This article explores the fascinating world of sheet metal fabrication, covering stainless steel, aluminum, and more. You’ll learn how these materials are chosen and why they’re essential for everything from household appliances to industrial machinery. Get ready to uncover the secrets behind their strength and versatility!

Code: SUS (Stainless Steel)

Common Grades:

Mechanical Properties:

Dimensional Specifications:

Material Characteristics:

Processing Considerations:

Applications:

Physical Properties:

Weight Calculation Formula:

Weight (kg) = Length (m) × Width (m) × Thickness (mm) × Density (7.95 g/cm³)

Examples:

Quality Control Notes:

Code: SPCC, CRS (SPCD: Cold Rolled Steel for Drawing, SPCE: Cold Rolled Steel for Extra Deep Drawing)

Hardness: HRB, 1/2H = 74 to 89, 1/4H = 65 to 80, 1/8H = 50 to 71, Full Hard (H) = above 89

Tensile Strength: Minimum 270 MPa (≈ 28 kgf/mm²)

Material Thickness: 0.25 to 3.2mm standard range. Thicknesses exceeding 3.2mm require custom production.

Material Width: Maximum 1524mm (5 feet), with 1219mm or 1250mm (4 feet) being more common. Custom widths available up to 1524mm.

Material Length: Customizable. Standard length typically 2438mm or 2500mm (8 feet).

Material Properties:

Cold rolled steel exhibits a characteristic gray luster. It is susceptible to scratching and corrosion, necessitating careful handling and prompt processing to maintain surface integrity.

Highly suitable for surface treatments including:

Density: 7.85 g/cm³

Weight Calculation: Length (m) x Width (m) x Thickness (mm) x Density = Weight (kg)

Examples:

Key Considerations:

1. Thickness Tolerance: Standard tolerance is ±0.08mm. For instance, a nominal 2.0mm sheet may measure between 1.92mm and 2.08mm.

2. Measurement Precision: Always use a micrometer for accurate thickness measurement, not a vernier caliper.

3. Corrosion Prevention:

4. Processing Implications:

5. Quality Control:

Code: AL, A1100P, A5052H32P, AL6061T6

Common Alloys: A1100P-O (O designates annealed condition for maximum formability), A1050P, A5052H32P, AL6061T6, AL6063T5.

Material Dimensions:

Material Properties:

Appearance: Silvery-white luster with high reflectivity. Prone to oxidation, forming a thin, protective oxide layer.

Surface Protection: PVC film often applied to prevent scratching and corrosion during handling and fabrication.

Surface Treatments:

Specific Gravity: 2.75 g/cm³

Weight Calculation: Length (m) x Width (m) x Thickness (mm) x 2.75 = Weight (kg)

Examples:

Processing Considerations:

Always consult material specifications and perform tests for critical applications to ensure suitability and performance.

Code: SPGC

Hardness: HRB, 1/2H = 74 to 89, 1/4H = 65 to 80, 1/8H = 50 to 71, H = above 89.

Tensile Strength: Above 40-55 kgf/mm².

Material Thickness: 0.4 to 3.2 mm. Materials thicker than 3.2 mm are difficult to find and are usually replaced by galvanized white zinc.

Material Width: The maximum width is 5′ (1524 mm), typically 4′ (1219 mm or 1250 mm), and any size smaller than 1524 mm can be cut to size.

Material Length: Any size can be cut to size. Typically 8′ (2438 mm or 2500 mm).

Material Properties:

Specific Gravity: 8.25

Weight Calculation: Length (m) x Width (m) x Thickness (mm) x Specific Gravity = kg.

Example:

SPGC 2.0 x 1220 x 2440 Weight: 2.0 x 1.22 x 2.44 x 8.25 = 49.1 kg.

Another Example:

SPGC 1.0 x 1000 x 2000 Weight: 1 x 1 x 2 x 8.25 = 16.5 kg.

Note:

Code: SPHC (Steel Plate Hot Rolled Commercial)

Mechanical Properties:

Dimensional Specifications:

Material Characteristics:

Finishing Recommendations:

Weight Calculation Formula:

Weight (kg) = Length (m) × Width (m) × Thickness (mm) × 7.85

Calculation Examples:

Important Processing Considerations:

Code: C1020, C1100, C2100, C2200, C2300, C2400 (red copper) and Brass alloys C2600 and above.

Common Models:

Tensile Strength:

Material Dimensions:

Material Properties:

1xxx series (99.9% Cu):

2xxx series (60-96% Cu):

Surface Treatments: Wire drawing, pickling, polishing, copper plating, tin plating, nickel plating

Specific Gravity: 8.9 g/cm³

Weight Calculation Formula:

Weight (kg) = Length (m) × Width (m) × Thickness (mm) × Specific Gravity

Examples:

Important Notes:

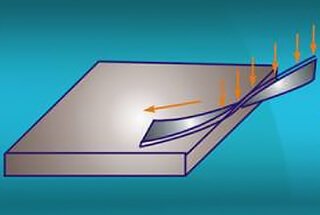

Cold Rolled Ordinary Steel Sheet, also known as ordinary carbon structural steel cold rolled sheet or simply “cold plate,” is a high-precision steel product with a thickness typically ranging from 0.15mm to 3mm. It is manufactured by subjecting hot rolled ordinary carbon structural steel to a sophisticated cold rolling process at ambient temperature.

This advanced manufacturing technique involves passing the hot rolled steel through a series of pressure rollers, which drastically reduce its thickness while simultaneously improving its metallurgical and surface properties. The cold working process eliminates the formation of surface oxide scale and induces strain hardening, resulting in a product with superior surface finish, tighter dimensional tolerances, and enhanced strength compared to its hot rolled counterpart.

Post-rolling thermal treatments, particularly batch or continuous annealing, can be applied to optimize the sheet’s mechanical properties. Annealing relieves internal stresses, improves ductility, and enhances formability, making the material ideal for complex forming operations in sheet metal fabrication.

Cold Rolled Ordinary Steel Sheet is widely utilized across various industries due to its excellent combination of properties:

This versatile material is available in various grades and specifications to meet diverse application requirements. Common standards include:

The selection of the appropriate grade depends on the specific application, required formability, and strength characteristics needed for the final product.

Continuous Electro Galvanized Steel Sheet, also known as electrolytic galvanized steel, is a high-performance steel product manufactured through an advanced electroplating process. In this technique, a precisely controlled zinc coating is deposited onto the surface of a carefully prepared cold-rolled steel substrate within an electrolytic cell. The process utilizes direct current to facilitate the electrochemical deposition of zinc ions from a zinc-rich electrolyte solution onto the steel surface.

The resulting zinc layer, typically ranging from 2.5 to 25 μm in thickness, provides superior corrosion protection through both barrier and sacrificial mechanisms. The electrogalvanizing process allows for exceptional coating uniformity, excellent surface finish, and precise thickness control, making it ideal for applications requiring high-quality appearance and consistent weldability.

This advanced steel product is classified under various international standards, including:

The choice of grade depends on the specific application requirements, such as formability, strength, and surface quality. Continuous electro galvanized steel sheets find extensive use in automotive components, household appliances, HVAC systems, and construction materials where corrosion resistance and superior surface finish are paramount.

Continuously Hot-Dip Galvanized Steel Sheet, often referred to as galvanized sheet or white iron sheet, is characterized by its distinctive surface appearance featuring spangle patterns of block or leaf-shaped zinc crystals. This surface not only provides aesthetic appeal but also contributes to the sheet’s exceptional resistance to atmospheric corrosion.

The galvanization process involves continuously passing steel sheet through a bath of molten zinc at temperatures around 450°C (842°F). This results in the formation of a metallurgically bonded zinc coating, typically composed of an iron-zinc alloy layer and a pure zinc outer layer. The thickness of this coating, measured in g/m² or μm, surpasses that of regular galvanized sheets, enhancing its corrosion protection capabilities.

Key advantages of this material include:

This versatile material is classified under various international standards:

The selection of grade depends on the intended application, required formability, and desired level of corrosion protection. These sheets find extensive use in construction, automotive, appliance manufacturing, and various other industries where a combination of corrosion resistance, formability, and cost-effectiveness is crucial.

Stainless steel is a corrosion-resistant alloy that maintains its integrity when exposed to various environmental and chemical agents. It is characterized by a minimum chromium content of 10.5%, which forms a protective chromium oxide layer on the surface. In industrial applications, “stainless steel” typically refers to alloys resistant to atmospheric corrosion, while “acid-resistant steel” denotes grades with enhanced chemical resistance.

Stainless steel can be classified into several categories based on their microstructure and properties:

It’s crucial to note that while stainless steel offers high strength and corrosion resistance, its machinability can be challenging. In sheet metal fabrication, the high work hardening rate and toughness of austenitic grades can lead to rapid tool wear during punching operations. This makes numerical control (NC) punching generally less suitable for stainless steel compared to other forming methods like laser cutting or waterjet cutting.

Grades and Standards:

The most commonly used grade in sheet metal processing is austenitic stainless steel, particularly Type 304 (US designation) or 1.4301 (European designation). This grade is equivalent to the Japanese Industrial Standard (JIS) SUS304, which corresponds to the chemical composition of 18% chromium and 8% nickel (18-8 stainless steel). For applications requiring higher corrosion resistance, grades like 316/316L (SUS316/SUS316L) with molybdenum addition are often employed.

When selecting stainless steel for sheet metal fabrication, consider factors such as:

Aluminum is a versatile, silver-white metal prized for its excellent thermal and electrical conductivity, high ductility, and low density. While pure aluminum lacks the strength for structural applications, its alloys are extensively used in sheet metal processing due to their enhanced mechanical properties.

Aluminum alloy plates are categorized into eight series based on their primary alloying elements: 1000 (pure aluminum), 2000, 3000, 4000, 5000, 6000, 7000, and 8000 series. Among these, the 2000, 3000, and 5000 series are most prevalent in sheet metal fabrication:

Common aluminum alloy designations include:

When selecting an aluminum alloy for sheet metal processing, consider factors such as strength requirements, corrosion resistance, formability, and weldability. The specific application, environmental conditions, and manufacturing processes will dictate the most suitable alloy choice.

Copper plates, particularly those made from red copper (also known as pure copper or C11000), are highly valued in industrial applications for their distinctive reddish-orange color and exceptional properties. These include superior electrical conductivity (around 100% IACS), thermal conductivity (401 W/m·K), excellent ductility (elongation 45-55%), and notable corrosion resistance due to its protective oxide layer formation.

While pure copper’s cost is higher compared to some alloys, its unparalleled performance in specific applications justifies its use. It finds extensive application in electrical power systems, particularly in high-current transfer components such as busbars, switchgear, and transformer windings. Its thermal properties make it ideal for heat exchangers, cooling systems, and thermal management in electronics.

The grades of red copper are classified as:

While red copper’s strength (69-365 MPa, depending on temper) is lower compared to structural metals like steel, it can be used in non-load-bearing components or in composite structures where its other properties are crucial. For applications requiring higher strength while maintaining good conductivity, copper alloys like beryllium copper or phosphor bronze might be considered.

To optimize the use of copper plates in manufacturing, techniques such as precision CNC machining, waterjet cutting for complex shapes, and specialized joining methods like electron beam welding or friction stir welding can be employed to maintain material integrity and performance.

Brass is a versatile copper-zinc alloy renowned for its excellent combination of high strength, corrosion resistance, and exceptional workability in both cold and hot forming processes. This alloy typically contains 60-70% copper and 30-40% zinc, with the precise composition determining its specific properties. Brass exhibits superior machinability, making it ideal for complex fabrication processes.

While brass can be susceptible to dezincification in certain aggressive environments, modern alloy compositions and surface treatments have significantly mitigated this issue. Its relatively low cost, coupled with its attractive golden appearance and antimicrobial properties, makes brass a popular choice in various industrial, architectural, and decorative applications.

Brass grades are typically categorized based on their copper content, with common designations including:

Each grade offers unique characteristics, allowing manufacturers to select the most appropriate type for specific applications, ranging from plumbing fixtures and musical instruments to electrical components and architectural hardware.