What makes stamping dies last longer? This blog explores the key factors that influence the longevity of cold stamping dies, including material selection, heat treatment, and maintenance practices. Learn how to optimize these elements to enhance die performance and avoid premature failures. Discover practical measures to boost the service life of your stamping dies and ensure efficient production.

Improving the quality of the die requires the reasonable selection of materials, the adoption of appropriate heat treatment processes and optimized processing techniques for different materials, which can improve the manufacturing accuracy and service life of the die and avoid early failure.

Based on this, this article mainly analyzes the factors that affect the service life of cold stamping dies and the measures to improve their life.

Today, with the rapid development of the economy, cold stamping dies are widely used in the mass production of mechanical parts by enterprises.

At the same time, in order to achieve maximum benefits, enterprises generally pay more attention to the service life of cold stamping dies.

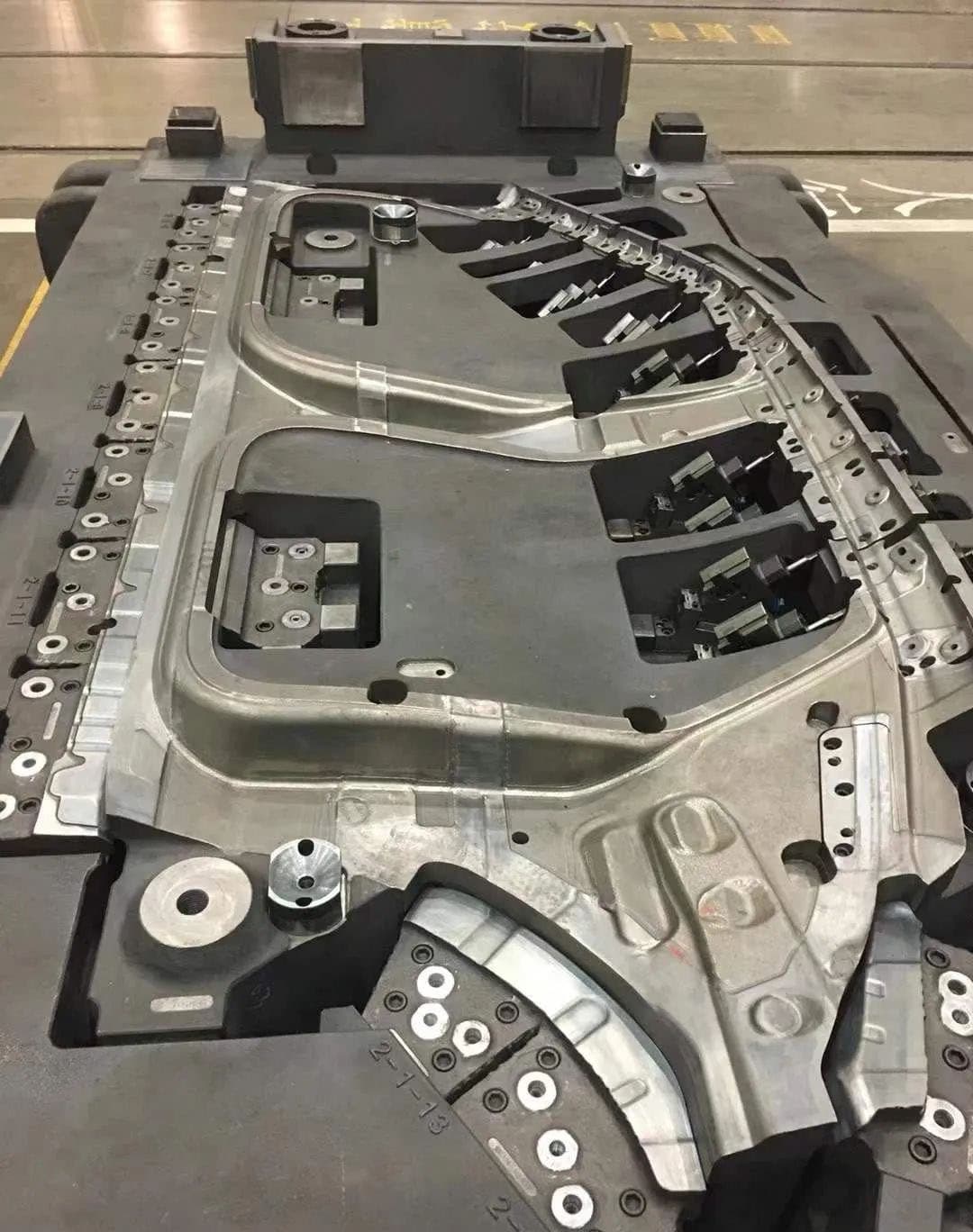

In actual production, the factors that affect the work of the die mainly include poor surface quality of the stamping material, large tolerances, unstable material properties, and impurities on the surface, all of which will accelerate the wear of the die.

In the case of drawing dies, the most important factors that affect the stamping load of the die and the degree of adhesion are the forming ability, thickness, and surface quality of the drawn material.

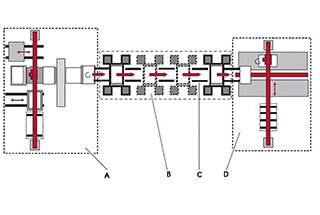

In the production of dies, due to the existence of concave and convex angles in integral dies, stress concentration can occur and cause the die to explode.

In addition, the shape and radius of concave and convex dies have a great influence on the wear of the die.

For example, in a drawing die, a smaller radius of curvature can increase the flow resistance of the blank, continuously increase the friction force, and thus cause wear on the die or fracture of the stamping.

(1) The influence of die materials on the life of the die

The die material has the greatest impact on the life of the die. The material properties of the die greatly affect the service life of the die.

For example, in the production of drawing dies, if Cr12MoV steel is used, it is easy to produce biting and drawing hair, but if GT35 type steel with a hard alloy structure is used, the tendency for biting can be greatly reduced and the service life of the die can be improved.

(2) The work hardness of the die affects the life of the die

The improvement of the hardness of the die mainly refers to the compressive strength, wear resistance, and anti-bite ability of the die steel, but it will also reduce the toughness, cold and hot fatigue resistance, and machinability of the die.

In production and daily life, the common form of failure is high hardness leading to die fracture, with deformation and wear occurring only in very few cases.

(3) The metallurgical quality of die materials affects the life of the die

The metallurgical quality of die materials primarily affects large and medium-sized sectional dies and die steels with high carbon and alloy element content.

Real-world manifestations include non-metal assimilation, carbide segregation, and intermediate looseness. For high-carbon and high-alloy steels, this easily leads to quenching cracking and initial damage to the die.

Preheat treatment, stress relief annealing after rough machining, quenching and tempering, stress relief annealing after grinding or electrical processing, etc. are all heat treatment methods for the die.

The quality of the heat treatment of the die also has a great impact on the performance and service life of the die.

A large number of facts have proved that poor heat treatment of the die can directly lead to quenching deformation and cracking of the die parts, as well as early failure during use.

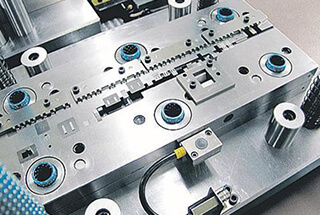

Cutting, grinding, and electrical discharge machining (EDM) are necessary machining processes for manufacturing dies. In production, these processes affect the wear resistance, fracture resistance, and strength of the die.

If the processing methods are improper, problems with processing quality are likely to occur.

(1) The impact of grinding

Improper grinding can reduce the fatigue strength and fracture resistance of the die, as a result of grinding burns and grinding cracks.

(2) The impact of EDM

Improper EDM can reduce the toughness and fracture resistance of the die. The primary reason for this phenomenon is that EDM can produce EDM burnt layers, which have large tensile stress. When the thickness is large, micro-cracks will appear.

Through the analysis of the factors affecting the service life of cold stamping dies, it can be seen that the factors affecting the service life of the die are multifaceted, and these factors should be comprehensively considered when designing the die, so as to design a more economical and efficient die.

For cold stamping dies with special purposes, economical and applicable dies should be designed based on their own requirements.

The working conditions of the convex die are worse than those of the concave die, so the material of the convex die should be of better quality than that of the concave die.

When stamping in large quantities, attention should be paid to selecting die materials with high strength, good wear resistance, and toughness.

The service life of cold stamping dies is closely related to the reasonable structural design.

At the beginning of the design, other design requirements of cold stamping dies must be guaranteed.

It is necessary to ensure the toughness, rigidity, and strength of the die to ensure that the convex and concave dies and other structural components of the die will not be deformed, damaged, or increased in wear degree due to the impact of stamping force during the stamping process.

The die design should adopt a design with guiding elements as much as possible, and the design clearance should also be considered. If the design clearance is too small or too large, it will also increase the wear degree of the convex and concave dies, leading to die damage and reduced service life.

During the stamping process, the cold-drawn billet should be phosphorized or copper-plated to reduce the friction resistance during work and prevent the adhesion and biting of the die.

Therefore, the metal plate before cold-drawing must be preheated to improve the material processing performance, reduce the possibility of cracking, and extend the service life of the die.

Lubrication during cold-drawing is also a good method. Good lubrication can obviously increase the surface smoothness of the metal plate, reduce friction resistance, reduce wear and tear, and extend the service life of the die.

Lubrication is even more important for complex-shaped parts during cold-drawing.

When storing the die, a certain gap should be maintained between the upper and lower dies to protect the cutting edge from damage.

During stamping, the depth of entry of the convex mold into the concave mold should be well controlled to prevent the wear from becoming more severe.

In stamping practice, after a period of punching and stamping, wear and groove marks will appear on the cutting edge of the die.

At this time, repairing the die can not only reduce the friction and resistance, and prevent cracks caused by wear and groove marks, but also avoid additional bending moments caused by the uneven clearance between the cutting edge of the concave die and convex die after wear, and extend the service life of the die.

After the cutting edge of the concave and convex dies is ground again, the clearance of the cutting edge becomes more uneven.

At this time, the cutting edge should be carefully ground and polished with a fine oilstone to remove grinding burrs.

Generally, the surface roughness value should reach Ra ≤ 0.10μm or below, in order to eliminate the hidden dangers of wear of the cutting edge of the concave and convex molds in a timely manner.

Good lubrication can provide the die with rust prevention function, reduce friction heat, friction and stamping force, and reduce the wear of the die, thereby extending the service life of the die.

For example, when punching silicon steel sheets in a transformer, if lubrication is good, the service life of the die is about 15 times that of the die with poor lubrication. Moreover, the proper use of lubricants can also extend the service life of the die.

The service life of cold stamping dies is proportional to their processing accuracy and quality, and the higher the accuracy and quality, the longer the service life.

During the installation of the die, we need to strictly control the gap between the convex and concave molds to reduce wear.

Correctly selecting suitable and high-precision stamping equipment and appropriate pressure can effectively extend the service life of the die.

At the same time, to reduce wear, appropriate lubricants should be applied to the stamped metal sheets, and the die should be sealed and stored properly when not in use.

With the continuous development of modern industrial technology, the structure and performance of industrial products are becoming more and more complex, and the demand for high-performance materials in high-temperature, high-speed, high-friction, and corrosive working environments is also increasing.

Cold stamping dies have unique advantages in high production efficiency, and are widely favored by enterprises.

However, the working environment of cold stamping dies is very harsh, so the working performance of cold stamping dies has very strict requirements, and the die must have high life, high precision, and high performance in the production process.

The economic cost and efficiency of processing are closely related to the service life of stamping dies. The service life of stamping dies is a major indicator of evaluating a country’s die manufacturing level.