Have you ever struggled with achieving precise bends in sheet metal? This article demystifies the manual folding machine, a versatile tool essential for bending steel and nonferrous metals. By reading, you’ll learn step-by-step instructions on operating and adjusting this machine to ensure smooth and accurate results. Discover practical tips on maintenance to keep your equipment running efficiently, making it an indispensable guide for professionals and hobbyists alike.

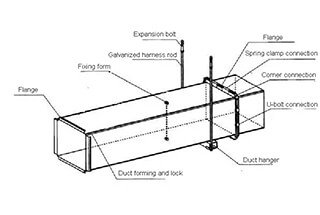

This series of manual folding machines are extensively utilized across diverse industries for precision bending and folding of metal sheets, including steel, non-ferrous alloys, and stainless steel. They accommodate materials up to 2.5 meters in length and 2mm in thickness, making them versatile for a wide range of applications. These machines have found particular prominence in manufacturing sectors such as:

The machines feature a robust manual operation system integrated with a precise positioning device, enabling efficient mass production of irregular workpieces with consistent, fixed-angle bends. This combination of manual control and accurate positioning makes these folding machines ideal for both small-batch custom work and high-volume production runs.

The folding mechanism employs upper and lower blades that work in concert to achieve clean, precise bends. A key advantage of this design is the absence of relative movement or impact during the folding process. This results in workpieces with smooth, unmarred surfaces – a critical feature especially valued in the production of high-quality stainless steel components where surface finish is paramount.

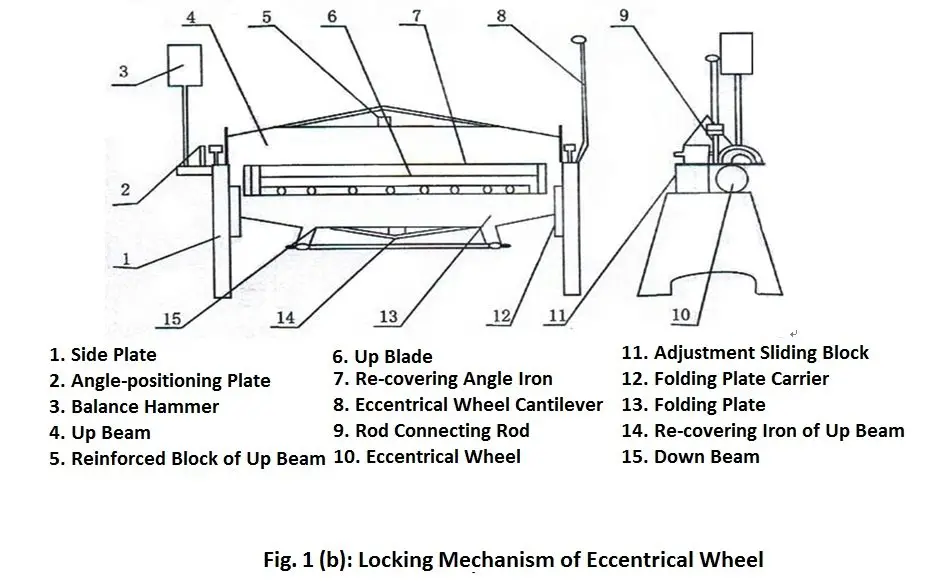

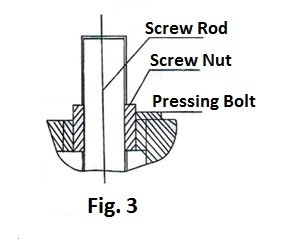

The locking mechanism, crucial for maintaining consistent fold angles, is engineered using one of three reliable systems:

These locking options ensure smooth, reliable operation across various material thicknesses and bend complexities. The overall design philosophy emphasizes simplicity without compromising functionality, resulting in a machine that is not only powerful and precise but also easy to maintain and adjust. This user-friendly approach minimizes downtime and enhances overall productivity in sheet metal fabrication workflows.

| Portable-type ( bevel gear locking) | ||||||

| Model | Max. Plate Thickness | Max. Bending Width | Max. Bending Angle | Weight | Max. Workpiece Dimension | Toolings |

| WS1.5×1300 | 1.5 | 1300 | 60° | 320 | 1950×650×1500 | Segmented Blade |

| WS1.5×1500 | 1.5 | 1500 | 60° | 360 | 2150×650×1500 | Segmented Blade |

| WS1.5×2000 | 1.5 | 2000 | 60° | 450 | 2650×650×1500 | Segmented Blade |

| WS1.2×2500 | 1.2 | 2500 | 60° | 550 | 3150×650×1500 | Segmented Blade |

| TDF1.5×1300 | 1.5 | 1300 | 60° | 320 | 1950×650×1500 | Segmented Blade |

| TDF1.5×1500 | 1.5 | 1500 | 60° | 360 | 2150×650×1500 | Segmented Blade |

| TDF1.5×2000 | 1.5 | 2000 | 60° | 450 | 2650×650×1500 | Segmented Blade |

| TDF1.2×2500 | 1.2 | 2500 | 60° | 550 | 3150×650×1500 | Segmented Blade |

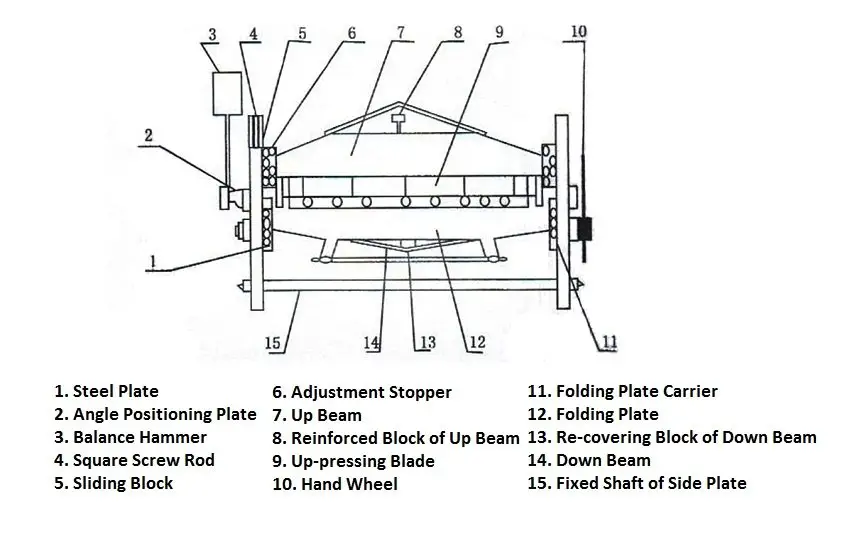

This series of manual folding machine tools, as shown in Figure 1, consists of upper and lower beams, plate-folding components, and blades. These three components have been adjusted to a rotational center, allowing users to adjust related parameters based on the machine specifications and plate thickness.

The adjustable parts of this series of the manual folding machine are as follows:

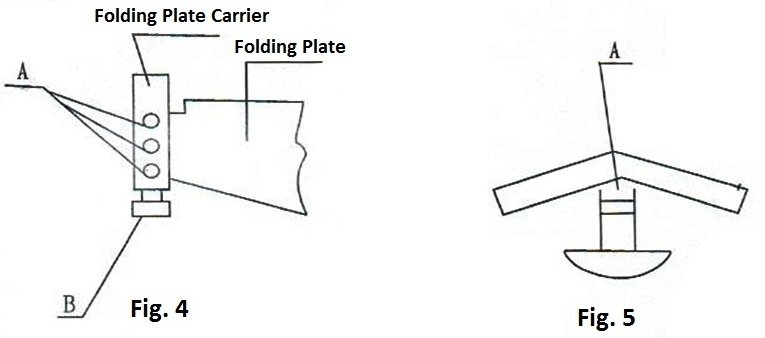

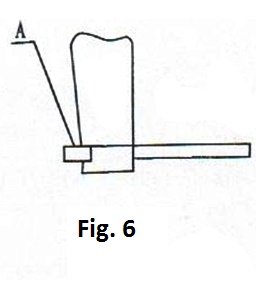

First, loosen bolt A connecting the folding plate and folding plate seat, then adjusts bilateral bolt B until the folding plate blade and beam blade are in the same line, and finally, re-locking bolt A.

All bearing points on the upper beam, lower beam, and folding plate are distributed at both ends, it is inevitable that some deflection will arise in the process of bending the plate, which directly affects the workpiece straightness, in order to overcome the shortcoming, the machine is equipped with the crowning device, through adjusting nut A to add some pre-stress on the center of the beam and folding plate (Max. adjustable height 0.5mm)for compensating the deflection deformation to guarantee the workpiece quality.

These manual folding machines are designed for user-friendly operation and efficient metal sheet bending.

To begin the folding process:

The upper beam is equipped with interchangeable blades, available in two standard angles:

Operators can select the appropriate blade angle based on the specific requirements of the workpiece and the desired bend characteristics. The modular nature of the 55° blade enhances the machine’s adaptability to diverse manufacturing needs.

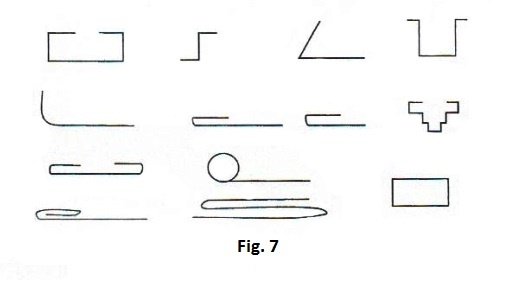

A typical setup and operation example is illustrated in Figure 7, demonstrating proper workpiece positioning and machine configuration.

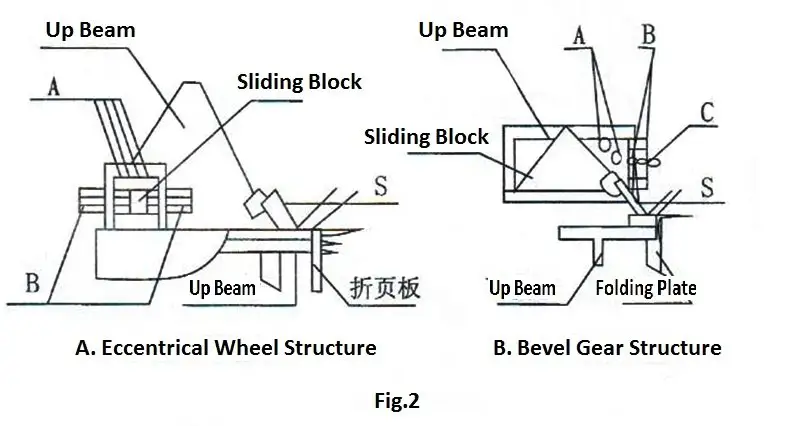

Prior to operating the machine, it is crucial to meticulously inspect the blade clearance, as illustrated in Figure 2 (S valve). This inspection ensures optimal cutting performance and prevents potential damage. It is strictly prohibited to fold plates that exceed the machine’s specified capacity, as this can lead to severe blade damage and compromise overall machine integrity.

For optimal performance and longevity, it is recommended to operate the machine at a moderate, consistent pace. This approach helps maintain uniform stress distribution across the components and ensures more precise folding results. Safety is paramount; therefore, no personnel should be positioned behind the balance hammer during operation to prevent accidents caused by unexpected material movement or machine recoil.

Regular maintenance is essential for the machine’s longevity and efficiency. Pay particular attention to the bearing assemblies and lubrication points. Implement a systematic lubrication schedule using manufacturer-recommended lubricants to minimize friction, reduce wear, and prevent premature component failure. Regularly inspect these areas for signs of wear, unusual noise, or excessive heat, addressing any issues promptly to avoid costly downtime and repairs.

Additionally, maintain a clean working environment around the machine, removing any debris or metal shavings that could interfere with moving parts or compromise fold quality. Periodically check and, if necessary, adjust the machine’s alignment and calibration to ensure consistent, high-quality output.