Imagine a world where welding is as precise as a surgeon’s scalpel. Laser welding robots bring this precision to life, using focused light to create flawless welds on metal surfaces. This article dives into the principles behind these advanced machines, explaining how laser energy is transformed into heat to fuse materials seamlessly. You’ll discover the science of laser-material interaction and the unique characteristics that make laser welding an industry game-changer. Prepare to explore the fascinating technology shaping the future of manufacturing.

A welding robot laser is a monochromatic and directionally focused energy beam produced using the principle of light amplification realized by stimulated radiation. It can generate an energy beam with a diameter of less than 0.01mm and power density as high as 10W/m2.

This energy beam can be used as a heat source for welding, cutting, and material surface cladding.

Welding robot

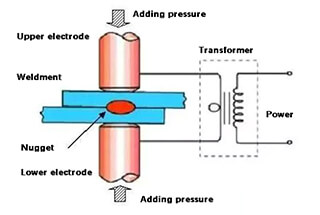

The laser welding process of a welding robot involves using visible or ultraviolet light as a heat source to melt and connect workpieces. Laser energy is highly focused to a point, which increases its energy density, making it an effective welding method.

During the welding process, the laser beam is directed at the material’s surface, where it is partially reflected and partially absorbed into the material. For opaque materials, the transmitted light is absorbed, and the metal’s linear absorption coefficient is typically 107-108/m.

In the case of metals, the laser is absorbed within a thickness of 0.01-0.1m on the metal surface, which transforms into heat energy, causing the metal’s temperature to increase and transmit to the metal interior. The vaporized metal helps prevent the residual energy from being reflected by the metal.

The penetration of the laser beam is affected by the material’s thermal conductivity. The reflection, transmission, and absorption of the laser on the material surface are the result of the interaction between the electromagnetic field of the light wave and the material.

When the laser light wave is incident on the material, the charged particles in the material vibrate according to the pace of the light wave electric vector, converting the radiation energy of the photon into kinetic energy of the electron. The excess energy of some particles, such as the kinetic energy of free electrons and excitation energy of bound electrons, is transformed into heat energy.

Compared to other light sources, the laser has unique characteristics, such as high directivity, brightness (photon intensity), monochromaticity, and coherence. The conversion of light energy absorbed by the material into heat energy occurs in a very short time (about 10s) and is limited to the laser radiation region.

The metal’s absorptivity of the laser depends on the laser wavelength, material properties, temperature, surface condition, and laser power density. YAG solid-state laser (Yttrium-Aluminum-Garnet) and CO2 gas laser are the two main types of lasers used in welding.