How do automakers achieve stronger, lighter, and more efficient vehicles? The answer lies in advanced laser welding techniques. This article explores seven innovative laser welding processes revolutionizing automobile manufacturing, from flight welding to multi-wavelength hybrid welding. Each method offers unique benefits, enhancing speed, precision, and material compatibility. Dive into this comprehensive guide to understand how these cutting-edge technologies are shaping the future of automotive engineering. Learn about the specific advantages of each process and how they contribute to building better, safer cars.

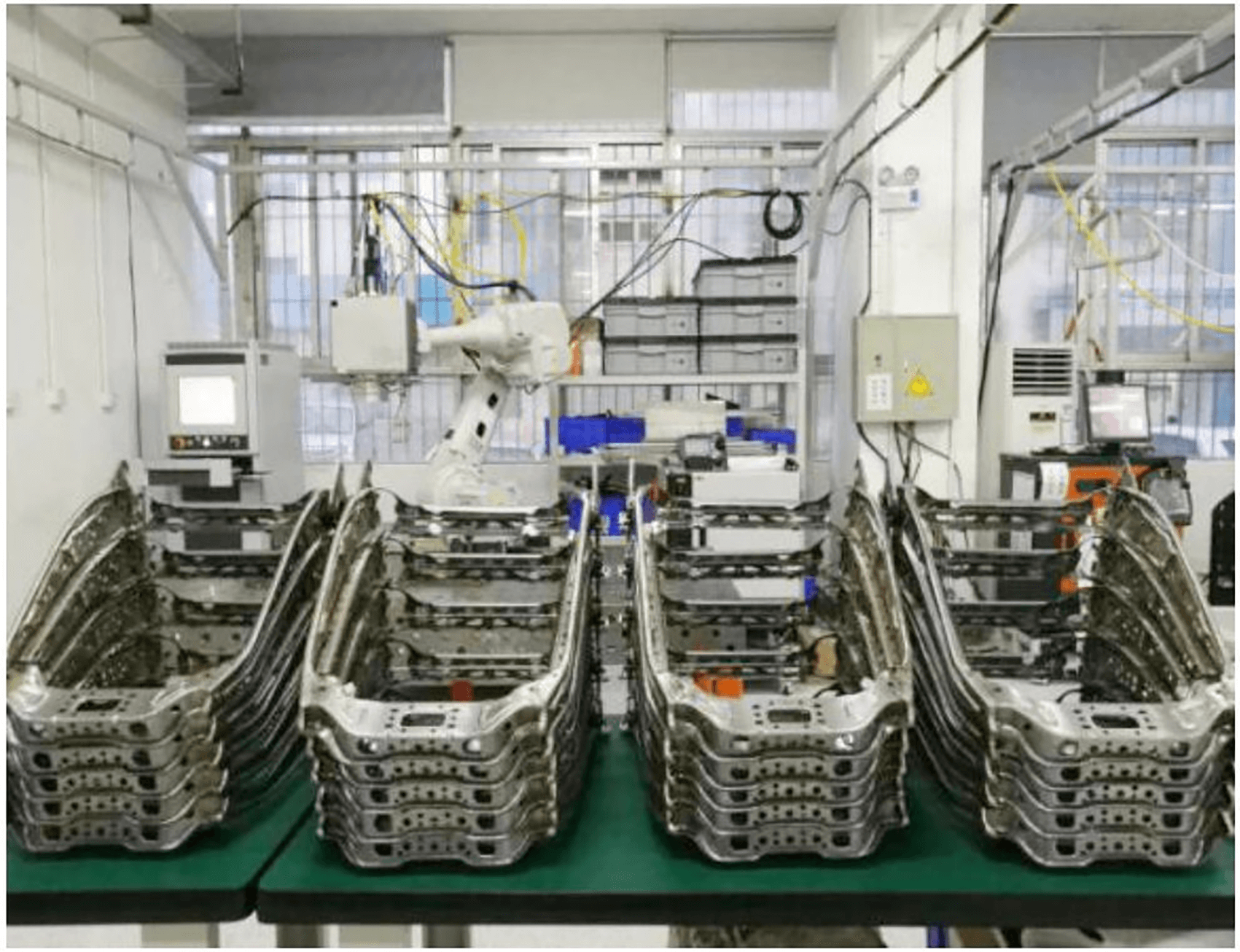

Laser flight welding combines the benefits of remote welding, galvanometer, and manipulator with professional graphic processing software to achieve instantaneous multi-track welding in three-dimensional space. This technology is primarily utilized in the production of automobile bodies, seats, and other common auto parts.

Materials-wise, it can be applied to a variety of steel plates, cold-rolled plates, aluminum alloys, and other common materials. Additionally, it can be used on composite materials and alloys, such as magnesium aluminum alloys.

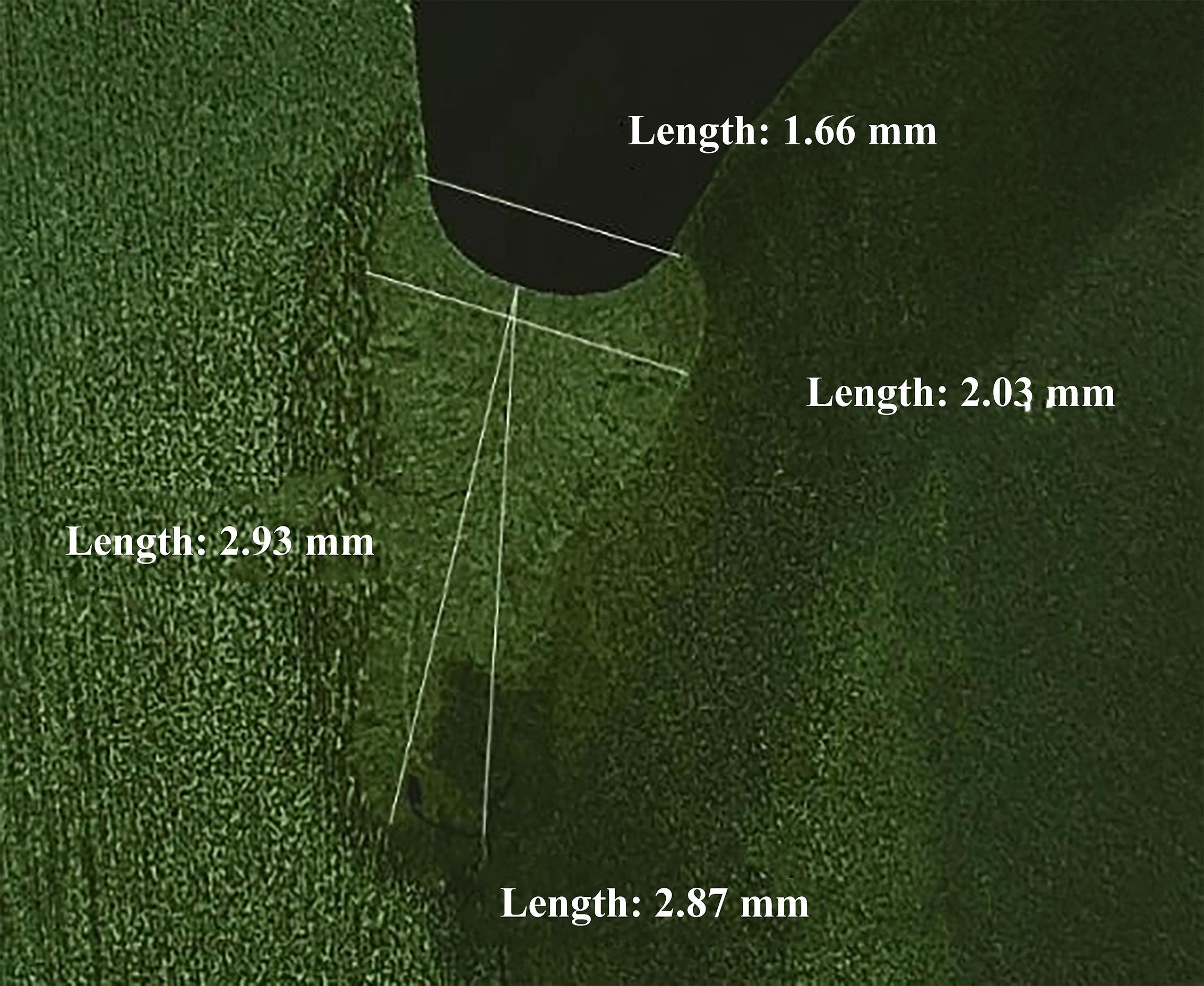

Fig. 1 Flight welding process

Flight welding experimental equipment

Fig. 2 Seat flight welding

Advantages:

The double wedge laser swing laser welding method is achieved by incorporating a unique wobble module on the welding joint. As the joint moves, the focus spot creates a spiral weld.

This method is primarily used for hinge welding, heat exchanger welding, tube heat exchanger welding, welding of thick pipes for oil and gas, flange welding, and aluminum alloy welding, among others.

Fig. 3 Spiral welding track chart

Advantages:

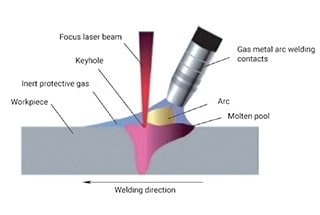

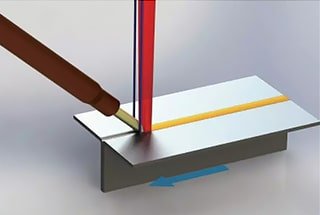

Laser brazing involves heating the filler metal to a temperature that is higher than its melting point but lower than the melting temperature of the base metal. This process utilizes liquid solder to wet the base metal, fill any gaps in the joint, and diffuse with the base metal to form a connection between the components being welded.

Laser brazing is mainly used in the welding of aluminum body frame structures, such as connecting the top cover and case wall or welding doors and other products.

Brazing principle

Brazing metallographic diagram

Advantages:

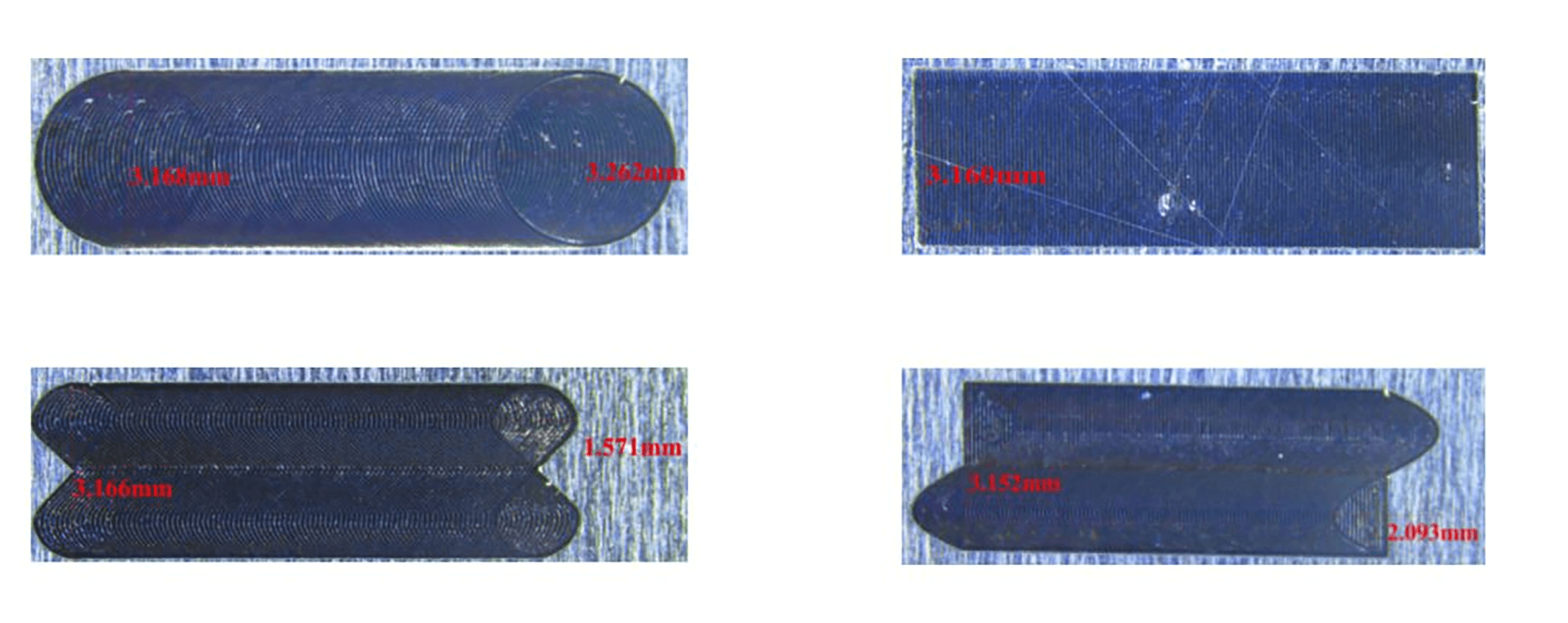

Laser filler metal welding is a welding technique that utilizes filler metal made of the same or a similar material as the base metal. This process involves melting the base metal and the filler metal together and then condensing them to form a weld.

This method is primarily used in the fabrication of whole body structural parts and auto parts products.

Fig. 4 Welding of automobile fork

Fig. 5 Welding metallographic diagram

Advantages:

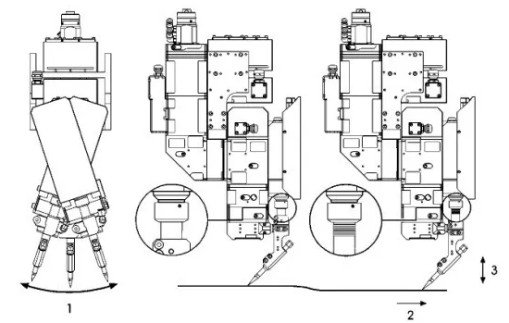

Through ALO3, the functions of beam forming and seam tracking are integrated into a single piece of equipment.

A filler wire can serve as a mechanical sensor.

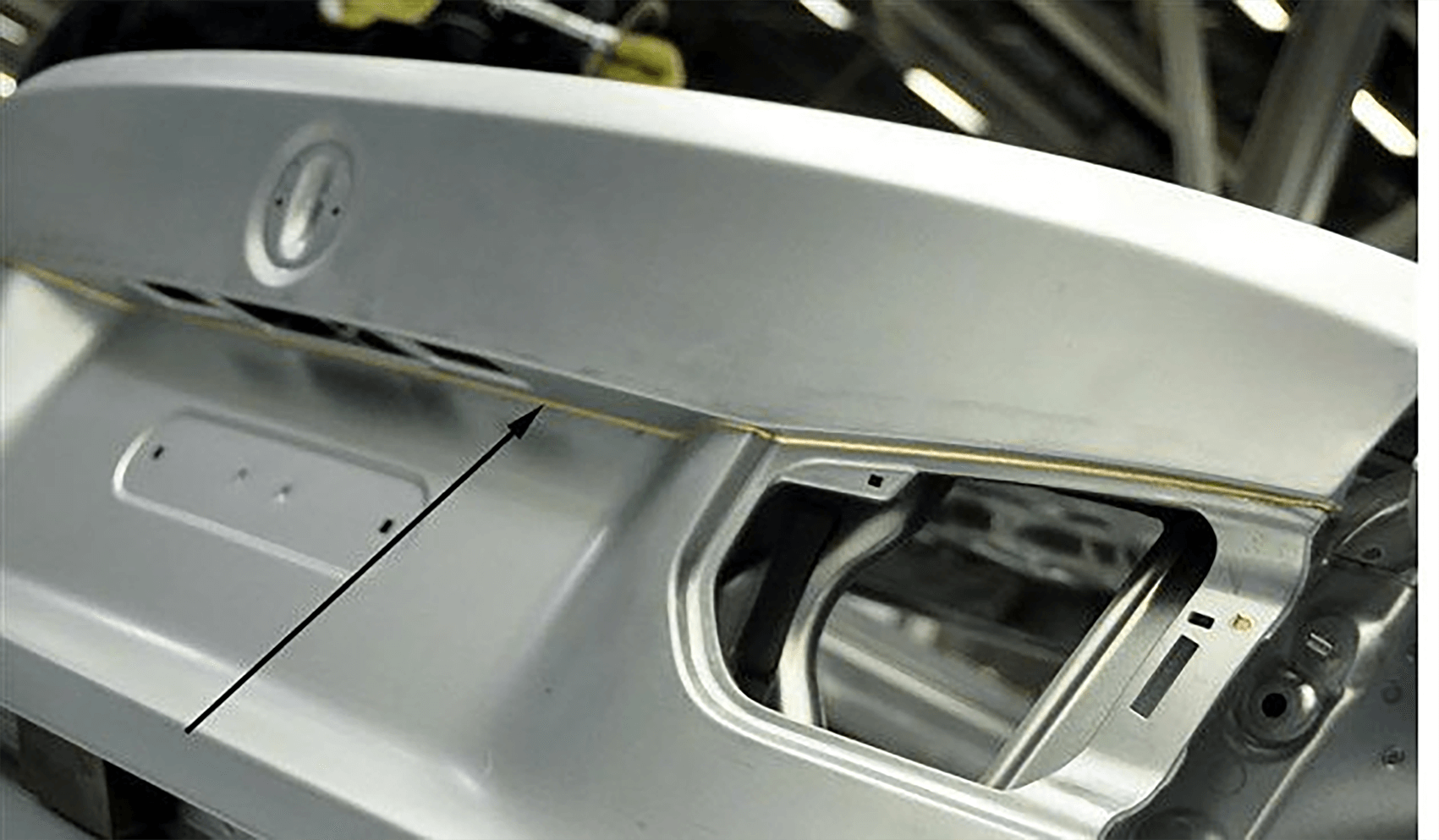

This equipment is mainly utilized in laser welding of body-in-white components, including the laser brazing of roof covers, trunk covers, and auto parts.

However, the fluctuation of parts and errors in the fixture can often complicate the laser brazing process, making the laser welding debugging process more challenging.

Swing soldering, on the other hand, can effectively adjust its welding direction, seam tracking, and focal length through automatic compensation functions.

This leads to an easier guidance and focusing of the laser beam, enabling all-directional transformations, a high degree of automation, fast welding speed, and high efficiency, thus ensuring the maintenance of welding quality.

ALO3

Fig. 6 Automotive tail door brazing

Sample brazing

Advantages:

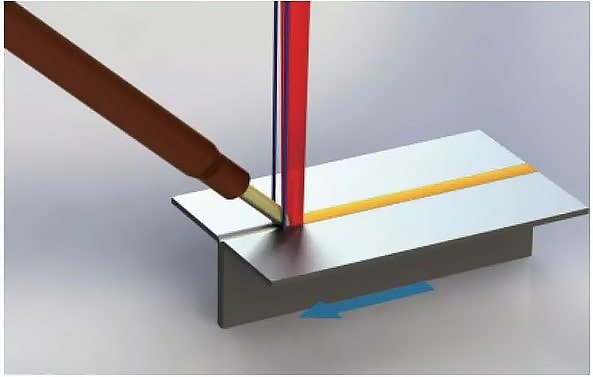

A double spot module has been added to the lens.

When welding, the three spot module in brazing optics distributes one beam into three beams, providing a solution for brazing hot-dip galvanized steel plates. This results in a smoother welding seam that does not crack.

This technology is mainly used in the aluminum alloy brazing of body-in-white components, laser brazing of roof covers and trunk covers, and brazing of automobile parts.

Principle of three spot brazing

Advantages:

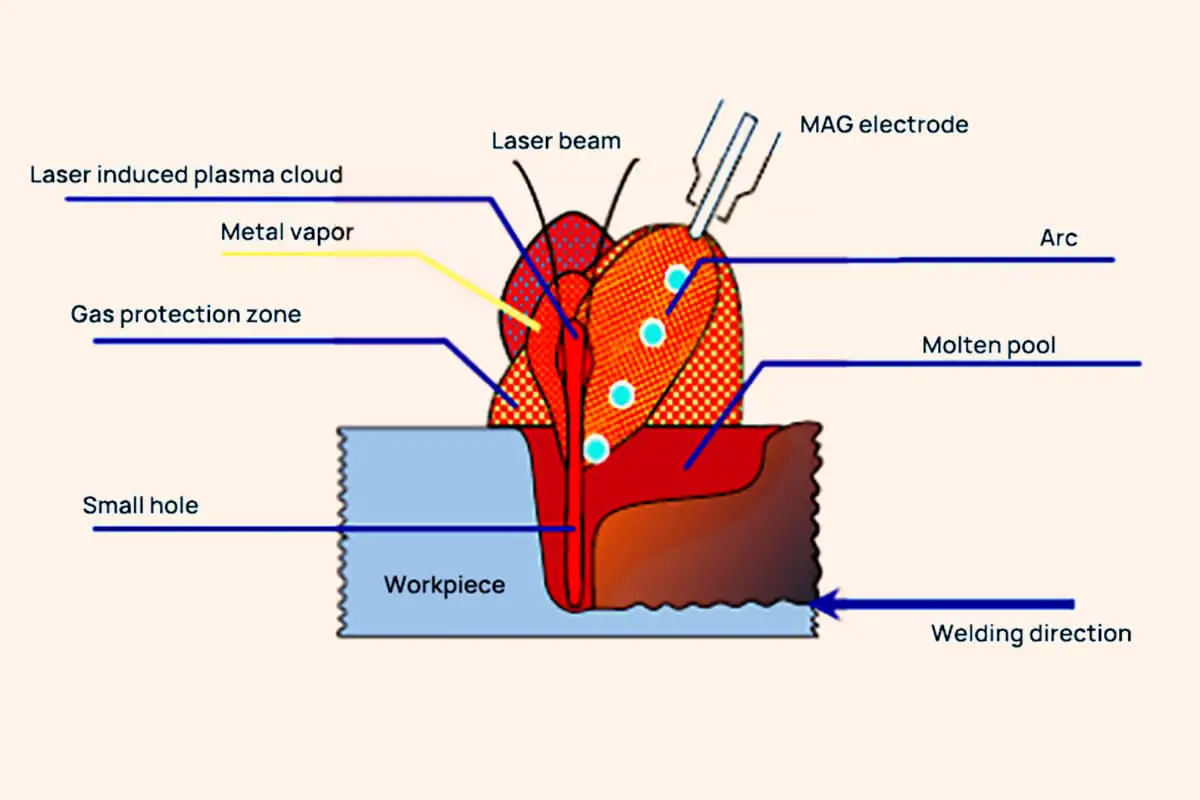

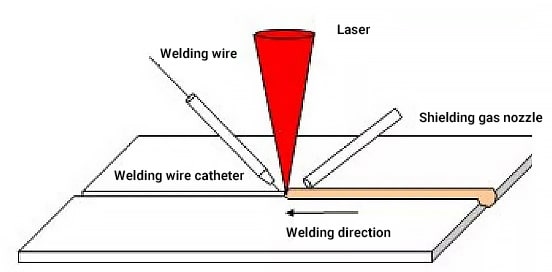

United-Win Laser was the first to create multi-wavelength hybrid welding.

This process involves overlapping the axes of two different wavelengths of laser in space by superimposing them. The main band laser is mainly used for welding, while the sub-band laser mainly preheats the welding wire and base metal, reducing the cooling rate of the molten metal in the welding pool.

Multi-wavelength hybrid welding is especially suitable for materials such as aluminum alloys, magnesium alloys, copper alloys, and others.

Hybrid welding beam

Advantages:

Currently, foreign technology and equipment still hold a leading position in the laser industry, including the laser host, optical processing head, chiller, power meter, welding monitoring, post-welding detection, TCP calibrator, and other auxiliary equipment. However, domestic enterprises are making significant strides in closing the gap.

In the area of laser welding applications, China’s technology has reached an advanced level comparable to the international standard, with several high-quality enterprises emerging.