Imagine a world without lubricants. Machines grind to a halt, engines seize up, and progress stalls. In this article, we dive into the complex world of lubricant classification and selection, shedding light on the crucial role these unsung heroes play in keeping our mechanical marvels running smoothly. Join us as we explore the intricacies of this fascinating field, guided by the insights of seasoned experts in mechanical engineering.

Lubricants can be categorized into four distinct types based on their physical states: liquid lubricants, semi-solid lubricants, solid lubricants, and gaseous lubricants. Each category possesses unique characteristics and applications in various industrial and mechanical processes

1. Liquid Lubricants

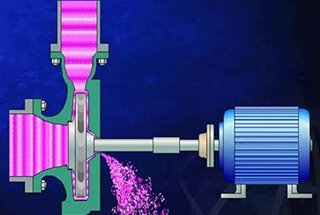

Liquid lubricants represent the most diverse and widely utilized category of lubrication materials in industrial applications. This group encompasses mineral lubricating oils, synthetic lubricating oils, bio-based oils (animal and vegetable), and water-based fluids.

The hallmark of liquid lubricants is their broad viscosity range, enabling precise selection for mechanical components operating under varied loads, speeds, and temperatures. This versatility allows for optimized lubrication across a wide spectrum of industrial processes and machinery.

(1) Mineral Lubricating Oil: Currently dominating the market, mineral oils account for approximately 90% of total lubricant volume. These oils are formulated by blending refined petroleum-based base oils with performance-enhancing additives. The additives typically include anti-wear agents, antioxidants, corrosion inhibitors, and viscosity modifiers, tailoring the oil’s properties to specific applications.

(2) Synthetic Lubricating Oil: Engineered through chemical synthesis, synthetic oils offer superior performance characteristics compared to mineral oils. They exhibit enhanced thermal stability, oxidation resistance, and viscosity index, making them ideal for extreme operating conditions. Common types include polyalphaolefins (PAOs), synthetic esters, and polyalkylene glycols (PAGs).

(3) Bio-based Oils: Derived from animal fats or plant sources, these environmentally friendly lubricants are gaining traction due to their biodegradability and renewability. Rapeseed, soybean, and palm oils are common vegetable-based lubricants, while sperm whale oil (now largely phased out) was historically used in precision instruments.

(4) Water-based Fluids: These lubricants incorporate water as a key component, offering excellent cooling properties and fire resistance. They are categorized into two main types:

2. Semi-solid Lubricants (Grease)

Semi-solid lubricants, commonly referred to as grease, exhibit a unique consistency between solid and liquid states at standard temperature and pressure. These lubricants are characterized by their colloidal structure, typically consisting of a thickening agent dispersed in a liquid lubricant base oil.

Grease possesses several key properties that make it invaluable in various industrial applications:

The consistency of grease is typically classified using the National Lubricating Grease Institute (NLGI) grade system, ranging from 000 (very soft) to 6 (very hard). This classification helps engineers select the appropriate grease for specific applications based on factors such as operating temperature, load, and speed.

Modern grease formulations often incorporate advanced additives to enhance performance characteristics, such as extreme pressure (EP) additives for high-load applications or anti-oxidants for extended service life. The choice of thickener (e.g., lithium, calcium, polyurea) and base oil (mineral or synthetic) significantly influences the grease’s properties and suitability for different industrial uses.

3. Solid Lubricants

Solid lubricants operate through three primary mechanisms, each leveraging unique material properties to reduce friction and wear in mechanical systems. These lubricants are particularly valuable in extreme conditions where conventional liquid lubricants may fail.

The first category forms a tenacious, low-shear strength film on friction surfaces, mimicking boundary lubrication. This film adheres strongly to the substrate while allowing easy shearing between sliding surfaces, effectively reducing friction and wear. Examples include molybdenum disulfide (MoS2) and tungsten disulfide (WS2).

The second type encompasses soft metal solid lubricants, such as lead, indium, and silver. These materials exploit their inherently low shear strength and high plasticity to provide effective lubrication. Under load, they deform easily, creating a thin, protective layer between moving parts that accommodates relative motion with minimal resistance.

The third mechanism involves lamellar solids with a characteristic layered crystal structure, exemplified by graphite and hexagonal boron nitride. These materials possess weak interlayer bonds, allowing easy shearing parallel to the basal planes. This structural feature enables the formation of a transfer film on mating surfaces, facilitating smooth relative motion.

In industrial applications, the most widely employed solid lubricants are:

These solid lubricants find extensive use in aerospace, automotive, and heavy industry sectors, where they often outperform liquid lubricants under extreme temperatures, pressures, or environmental conditions.

4. Gas Lubricants

Gases, as compressible fluids, adhere to the principles of fluid dynamics and lubrication theory, enabling them to function as effective lubricants under specific conditions, similar to their liquid counterparts.

The advantages of gas lubricants are manifold:

However, gas lubricants also present certain limitations:

These characteristics make gas lubrication particularly suitable for high-speed, low-load applications such as air bearings in precision metrology equipment, turbomachinery, and certain aerospace components. The choice between gas and liquid lubrication ultimately depends on the specific requirements of the application, including speed, load, temperature, and environmental considerations.

Base oil is the fundamental component of lubricants, typically constituting 80% to 95% of the total volume, and serves as the carrier for performance-enhancing additives. Base oils are broadly categorized into two main types: mineral oils and synthetic oils.

(1) Mineral Oil

Mineral oils, derived from crude oil through refining processes, are classified in most countries, including ours, into three primary categories based on their molecular structure and properties:

(2) Synthetic Oil

Synthetic base oils are engineered through controlled chemical reactions, resulting in molecules with specific, desired properties. They offer several advantages over mineral oils:

These characteristics make synthetic oils the preferred choice for high-performance applications and represent the future trajectory of lubricant technology.

Synthetic oils are currently indispensable in aerospace applications and are rapidly gaining traction in industrial machinery. The most common types of synthetic base oils include:

Additives are minor yet crucial constituents incorporated into lubricants to significantly enhance specific characteristics or introduce new properties. Their functions are as follows:

(1) Detergents.

Primarily utilized in internal combustion engine oils to remove lacquer and carbon deposits from cylinder walls and piston rings. They also effectively disperse gum and soot particles throughout the oil, preventing agglomeration and the formation of larger, potentially harmful particulates.

(2) Antioxidants.

These compounds inhibit the oxidation process of the lubricating oil, thereby extending its service life and maintaining its performance characteristics over time. They work by neutralizing free radicals and breaking down peroxide compounds.

(3) Anti-wear agents.

These additives improve the oil’s resistance to wear and scuffing by forming a protective film on metal surfaces. They reduce equipment wear, prevent seizing or sintering, and are particularly crucial in high-pressure and high-temperature applications.

(4) Oiliness agents.

Also known as friction modifiers, these additives reduce the friction coefficient and enhance lubrication performance by forming a tenacious, adsorbed film on metal surfaces. This film provides boundary lubrication under severe operating conditions.

(5) Metal deactivators.

They form a passive film on metal surfaces to minimize the corrosive impact of the oil on the metal and inhibit the catalytic oxidation of the oil by metal ions. This is particularly important in systems containing copper or its alloys.

(6) Viscosity index improvers.

These polymeric additives increase the oil’s viscosity index, enhancing its visco-thermal performance. They expand at higher temperatures, counteracting the natural tendency of oil to thin out, thus maintaining adequate lubrication across a wide temperature range.

(7) Rust inhibitors.

These additives act upon the metal surface to prevent rust or corrosion when in contact with water. They form a protective barrier that repels water and prevents its interaction with the metal surface.

(8) Pour point depressants.

They lower the oil’s pour point by modifying the crystallization of wax particles at low temperatures, thus improving the oil’s low-temperature fluidity and pumpability. This is crucial for cold-start performance and operation in low-temperature environments.

(9) Defoamants.

These additives alter the oil’s tendency to foam by reducing surface tension and causing surface bubbles to burst quickly. This prevents air entrainment, which can lead to reduced lubricant effectiveness and increased oxidation.

(10) Emulsifiers and anti-emulsifiers.

Emulsifiers are used in emulsifying oils to form a uniform and stable emulsion with water, essential for certain lubricant applications like metalworking fluids. Conversely, anti-emulsifiers, or demulsifiers, are used in general lubricants to facilitate rapid separation of water from oil, maintaining lubricant integrity and preventing corrosion.

Thickeners are a critical component of lubricating grease, fundamentally distinguishing it from lubricating oil. Lubricating grease is a complex colloidal system composed of thickeners dispersed in base oil, along with performance-enhancing additives. This unique composition results in a solid or semi-solid substance with viscoelastic properties, capable of withstanding high loads and maintaining its structure under shear stress.

Thickeners play a multifaceted role in grease formulation, significantly influencing several key properties:

The selection of appropriate thickeners is critical in tailoring grease properties to specific applications, from high-speed bearings to heavy industrial machinery operating in challenging environments.

The selection of lubricating oil is governed by three primary factors: the equipment’s actual operating conditions, the manufacturer’s specifications or recommendations, and the oil supplier’s guidelines. While manufacturers’ recommendations typically form the basis for lubricant selection, it’s crucial to consider the equipment’s specific load, speed, and temperature conditions in real-world applications.

When selecting a lubricating oil, the following performance indicators are critical:

Viscosity serves as the primary criterion for classifying and grading lubricating oils, playing a decisive role in quality identification and performance determination. The optimal viscosity for equipment lubrication is determined based on design specifications or calculated data, often referencing industry-standard viscosity charts and operating conditions.

The pour point is an indirect measure of a lubricating oil’s low-temperature fluidity, critical for storage, transportation, and usage in cold environments. Industry best practices dictate that the operating temperature should be 5-10°C higher than the pour point to ensure adequate flow and lubrication.

As a key safety indicator, the flash point is crucial for the safe storage, transportation, and use of lubricating oil. A general rule of thumb is to set the flash point at least 50% higher than the maximum expected operating temperature. For instance, in an internal combustion engine where the oil temperature in the bottom shell doesn’t exceed 120°C, the minimum flash point for the engine oil should be set at 180°C.

This property indicates the oil’s resistance to degradation under high temperatures and in the presence of oxygen, affecting its service life and performance over time.

Modern lubricating oils often contain additives to enhance specific properties such as anti-wear characteristics, corrosion resistance, and detergency. The selection of an appropriate additives package is crucial for optimizing performance in specific applications.

Ensure the chosen lubricant is compatible with the equipment’s materials, including seals, gaskets, and metal surfaces, to prevent degradation or chemical reactions.

Given the complexity of lubricating oil performance indicators and the significant variations between different types, the final selection should be made through a rational analysis of the equipment’s operating conditions, manufacturer requirements, and the oil product’s specifications. It’s advisable to consult with both equipment and lubricant manufacturers when making the final decision, especially for critical applications or when operating conditions deviate significantly from standard parameters.

Proper lubricant selection is critical for optimal equipment performance and longevity. Each lubricant possesses unique characteristics tailored to specific applications, making direct substitution challenging. When substitution becomes unavoidable, adhere to these comprehensive guidelines to minimize potential risks:

(1) Select a substitute from the same lubricant family or with closely matched performance attributes. This ensures compatibility with seals, bearings, and other system components. Pay particular attention to base oil type, additive package, and performance ratings (e.g., API, ISO, DIN standards).

(2) Maintain viscosity consistency within a narrow range. The kinematic viscosity of the substitute oil should not deviate by more than ±15% from the original at the operating temperature. Preference should be given to slightly higher viscosity options to ensure adequate film thickness and load-carrying capacity, especially in boundary lubrication conditions.

(3) Opt for higher quality substitutes when feasible. Superior base stocks (e.g., Group III or synthetic oils) and advanced additive technologies can offer enhanced oxidation stability, improved wear protection, and extended service intervals. However, ensure compatibility with system materials and existing lubricants if a complete oil change is not possible.

(4) Consider the equipment’s operating environment holistically. Factors such as ambient temperature range, potential contaminants, humidity levels, and load variations should influence the substitute selection. For extreme temperature applications, synthetic lubricants with high viscosity index (VI) may be preferable to maintain proper viscosity across a wider temperature range.

(5) Consult equipment manufacturers and lubricant suppliers for specific recommendations. They can provide valuable insights into potential compatibility issues, performance trade-offs, and any necessary modifications to maintenance schedules or procedures following a lubricant substitution.

(6) Implement a thorough flushing procedure when switching between incompatible lubricants to prevent adverse reactions or deposit formation. Monitor equipment performance closely after substitution, including oil analysis at shortened intervals, to ensure the new lubricant meets system requirements.

Mixing different types, brands, manufacturers, and conditions (new or used) of lubricating oils should be avoided whenever possible due to potential incompatibilities and performance degradation. The following combinations are strictly prohibited:

(1) Specialty or application-specific oils must not be mixed with other oil types.

(2) Oils formulated for emulsion resistance must not be combined with non-emulsion resistant variants.

(3) Ammonia-resistant turbine oils must remain separate from standard turbine oils.

(4) Zinc-containing anti-wear hydraulic oils are incompatible with silver-safe hydraulic fluids.

(5) Conventional gear oils must not be mixed with worm gear lubricants due to different additive packages and viscosity requirements.

However, certain oil combinations may be acceptable under specific circumstances:

(1) Products from the same manufacturer with comparable quality ratings and specifications.

(2) Different branded products from a single manufacturer, provided they share similar base stocks and additive chemistries.

(3) Base oils of different types, if mixed in a formulation without additives (though this is rare in modern lubricants).

(4) Oil types that have demonstrated compatibility through rigorous mixing tests and stability studies.

(5) Internal combustion engine oils, despite containing various additives, may be mixed in emergency

When selecting a lubricating grease, the primary consideration should be its function, namely, its role in lubrication, friction reduction, protection, and sealing.

For friction-reducing greases, main factors include resistance to high and low temperatures, load, and rotational speed.

For protective greases, the focus is on the media and materials in contact, particularly the protective properties and stability for metals and non-metals. For sealing greases, considerations should include the materials and media in contact and the compatibility of the grease with the material (especially rubber) to select the appropriate lubricating grease.

The choice of lubricating grease should consider the operating temperature, rotational speed, load size, working environment, and grease supply method of the machinery. General considerations include the following factors:

(1) Temperature.

The impact of temperature on lubricating grease is significant.

It is generally believed that when the operating temperature of the lubrication point exceeds the upper limit of the grease temperature, evaporation loss, oxidative degradation, and colloidal shrinkage of the base oil of the grease accelerate.

For every increase in temperature by 10℃ to 15℃, the oxidation speed of the grease increases by 1.5 to 2 times, and the lifespan of the grease decreases by half. The operating temperature of the lubrication point also changes with the ambient temperature.

In addition, factors such as load, speed, continuous operation, and overfilling of grease can also affect the operating temperature of the lubrication point.

For environments with high ambient temperatures and machines operating at high temperatures, high-temperature-resistant grease should be used. The temperature of the general grease should be 20℃ to 30℃ below its dropping point (temperature).

(2) Rotational Speed.

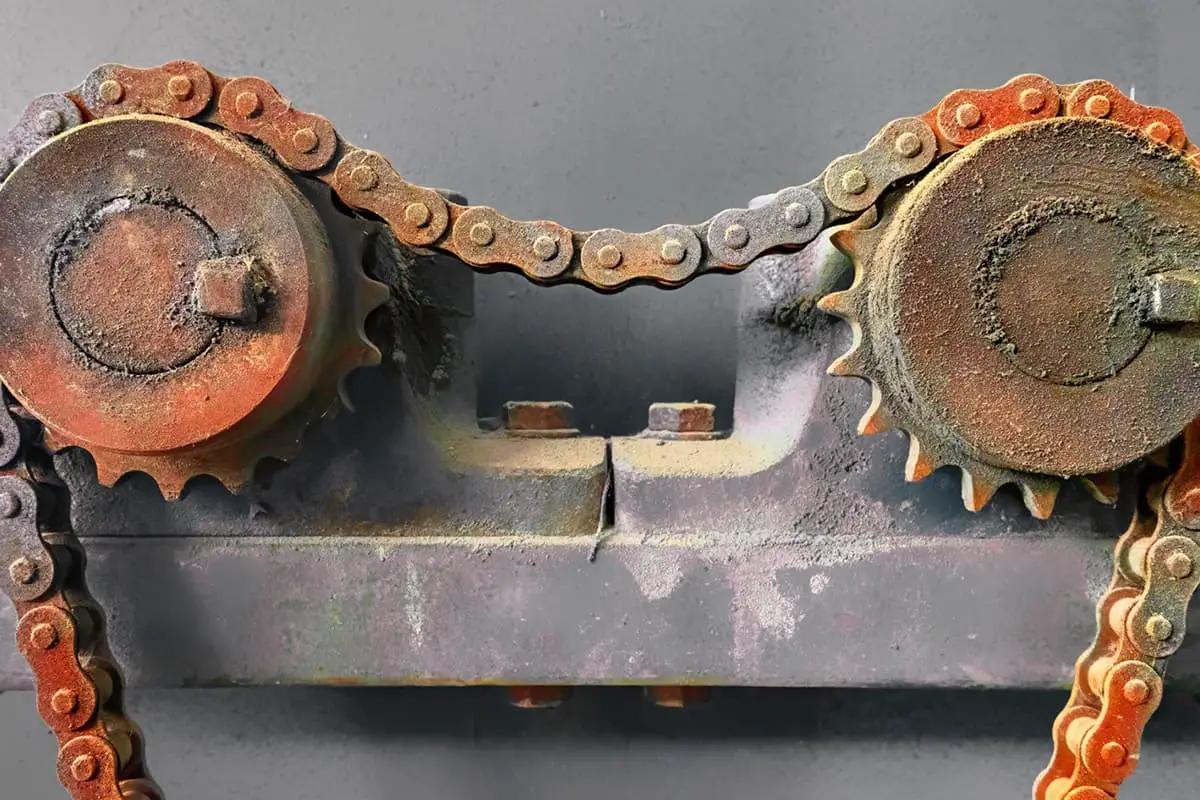

The higher the operating speed of the lubricated components, the greater the shear stress experienced by the lubricating grease, and the more significant the damage to the fibrous structure formed by the thickener, thereby shortening the lifespan of the grease.

If the equipment’s operating speed doubles, the lifespan of the lubricating grease reduces to one-tenth of its original duration.

Components operating at high speeds generate more heat and at a faster rate, potentially thinning the lubricating grease and causing it to leak out. Therefore, a thicker lubricating grease should be used in such scenarios.

(3) Load.

Choosing the right lubricating grease according to the load is a key aspect in ensuring effective lubrication.

For high-load lubrication points, lubricating grease with a high viscosity base oil, high thickener content, and superior extreme pressure and anti-wear properties should be selected. The cone penetration of the lubricating grease is directly related to the load it can handle during use.

For high-load conditions, lubricating grease with a smaller cone penetration (higher viscosity) should be selected.

If the application involves both heavy and impact loads, lubricating grease with extreme pressure additives, such as those containing molybdenum disulfide, should be used.

(4) Environmental Conditions.

Environmental conditions refer to the working environment and surrounding media of the lubrication point, such as air humidity, dust, and the presence of corrosive substances.

In damp environments or situations involving contact with water, water-resistant lubricating grease should be selected, such as calcium-based, lithium-based, complex calcium, or complex sulfonate calcium greases. Under severe conditions, rust-preventive lubricating grease should be used instead of sodium-based grease with poor water resistance.

In environments with strong chemical media, synthetic greases resistant to chemical media, such as fluorocarbon greases, should be used.

(5) Other Factors.

In addition to the points mentioned above, the cost-effectiveness of the lubricating grease should also be considered when selecting it.

This involves a comprehensive analysis of whether using the grease extends the lubrication cycle, the number of grease additions, grease consumption, bearing failure rate, and maintenance costs, among other factors.

(6) The Relationship Between Grease Viscosity and Application.

Table: Applicability range with respect to grease viscosity.

| NLGI Grade | Application Scope |

| 000 Grade, 00 Grade | Primarily used for lubricating open gears and gearboxes. |

| 0 Grade | Primarily used for lubricating open gears, gearboxes, or centralized lubrication systems. |

| 1 Grade | Primarily used for lubricating needle bearings or roller bearings operating at higher speeds. |

| 2 Grade | Most widely used for lubricating anti-wear bearings operating under medium load and medium speed. |

| 3 Grade | Primarily used for lubricating anti-wear bearings operating under medium load and medium speed, as well as automotive wheel bearings. |

| 4 Grade | Primarily used for lubricating bearings and shaft collars in water pumps and other high-load, low-speed applications. |

| 5 Grade, 6 Grade | Primarily used for lubrication under special conditions, such as ball mill neck lubrication. |

Reference Indicators for Grease Failure

| Project | Reference Indicators for the Failure of Lubricating Grease |

| Drip Point | Lubricating grease should be discarded when the drop point falls into the following ranges: 1. Lithium-based lubricating grease drop point (temperature) falls below 140°C. 2. Composite lithium-based lubricating grease drop point (temperature) falls below 200°C. 3. Calcium-based lubricating grease drop point (temperature) falls below 50°C. 4. Composite calcium-based lubricating grease drop point (temperature) falls below 180°C. 5. Sodium-based lubricating grease drop point (temperature) falls below 120°C. |

| Viscosity | When the cone penetration of the lubricating grease changes by more than +20%, the grease should be discarded. |

| Oil Content | If the percentage of the oil content in the used lubricating grease to the oil content in the new grease falls below 70%, the grease should be discarded. |

| Ash Content | When the ash content change rate of the tested sample exceeds 50%, the grease should be discarded. |

| Corrosion | If the lubricating grease fails the copper strip corrosion test, it should be discarded. |

| Oxidation | When the lubricating grease generates a strong rancid odor, or the acid value of the lithium-based grease exceeds 0.3mg/g (KOH), it should be replaced with new grease. |

| Mechanical Impurities | If particles larger than 125μm are mixed into the lubricating grease during use, it should be replaced with new grease. |