

(2) Beam Focal Spot

The beam spot size is a critical factor in laser welding, as it influences the power density. The measurement of beam spot size is challenging in high-power laser applications, although there are many indirect measurement techniques available.

The diffraction limit of the beam focal spot size can be calculated using light diffraction theory, but actual spots are larger than calculated values due to lens aberrations in the focusing lens.

The simplest measurement method is the isothermal profile method, which involves measuring the focal spot and perforation diameter after burning and penetrating a polypropylene plate with a thick sheet of paper.

This method requires mastering the laser power size and the duration of beam action through practice.

(3) Material Absorption Value

The absorption of a laser by the material depends on various important material properties, such as the absorption rate, reflectivity, thermal conductivity, melting temperature, and evaporation temperature.

Of these properties, the absorption rate is the most significant. Factors affecting the absorption rate of a material to a laser beam can be classified into two aspects.

First of all, the resistivity of the material has a proportional relationship with the square root of the resistivity coefficient, which in turn changes with temperature. This relationship was discovered by measuring the absorbance of the polished surface of the material.

Secondly, the surface condition (or finish) of the material has a more significant impact on the beam absorbance and thus has a significant effect on the outcome of the welding process.

The output wavelength of a CO2 laser is typically 10.6 μm. Non-metallic materials such as ceramics, glass, rubber, and plastic have high absorption at room temperature, while metallic materials have poor absorption until it increases sharply when the material melts or vaporizes.

The use of surface coating or surface generation of an oxide film method is effective in improving the material’s absorption of the beam.

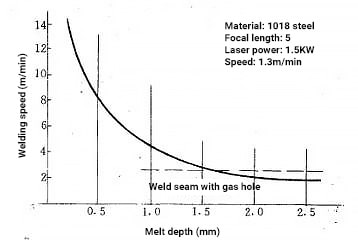

(4) Welding Speed

Welding speed greatly impacts the depth of melt. Increasing the speed will result in a shallower depth of melt, but if the speed is too low, it can lead to excessive melting of the material and the workpiece will be welded through.

A specific laser power and material thickness have a suitable welding speed range, where the maximum depth of melt can be achieved at the corresponding speed value.

The figure below illustrates the relationship between welding speed and depth of melt for 1018 steel.

(5) Protective Gas

Laser welding processes often use inert gases to protect the melt pool during the welding process.

Typically, helium, argon, and nitrogen are used to prevent oxidation of the workpiece.

Helium, with its high ionization energy, is the most effective shielding gas for laser welding but is more expensive.

Argon is less expensive and denser, providing better protection, but it is susceptible to high-temperature metal plasma ionization which can impair the welding speed, depth of melt, and reduce the effective laser power.

Welds protected by argon tend to have smoother surfaces compared to those protected by helium.

Nitrogen is the least expensive shielding gas, but it is not suitable for welding certain types of stainless steel due to absorption and porosity in the lap zone.

In addition to protecting the melt pool, shielding gases also protect the focusing lens from contamination and sputtering caused by metal vapor and molten droplets, particularly in high-power laser welding.

Another function of the shielding gas is to disperse plasma that is produced by high-power laser welding. As the metal vapor absorbs the laser beam and ionizes into a plasma cloud, the protective gas surrounding the metal vapor is also ionized by heat.

If there is too much plasma present, the laser beam will be partially consumed, making the depth of melt shallower and the weld pool surface wider.

The compounding rate of electron complexation can be reduced by increasing the number of electron-ion and neutral-atom three-body collisions. Lighter neutral atoms have a higher collision frequency and compounding rate.

Protective gases with high ionization energy do not increase electron density as they do not ionize themselves.

Table Atomic (molecular) weight and ionization energy of common gases and metals

| Materials | He | Ar | N | Al | Mg | Fe |

| Atomic (molecular) Qty. | 4 | 40 | 28 | 27 | 24 | 56 |

| Ionization energy (eV) | 24.46 | 15.68 | 14.5 | 5.96 | 7.61 | 7.83 |

As seen from the table, the size of the plasma cloud varies depending on the protective gas used, with helium having the smallest size, followed by nitrogen, and the largest when argon is used.

The larger the plasma cloud, the shallower the melting depth. This variation is due to the different levels of ionization of the gas molecules and the different diffusion of metal vapor caused by the protective gases’ different densities.

Helium is the least ionized and least dense, causing it to quickly disperse the rising metal vapor from the molten metal pool.

Thus, the use of helium as a shielding gas results in the maximum suppression of plasma, increasing the depth of melt and improving welding speed. Due to its light mass, it is less prone to causing porosity.

The effects of the plasma cloud on the melt depth are most pronounced in low welding speed zones, with influence diminishing as the welding speed increases.

The protective gas is delivered to the workpiece surface through a nozzle at a specific pressure.

The shape of the nozzle and the outlet diameter size are important for effective protection. The nozzle must be large enough to cover the welding surface, but also limited in size to prevent metal vapor contamination or damage to the lens.

The flow rate of the shielding gas must also be controlled, as an uncontrolled flow can result in turbulence, causing the atmosphere to mix with the molten pool and resulting in porosity.

To improve the protective effect, lateral blowing through a smaller diameter nozzle can also be used, directing the gas at an angle directly into small holes in deep fusion welding.

The shielding gas not only suppresses the plasma cloud on the surface of the workpiece, but also affects the plasma in the hole and the formation of small holes, resulting in deeper and wider weld seams.

However, precise control of the gas flow size and direction is necessary, as turbulence can damage the melt pool and disrupt the stability of the welding process.

(6) Lens Focal Length

Welding typically requires focusing the laser, and the commonly used lens has a focal length of 63-254mm (2.5″-10″). The spot size is proportional to the focal length – the shorter the focal length, the smaller the spot.

However, the focal length also affects the focal depth, meaning that the focal depth increases along with the focal length.

A shorter focal length can improve the power density, but because of the small focal depth, the distance between the lens and workpiece must be accurately maintained, resulting in limited melting depth.

In actual welding, the shortest depth of focus is mostly 126mm (5″) due to the influence of spatter generated during the welding process and the laser mode.

When welding larger seams or increasing the spot size, a lens with a focal length of 254mm (10″) can be selected, but this would require a higher laser output power (power density) to achieve a deep fusion small hole effect.

For laser power exceeding 2kW, especially for the 10.6μm CO2 laser beam, to avoid the risk of optical damage to the focusing lens, a reflection focusing method is often used, employing a polished copper mirror as the reflector.

This is often recommended for high-power laser beam focusing due to its effective cooling.

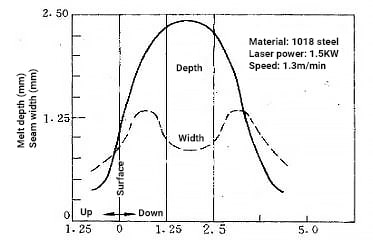

(7) Focus Position

When welding, the position of the focal point is critical for maintaining adequate power density. Changes in the position of the focal point relative to the surface of the workpiece directly impact the width and depth of the weld.

The figure below illustrates the effect of the focal point position on the depth of melt and seam width in 1018 steel.

In most laser welding applications, the focal point is usually positioned about a quarter of the intended fusion depth beneath the surface of the workpiece.

(8) Laser Beam Position

The position of the laser beam plays a crucial role in determining the quality of the weld, particularly in the case of butt joints which are more sensitive to it than lap joints.

For instance, when welding hardened steel gears to mild steel drums, proper control of the laser beam position will result in a weld with a lower carbon content and improved crack resistance.

In some applications, the shape of the workpiece to be welded requires the laser beam to be deflected at an angle.

The laser energy absorption by the workpiece remains unaffected as long as the deflection angle between the beam axis and the joint plane is within 100 degrees.

(9) Gradual Rise and Decline Control of Laser Power at the Start and End of Welding

In laser deep fusion welding, small holes are always present regardless of the weld depth. Upon terminating the welding process and turning off the power switch, a crater will form at the end of the weld.

Additionally, if the new laser welding layer covers the previous weld, there will be an excessive absorption of the laser beam, leading to overheating or porosity of the weld.

To avoid these issues, the starting and stopping points of the power can be programmed, making the power start and stop times adjustable.

This means that the starting power can be electronically increased from zero to the set power value in a short period, the welding time can be adjusted, and finally, the power can be gradually reduced from the set value to zero when the welding process is completed.

(1) Characteristics of Laser Deep Fusion Welding

(2) Advantages of Laser Deep Fusion Welding

(3) Disadvantages of Laser Deep Fusion Welding

Laser Deep Fusion Welding typically employs continuous wave CO2 lasers, which are capable of maintaining a sufficient output power to create a “small hole” effect.

This enables the laser to melt through the entire cross-section of the workpiece and result in a robust welded joint.

Regarding the laser, it is a simple device that generates a parallel beam with excellent directionality and functions as a heat source.

Laser welding offers high-quality joint strength and a large depth-to-width ratio, and is relatively fast in welding speed.

It also allows for remote control and automation in production through the use of lenses and optical fibers, as it does not require a vacuum environment.

The laser boasts a high power density, making it suitable for welding challenging materials such as titanium and quartz, as well as materials with varying properties.

Micro welding can also be performed with laser welding. The laser beam is focused to produce a tiny spot and can be accurately positioned, making it ideal for high-volume automated production in the welding of micro and small workpieces.

The laser and accessories for the welding system are more costly, leading to a higher initial investment and maintenance cost compared to traditional welding processes, resulting in a poor economic efficiency.

Additionally, the conversion efficiency of laser welding is typically low, ranging from 5% to 30%, due to the low absorption of laser light by solid materials, particularly with the presence of plasma, which has an absorption effect on laser light.

The small focused spot in laser welding requires high accuracy in equipment for the workpiece joint, as even small deviations in equipment can cause significant processing errors.

Moreover, laser welding requires a high level of workpiece assembly accuracy due to its small laser-focused spot size and narrow weld seam.

The position of the welded component must be highly precise, requiring that the beam’s position on the workpiece must be kept within the laser beam’s focus range and must not deviate significantly.

Inadequate accuracy in the workpiece assembly or beam positioning may lead to welding defects.

The requirements for the shape of the weld seam in laser welding are illustrated in the figure below.

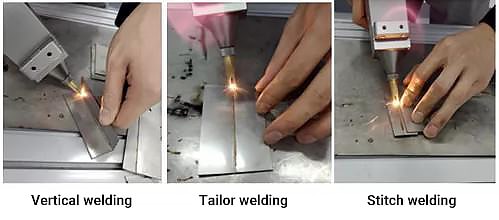

Laser fillet welding is a challenging process to control. It is a fusion welding process where a focused spot is directed onto the workpiece and wire, respectively.

The melt pool is small, making accurate control of the relative positions of the filaments crucial for achieving uniform melting of the continuously fed wire.

The weld channel solidifies relatively quickly, which may result in porosity and brittleness defects.

Compared to brazing, the weld seam of penetration welding has a rougher appearance due to the significant spatter, but is much stronger than conventional spot welding.

Compared to other welding techniques, the cost of the laser and its accompanying systems is higher and requires a larger initial investment.

The main types of lasers used for welding are CO2 lasers, Nd:YAG lasers, fiber lasers, and semiconductor lasers.

CO2 Laser

The CO2 laser is a gas laser with a far-infrared beam and a wavelength of 10.6 μm. It typically operates in a continuous mode and has a high output power, making it widely used in high-power laser welding.

When used for welding at high power levels of 10 kW or more, the use of argon shielding gas can produce strong plasma, resulting in shallow melt depth.

To address this, helium, which does not produce plasma, is often used as the shielding gas for high-power CO2 laser welding.

Fiber Laser

Fiber lasers are primarily used for overlap welding of thin materials with high stability requirements for the weld joint.

Overlap welding can achieve melt depth of 0.01in or higher at higher speeds. For example, a 200W single-mode fiber laser can achieve a melt depth of 0.004in at speeds up to 50in/s.

Nd:YAG Laser

The Nd:YAG laser is a solid-state laser that emits a beam of primarily near-infrared light with a wavelength of 1.06 μm.

The thermal conductivity of the material has a high light absorption rate at this wavelength, and the laser can operate in both continuous and pulsed modes, making it competitive in the welding of critical components.

Semiconductor Laser

Semiconductor lasers are characterized by their small size, high conversion efficiency, low operating cost, and long life, making them an important direction for future laser development.

Scholars both domestically and abroad have begun researching the use of high-power semiconductor lasers for welding aluminum alloys.

The short wavelength of the semiconductor laser results in a much higher metal absorption rate compared to the CO2 laser and Nd:YAG laser, making it a promising option for welding applications.

However, the low power density of the semiconductor laser when applied to the material surface makes it more suitable for thin plate welding and electronic component welding in laser welding applications.

The characteristics of laser and TIG compound welding are.

For instance, when a CO2 laser with a power of 0.8 kW is used in combination with a TIG arc current of 90A and a welding speed of 2m/min, it has equivalent welding capacity to that of a 5kW CO2 laser welder.

When welding at speeds ranging from 0.5 to 5m/min with a 5kW CO2 laser, the depth of melt obtained is 1.3 to 1.6 times greater than that obtained with the 5kW CO2 laser alone.

Related reading: MIG vs TIG Welding

Laser plasma composite welding is conducted in a coaxial manner, as illustrated in Figure 3. The plasma arc is generated by an annular electrode, and the laser beam travels through the center of the plasma arc.

The plasma arc serves two primary functions.

Firstly, it provides additional energy for the laser welding process, increasing the speed and efficiency of the welding.

Secondly, the plasma arc surrounds the laser, resulting in a heat treatment effect that extends the cooling time and reduces the risk of hardening and residual stresses, leading to improved microstructural properties of the weld.

The basic principle of laser-MIG composite welding is shown in Figure 4.

In addition to the energy input to the weld zone from the arc, the laser also provides heat to the weld metal. The laser and arc composite welding technology operates simultaneously, with both methods acting on the weld zone.

The laser and the arc each contribute to the performance of the composite weld in varying degrees and forms.

In laser-MIG composite welding, volatilization occurs not only on the workpiece surface but also on the filler wire, resulting in more metal volatilization and easier energy transfer from the laser.

MIG welding has the advantage of a low power source cost, good weld bridging, stable arc, and the ability to improve weld structure with filler metal.

On the other hand, laser beam welding is characterized by a deep melt depth, high welding speed, low heat input, and a narrow weld seam.

However, welding thicker materials requires a more powerful laser.

The melt pool in laser composite welding is smaller than that in MIG welding, which results in less workpiece deformation and significantly reduces the need for post-weld correction.

With laser-MIG composite welding, two separate pools are formed, and the heat input from the arc serves as a simultaneous post-weld tempering treatment, reducing the hardness of the weld, particularly in steel.

Due to the very high welding speed of laser composite welding, production time and costs can be reduced.

In the laser welding process, the high laser power density causes the base material to rapidly heat up, melt, and vaporize, resulting in high-temperature metal vapor.

However, the continuous high power density can also cause the formation of a plasma cloud, which reduces the laser’s absorption by the workpiece and makes the welding process unstable.

To address this, a pulsed laser with high peak power or a combination of two pulsed lasers with different pulse widths, repetition frequencies, and peak powers can be used to compound the workpiece for welding.

The two laser beams work together to create a large, deep melt hole periodically, and by stopping the irradiation of one laser beam at the right time, the plasma cloud can be reduced or eliminated, which improves the absorption and utilization of laser energy and increases the welding depth and capacity.

Reducing the laser power density after the formation of a large, deep melt hole and continuing to irradiate can also help to reduce the plasma cloud.

As the laser energy acting on the metal vapor is reduced, the plasma cloud can diminish, leading to a more stable welding process.

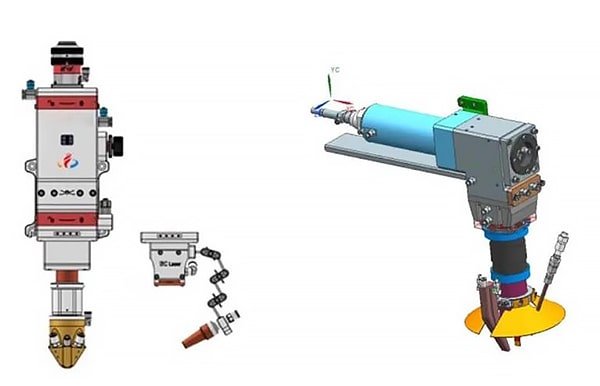

This refers to a series of optical processing of laser light to obtain a beam with desired characteristics for laser applications.

For welding applications, there are three types of heads available: fusion welding head, brazing head, and laser welding head.

Robots are more common, with enough precision and weight to apply.

Currently, the world ABB, FANUC, MOTOMAN, KUKA, etc. have laser applications.

Power Density

Power density is a critical factor in laser processing. When power density is high, the surface layer of the material can be heated to boiling in a matter of microseconds, resulting in a large amount of vaporization.

This makes high power density ideal for material removal processes such as cutting, punching, and engraving.

On the other hand, lower power densities require several milliseconds to reach the boiling point, causing the bottom layer to melt before the surface layer vaporizes, making it easier to form a good melt weld.

Laser Pulse Waveform

When a high-intensity laser beam is aimed at a material’s surface, 60-98% of the laser energy is reflected and lost, especially for materials that reflect strongly, such as gold, silver, copper, aluminum, titanium, etc. The reflectivity of the metal changes over time during the laser pulse signal.

As the surface temperature of the material rises to the melting point, the reflectivity decreases rapidly. Once the surface is melted, the reflectivity stabilizes at a certain value.

Laser Pulse Width

Pulse width is a crucial parameter in pulsed laser welding. The pulse width determines the size of the heat-affected zone and the melt depth. The longer the pulse width, the larger the heat-affected zone and the greater the melt depth, which increases with the 1/2 power of the pulse width.

However, increasing the pulse width decreases the peak power, so it is typically used in heat conduction welding methods to form a wide and shallow weld. But a lower peak power results in excess heat input, and each material has an optimum pulse width that maximizes the melt depth.

Off-Focus Volume

Laser welding usually requires a certain degree of defocus, as the power density at the center of the spot at the laser focal point is too high and tends to evaporate into a hole.

On the other hand, the power density is relatively evenly distributed in all planes away from the laser focal point.

There are two types of defocusing: positive and negative. The focal plane is above the workpiece for positive defocus and vice versa for negative defocus.

In theory, when the positive and negative defocus planes and the welding plane are equal, the corresponding power density planes are approximately the same.

However, in practice, the shape of the molten pool obtained may differ. Negative defocus results in a deeper melt, which is related to the formation process of the melt pool.

Welding Speed

Welding speed greatly affects the depth of melt. Increasing the speed leads to a shallower depth of melt, but a speed that is too low causes excessive material melting and the workpiece to weld through.

Therefore, there is a suitable speed range for a certain laser power and thickness of a particular material, and the maximum depth of melt can be obtained at the corresponding speed value within that range.

Protective Gas

The laser welding process often uses inert gases, such as helium, argon, and nitrogen, to protect the melt pool.

The shielding gas also protects the focusing lens from metal vapor contamination and liquid droplet sputtering. In high-power laser welding, the ejected material is powerful, making lens protection even more crucial.

The third role of the shielding gas is to disperse the plasma shielding generated by high-power laser welding effectively.

The metal vapor absorbs the laser beam and ionizes into plasma, and if there is too much plasma present, the laser beam will be partially consumed by the plasma.

1. Sheet-to-sheet welding

It includes 4 types of process methods:

2. Wire–to–wire welding

It includes 4 types of process methods:

3. Welding of metal wire and block components

The connection of wire to lumped elements can be successfully achieved using laser welding, where the lumped elements can be of any size.

Attention should be paid to the geometry of the wire element during welding.

4. Welding of different metals

Welding of different types of metals has to address the range of weldability and weldability parameters.

Laser welding between different types of metals is only possible for specific combinations of materials.

While laser brazing may not be suitable for connecting some components, it can be used as a heat source for both soft and hard brazing and has its own advantages.

Laser soft brazing is mainly used in the soldering of printed circuit boards and is particularly useful in chip component assembly technology.

There are various methods of using brazing, and laser soft brazing is just one of them.

Laser welding is a process where a high-energy laser light beam is directed toward a workpiece, causing an increase in temperature, leading to the melting and joining of the workpiece to form a permanent joint.

Laser welding is known for its high shear strength and tear strength.

Several factors can affect the quality of laser welding, some of which are highly unstable and volatile. The correct setting and control of these parameters is crucial to maintain the right range for high-speed continuous laser welding to ensure the quality of the weld.

The stability and reliability of weld formation is a significant issue for the practical implementation and industrialization of laser welding technology.

The factors affecting the quality of laser welding can be classified into three aspects: welding equipment, workpiece condition, and process parameters.

Welding Equipment:

The most important quality requirements for lasers are the stability of the beam pattern and output power. A lower beam pattern order is preferred for better beam focusing performance, a smaller spot size, and a higher power density at the same laser power, resulting in deeper and wider welds. It is generally required to use a base mode (TEM00) or low-order mode to achieve high-quality laser welding.

Currently, China faces difficulties in using lasers for welding due to issues with beam quality and power output stability. However, in other countries, the laser beam quality and output power stability is at a high level and does not pose a problem for laser welding.

The optical system and its focus mirror are the most significant factors affecting the welding quality.

The focal length used is generally between 127mm (5in) to 200mm (7.9in), and a smaller focal length reduces the focus beam waist spot diameter but is more prone to contamination and spatter damage during the welding process.

The shortness of wavelength leads to higher absorption.

Materials with good conductivity generally have high reflectivity. When it comes to YAG laser, the reflectivity rate is 96% for silver, 92% for aluminum, 90% for copper, and 60% for iron.

The temperature has a linear relationship with absorbance; the higher the temperature, the higher the absorbance. Surface coating materials, such as phosphate, carbon black, graphite, etc., can improve the absorption rate.

Condition of the Workpiece

For laser welding to be successful, the workpiece must have precise edges and the laser spot must be aligned precisely with the weld seam. The precision and alignment must not change during the welding process due to heat distortion.

This is because the laser spot is small, the weld seam is narrow, and there is generally no filler metal added.

If the assembly gap is too large, the laser beam may pass through it, preventing it from melting the base material, or causing visible nibbling or depression. A slight deviation in spot alignment may result in unfused or unwelded spots.

Therefore, the general plate butt assembly gap and spot seam deviation should not be greater than 0.1mm, and the deviation on the wrong side should not be greater than 0.2mm.

In some cases, laser welding technology cannot be used because these requirements cannot be met.

To achieve good welding results, the allowable butt gap and lap gap should be controlled within 10% of the thin plate thickness. The substrates being welded must have close contact for successful laser welding, which requires careful tightening of the parts.

The power density of the laser spot is the most important factor affecting the laser welding mode and weld forming stability. As the power density increases from small to large, the welding modes change from stable thermal conduction welding to mode instability welding and then to stable deep fusion welding.

The laser spot power density is mainly determined by the laser power and the beam focus position, with the laser power density being proportional to the laser power. The optimum position for the beam focus exists for the best effect.

When the beam focus is at a certain position under the surface of the workpiece (within 1 to 2 mm, depending on the plate thickness and parameters), the ideal weld seam can be achieved.

Deviation from this optimal position increases the size of the workpiece surface spot, reducing the power density, and potentially causing changes in the welding process form.

Welding speed has a less significant effect on the welding process form and stability compared to the laser power and focus position.

However, when the welding speed is too high, the heat input may become too small to maintain a stable deep fusion welding process.

In practice, the choice of welding should be based on the depth of melt required for the welded parts and should avoid mode instability welding.

In the stable deep fusion welding range, the laser power has a direct effect on the depth of melt, with the depth increasing as the power increases (at about 0.7 times the relationship). The higher the welding speed, the shallower the depth of melt.

When certain laser power and welding speed conditions are met, the optimal focus position will result in the maximum depth of melt.

Deviation from this position decreases the depth of melt and may cause mode instability or stable thermal conduction welding.

The main role of the shielding gas is to protect the workpiece from oxidation during welding, protect the focusing lens from metal vapor contamination and sputtering of liquid molten droplets,

For the above two cases,

On one hand, the use of high-quality and highly stable optical components with frequent maintenance is crucial to prevent pollution and keep them clean.

On the other hand, the development of real-time monitoring and control methods for the laser welding process is necessary to optimize parameters, monitor changes in laser power and focal point position as it reaches the workpiece, and achieve closed-loop control to improve the reliability and stability of the laser welding quality.

Laser Welding of Carbon Steel and Common Alloy Steel

Laser welding of carbon steel generally works well, and the quality of the weld depends on the level of impurities. Factors such as sulfur and phosphorus can affect the risk of weld cracking.

When welding carbon steel with a content greater than 0.25%, preheating is necessary to achieve satisfactory weld quality.

When welding different carbon content steels together, it’s best to slightly bias the torch towards the lower carbon content material to ensure a high-quality joint.

However, low-carbon boiling steel should not be laser welded due to its high sulfur and phosphorus content.

Conversely, low-carbon quelling steel is suitable for laser welding because of its low impurity content. Medium and high carbon steels and common alloy steels can be laser welded, but preheating and post-weld treatment are required to reduce stress and prevent crack formation.

Laser Welding of Stainless Steel

In general, obtaining high-quality joints through laser welding of stainless steel is easier than with conventional welding methods. The high welding speed results in a small heat-affected zone and eliminates the risk of sensitization.

Additionally, the low thermal conductivity of stainless steel makes it easier to achieve deep fusion and narrow weld seams.

Laser Welding of Different Metals

The rapid cooling rate and reduced heat-affected zone of laser welding provide favorable conditions for the compatibility of materials with varying structures after welding and fusing of various metals.

The following metals have been demonstrated to be successfully welded using laser deep-fusion methods:

Manufacturing Applications

Tailored bland laser welding technology is widely used in car manufacturing. In Japan, it has replaced flash butt welding in the steel-making industry for joining rolled steel coils.

The study of ultra-thin plate welding, such as a plate thickness of less than 100 microns, is not feasible with fusion welding, but YAG laser welding with a special output power waveform has been successful, demonstrating a broad future for laser welding.

In Japan, YAG laser welding has been developed for the first time in the world for the repair of thin tubes in nuclear reactor steam generators, and some companies have also utilized laser welding technology for gears.

Powder Metallurgy Field

With the continuous advancement of science and technology, traditional smelting and casting methods of manufacturing materials can no longer meet the special requirements of industrial materials.

Due to the unique properties and manufacturing benefits of powder metallurgical materials, they are replacing traditional materials in industries such as automobiles, aircrafts, and tool manufacturing.

As the development of powder metallurgical materials increases, connecting parts has become increasingly challenging, limiting the application of powder metallurgical materials.

In the early 1980s, laser welding with its distinct advantages entered the field of powder metallurgical materials processing and opened up new prospects for the application of powder metallurgical materials.

For example, brazing methods of welding diamonds, commonly used in powder metallurgical materials, have low bonding strength, a wide heat-affected zone, and cannot withstand high temperatures and strength requirements. However, the use of laser welding can improve welding strength and high-temperature resistance.

Automotive Industry

In the late 1980s, kilowatt-class lasers were applied to industrial production, and today laser welding lines have become widespread in the automotive manufacturing industry.

European car manufacturers, such as Audi, Mercedes-Benz, Volkswagen, and Volvo in Sweden, were among the first to use laser welding for roof, body, side frames, and other sheet metal welding in the 1980s.

In the 1990s, General Motors, Ford, and Chrysler in the United States introduced laser welding into automotive manufacturing, although it started late, it developed rapidly.

In Italy, Fiat used laser welding for the welded assembly of most steel sheet components.

In Japan, Nissan, Honda, and Toyota use laser welding and cutting processes in the manufacture of body coverings.

The use of laser-welded assemblies of high-strength steel in auto body manufacturing is increasing due to their excellent performance.

According to US metal market statistics, by the end of 2002, the consumption of laser-welded steel structures will have reached 70,000 tons, a threefold increase from 1998.

The laser welding equipment used in the automotive industry is high-powered and multi-path to meet the needs of the industry’s batch and high degree of automation.

Electronics Industry

Laser welding is widely used in the electronics industry, particularly in the microelectronics industry.

Its advantages, such as a small heat-affected zone, rapid heating concentration, and low thermal stress, make it the preferred choice for integrated circuits and semiconductor device housing packaging.

Laser welding has also been used in the development of vacuum devices, such as molybdenum focusing poles with stainless steel support rings and fast heat cathode filament assemblies.

In the electronics industry, laser welding is also useful for welding elastic thin-walled corrugated sheets with thicknesses of 0.05-0.1mm, which are difficult to solve with traditional welding methods and TIG welding is prone to welding through, while plasma stability is poor and has many influencing factors. The use of laser welding is very effective and widely used in these cases.

Biomedical

The use of laser welding in biological tissues started in the 1970s, and its success in welding fallopian tubes and blood vessels led to more research into welding a variety of biological tissues.

Today, research on laser welding of nerves focuses on laser wavelength, dose, and its effect on functional recovery, as well as the selection of laser welding materials.

Compared to traditional suturing methods, laser welding offers faster anastomosis and eliminates the risk of foreign body reaction during the healing process, while also preserving the mechanical properties of the welded area. As a result, it is expected to be more widely used in biomedicine in the future.

Other industries

Laser welding is also gradually gaining popularity in other industries, particularly in special material welding.

For example, in China, there have been many studies on laser welding of materials such as BT20 titanium alloy, HEl30 alloy, and Li-ion batteries.

Additionally, the German glass machinery manufacturer GlamacoCoswig, in collaboration with IFW Joining Technology and Materials Experimental Institute, has developed a new technology for laser welding of flat glass.

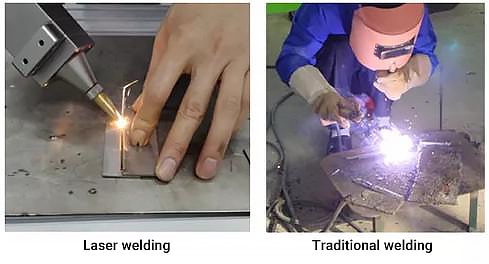

The initial impression of many entrepreneurs towards laser welding machines is that they are too expensive, compared to traditional welding machines like argon arc welding which only cost around 10,000 RMB. However, this is a misperception as they are yet to understand the benefits of using laser welding machines.

For a company to survive and grow, it needs to be strong and capable of producing high-quality products that attract customers.

In today’s market, customers are becoming more discerning and are looking for products that are not only functional but also beautiful and delicate.

To stay ahead in the competition and increase market appeal, it’s important for companies to adopt advanced technology equipment and processes to produce new and sophisticated products. This not only improves competitiveness but also enhances profits and sales.

Laser welding machines, compared to traditional welding equipment, offer several advantages that can help improve production quality and efficiency.

The laser welding machine is a type of non-contact processing, which means it will not cause any damage to the workpiece during the welding process.

Its advantages include fast welding speed, high welding strength, smooth weld seams, minimal deformation, and the ability to weld in special conditions such as tight spaces.

The laser welding machine is capable of welding special materials with high melting points, such as refractory metals, and can even be used for welding non-metallic materials like ceramics. It is highly flexible and has a good effect on welding special materials.

The non-contact remote welding capability makes it suitable for parts that are difficult to access with a traditional welding machine.

The laser beam can be precisely focused to produce a small spot, and it is not affected by magnetic fields, making it ideal for micro welding. Its accurate positioning makes it suitable for automatic mass production of small and micro workpieces.

Laser welding is a fusion of modern and traditional technologies. It is unique compared to traditional welding techniques and has a wider range of applications, which can significantly improve welding efficiency and accuracy.

The power density is high and energy is quickly released, making the welding process more efficient. The smaller focal point of laser welding also enhances the bond between the materials being welded and eliminates the need for post-weld processing, avoiding damage and deformation to the materials.

This technology is mainly used in high-tech industries, and as people continue to gain a deeper understanding and mastery of it, it will inevitably be applied to more fields and industries.

Laser welding can easily meet various welding requirements for different materials, including metals and non-metals, and has the ability to focus randomly within 360 degrees due to the laser’s penetrability and refraction.

In addition, laser welding can be carried out under general room temperature conditions, as it releases a large amount of heat in a short period of time, reducing environmental requirements and eliminating the need for a vacuum or gas-protected environment.

Over the years, laser technology has been widely recognized and has evolved from its initial use in military applications to a widespread use in the civilian sector. The development of laser welding technology has further expanded the scope of laser technology.

In the future, laser welding will be used not only in industries such as automobiles, steel, and instrument manufacturing, but also in military, medical, and other fields.

In particular, the high heat and temperature of laser welding make it a suitable choice for medical applications, such as in neuromedicine and reproductive medicine.

Its precision advantages will also benefit industries that require precision instrument manufacturing, contributing to the ongoing development of humanity and society.