Imagine cars, planes, and even buildings being stronger yet significantly lighter. This isn’t science fiction—it’s the promise of lightweight design. In this article, we explore innovative materials like aluminum, magnesium, and titanium, and cutting-edge manufacturing techniques that make it possible. Discover how these advancements not only improve performance but also contribute to a greener planet by reducing energy consumption and emissions. Dive in to learn how lightweight design is revolutionizing various industries and shaping a sustainable future.

Lightweight design is the future of manufacturing—it reduces carbon emissions and enhances component performance.

The substantial environmental and economic benefits of pursuing lightweight design innovations ensure its continued significance as a key area of investment and research across many industries, both now and in the coming years.

This article presents an overview of the materials, techniques, and future solutions of lightweight design.

Essentially, lightweight design is the practice of reducing the amount of material in a component, without compromising reliability or functionality, to diminish its overall weight.

Currently, nations worldwide are imposing demands across all industries to reduce energy consumption and greenhouse gas emissions.

Lightweight design aims to provide manufacturers with the necessary solution to address the challenges of climate change, while achieving superior component performance and extending product lifespan.

Most commonly observed in the automotive and aerospace industries, lightweight design improves fuel efficiency and boosts the performance of airplanes and electric vehicles.

However, it’s worth noting that lightweight design is also driving innovation in the construction, renewable energy, and the manufacturing sectors of electronic and electrical products. Lighter components lower transportation and energy costs, and more resource-efficient production methods are adopted across all these sectors.

Lightweight materials are those that can be used to decrease product weight and enhance overall product performance. Material lightweighting involves reducing weight by using lightweight metals and non-metals that meet mechanical performance requirements.

In the current automotive manufacturing sector, lightweight materials primarily include aluminum, magnesium, and titanium alloys.

Aluminum is widely used in the automotive industry due to its lightweight properties. Automotive industry analysts suggest that using aluminum alloy parts can reduce vehicle weight by up to 50% without sacrificing safety or performance.

Aluminum’s malleability, durability, and lightness also make it a popular material for manufacturing consumer goods, electronics, and airplanes.

As hybrid and electric vehicle trends continue, car manufacturers will continue to regard aluminum as the material of choice due to its low cost, high performance, and exceptional weight reduction characteristics.

Magnesium alloys have the lowest density of all structural metals, being 33% lighter than aluminum, 50% lighter than titanium, and 75% lighter than steel, potentially reducing component weight by up to 70%.

Magnesium has proven to be a valuable material for lightweight design engineers. It’s easy to process, has good structural strength, and is widely used in the automotive and aerospace industries as well as in manufacturing consumer goods. In the automotive sector, magnesium is currently used for powertrain or subcomponent enclosures.

Its low density and high specific strength mean that magnesium is used as a lightweight component in everything from airplanes and missiles to laptops and TVs. In addition to components and structural elements, magnesium-based batteries are currently being developed for the automotive industry.

An analysis by the US Automotive Materials Partnership indicated that 113 kg of magnesium could replace 226 kg of steel. 40 kg of magnesium could replace 68 kg of aluminum. This leads to a reduction in vehicle weight by 15%.

China plans to increase the amount of magnesium components used in vehicle production to 45 kg per vehicle by 2030.

The global magnesium market was valued at $4.115 billion in 2019 and is expected to reach $5.9281 billion by 2027. China produces about 85% of the world’s magnesium.

Titanium has excellent corrosion resistance, anti-magnetic properties, good shielding against electric fields and electromagnetic fields, resistance to extreme temperatures, and higher tensile strength than steel, while only weighing half as much.

In recent years, the production of titanium alloys has made significant progress. They are used to manufacture turbine blades, aircraft frames, resistors, circuit boards, surgical instruments, and more. The automotive industry manufactures lightweight titanium alloy exhaust systems, engines, transmissions, and frames.

The global demand for titanium is expected to increase from $24.7 billion in 2021 to $33.5 billion in 2026.

As various industries strive to create lighter components to fulfill their environmental objectives, innovative manufacturing techniques are propelling this forward. Companies are seeking new methods for fabricating low-cost, high-performance components, and rheocasting is now broadly superseding thixocasting.

One of the primary advantages of rheocasting is its capacity to cast metals with a vast range of solid fractions, effectively and economically producing lightweight parts with high strength and good ductility.

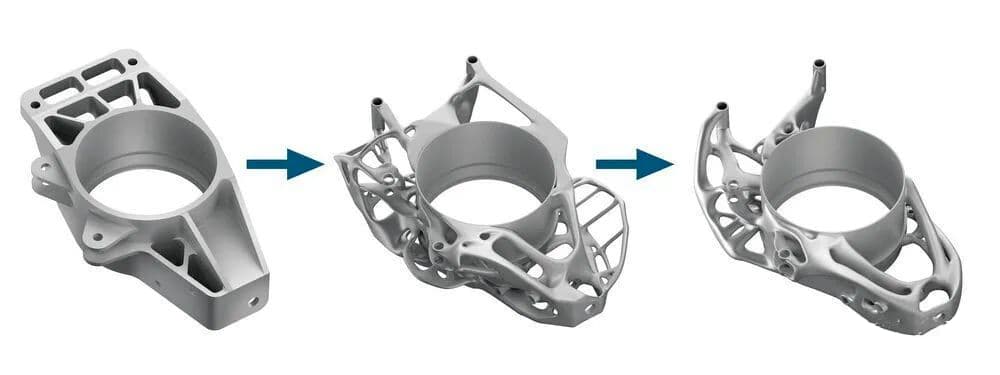

Advancements in additive manufacturing (3D printing) technologies have granted engineers unprecedented design freedom. Additive manufacturing allows manufacturers to fabricate complex geometries at significantly reduced costs compared to traditional die casting techniques.

It’s also utilized to decrease part weight by transforming solid geometries into hollow structures or replacing solid structures with internal lattice designs. Indeed, there now exists a range of lightweight parts that can only be produced using additive manufacturing techniques.

The future of lightweight design will continue to focus on the use of aluminum, magnesium, and titanium alloys, but will also incorporate composite materials like carbon or glass fiber-reinforced polymers.

Many companies are currently concentrating on developing plastic-based hybrid lightweight parts for the aerospace and automotive industries.

Innovations in computer software and additive manufacturing technologies will enable the development of lighter products, parts, and structures.

Engineers can identify areas where weight can be most effectively reduced using specialized software, achieving maximum topology optimization for a range of components. Digital 3D models can then test the performance of the lightweight parts to determine the best design options.

Biomimicry design and bionics may represent the future of lightweight design. Engineers and scientists are producing components based on lightweight, multifunctional structures found in nature.

Examples of this include the Airbus 2050 concept plane, which has adopted a skeleton-based fuselage. Recent research focuses on the exoskeletons of single-celled plankton, honeycomb structures, grass stem structures, and the epidermal cells and wings of butterflies.

By combining ongoing technological and scientific innovation with a deeper understanding of nature, manufacturers and industries will continue to develop lighter, stronger components to assist humanity in achieving shared goals of reducing CO2 emissions and addressing climate change.