Imagine a world where welding metals is as precise and efficient as drawing a line with a laser pointer. Laser welding of metals, from carbon steel to titanium alloys, achieves just that, offering unmatched precision and strength. This article delves into the intricacies of laser welding, exploring the unique challenges and solutions for different metals. By the end, you’ll understand how this advanced technique revolutionizes manufacturing, enabling stronger, cleaner welds in everything from aerospace components to everyday appliances.

(1) When the carbon equivalent exceeds 0.3%, the challenges in welding increase due to higher difficulty, increased cold crack sensitivity, and increased brittle fracture tendency of the material in fatigue and low-temperature conditions. To mitigate these challenges, the following measures can be taken:

(2) Welding high-carbon materials and low-carbon materials can be made easier by using offset welding, which limits the transformation of martensite and reduces the formation of cracks.

(3) The laser welding performance of killed steel and semi-killed steel is superior because deoxidizers such as silicon and aluminum are added prior to pouring, reducing the oxygen content in the steel to very low levels.

(4) Steel with sulfur and phosphorus content exceeding 0.04% is prone to thermal cracks during laser welding.

(5) Laser welding is generally not recommended for galvanized steel with overlapping structures.

(1) Stainless steel has excellent laser welding performance.

(2) Compared to carbon steel, austenitic stainless steel has a lower thermal conductivity, being only 1/3 of that of carbon steel. However, it has a slightly higher absorption rate. This results in slightly deeper penetration during laser welding (by about 5% to 10%) compared to ordinary carbon steel.

(3) During laser welding of Cr-Ni stainless steel, the material has high energy absorption and efficient melting.

(4) Ferritic stainless steel has improved weld plasticity and toughness when welded using laser welding compared to other welding methods.

(5) Laser welding of stainless steel is used in various industrial applications, such as welding stainless steel tubes and nuclear fuel packages in nuclear power plants, as well as in the chemical industry.

Deep penetration welding is a commonly used technique in aluminum alloy laser welding. The main challenges in this process are the high reflectivity of the aluminum alloy to the laser beam and its high thermal conductivity.

One issue that arises during laser welding of aluminum and aluminum alloys is the sharp increase in the solubility of hydrogen in the material as the temperature rises, leading to the formation of pores in the weld.

In deep penetration welding, there is also a risk of cavities in the root and poor formation of the weld bead.

When laser welding aluminum and aluminum alloys, there are three key challenges that must be addressed: porosity, thermal cracking, and significant irregularity in the weld.

The high reflectivity of aluminum alloys makes laser welding very challenging. To overcome this, a high-power laser must be used.

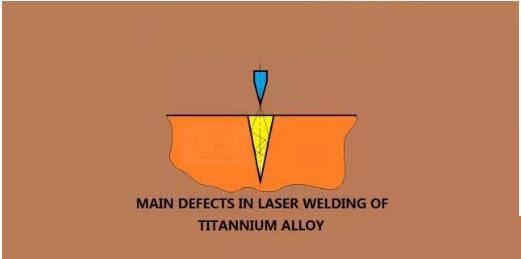

Titanium alloy is an outstanding structural material with remarkable specific strength, good ductility and toughness, and exceptional resistance to corrosion.

However, titanium has highly reactive chemical properties and is highly susceptible to oxidation.

Additionally, titanium is also extremely sensitive to gap embrittlement caused by the presence of oxygen, hydrogen, nitrogen, and carbon atoms.

Therefore, it is essential to pay close attention to cleaning the joints and providing adequate protection against gases during welding and fabrication processes.

Laser welding is capable of welding all types of superalloys, including those with high levels of Al and Ti that are difficult to weld using arc welding, resulting in high-quality joints.

For superalloy welding, laser generators typically used are pulse lasers or continuous CO2 lasers with a power output of 1 to 50 kW.

It is recommended to use helium or a mixture of helium and a small amount of hydrogen as the shielding gas during laser welding of superalloys.

Laser welding can be used to join dissimilar metals such as copper-nickel, nickel-titanium, titanium-aluminum, and low carbon steel-copper under specific conditions.

In addition to metals, laser welding can also be used to weld ceramics, glass, composite materials, and more.

When welding ceramics, preheating is necessary to prevent cracking. The recommended preheat temperature is 1500°C and the welding is performed in air.

A long focal length focusing lens is typically used for laser welding of ceramics, and filling with a welding wire can also be done to improve joint strength.

However, when welding metal matrix composites, brittle phases can easily form, leading to cracks and decreased joint strength.