Have you ever wondered why some metal parts suddenly fracture even under normal conditions? This phenomenon, known as hydrogen embrittlement, poses a significant risk in various industries. Our article explores how hydrogen permeates metal during processes like electroplating, leading to unexpected failures. By understanding the mechanisms behind this issue and implementing preventive measures, you can enhance the durability and safety of your metal components. Dive into our guide to learn practical solutions for combating hydrogen embrittlement.

In every electroplating solution, there is a presence of hydrogen ions as a result of the dissociation of water molecules.

As a result, during the plating process, metal is deposited from the cathode (main reaction) and hydrogen is also deposited (side reaction).

Hydrogen evolution has multiple impacts, with hydrogen embrittlement being the most significant one.

Hydrogen embrittlement is a major quality hazard in surface treatment and can lead to parts breaking during use, causing serious accidents.

It is crucial for surface treatment technicians to have a thorough understanding of techniques to prevent and eliminate hydrogen embrittlement in order to minimize its effects.

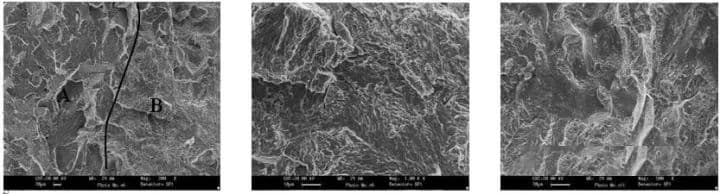

Hydrogen embrittlement typically manifests as delayed fracture under stress.

Galvanized parts, such as automobile springs, washers, screws, and leaf springs, have been known to break just a few hours after assembly with a fracture rate of 40% to 50%.

In the case of a special product with cadmium plated parts, a batch experienced cracks and fractures.

A nationwide investigation was conducted, and a strict dehydrogenation process was established.

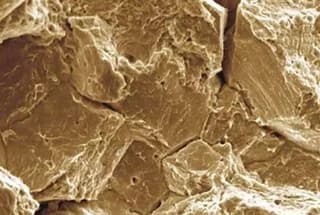

Additionally, some instances of hydrogen embrittlement do not result in delayed fracture.

For instance, the plating hanger, made of steel wire and copper wire, can become permeated with hydrogen due to repeated electroplating, pickling, and deplating, leading to brittle fracture after just one use.

Similarly, the core rod used for precision forging of hunting guns can break after multiple chromium plating processes.

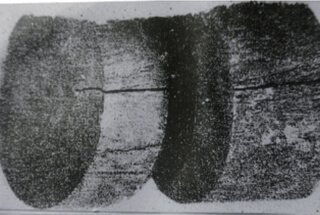

In some cases, quenched parts with high internal stress can crack during pickling, due to serious hydrogen permeation. These cracks can occur without external stress, and the original toughness cannot be restored by removing hydrogen.

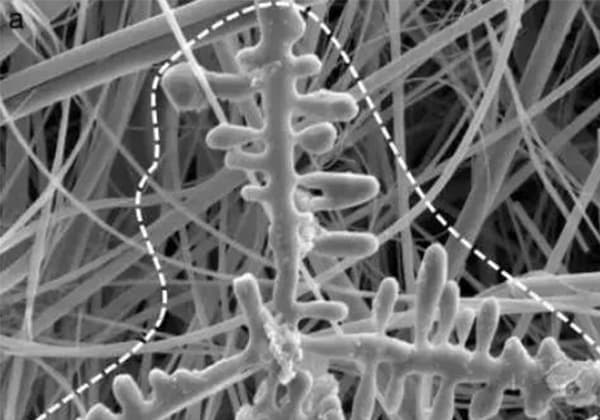

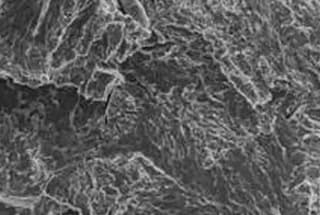

The occurrence of delayed fracture is caused by the diffusion and buildup of hydrogen in parts, specifically in areas of stress concentration that have metal defects, such as atomic lattice dislocations or holes.

As hydrogen diffuses to these defects, hydrogen atoms combine to form hydrogen molecules, which generate high pressure.

This pressure creates a force in combination with the residual stress within the material and the external stress on the material.

If the resulting force exceeds the yield strength of the material, it will fracture.

The speed of hydrogen diffusion and, therefore, the occurrence of hydrogen embrittlement, is dependent on the concentration gradient, temperature, and type of material.

Materials with small atomic radii, such as steel and copper, are more susceptible to hydrogen diffusion, while it is more difficult for hydrogen to diffuse in cadmium, tin, zinc, and their alloys.

The cadmium plating layer is particularly resistant to hydrogen diffusion, as hydrogen generated during cadmium plating remains in the plating layer and the metal surface layer underneath, making it difficult to diffuse outward and remove.

Over time, hydrogen diffuses into the metal and can enter defects within the metal, making it difficult to remove.

The diffusion of hydrogen is slow at normal temperatures and must be heated to remove it.

As the temperature increases, the solubility of hydrogen in steel also increases.

However, too high a temperature can reduce the hardness of the material.

It is important to consider the temperature for stress removal before plating and hydrogen removal after plating, so as not to reduce the hardness of the material, avoid the brittle tempering temperature of some steels, and maintain the performance of the coating.

In the process of rust and scale removal, sandblasting should be utilized as much as possible.

If acid washing is required, a corrosion inhibitor such as rutin should be added to the solution.

For oil removal, chemical oil removal, cleaning agents, or solvents with low hydrogen permeation should be used.

If electrochemical oil removal is chosen, the cathode should be followed by the anode.

In electroplating, the amount of hydrogen permeation is low in alkaline plating solutions or solutions with high current efficiency.

It is widely accepted that when electroplating with Cr, Zn, Cd, Ni, Sn, and Pb, hydrogen can easily penetrate into steel parts, while coatings made of metals such as Cu, Mo, Al, Ag, Au, and W have low hydrogen diffusivity and low hydrogen solubility, leading to less hydrogen permeation.

When product technical requirements are met, coatings that do not cause hydrogen permeation can be used.

For instance, the Dacromet coating can be used as an alternative to zinc plating, without causing hydrogen embrittlement.

This coating offers improved corrosion resistance of 7-10 times and has good adhesion.

The film thickness of 6-8um is similar to a thin zinc coating and will not affect assembly.

If parts have high internal residual stress after quenching, welding, or other processes, tempering treatment should be conducted before plating to reduce the risk of hydrogen permeation.

In general, parts with high hydrogen permeation during plating should be dehydrogenated as soon as possible, as the hydrogen in the plating layer and the surface base metal will continue to diffuse into the steel matrix over time.

International standards draft stipulate that dehydrogenation treatment should ideally be performed within 1 hour of plating, but no later than 3 hours.

There are also similar standards in China regarding dehydrogenation before and after galvanizing.

Post-plating dehydrogenation is commonly achieved through heating and baking, with a temperature range of 150-300°C and insulation for 2-24 hours.

The exact temperature and time for treatment should be determined based on the size, strength, coating properties, and plating time of the parts.

Dehydrogenation is typically performed in an oven, with the temperature for galvanized parts ranging from 110-220°C, and the temperature should be controlled based on the base material.

For elastic materials, thin-walled parts less than 0.5mm, and steel parts with high mechanical strength requirements, hydrogen removal treatment must be carried out after galvanizing.

To prevent “cadmium embrittlement”, the dehydrogenation temperature for cadmium plated parts should not be too high, typically between 180-200°C.

The sensitivity to hydrogen embrittlement increases with the strength of the material, which is a fundamental concept that surface treatment technicians must understand when preparing electroplating process specifications.

International standards require that steel with a tensile strength of σb > 105kg/mm2 undergo pre-plating stress removal and post-plating hydrogen removal treatment.

The French aviation industry requires corresponding dehydrogenation treatment for steel parts with a yield strength of σs > 90kg/mm2.

Because there is a strong correlation between the strength and hardness of steel, it is easier to judge the hydrogen embrittlement sensitivity of materials by their hardness than by their strength.

Product drawings and machining processes usually include the steel hardness, making it more convenient to assess.

In electroplating, it has been observed that steel with a hardness of approximately HRC38 begins to exhibit a risk of hydrogen embrittlement fracture.

For parts with a hardness greater than HRC43, dehydrogenation should be considered after plating.

If the hardness is around HRC60, dehydrogenation treatment must be performed immediately after surface treatment, otherwise the steel parts will crack within a few hours.

In addition to the hardness of steel, the following factors should also be taken into account:

Hydrogen embrittlement removal

The main issue is the “hydrogenation” phenomenon that occurs in the electroplating process. The unqualified products you are using are not necessarily a result of the electroplating process itself, as most electroplating methods (except vacuum plating) will cause hydrogenation in the metal.

However, many metal surface treatment facilities omit the final step, specifically the “dehydrogenation” process, to save on production costs. This process, which is essential for metal parts with strength requirements, involves heating the parts to a high temperature of 120-220°C for 1-2 hours after electroplating.

If the user is unaware or has not requested or accepted this process, it can save 5-15% of the cost. This may result in the plated bolts, spring pads, and other parts being “brittle.”

The specific conditions for dehydrogenation treatment should be controlled according to the requirements of the parts.