Bearings are an important component in modern machinery. Their main function is to support rotating parts of the machinery, reduce friction coefficients during their motion, and ensure their rotational accuracy. As manufacturing technology advances, there is an increasing demand for bearings. However, problems such as premature damage and short service life have become more apparent. […]

Bearings are an important component in modern machinery. Their main function is to support rotating parts of the machinery, reduce friction coefficients during their motion, and ensure their rotational accuracy.

As manufacturing technology advances, there is an increasing demand for bearings. However, problems such as premature damage and short service life have become more apparent.

Today, I want to share with you some methods and techniques for extending the service life of bearings.

How to improve the service life of bearings?

The number of rotations or hours that a bearing can withstand before the occurrence of spalling under a certain load is known as the bearing life.

Within this life, the bearing should experience only initial fatigue damage on any of its bearing raceways or rolling elements.

However, in practical use, it can be observed that bearings with the same appearance and operating conditions have significantly different service lives.

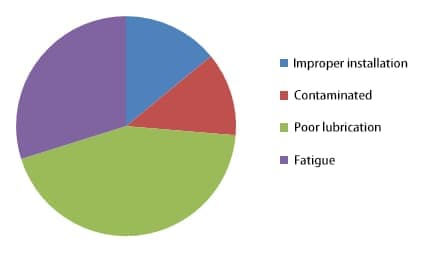

What causes this? Here are a few points that I have summarized:

1)Excessive force during installation, and hitting the bearing with a hammer causes the greatest damage and deformation.

2)Deviation in installation or failure to install the bearing correctly may result in too little bearing clearance. The inner and outer rings are not in the same rotational center, resulting in eccentricity.

Recommendation: Use appropriate or professional bearing installation tools, and use specialized equipment to check after installation.

During assembly or installation, if the internal clearance of the bearing is too large or too small, or in some cases, if the preload is too high, it may lead to early damage and a shortened lifespan of the bearing. Improper assembly and installation of bearings can cause not only downtime and costly repairs but also have additional negative effects, such as impacting the operation of other parts and shortening their service life.

Following the equipment manufacturer’s user manual for assembly, installation, and regular maintenance is the best way to prevent issues. If time is of the essence, adjustments can be made by advancing the setting device or removing shims to correct a loose tapered roller bearing unit.

On the other hand, if the bearing is adjusted too tightly, it may overheat and damage, necessitating bearing replacement. The processes for assembling and installing bearings must be accurate, repeatable, and verifiable upon completion.

It’s also essential to consider the parameters of other parts to optimize system performance. Furthermore, using the equipment according to OEM requirements and setting appropriate predictive maintenance tasks, such as monitoring lubricants or greases, which should include root cause analysis of failures, can significantly extend the operational life of problematic equipment. Proper lubrication and maintenance are critical, as is proper installation and use, supplemented by making full use of existing condition monitoring equipment.

Failing to follow installation and maintenance requirements can lead to equipment failure, posing a significant safety risk. Performing a thorough inspection after bearing installation is crucial, as it directly affects the lifespan and precision of the machine.

Improper installation can cause vibrations, excessive noise, low precision, increased temperature rise, and even the risk of seizure and burning; conversely, proper installation not only ensures precision but also significantly extends the lifespan.

Contamination can also cause premature bearing failure, which refers to the entry of sand, dust, metal chips, etc., into the bearing.

The main reasons include:

1)Opening the bearing packaging too early before use, causing contamination;

2)The installation environment is not clean, causing contamination;

3)The working environment of the bearing is not clean, and the working medium is contaminated, etc.

Recommendation: Do not open the bearing packaging before use if possible; maintain a clean installation environment, and clean the bearing before use; enhance the sealing device of the bearing.

According to research, poor lubrication is one of the main causes of premature bearing failure, which includes:

1)Failure to timely add lubricants or lubricating oil;

2)Lubricants or lubricating oil not added properly;

3)Improper selection of lubricants or lubricating oil;

4)Incorrect lubrication method, etc.

Recommendation: Select the correct lubricant or lubricating oil, and use the appropriate lubrication method.

Selecting the appropriate lubrication system and high-quality lubricants is critical. The lubricating oil film separates the contacting surfaces, providing essential protection against corrosion and wear.

Thus, for all rotating or reciprocating parts, especially bearings and gears, to function normally, the oil film is indispensable. In splash or circulating lubrication systems, the oil film also facilitates heat transfer.

Factories often experience unnecessary downtime and equipment deterioration due to improper lubrication. Insufficient lubrication can lead to increased wear and temperature rise, causing excessive wear and/or early bearing failure and damage.

Over-lubrication, especially in high-speed equipment, can generate excessive heat due to oil agitation, leading to chemical degradation of the lubricant and bearing damage. Correct lubrication and regular maintenance can prevent bearing damage caused by lubrication issues.

To ensure proper lubrication, one should:

1) Follow the usage guidelines set by the equipment manufacturer for each device;

2) When adding grease, ensure it is filled between the rolling elements of the bearing and the casing (or shield) to guarantee adequate lubrication and thorough lubrication of the critical raceway surfaces;

3) Be aware of when the bearing should be greased;

4) Monitor the equipment’s gauges to detect early signs of problems, such as temperature fluctuations and/or unusually high temperatures;

5) Pay attention to equipment noise or abnormal vibrations;

6) Observe for any lubricant leaks;

7) Regularly sample the lubricant and check for contamination.

Fatigue failure is a common way for bearings to fail. The reasons for fatigue failure may include:

1)Bearings operating under long-term overload;

2)Failure to perform timely maintenance;

3)Improper maintenance;

4)Equipment aging, etc.

Recommendation: Select the appropriate type of bearing and regularly replace fatigued bearings in a timely manner.

After installing the bearing, it is essential to perform an inspection.

(1) Inspect the Installation Position

First, check whether the moving parts collide with the fixed parts after the bearing installation, if the lubricant can flow smoothly into the bearing, and if the sealing and axial fastening devices are correctly installed.

(2) Radial Clearance Inspection

Except for bearings installed with a predetermined interference fit, the radial clearance should be checked. Deep groove ball bearings can be manually rotated for inspection, aiming for smooth, flexible movement without vibration or lateral sway.

Cylindrical roller and spherical roller bearings can be inspected using a feeler gauge. The gauge should be inserted between the roller and the bearing ring, with the insertion depth greater than half the length of the roller. When radial clearance cannot be measured with a feeler gauge, the axial movement of the bearing can be measured as an alternative to the reduction in radial clearance.

Generally, if the bearing inner ring has a tapered hole, the axial movement on the tapered surface is approximately 15 times the reduction in radial clearance. Some bearings, such as angular contact ball bearings and tapered roller bearings, allow for post-installation adjustment of radial clearance.

Others, like deep groove ball bearings, spherical ball bearings, cylindrical roller bearings, and spherical roller bearings, are pre-adjusted during manufacturing and cannot be adjusted after installation.

If these bearings fail to meet the required specifications after installation, indicating that the radial assembly clearance is too small, it could mean improper bearing selection or incorrect machining of the assembly area.

In such cases, the bearing must be removed, the cause identified and rectified before reinstallation. Excessive clearance is also problematic.

(3) Inspect the Tightness of the Bearing Against the Shaft Shoulder

In general, bearings installed with a tight interference fit must press tightly against the shaft shoulder. Inspection methods include the light method, where a lamp is aimed at the junction between the bearing and the shaft shoulder to check for light leakage.

No leakage indicates correct installation; uniform leakage around the shaft shoulder suggests the bearing is not pressed tightly enough, requiring additional pressure; partial leakage indicates a tilted installation, necessitating adjustment with a hammer, brass rod, or sleeve.

The thickness gauge method starts with a gauge of 0.03mm thickness. Inspect several points around the circumference of the inner ring end face and the shaft shoulder for gaps. Uniform gaps indicate the bearing is not properly seated, requiring more pressure on the inner ring to tighten against the shaft shoulder.

If increased pressure does not achieve tightness, the shaft neck’s fillet radius might be too large, trapping the bearing, necessitating fillet modification. If the thickness gauge passes through only at certain points, the bearing must be removed, adjusted, and reinstalled.

For bearings installed with interference fit in the bearing seat hole, the tightness of the outer ring end face against the housing shoulder can also be checked with a thickness gauge.

(4) Post-Installation Inspection of Thrust Bearings

When installing thrust bearings, check the perpendicularity of the shaft ring and the shaft centerline. This can be done by fixing a dial indicator to the housing end face and rotating the bearing while observing the dial.

If the dial indicator needle sways, it suggests the shaft ring and centerline are not perpendicular. For deep housing holes, an extended dial indicator head can be used. Properly installed thrust bearings automatically accommodate rolling element movement, ensuring the elements roll correctly between the upper and lower raceways.

Incorrect installation not only disrupts bearing function but also leads to severe wear on mating surfaces. Since the shaft ring and seat ring are not easily distinguishable, extra care is needed during assembly to avoid mistakes.

Additionally, a 0.2-0.5mm gap between the thrust bearing seat ring and the bearing seat hole compensates for machining and installation inaccuracies. This gap allows the bearing ring to adjust automatically during operation, preventing contact and friction for normal operation. Otherwise, severe bearing damage may occur.

(5) Check if Bearing Noise, Temperature Rise, and Vibration Meet the Requirements

Typically, the bearing operating temperature should remain below 90°C. Temperatures exceeding this limit may cause bearing overheating, annealing, or burnout, reducing its service life.