Ever wondered how precise measurements shape the world of mechanical engineering? This article explores essential tools like steel rulers, calipers, and vernier calipers, revealing their uses and accuracy. Learn how these instruments ensure the precision and reliability of countless engineering projects. Dive in to uncover the secrets behind accurate measurements!

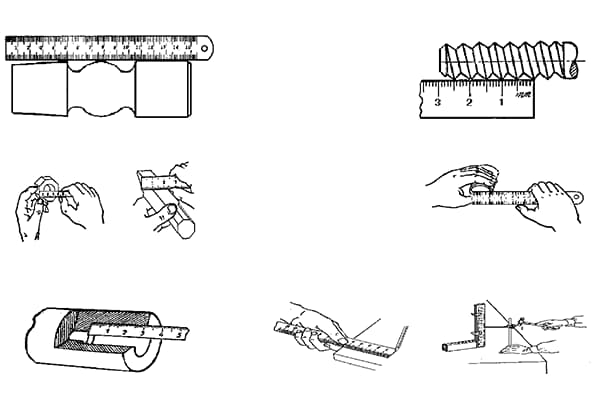

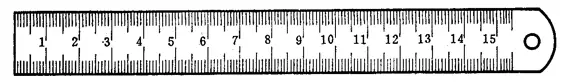

A steel ruler is the simplest length measuring tool available, and it comes in four sizes: 150mm, 300mm, 500mm, and 1000mm. The following image shows a commonly used 150mm steel ruler.

Steel rulers are used to measure the length dimensions of parts, but their measurement results are not very accurate. This is because the spacing between the markings on a steel ruler is 1mm, and the width of each marking itself is between 0.1-0.2mm.

Therefore, when measuring, there can be significant reading errors. Only millimeter values can be read, and the smallest reading value is 1mm. Values smaller than 1mm can only be estimated.

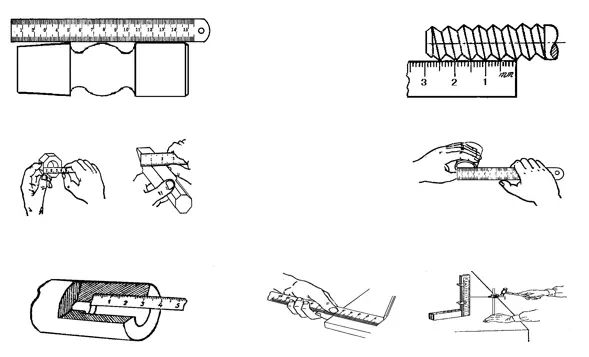

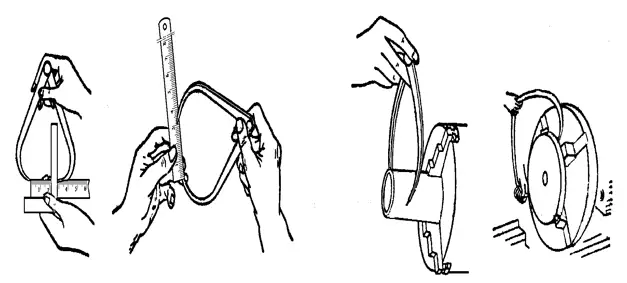

Method of using a steel ruler.

a) Measure length.

b) Measure thread pitch.

c) Measure width.

d) Measure internal diameter.

e) Measure depth.

f) Draw lines.

Directly measuring the diameter size (shaft or hole) of a part with a steel ruler will result in lower measurement accuracy. The reason for this is that, in addition to the large reading error of the steel ruler itself, it is difficult to place the steel ruler at the correct position on the part diameter.

Therefore, for measuring the diameter size of parts, a combination of a steel ruler and inside/outside calipers can be used instead.

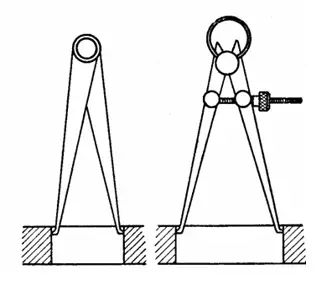

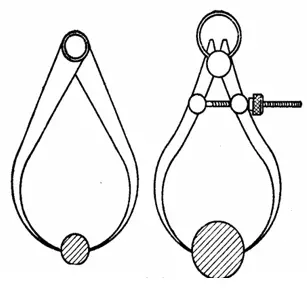

There are two common types of calipers, inside and outside calipers. Inside calipers are generally used to measure internal diameters and grooves, whereas outside calipers are used to measure outer diameters.

They cannot directly read the measurement results, but instead transfer the length measurement to a steel ruler for reading or take the required size from the steel ruler and then check whether the part diameter is compliant.

Calipers are simple measuring tools characterized by their simplicity in structure, ease of manufacture, low cost, maintenance, and use.

They are widely used for measuring and inspecting parts with low dimensional requirements, particularly for measuring and inspecting forgings and castings. Calipers are the most suitable measuring tool for these applications.

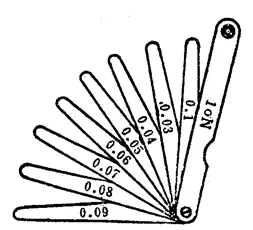

Feeler gauge, also known as thickness gauge or gap gauge.

It is mainly used to check the gap size between two mating surfaces.

The feeler gauge is made up of many layers of steel sheets with varying thicknesses. They are grouped into sets and each set contains multiple gauges. Each piece of the feeler gauge has two parallel measuring surfaces and thickness markings for combination use.

During measurement, one or more pieces of the feeler gauge are overlapped and inserted into the gap according to the size of the gap between the mating surfaces.

For example, if a 0.03mm gauge can be inserted into the gap while a 0.04mm gauge cannot, it indicates that the gap is between 0.03mm and 0.04mm, making the feeler gauge a type of limit gauge.

When using a feeler gauge, the following points should be noted:

Select the appropriate number of gauges according to the gap between mating surfaces, but use as few gauges as possible.

Do not apply too much force during measurement to avoid bending or breaking the feeler gauge.

Do not measure workpieces with high temperatures.

Vernier calipers are measuring tools made using the principle of Vernier scale. They include vernier caliper, height gauge with a vernier scale, depth gauge with a vernier scale, protractor angle gauge (such as universal bevel protractor), and gear tooth vernier caliper.

These tools are used to measure the outer diameter, inner diameter, length, width, thickness, height, depth, angle, and gear tooth thickness of parts and have a wide range of applications.

The vernier caliper is a commonly used measuring tool, which is characterized by its simple structure, convenient use, moderate accuracy, and a large range of measured sizes.

It can be used to measure the outer diameter, inner diameter, length, width, thickness, depth, hole spacing of parts, etc., and has a wide range of applications.

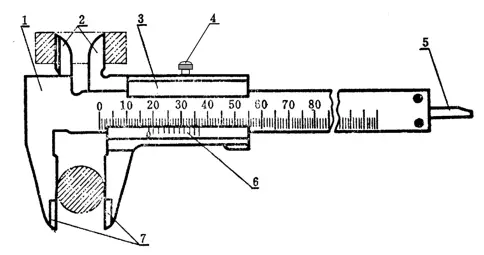

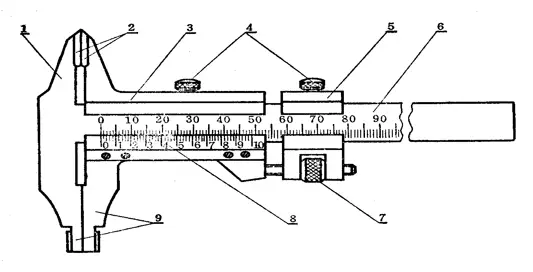

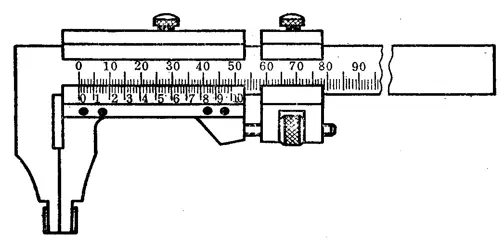

There are three types of structural forms for the vernier caliper.

(1) A vernier caliper with a measuring range of 0 to 125mm, which is made in the form of upper and lower jaws with a knife-edge shape and equipped with a depth gauge.

(2) Vernier calipers with measuring ranges of 0-200mm and 0-300mm can be made in the form of lower jaws with internal and external measuring surfaces and upper jaws with knife-edge shape.

(3) Vernier calipers with measuring ranges of 0-200mm and 0-300mm can also be made in the form of lower jaws with only internal and external measuring surfaces.

The measuring range and the corresponding reading values of the Vernier caliper.

| Measuring range | Cursor reading value | Measuring range | Cursor reading value |

| 0~25 | 0.02 0.05 0.10 | 300~800 | 0.05 0.10 |

| 0~200 | 0.02 0.05 0.10 | 400~1000 | 0.05 0.10 |

| 0~300 | 0.02 0.05 0.10 | 600~1500 | 0.05 0.10 |

| 0~500 | 0.05 0.10 | 800~2000 | 0.10 |

The reading principle and method of the Vernier caliper.

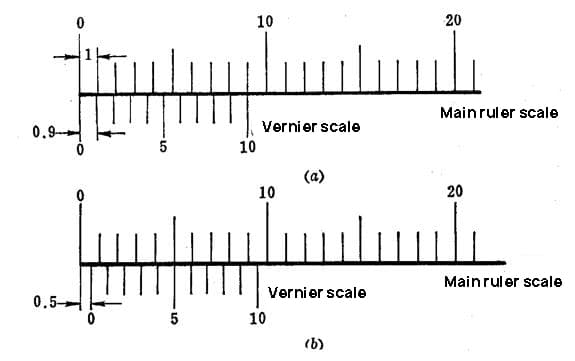

For a Vernier caliper with a reading value of 0.1mm, the distance between each main scale line is 1mm.

When the zero line on the Vernier scale is aligned with the zero line on the main scale (the jaws are closed), the 10th line on the Vernier scale points exactly to 9mm on the main scale, while none of the other lines on the Vernier scale align with any lines on the main scale.

The measurement interval of the vernier caliper is calculated as follows:

Interval = 9mm ÷ 10 = 0.9mm

The difference between the main scale interval and the vernier scale interval is:

1mm – 0.9mm = 0.1mm

Therefore, the minimum reading that can be obtained from the vernier caliper is 0.1mm, and no smaller value can be measured.

A caliper with a vernier scale reading of 0.05mm.

When the two jaws are closed, and the distance between them is 39mm as indicated by the main scale, the vernier scale on this caliper is divided into 20 equal parts. Therefore, the distance between each division on the vernier scale is calculated as follows:

Distance between divisions on the vernier scale = 39mm ÷ 20 = 1.95mm

The difference between the distance of two main scale divisions (2mm) and the distance of one vernier scale division (1.95mm) is:

2mm – 1.95mm = 0.05mm

Therefore, the minimum reading value of this caliper is 0.05mm.

Similarly, if the vernier scale has 20 divisions but the distance between the jaws is only 19mm according to the main scale, the same principle applies.

A caliper with a vernier scale reading of 0.02mm.

When the two jaws are closed, and the distance between them is 49mm as indicated by the main scale, the vernier scale on this caliper is divided into 50 equal parts. Therefore, the distance between each division on the vernier scale is calculated as follows:

Distance between divisions on the vernier scale = 49mm ÷ 50 = 0.98mm

The difference between the distance of one main scale division (1mm) and the distance of one vernier scale division (0.98mm) is:

1mm – 0.98mm = 0.02mm

Therefore, the minimum reading value of this caliper is 0.02mm.

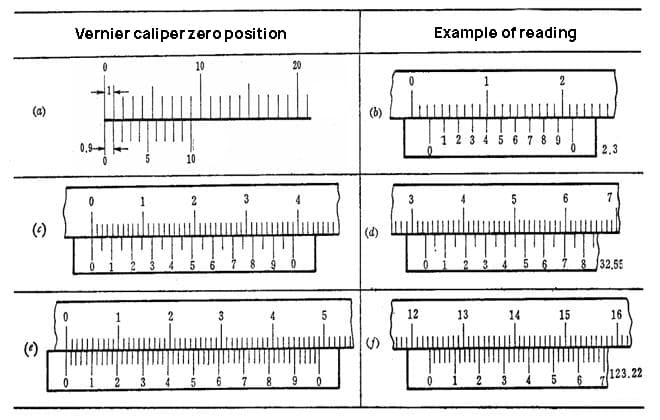

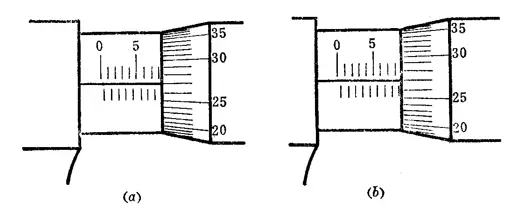

(a) A caliper with a vernier scale reading of 0.1mm.

(b) A caliper with a vernier scale reading of 0.05mm.

(c) A caliper with a vernier scale reading of 0.02mm.

The measurement accuracy of the Vernier caliper.

When measuring or inspecting the size of a part, it is necessary to select an appropriate measuring tool according to the precision requirements of the part size. The Vernier caliper is a measuring tool with medium precision, which is only suitable for measuring and inspecting dimensions of medium precision.

It is not reasonable to use the Vernier caliper to measure the rough castings or dimensions with high accuracy requirements.

The former can easily damage the measuring tool, while the latter cannot meet the required measurement accuracy since all measuring tools have certain indication errors, which are listed in the table below.

| Reading value | Total error of indication |

| 0.02 | ±0.02 |

| 0.05 | ±0.05 |

| 0.10 | ±0.10 |

The indication error of the Vernier caliper is due to the manufacturing precision of the caliper itself. No matter how correctly it is used, the caliper may still produce these errors.

For example, when using a Vernier caliper with a reading value of 0.02mm and an indication error of ±0.02mm to measure a shaft with a diameter of 50mm, if the reading on the caliper is 50.00mm, the actual diameter may be either 50.02mm or 49.98mm.

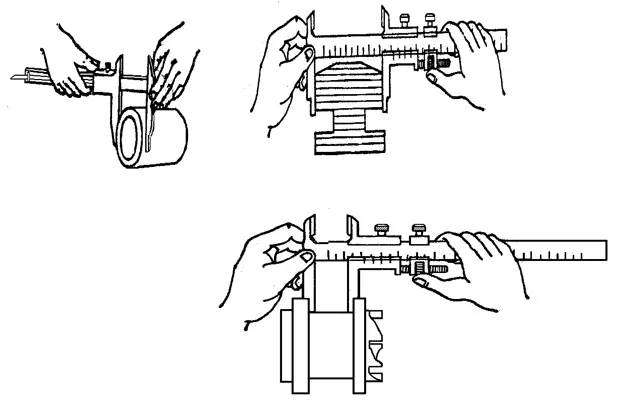

When using Vernier calipers to measure part sizes, the following points must be noted:

1. Before measuring, the caliper should be cleaned and inspected to ensure that both measuring surfaces and the measuring edges are flat and undamaged. When the two jaws are tightly fitted, there should be no obvious gap, and the zero marking lines of the vernier and the main scale should be aligned with each other. This process is called checking the zero position of the vernier caliper.

2. When moving the caliper frame, it should move smoothly without being too loose or tight, and there should be no shaking. When fixing the caliper frame with a fixing screw, the readings of the caliper should not change. When moving the caliper frame, do not forget to loosen the fixing screw, and do not make it too loose so as not to lose control.

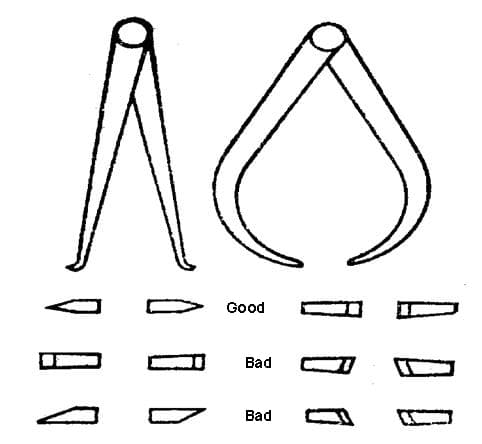

3. When measuring the external dimensions of the measured parts, the connecting line between the two measuring faces of the caliper should be perpendicular to the surface being measured and must not be skewed. During measurement, the caliper can be gently rocked to align it vertically. Never adjust the two jaws of the caliper to be close to or even less than the measured size, and force the caliper onto the part. Doing so will cause the jaws to deform or the measuring surfaces to wear prematurely, causing the caliper to lose its necessary accuracy.

Correct Measurement Method

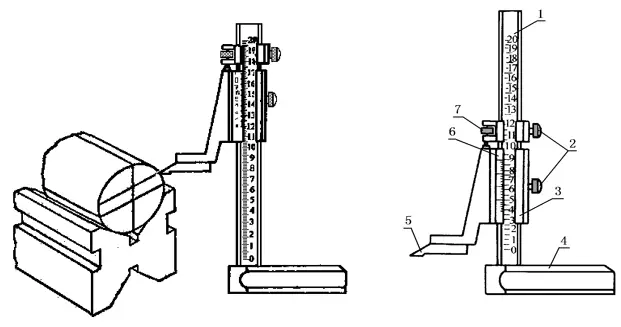

The Height Gauge Vernier Caliper, as shown in the picture, is used to measure the height of parts and precision marking.

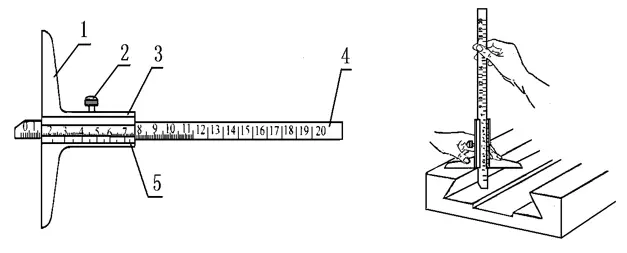

The Depth Gauge Vernier Caliper, as shown in the picture, is used to measure the depth dimension or step height and groove depth of parts.

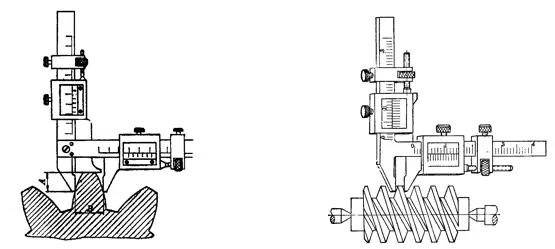

The Vernier caliper with tooth thickness is used to measure the chordal tooth thickness and chordal tooth top of gears (or worm gears). This type of Vernier caliper consists of two perpendicular main scales, each with its own Vernier scale.

All kinds of Vernier calipers mentioned above share a common issue, which is that the readings are not very clear and can be easily misread. Sometimes, it is necessary to use a magnifying glass to enlarge the reading portion.

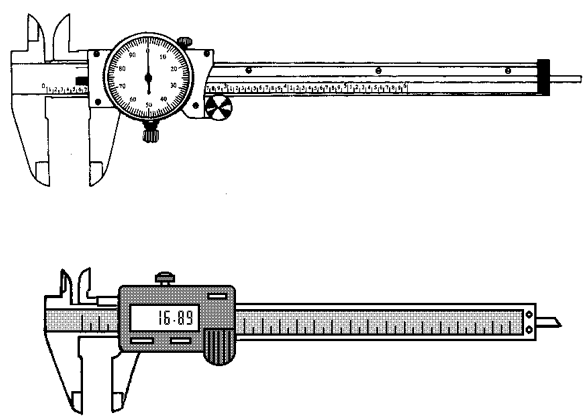

In order to eliminate parallax error caused by tilting the line of sight during reading, some calipers are equipped with micrometers, becoming micrometer calipers, which facilitate accurate reading and improve measurement accuracy.

There is also a type of Vernier caliper with a digital display device, which directly displays the dimensions measured on the surface of the part in numbers. Its use is extremely convenient.

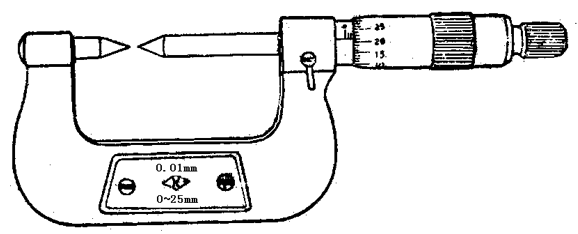

Instruments made using the principle of screw thread micrometer are called screw thread micrometers. They have a higher measurement accuracy than Vernier calipers and are more flexible in measuring, so they are often used when high machining accuracy is required.

The commonly used screw thread micrometers have scales with graduations of hundredths of a millimeter (0.01mm) and thousandths of a millimeter (0.001mm).

Currently, in workshops, a large number of hundredths of a millimeter reading (0.01mm) scale screw thread micrometers are used.

There are many types of hundredths of a millimeter reading scales, which are commonly used in mechanical machining workshops, including outside diameter micrometers, inside diameter micrometers, depth micrometers, thread micrometers, and gear tooth thickness micrometers.

They are respectively used to measure or inspect the outer diameter, inner diameter, depth, thickness, the midpoint of the thread, and the normal length of the gear.

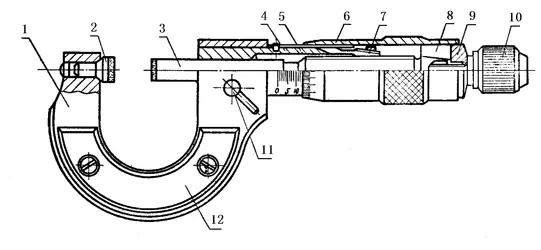

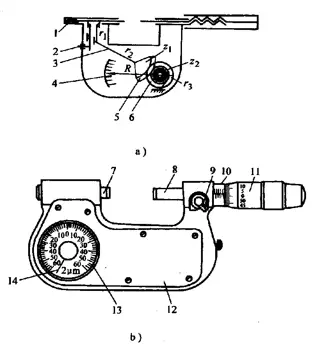

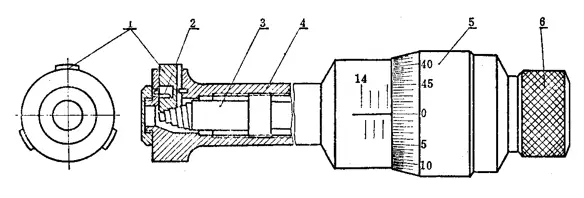

1. Frame; 2. Fixed measuring anvil; 3. Measuring screw; 4. Threaded spindle sleeve; 5. Fixed scale sleeve; 6. Vernier sleeve; 7. Adjusting nut; 8. Connector; 9. Washer; 10. Measuring force device; 11. Locking screw; 12. Insulating plate.

Method of Reading Vernier Caliper

The micrometer’s circular scale is marked with 50 equally spaced lines, and when the micrometer is turned one full revolution, the measuring screw advances or retracts by 0.5mm.

When the micrometer barrel rotates one small division on its own circular scale, the distance between the two measuring surfaces that rotate is:

0.5 ÷ 50 = 0.01 (mm).

Therefore, it can be known that the spiral reading mechanism on the vernier caliper can read out the value of 0.01mm correctly, which means the reading value of the vernier caliper is 0.01mm.

The specific reading method of the vernier caliper can be divided into three steps:

(1) Read the size of the exposed graduation line on the fixed sleeve, and be sure to pay attention not to miss the value of the 0.5mm graduation line that should be read.

(2) Read the size on the micrometer barrel, and see which division on the micrometer barrel’s circumference aligns with the center line benchmark of the fixed sleeve. Multiply the number of divisions by 0.01mm to get the size on the micrometer barrel.

(3) Add the above two numbers together to obtain the measured size on the vernier caliper.

As shown in Figure (a), the size read on the fixed sleeve is 8mm, and the size read on the micrometer barrel is 27 (divisions) x 0.01mm = 0.27mm. Adding the above two numbers gives a measured size of the part being inspected as 8.27mm.

In Figure (b), the size read on the fixed sleeve is 8.5mm, and the size read on the micrometer barrel is 27 (divisions) x 0.01mm = 0.27mm. Adding the above two numbers gives a measured size of the part being inspected as 8.77mm.

When using a vernier caliper to measure the dimensions of a part, please pay attention to the following points:

(1) Before using, clean the two measuring faces of the vernier caliper and rotate the measuring force device to make the two measuring faces contact (if the upper limit of measurement is greater than 25mm, insert a setting gauge or corresponding size block between the two measuring faces), and there should be no gap or light leakage phenomenon on the contact surface. At the same time, align the micrometer and fixed sleeve briefly to zero.

(2) When rotating the measuring force device, the micrometer should be able to move freely along the fixed sleeve without any jamming or inflexibility.

(3) Before measurement, wipe the measured surface of the part clean to avoid affecting the measurement accuracy due to the presence of dirt. It is absolutely not allowed to use a vernier caliper to measure surfaces with abrasive, in order to avoid damaging the accuracy of the measuring surface. Measuring parts with rough surfaces using a vernier caliper is also incorrect, as it can cause premature wear of the measuring faces.

(4) When using a vernier caliper to measure a part, hold the rotating cap of the measuring force device to turn the micrometer screw, so that the measuring face maintains the standard measuring pressure, that is, when you hear a “click” sound, indicating that the pressure is appropriate, and you can start to read the measurement. Be sure to avoid measurement errors caused by uneven measuring pressure.

(5) When using a vernier caliper to measure parts, make sure that the micrometer screw is aligned with the direction of the part being measured.

(6) When measuring a part with a vernier caliper, it is best to read the measurement while it is still on the part and then remove the caliper after releasing pressure. This can reduce wear on the measuring faces.

(7) When reading the measurement value on the vernier caliper, pay special attention not to misread 0.5mm.

(8) To obtain accurate measurement results, it is recommended to take a second measurement at the same position.

(9) For workpieces that are abnormally hot, do not perform measurements to avoid reading errors.

(10) When using an outside vernier caliper with one hand, hold the movable sleeve with your thumb and index or middle finger, hook the small finger on the frame, and press it against the palm. Then, rotate the measuring force device with your thumb and index finger to take the measurement.

Lever Dial Indicator

The lever dial indicator, also known as the dial test indicator, is a precision measuring instrument composed of the micrometer part of an outside micrometer and the indicating mechanism of a lever-type depth gauge.

A dial indicator, also known as a dial test indicator, is the primary tool used to find the center of a shaft or other cylindrical work. It measures small linear distances and provides precise readings to ensure alignment and accuracy during machining processes.

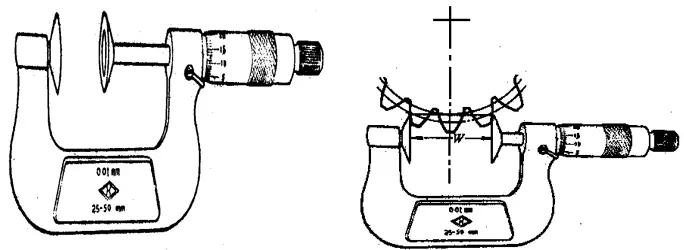

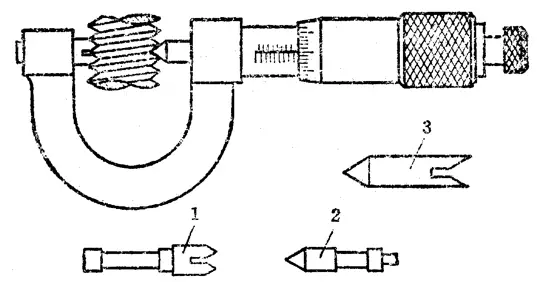

Inside Vernier Caliper

The inside vernier caliper, as shown in the picture, is read using the same method as the outside vernier caliper.

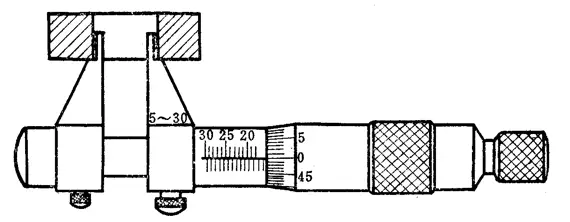

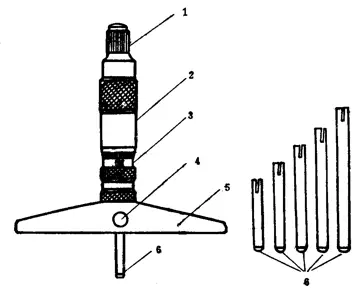

Depth Vernier Caliper

The depth vernier caliper, as shown in the picture, is used to measure small inner diameters and groove widths on internal surfaces. Its feature is that it is easy to find the correct diameter of an internal hole and is convenient to use for measurement.

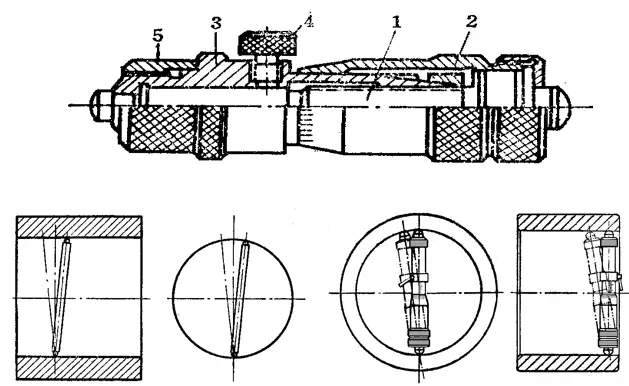

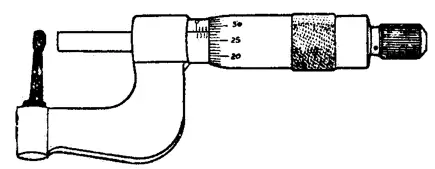

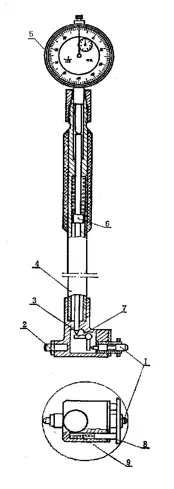

Three-Jaw Inside Micrometer

The three-jaw inside micrometer is suitable for measuring the precise inner diameter of small and medium-sized holes, especially for measuring the diameter of deep holes.

The measurement range (mm) includes: 6-8, 8-10, 10-12, 11-14, 14-17, 17-20, 20-25, 25-30, 30-35, 35-40, 40-50, 50-60, 60-70, 70-80, 80-90, 90-100.

The zero position of the three-jaw inside micrometer must be calibrated inside a standard hole.

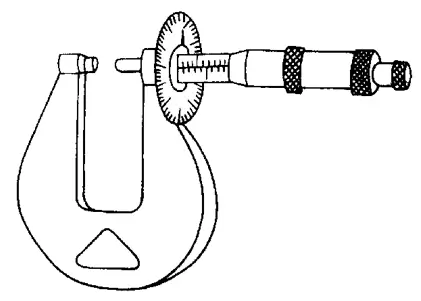

Gear Tooth Vernier Caliper

The gear tooth vernier caliper, as shown in the picture, is mainly used to measure the lengths of two different normal lines on the outer meshing cylindrical gears.

It can also be used to check the original shape dimensions of a gear along its normal line when inspecting the accuracy of a gear cutting machine.

Its structure is similar to the outside vernier caliper except that it has two measuring jaws (measuring faces) with precise planes installed on the measuring surface instead of the original measuring faces.

Wall Thickness Vernier Caliper

The wall thickness vernier caliper, as shown in the picture, is mainly used to measure the wall thickness of precision tubular parts. The measuring faces of the wall thickness vernier caliper are inlaid with hard alloy to improve its service life.

Measurement range (mm): 0-10, 0-15, 0-25, 25-50, 50-75, 75-100. Reading value (mm) 0.01

Thickness Vernier Caliper

The thickness vernier caliper, as shown in the picture, is mainly used to measure the thickness dimension of sheet metal.

Pointed Jaw Vernier Caliper

The pointed jaw vernier caliper, as shown in the picture, is mainly used to measure the thickness, length, diameter, and small grooves of parts. For example, it can be used to measure the groove diameter of drill bits and even-numbered thread taps.

Thread Vernier Caliper

The thread vernier caliper, as shown in the picture, is mainly used to measure the pitch diameter of a standard thread.

1, 2 Two-point Measuring Head 3. Setting Ring

Depth Vernier Caliper

The depth vernier caliper, as shown in the picture, is used to measure hole depth, groove depth, step height, and other dimensions. Its structure is similar to that of an outside vernier caliper, except that it has a base instead of a frame and measuring face.

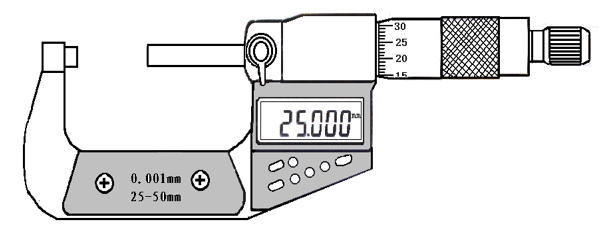

Digital Outside Vernier Caliper

Recently, digital outside vernier calipers are becoming more popular in China due to their ease of use. These calipers display readings digitally, which eliminates the need for manual interpretation.

Some digital calipers also have a fixed sleeve with markings that allow for readings as small as 0.002mm or even 0.001mm using a graduated cursor.

The Usage and Accuracy of Gauge Blocks

Gauge block, also known as a “block gauge,” is the most fundamental measuring tool used in the machine manufacturing industry. It serves as an intermediary for transferring measurements between a standard length and the dimensions of a part.

Gauge blocks are the benchmark for length measurement in technical measurement due to their high precision.

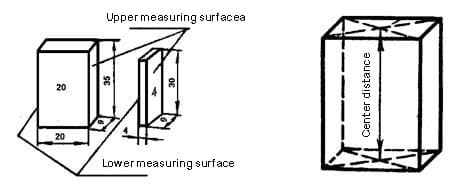

The working size of a gauge block does not refer to the distance between any two measuring surfaces because these surfaces are not absolutely parallel.

Therefore, the working size of a gauge block refers to its center length, which is the vertical distance from the center of one measuring surface to the bonding surface (whose surface quality is consistent with that of the gauge block) of the other measuring surface.

Each gauge block is marked with its working size: when the size of the gauge block is equal to or greater than 6mm, the working mark is on a non-working surface; when the gauge block is less than 6mm, the working size is directly marked on the measuring surface.

Gauge blocks are classified into five accuracy grades based on the accuracy of their working sizes (i.e., center lengths) and the accuracy of the flatness parallelism between the two measuring surfaces.

These grades are 00, 0, 1, 2, and 3. The accuracy of the 0-grade gauge block is the highest, with very precise working sizes and flatness parallelism, and an error of only a few microns. They are generally used by provincial and municipal metrology institutes to calibrate precision instruments.

The accuracy of the 1-grade gauge block is slightly lower, followed by the 2-grade gauge block. The accuracy of the 3-grade gauge block is the lowest, and is usually used in factory or workshop measurement stations to calibrate commonly used precision measuring tools.

Gauge blocks are precise dimensional standards that are difficult to manufacture.

In order to ensure that gauge blocks with larger deviations in working sizes can still be used as accurate length standards, their working sizes can be verified more accurately, and the correction value from the gauge block calibration is added during use.

Although this method may be more complicated to use, it allows gauge blocks with larger deviations to still be used as precise dimensional standards.

Gauge blocks are precise measuring tools, and the following points should be noted when using them:

Before use, wash off the rust preventive oil with gasoline, and then wipe it clean with a clean chamois or soft cloth. Do not use cotton yarn to wipe the working surface of the gauge block to avoid damaging the measuring surface.

Do not directly handle the cleaned gauge block with your hands; instead, place it on a soft cloth before handling. If you must handle the gauge block with your hands, wash them first, and hold the block on its non-working surface.

When placing the gauge block on a workbench, the non-working surface of the block should contact the work surface. Do not place the gauge block on blueprints because the residual chemicals on the blueprint surface can cause the gauge block to rust.

Do not push or rub the working surface of the gauge block against the non-working surface to avoid scratching the measuring surface.

After use, clean the gauge block promptly with gasoline, wipe it dry with a soft cloth, apply rust preventive oil, and store it in a dedicated box. If frequent use is required, the gauge block can be stored in a drying cylinder after cleaning without applying rust preventive oil.

It is absolutely not allowed to keep gauge blocks bonded together for a long time to avoid unnecessary damage caused by metal bonding.

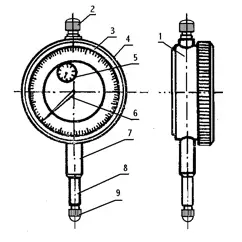

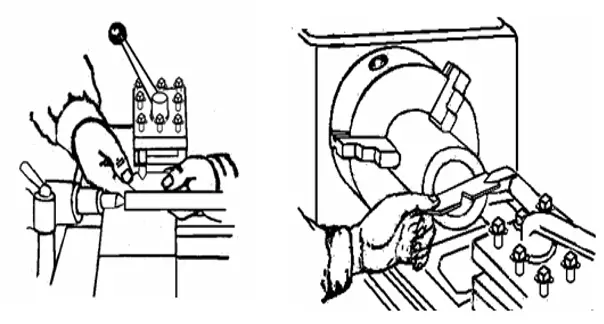

Indicating measuring tools are measuring instruments that indicate the measurement results through a pointer.

The indicating measuring tools commonly used in workshops include dial indicators, digital indicators, lever-type dial indicators, and internal diameter indicators.

They are mainly used to calibrate the installation position of parts, check the shape accuracy and mutual position accuracy of parts, as well as measure the inner diameter of parts, etc.

Dial indicators and digital indicators are used to calibrate the installation positions of parts or fixtures, as well as check the shape accuracy or mutual position accuracy of parts.

There is not much difference in the structural principle between them, except that the reading precision of digital indicators is higher. The reading value of a digital indicator is 0.001 mm, while that of a dial indicator is 0.01 mm.

Dial indicators and digital indicators are divided into three accuracy grades, 0, 1, and 2, with grade 0 having higher accuracy. When using dial indicators or digital indicators, you should choose the appropriate accuracy grade and measuring range according to the shape and precision requirements of the part.

When using dial indicators or digital indicators, pay attention to the following:

(1) Before use, check the flexibility of the measuring rod. Gently push the measuring rod, and it should move flexibly inside the sleeve without any jamming. After each relaxation, the pointer should return to its original position.

(2) When using a dial indicator or digital indicator, it must be fixed on a reliable clamping device (such as a universal table stand or magnetic base). The clamping device should be placed stably to avoid inaccurate measurement results or damaging the dial indicator due to instability.

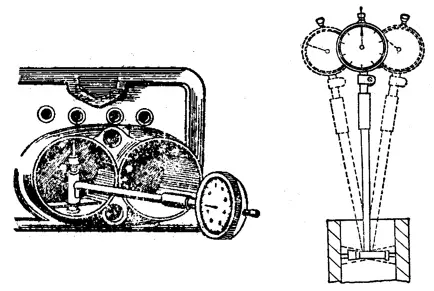

Internal diameter indicator:

An internal diameter indicator is a combination of an internal measuring lever-type frame and dial indicator, as shown in the figure. It is used to measure or check the inner hole, deep hole diameter, and shape accuracy of parts.

Universal Angle Ruler:

A universal angle ruler is an angle measuring tool used to measure the inner and outer angles of precision parts, or to draw angle lines. It includes a protractor and a universal angle ruler.

The scale lines on the base of the universal angle ruler are marked every 1º. Since there are 30 grids on the cursor, the total angle covered by them is 29º.

Therefore, the degree difference between each grid line is:

Yes, the accuracy of the universal angle ruler is 2′.

The reading method of the universal angle ruler is similar to that of a vernier caliper. Firstly, read the angle value before the zero line of the cursor, and then read the “minutes” value from the scale on the cursor. The sum of these two values is the measured angle value of the workpiece.

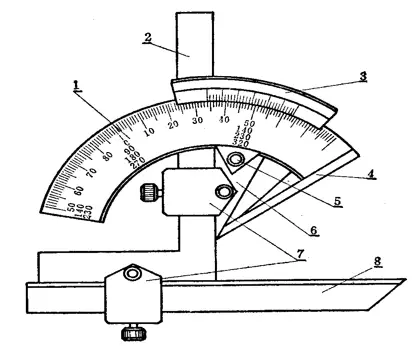

In the universal angle ruler, the base rule 4 is fixed on the base, and the angle rule 2 is fixed on the circular plate with a locking block 7. The movable rule 8 is fixed on the angle rule by a locking block.

If the angle rule 2 is removed, the straight rule 8 can be fixed on the circular plate. Because the angle rule 2 and the straight rule 8 can be moved and interchanged, the universal angle ruler can measure any angle from 0° to 320°, as shown in the following figure.

As shown in the above figure, when the angle rule and straight rule are fully assembled, the universal angle ruler can measure exterior angles from 0° to 50°.

When only the straight rule is installed, it can measure angles from 50° to 140°. When only the angle rule is installed, it can measure angles from 140° to 230°.

When both the angle rule and straight rule are removed, it can measure angles from 230° to 320° (i.e., interior angles from 40° to 130°).

On the scale lines of the base of the universal angle ruler, the basic angle markings are only from 0° to 90°. If the angle being measured is greater than 90°, a base value (90°, 180°, 270°) should be added to the reading. When the measured angle range is:

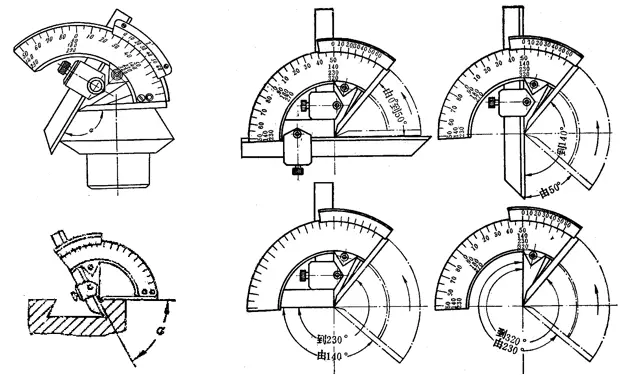

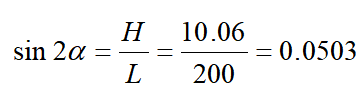

Universal Bevel Protractor

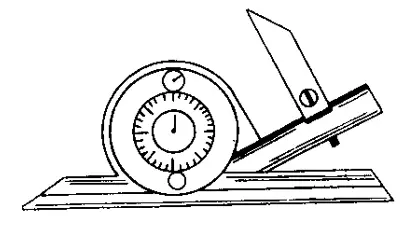

The Universal Bevel Protractor is shown in the figure. It is mainly used to measure general angles, lengths, depths, horizontalness as well as locating the center on circular workpieces.

It is also known as the Universal Steel Angle Ruler, Universal Angle Protractor, and Combination Angle Ruler. It consists of a steel ruler (1), a movable protractor (2), a center angle gauge (3), and a fixed angle gauge (4). The length of its steel ruler is 300mm.

1- Steel ruler

2- Movable protractor

3- Center angle gauge

4- Fixed angle gauge

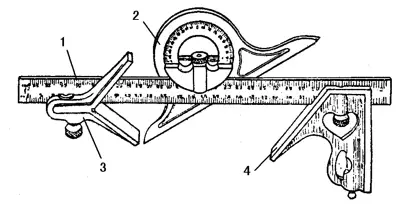

Protractor with Vernier Scale

The Protractor with Vernier Scale is shown in the figure. It is used to measure any angle, and has a higher measurement accuracy than a general protractor. The measurement range is 4×90º, with a reading value of 2′ and 5′, and a range of 0-360º with a graduation value of 5′.

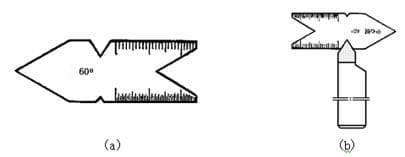

Center Gauge

The Center Gauge is shown in figure (a). It is mainly used to inspect the angle of threads and threading tools (shown in figure (b)), and to correct the position of threading tools during installation.

When cutting threads, higher requirements are put forward for the installation of threading tools in order to ensure correct tooth shape. For triangular threads, their tooth shapes are required to be symmetrical and perpendicular to the axis of the workpiece, that is, the two half angles are equal.

To make the two half angles equal during installation, the center gauge can be used as shown in figure 6-9. The accuracy of the lathe top needle can also be checked. It comes in two specifications: 55º and 60º.

Sine bar

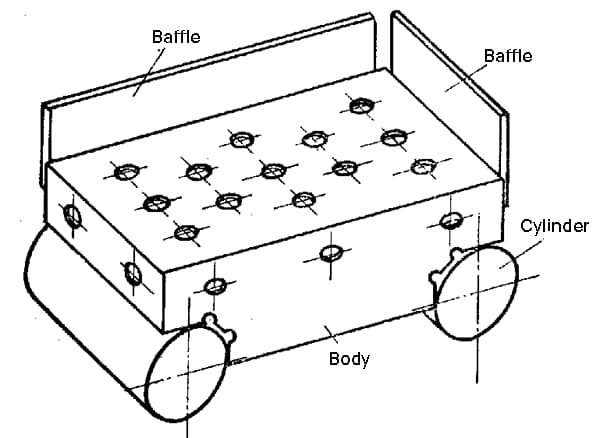

The sine bar is a measuring tool used for accurately checking the angles and tapers of parts and gauges. It is measured using the trigonometric relationship of sine, hence its name as a sine bar or sine rule.

The main body of the sine bar has precision working surfaces and two precision cylinders, and can be equipped with four stoppers (only two of which are installed when in use) perpendicular to each other as positioning plates for placing parts during measurement.

There are two types of domestic sine bars: wide and narrow.

Sine bar specifications.

| Center distance between two cylinders | Cylinder diameter | Workbench width (mm) | Accuracy level |

| (mm) | (mm) | Narrow Wide | |

| 100 | 20 | 25 80 | 0.1 level |

| 200 | 30 | 40 80 |

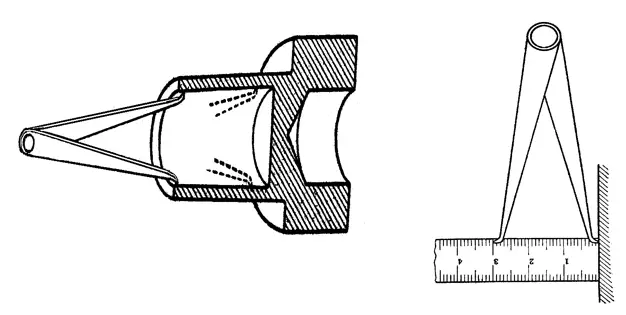

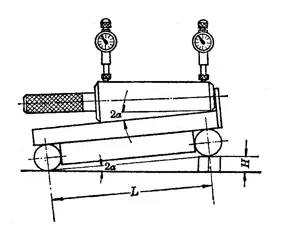

The following figure is a schematic diagram of measuring the taper angle of a conical plug gauge using a sine bar.

When using a sine bar to measure the angle of a part, such as a conical plug gauge, first place the sine bar on a precision platform and place the part to be measured on the working surface of the sine bar, with the positioning surface of the part to be measured lying flat against the stopper of the sine bar (such as the front end face of the conical plug gauge against the front stopper of the sine bar).

Place a gauge block under one of the cylinders of the sine bar and use a dial gauge to check the height of the part over its entire length.

Adjust the size of the gauge block so that the reading of the dial gauge is the same over the entire length of the part. At this point, you can use the sine formula of a right triangle to calculate the angle of the part.

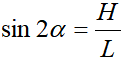

Sine formula:

Where:

For example, when measuring the taper angle of a conical plug gauge using a narrow sine bar with a center distance L=200mm, and when the gauge block is placed under one cylinder with a height H=10.06mm, the dial gauge reads the same over the entire length of the conical plug gauge. At this time, the calculation of the taper angle of the conical plug gauge is as follows:

By looking up the sine function table, we get 2α=2º53′. Therefore, the actual taper angle of the conical plug gauge is 2º53′.

Tool Angle Measuring Stand

The tool angle measuring stand is a special instrument used to measure the angles of cutting tools. It consists of a base 1, an indicator board 2, a platform 3, a positioning block 4, a pointer 5, a sector plate 6, a column 7, and a nut 8. The base 1 is disk-shaped with scales of 100° on both sides of the zero line. The platform 3 can rotate left and right around the Z-axis on the base, and the angle of rotation can be indicated by the indicator board 2 fixed at the bottom of the platform. The sector plate 6 has scales of ±45°. The pointer 5 can rotate around its axis, and the angle of rotation can be indicated on the scale of the sector plate. The lower end of the pointer 5 is a measuring plate, which has a lower blade A, a right blade B, a left blade C, and a front measuring surface D. The column 7 has threads. Rotating the nut 8 can move the sector plate 6 up and down.

The spirit level is a commonly used measuring tool for measuring angle changes. It is mainly used to measure the horizontal position of machine parts relative to each other and the flatness, straightness, and perpendicularity of equipment during installation. It can also measure the small inclination of parts.

Commonly used spirit levels include line spirit levels, frame spirit levels, and digital optical collimator spirit levels, etc.

Line Spirit Level

The following figure shows a common line spirit level used by mechanics. The line spirit level consists of a V-shaped base surface as the working surface and a level (commonly known as a bubble) parallel to the working surface. Both the flatness of the working surface and the parallelism of the level to the working surface are very precise.

When the base surface of the spirit level is placed in an accurate horizontal position, the bubble in the level is in the middle position (i.e. the horizontal position).

When there is a small difference between the base surface of the line spirit level and the horizontal position (i.e. when the two ends of the base surface of the spirit level are at different heights), the bubble in the level always moves towards the highest side of the level due to the effect of gravity, which is the principle of using the spirit level.

When the height difference between the two ends is small, the bubble also moves only slightly, but when the height difference between the two ends is large, the movement of the bubble is also large, and the height difference between the two ends can be read on the scale of the level.

Specification of the Level Gauge:

| Varieties | Overall dimensions (mm) | Graduation value | |||

| long | wide | high | group | (mm/m) | |

| Box type | 100 | 25~35 | 100 | I | 0.02 |

| 150 | 30~40 | 150 | |||

| 200 | 35~40 | 200 | |||

| 250 | 40~50 | 250 | II | 0.03~0.05 | |

| 300 | 300 | ||||

| Bar form | 100 | 30~35 | 35~40 | ||

| 150 | 35~40 | 35~45 | |||

| 200 | 40~45 | 40~50 | Ⅲ | 0.06~0.15 | |

| 250 | |||||

| 300 | |||||

Explanation of Graduation Value of the Bar Level Gauge

For example, if the graduation value is 0.03mm/m, it means that when the bubble moves one grid, the height difference between the two ends of a measured length of 1m is 0.03mm. Additionally, using a level gauge that is 200mm long with a graduation value of 0.05mm/m to measure the flatness of a plane that is 400mm long.

First, place the level gauge on the left side of the plane. If the bubble moves two grids to the right, then place the level gauge on the right side of the plane. If the bubble moves three grids to the left, it indicates that the plane is a convex surface that is higher in the middle and lower on both sides.

How much higher in the middle? Looking from the left side, the middle is two grids higher than the left end, which means that at a measured length of 1m, the middle is 2×0.05=0.10mm higher. Since the actual measured length is 200mm, which is 1/5 of 1m, the actual height difference is 0.10×1/5=0.02mm higher in the middle than on the left end.

Looking from the right side, the middle is three grids higher than the right end, meaning that at a measured length of 1m, the middle is 3×0.05=0.15mm higher. Since the actual measured length is also 200mm, which is 1/5 of 1m, the actual height difference is 0.15×1/5=0.03mm higher in the middle than on the right end. Therefore, it can be concluded that the height difference between the middle and both ends is (0.02+0.03)÷2=0.025mm.

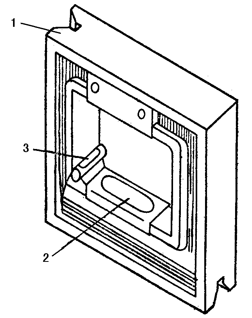

Box Level Gauge

The following image shows a commonly used box level gauge, which is mainly composed of a frame 1 and the main circular glass tube level gauge 2 and the adjustment level gauge 3. The movement of the bubble in the level gauge is used to measure the change in angle of the part being measured.

1 – Frame

2 – Main Level Gauge

3 – Adjustment Level Gauge

There are two methods for reading the level gauge: direct reading and mean reading.

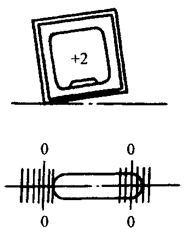

(1) Direct Reading Method

The long mark lines on both ends of the bubble in the level gauge are used as the zero line, and the number of grid shifts of the bubble relative to the zero line is used as the reading. This method is the most commonly used method, as shown in the figure below.

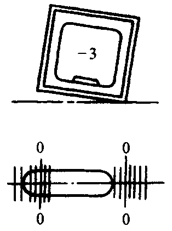

(2) Mean Reading Method

Due to large changes in ambient temperature, the bubble may elongate or contract, causing reading errors and affecting the accuracy of the measurement. To eliminate reading errors, the mean reading method can be used.

In the mean reading method, readings are taken from both long mark lines towards the end of the bubble in the direction of movement. Then, the average value of these two readings is taken as the reading for this measurement.

Due to the high ambient temperature, the bubble has elongated, causing it to shift to the left during measurement. When reading, start from the long mark line on the left and read “-3” to the left. Then, start from the long mark line on the right and read “-2” to the left. The average of these two readings is taken as the reading value for this measurement.