Have you ever considered the importance of proper maintenance for your mechanical punch press? In this blog post, we’ll explore the key aspects of maintaining these powerful machines, drawing insights from seasoned experts in the field. Discover essential tips and techniques that will help you keep your punch press running smoothly, minimize downtime, and extend its lifespan. Get ready to learn how to optimize your machine’s performance and efficiency!

The inspection and maintenance of a punch press are vital measures to ensure its normal operation and prolong its service life. Here are some key aspects of punch press inspection and maintenance:

Daily Cleaning and Lubrication: Regularly clean the machine surface, check oil pressure, ensure each switch and function button is working properly, clean and oil the slide rails and screws weekly, and monthly add grease to the linear slide rails, screws, and sliders, clean the oil delivery tube, and inspect and clean the main engine box and distribution box.

Electrical System Inspection: This includes electromagnetic valves other than the clutch electromagnetic valve, ensuring they are clean, dust-free, water-free, and properly tightened. Also, check the pneumatic system to ensure the air path is clear, cylinders are flexible, and valves are reliable.

Inspection and Adjustment of Mechanical Parts: This includes comprehensive clearance, parallelism, and perpendicularity inspection and adjustment of the machine body, transmission parts, clutch parts, brake, and balance cylinder. Particularly, the clearance adjustment between the slider and the guide rail is crucial for precision.

Safety Device Inspection: Ensure each safety device, such as photoelectric protection safety eyes, emergency stop button switches, etc., is working properly.

Troubleshooting and Maintenance: During operation, if issues like insufficient clearance or poor lubrication arise, the guide rail should be re-ground, clearance adjusted, and lubrication monitored. For CNC punch presses, it is also necessary to check whether the oil in the bearings is clean and whether there is enough lubricating oil.

Regular Maintenance: After every 1500-2000 hours of use, maintenance should be performed, including inspection and adjustment of the punch press slide grease discharge volume and pressure detection function, filter, oil feeder adjustment valve, and other functions, as well as water impurity testing and necessary adjustments.

Consideration of Environmental Factors: Choose an appropriate operating environment, such as temperature, humidity, vibration, power voltage, etc., to accommodate the characteristics of the CNC punch press.

The best practices for daily cleaning and lubrication of punch presses primarily include the following aspects:

Clean and lubricate the guide rails every day to ensure the normal operation of the machine tool and extend its service life. For machine tools with automatic lubrication systems, regularly check and clean the automatic lubrication system, check the oil level, timely add lubricating oil, and ensure the oil pump starts and stops on schedule.

Regularly wipe down all parts of the machine tool to keep it clean, while also checking if any fasteners are loose, and cleaning the wool line and felt, etc., to maintain the good working condition of the machine tool.

For new machines or specific parts (like flywheels), add a suitable amount of lubricating oil (such as yellow oil) during the initial use to reduce wear and increase work efficiency.

Ensure that the lubrication oil pump works normally, the oil pressure switch functions correctly, and the air system can regulate pressure and filter, ensuring the stable operation of the system.

For precision high-speed punch presses, the oil tank, pipelines, and filters should be cleaned and the oil changed once two months after the first use, and then cleaned every six months, and regularly change the oil and clean it according to actual conditions to maintain the cleanliness and effectiveness of the lubrication system.

When using lubricating grease, pay attention to its application areas on the punch press, which should be roughly the same as those of the lubricating oil, because the lubricating grease has sealing, gap filling, and rust prevention functions, but the appropriate hardness should be selected according to the load or usage conditions.

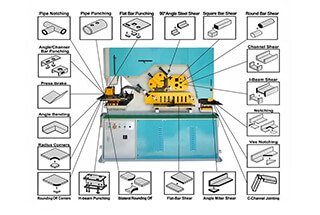

The standard procedures and techniques for adjusting the mechanical parts of a punch press mainly include the following aspects:

Stroke Adjustment: In actual production, the stroke of the punch press is adjusted by installing limit switches to switch circuits. This requires installing the limit switch at a prearranged position so that when the moving parts hit the limit switch, the contacts act, thereby completing the stroke adjustment.

Safe Operation Procedures: When installing the mold, you must ensure that the slider opens to the bottom dead point, the closed height is correct, and eccentric loads are avoided as much as possible. After initial positioning of the mold, tighten it, bring the punch close to the mold in a jog mode, then observe and tighten the punch nut to ensure the accuracy of the mold alignment.

Leveling Adjustment: After using the punch press for some time, there may be parts loosening or other problems, at which time it needs to be leveled and adjusted. First, the punch press frame needs to be completely secured.

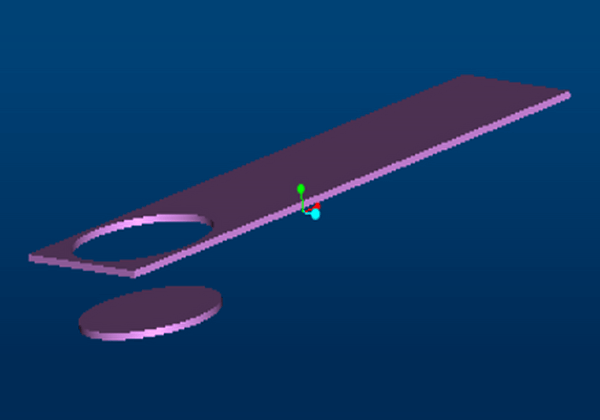

Raw Material Adjustment: Before stamping, there must be a sheet metal straightening adjustment process or an automatic correction jig to ensure that raw materials smoothly enter the mold cavity.

CNC Punch Press Operation and Maintenance: The CNC punch press must be operated and maintained by a specialist, overlapping punching is prohibited to avoid machine overload. Also, it’s forbidden to loosen or adjust the material stop or blade gap by hitting.

Mold Installation and Adjustment: Before the experiment, check if lubricating oil has been added to the moving parts of the punch press, and start the punch press to check if the clutch and brake are normal. After turning off the power, wait for the moving parts of the punch press to stop running before starting to install and adjust the mold. After the installation and adjustment are completed, manually move the flywheel to try punching twice, and only after being checked by the instructor can the punch press be started.

Spindle Bearing Installation and Adjustment: After the spindle component has been used for a while, the bearing wear gap will increase and needs to be readjusted. Therefore, the spindle component must have a bearing gap adjustment structure.

Adjustment of Main Components of Precision Punch Press: This includes adjustments of the top dead center stop position of the slider, the rotating cam controller, the closed height, the stamping speed (SPM), and so on. These adjustments are an important part of operating a precision punch press.

The common issues and solutions related to safety protection devices in the use of punch presses include the following aspects:

The solution is to enhance safety protection, increase mechanization, and ensure that all necessary safety protection devices are complete and effective.

Maintenance and upkeep of photoelectric protective devices: Photoelectric protective devices safeguard the operator by emitting infrared rays to form a light curtain. To ensure their normal operation and extend their lifespan, regular maintenance and upkeep are necessary.

Sensitivity and reliability of clutches and brakes: High-performance punch presses can lead to safety accidents if they do not have clutches and brakes, or if these components are not sensitive and reliable enough. The solution is to ensure that the clutches, brakes, and their control devices are sensitive and reliable, fasteners should not be loose, and the grounding protection of the electrical appliances should be reliable.

Necessity of automatic feed protection devices: During continuous stamping, there must be automatic feed protection devices or other protective measures to prevent injuries caused by improper operation.

Training and awareness enhancement of operators: Punch press operators must undergo training to master the structure and performance of the equipment, familiarize themselves with operating procedures, and obtain operation permits before they can operate independently. They must properly use the safety protection and control devices on the equipment and should not disassemble them arbitrarily.

In the maintenance of a punch press, the method to effectively measure and adjust the quantity and pressure of the lubricating oil involves several steps and techniques.

First, for the detection of lubricating oil, we can conduct tests through physicochemical indicators, trend analysis of oil additives, and qualitative and quantitative analysis of wear particles and contaminants.

Specifically, physical performance indicators require the measurement of viscosity, viscosity index, moisture, flash point, pour point and cloud point, mechanical impurities, insolubles, spot tests, oxidation resistance, emulsion resistance, foaming resistance, wear resistance, and extreme pressure performance.

Chemical performance indicators include total acid number and total base number.

Additionally, professional instruments such as infrared spectrometers, viscometers, and elemental analyzers can be used to test the quality of the lubricating oil.

For the adjustment of lubricating oil pressure, if it is a hydraulic punch press, you need to adjust the valves, especially the overflow valve and overall system pressure, to maintain an appropriate adjusting pressure.

For an air pressure punch press, pressure adjustment can be accomplished by adjusting the air pressure gauge to the desired pressure value, ensuring that the machine tool is stopped and the power is disconnected for safety. If the pressure is unstable, consider adjusting it by changing the motor wheel diameter through the speed control device.