Have you ever wondered why your CNC turret punch suddenly stops working efficiently? Maintaining and troubleshooting these machines can be quite a challenge. In this article, we dive into the essential maintenance practices and common troubleshooting techniques for CNC turret punches. By following these expert tips, you can enhance your machine’s performance, extend its lifespan, and minimize downtime. Whether you’re a seasoned operator or new to CNC machinery, you’ll find valuable insights to keep your equipment running smoothly.

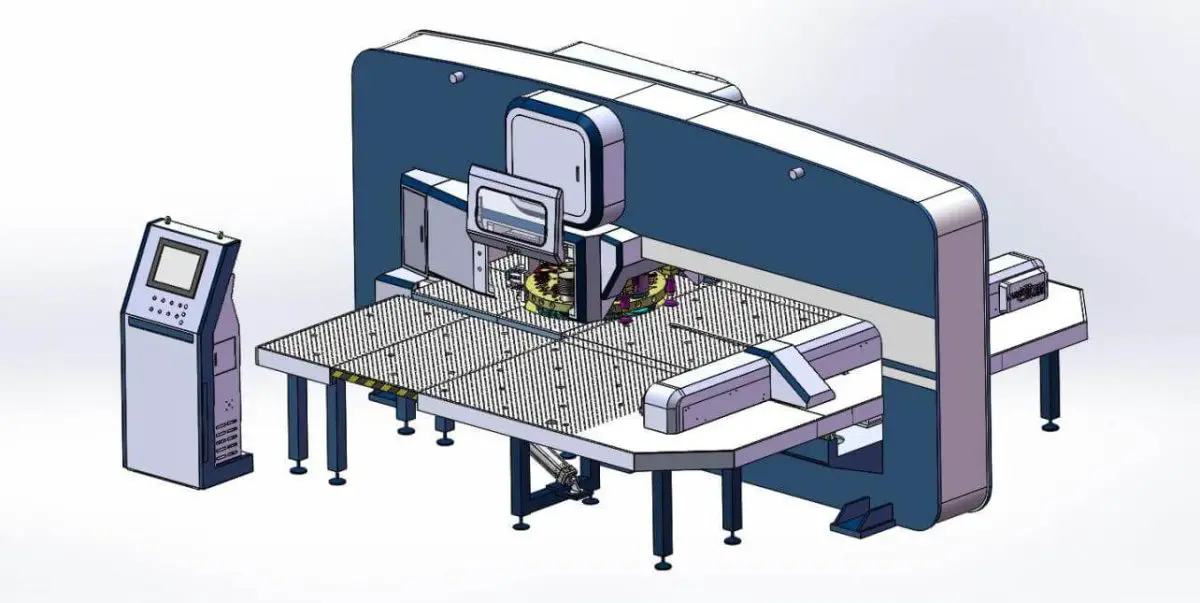

The CNC turret punch is a highly sophisticated and versatile sheet metal processing equipment, integrating advanced CNC systems with precision mechanical components. It represents the pinnacle of modern pressure processing technology, seamlessly combining electrical, hydraulic, and pneumatic systems to achieve unparalleled efficiency and accuracy.

This state-of-the-art machine excels in performing a wide array of complex operations, including punching, nibbling, forming, and even shallow drawing, all in a single setup. Through precise CNC programming, the machine can position workpieces with micron-level accuracy along both X and Y axes. The rotary turret, housing a diverse selection of tools, allows for rapid tool changes, significantly reducing setup times and enhancing productivity.

One of the most remarkable features of the CNC turret punch is its ability to create complex geometries through innovative techniques. By employing small punching dies in a strategic pattern, operators can produce large-scale features such as circular openings, rectangular cutouts, and intricate contours. This method, known as nibbling or step punching, offers tremendous flexibility in design without the need for specialized large-scale tooling.

Moreover, the CNC turret punch is capable of executing a range of specialized forming operations, pushing the boundaries of traditional sheet metal fabrication. These include:

The versatility of the CNC turret punch, combined with its high-speed operation and precision control, makes it an indispensable tool in modern sheet metal fabrication. It excels in both prototype development and high-volume production scenarios, offering manufacturers the flexibility to respond quickly to changing market demands while maintaining exceptional quality standards.

To extend the service life of the CNC turret punch press, it is generally recommended to maintain a moderate room temperature. Avoid exposing the machine to direct sunlight or other sources of thermal radiation. It is also important to place the machine in an environment that is free from excessive moisture, dust, or corrosive gases.

Additionally, keep the CNC turret punch press away from high-frequency and electromagnetic equipment, such as hydrogen arc welding machines and electric welding machines.

Special power lines are typically used to supply power to the CNC turret punch press. To minimize fluctuations and high-order harmonics in the power grid, three-phase AC voltage stabilizing devices are usually installed to reduce the impact of power supply quality and electrical interference.

The starting end of the power supply must be properly grounded. The CNC turret punch press should be connected to a three-phase five-wire power supply system, with the neutral line (N) and grounding (PE) kept strictly separate. It is also important to ensure that protective grounding is properly installed.

In the operation and management of the CNC turret punch, it is important to establish practical and effective operating procedures. This can include regular lubrication and maintenance, reasonable usage, and the implementation of a standardized shift system.

Adhering to these operating procedures is a critical step in ensuring the safe operation of the CNC machine tool. Experience has shown that many faults can be prevented by following established operating procedures.

The operator of the CNC turret punch must undergo special training and qualifications before operating the equipment to prevent damage to the machine tool and ensure personal safety.

There have been numerous examples of the consequences of untrained operators, which should serve as a reminder of the importance of proper training.

The personnel operating the equipment should be experienced, skilled, and familiar with the conditions of the equipment to ensure its stable operation.

Performing daily maintenance on the CNC punch can help maintain its good condition and extend its service life. This routine maintenance can also identify and address potential problems before they cause significant damage or loss.

After purchasing the CNC turret punch, it is important to make full use of it, especially in the first year of operation, to identify any weak points that may cause problems. These issues should be addressed within the warranty period.

When not in use, it is recommended to power on the CNC turret punch regularly, ideally once a week, to reduce humidity inside the machine by utilizing its own heat. This will prevent moisture from affecting the electronic components and detect any alarms for insufficient battery power in a timely manner, avoiding the loss of system-set parameters.

(1) Maintain a clean and organized environment around the machine tool. Regularly clean the surface of the machine tool to remove oil stains and keep the workbench free of debris. Clean the moving surfaces, such as lead screws and guide rails, once a week. Remove waste materials around the turntable promptly to prevent scratches, material buildup, and collisions.

(2) Properly lubricate the machine tool and ensure that all lubrication pipelines are unobstructed. Regularly inspect the centralized lubrication device and hydraulic station to ensure that the oil level is adequate and the oil quality is good. Drain the air compressor daily and the water distributor equipped on the machine tool, and check the oil level of the oil mist to ensure sufficient lubrication for the air pipeline.

(3) Regularly inspect the molds to prevent damage due to wear of the die opening or guide key.

(4) Do not press the “emergency stop” button unnecessarily, especially when using the rotary die.

(5) Do not manually pull the synchronous belt of the rotary die to avoid misalignment of the C-axis.

(6) Check for dust on components in the electrical cabinet, particularly those with cooling fans, and clean them at least once a month. Keep the electric control cabinet dry and clean.

(7) Check for oil and air leaks in the hydraulic and pneumatic components.

Daily maintenance and upkeep:

The punch may not retract from the sheet when the die rises, or the die may rise with the sheet, due to a lack of material return force or improper timing during continuous stamping.

Reasons:

Measures:

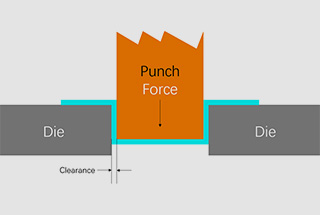

During the punching process, the upper die removes the blank from the lower die after the hole is punched.

Reasons:

Measures:

When the CRT gives an alarm indicating that the T-pin is not in place or the pin is missing, the rotary table experiences vibrations.

Cause:

After a period of use, the rotary table positioning pin may become dislocated from the positioning hole due to deformation of the chain or other factors. This can result in misalignment of the upper and lower rotary tables, or just one of the rotary tables.

Regardless of the situation, the adjustment process remains the same.

Adjustment Method:

In the case of a 1050 alarm, the punch is not at the top dead center and the X-axis, Y-axis, and T-axis are unable to function. This occurs on the VT-500 model with a FANUC Oi-P CNC system and a Rexroth hydraulic system.

Upon encountering this fault, a review of the maintenance technical data only reveals that the main hydraulic pump is not engaged, without any further prompts. However, the oil pump has been functioning normally.

The hydraulic system has a known issue with high oil temperature, and the temperature of the 4WRSE servo valve is also elevated.

It is possible that the servo valve is faulty. However, as the valve is difficult to inspect without disassembling it, it is challenging to determine its condition.

Troubleshooting Steps:

(1) During the stamping process, if the pressure stops, the system will automatically restart and be able to function normally again.

This fault repeatedly occurs during the stamping process without any alarm prompts, making it difficult to determine the cause in normal conditions.

In most cases, this fault is related to vibration.

If the three-phase voltage is found to be stable, it is usually because there was an instantaneous short circuit in the DC24V voltage of a valve or induction switch, causing a drop in voltage and resulting in the system restarting.

Due to the rapid stamping of the CNC punch, high-frequency vibration can easily cause damage to the DC24V power line of each valve and induction switch or cause loose wiring, leading to a short circuit between phases. This problem has been encountered frequently during maintenance.

To resolve this issue, maintenance personnel must carefully inspect each component, focusing on the signal lines near the turret.

(2) During the continuous stamping process, it often stops for about 2 seconds and then continues to work without a fault alarm.

This fault is mostly related to vibration, and the likelihood of it occurring increases with the thickness of the punching plate, meaning that the greater the vibration, the greater the likelihood of the fault.

Upon careful observation, it was discovered that the instrument pointer on the air pressure gauge attached to the bed exceeded the minimum air pressure set value due to the vibration amplitude, causing an instantaneous air pressure alarm and a stop. The solution was to remove the air pressure gauge from the punch bed and resolve the fault.

Achieving optimal performance and precision with CNC turret punch machines hinges on the expertise and dedication of both operators and maintenance personnel. These professionals must possess not only technical proficiency but also a strong sense of responsibility and unwavering professional ethics.

Operators should have an in-depth understanding of the machine’s capabilities, including its mechanical, electrical, and software systems. They must adhere strictly to operational protocols and maintenance schedules, with a particular emphasis on routine tasks such as cleaning, lubrication, and tooling inspection. This proactive approach ensures consistent accuracy, extends tool life, and minimizes unexpected downtime.

Maintenance personnel play a crucial role in maximizing machine uptime and longevity. Their responsibilities extend beyond mere problem-solving to include continuous learning and critical analysis. They should stay abreast of the latest advancements in CNC technology, predictive maintenance techniques, and Industry 4.0 practices.

When troubleshooting, maintenance experts should employ a systematic approach. By carefully examining fault symptoms and analyzing potential root causes, they can efficiently diagnose and resolve issues. This process should involve data analysis from machine logs, understanding of error codes, and application of diagnostic tools to pinpoint problems accurately.

A methodical and thoughtful approach to maintenance is essential. Hasty conclusions or unnecessary component replacements can lead to increased costs and extended downtime. Instead, maintenance personnel should prioritize thorough investigation and targeted interventions.

In conclusion, a robust preventive maintenance strategy is the cornerstone of efficient CNC turret punch operations. By investing time and resources in proactive maintenance, companies can significantly reduce unplanned downtime, extend machine lifespan, and optimize production efficiency. This approach not only minimizes reactive repairs but also contributes to improved product quality, reduced operational costs, and enhanced overall equipment effectiveness (OEE).