How often should you lubricate your guillotine shear to ensure its optimal performance? In this article, we delve into the essential lubrication practices that keep this vital equipment running smoothly. Learn the recommended types of lubricants, specific lubrication points, and the ideal maintenance schedule to extend your machine’s lifespan and efficiency. This guide will provide you with practical tips and a clear understanding of proper lubrication techniques.

Proper lubrication is crucial for ensuring optimal performance and extending the service life of machinery. Adherence to manufacturer-specified lubrication protocols is essential for all users.

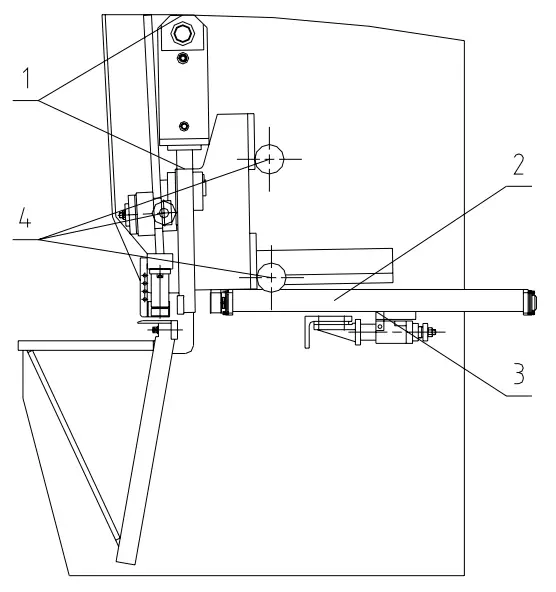

During the lubrication process, utilize a grease gun to apply calcium-based grease to each designated lubrication point. Regular inspection, maintenance, and cleaning of these lubrication points are necessary to prevent contamination and ensure effective lubrication.

The table below outlines the primary lubrication points, recommended lubrication intervals, and specified lubricants for the machine:

| No. | Lubrication point | Refueling interval | Type of lubricating oil |

| 1 | Upper and lower ends of left and right cylinders | One month | Calcium base grease |

| 2 | Left and right linear guide rail pairs of rear stop | One week | Calcium base grease |

| 3 | Rear stop left and right ball screw pairs | One week | Calcium base grease |

| 4 | Joint bearing with six rolling fulcrum | One day | Calcium base grease |

Note: Refer to the machine’s technical documentation for the exact location of lubrication points and any specific application instructions. Ensure that the calcium-based grease used meets the manufacturer’s specifications for viscosity, temperature range, and load-bearing properties to maintain optimal equipment performance and longevity.