Imagine a machine that can slice through metal with the precision of a surgeon’s scalpel. Metal laser cutting machines offer this capability, transforming how industries work with metals. This article explores the types, principles, and applications of these cutting-edge tools. By the end, you’ll understand how these machines achieve high accuracy, efficiency, and versatility in metal processing, making them indispensable in modern manufacturing.

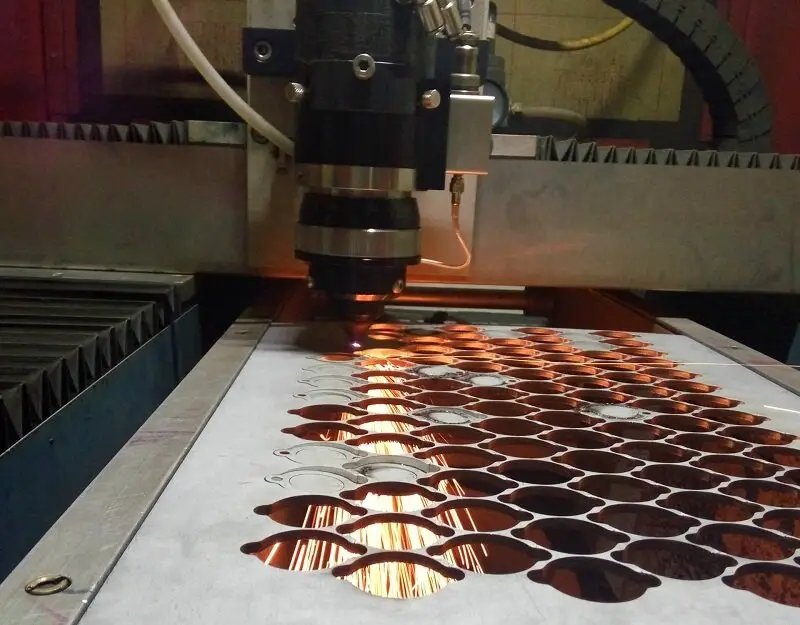

A metal laser cutter is a precision manufacturing tool specifically engineered to cut and process metallic materials using high-powered laser technology. This advanced machine employs a focused laser beam to melt, vaporize, or blow away metal with exceptional accuracy and efficiency. Capable of handling a wide range of metals, including stainless steel, aluminum, mild steel, and even exotic alloys, metal laser cutters offer unparalleled versatility in industrial applications.

These systems typically utilize CO2 or fiber lasers, with fiber lasers becoming increasingly prevalent due to their superior performance on reflective metals and thinner materials. The cutting process is computer-controlled, allowing for intricate designs and complex geometries to be produced with minimal material waste. Metal laser cutters excel in producing clean, precise cuts with narrow kerfs and minimal heat-affected zones, making them ideal for industries such as automotive, aerospace, electronics, and general fabrication where precision and quality are paramount.

The metal laser cutting industry currently features three predominant types of machines:

CO2 laser cutting machines remain a cornerstone in the industry due to their robust cutting capacity and versatility across a wide range of materials and thicknesses. Their ability to efficiently process both metallic and non-metallic materials has solidified their position as mainstream equipment in the market. These machines excel in cutting thicker materials (up to 25mm in mild steel) and are particularly effective for processing acrylic, wood, and other non-metals.

Fiber laser cutting machines have rapidly gained prominence in recent years, driven by technological advancements and operational benefits. These systems offer superior energy efficiency, lower maintenance requirements, and exceptional cutting speed, especially for thin to medium-thickness metals (up to 10mm). Their compact design, coupled with the absence of mirrors or moving parts in the beam delivery system, contributes to reduced operational costs and increased reliability. Fiber lasers are particularly adept at cutting reflective materials like aluminum and copper, which can be challenging for CO2 lasers.

YAG (Yttrium Aluminum Garnet) laser cutting machines, while less common than CO2 or fiber lasers, still maintain a niche in specific applications. They are particularly effective for precision cutting of thin materials and are often employed in the jewelry and medical device industries. YAG lasers can be operated in both pulsed and continuous wave modes, offering flexibility for various cutting requirements.

The rising popularity of fiber laser technology in the metal cutting market can be attributed to its relatively lower technical requirements for operation and maintenance, coupled with its high cutting speed and precision. As manufacturers continue to push the boundaries of fiber laser power and beam quality, these machines are increasingly capable of competing with CO2 lasers even in thicker material applications, further solidifying their market position.

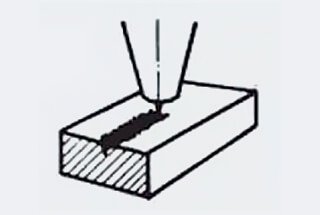

The laser cutting process relies on the focused energy of a high-power laser beam to rapidly heat and vaporize the material, creating a narrow kerf. When the heat input from the laser exceeds the material’s capacity for reflection, conduction, or diffusion, a localized melt pool forms, which is then ejected from the cut zone.

As the laser beam traverses the workpiece in a programmed path, it continuously generates a precise cut (typically 0.1-0.5 mm wide) without inducing significant thermal distortion in the surrounding material. This ability to maintain tight tolerances and minimal heat-affected zones is a key advantage of laser cutting over traditional thermal cutting methods.

The process is enhanced by the use of assist gases, carefully selected based on the material being cut and the desired cut quality:

The assist gas also plays a crucial role in protecting the focusing optics from contamination and overheating, thereby maintaining beam quality and extending component life.

Laser cutting demonstrates exceptional versatility across a wide range of materials. In industrial metalworking applications, it excels at cutting various metals and alloys with thicknesses up to 25 mm for mild steel and 15 mm for stainless steel, while maintaining high precision and minimal distortion.

However, materials with high reflectivity or thermal conductivity, such as copper, aluminum alloys, and precious metals, present challenges for continuous wave (CW) lasers. These materials often require specialized techniques or alternative laser sources:

As laser technology continues to evolve, ongoing research focuses on expanding the range of materials and thicknesses that can be efficiently processed, further cementing laser cutting’s position as a cornerstone of modern manufacturing.

Fiber laser cutting technology finds extensive application across a wide spectrum of industries, ranging from high-precision manufacturing to heavy industrial production. Its versatility and efficiency make it an indispensable tool in:

The technology excels in processing a diverse range of metallic materials, including:

Fiber laser cutting’s ability to handle various material thicknesses with high precision, minimal heat-affected zone, and excellent edge quality makes it a preferred choice for both mass production and custom fabrication across these industries.

Cutting widths are customizable to meet specific project requirements, offering flexibility in material processing.

Cutting (traverse) speed: 0 – 30,000 mm/min, allowing for precise control over material removal rates and surface finish quality.

Motion control: Offline CNC system for enhanced precision and repeatability in complex cutting patterns.

Work platform: Reinforced blade platform designed to minimize vibration and maintain flatness during high-speed operations.

Laser power modulation: Continuous 0-100% output adjustment, enabling real-time energy regulation for optimal cutting performance across various materials and thicknesses.

Positioning accuracy: ≤ ±0.1 mm, ensuring high-precision cuts and intricate detailing capabilities.

Power requirements: 220V ± 5%, 50Hz, compatible with standard industrial power supplies.

Supported file formats: AI, BMP, PLT, DXF, DST, among others, facilitating seamless integration with common CAD/CAM software.

Standard configuration:

Optional enhancements:

High cutting accuracy and stability:

Utilizing a precision ball screw drive mechanism and optimized CNC system control, this machine achieves exceptional accuracy for precision parts processing. The system’s dynamic performance remains stable over extended operating periods, ensuring consistent quality output.

Superior cutting section quality:

The machine incorporates a mechanical follow-up cutting head system that automatically adjusts to plate height variations. This maintains a constant cutting point position, resulting in flat, smooth kerfs. The high-quality cross-sections typically require no post-processing, making the system ideal for both flat and curved plate cutting applications.

Versatile cutting capabilities:

With its large cutting width, the machine accommodates a diverse range of materials and applications. It can process metal plates up to 2500mm × 1250mm, handling materials such as plain carbon steel, stainless steel, alloy steel, aluminum, copper, titanium, and various other metal alloys.

Cost-effective solution:

For thin plate cutting operations, this system can effectively replace CO2 laser cutting machines, CNC punching machines, and shearing equipment. Its initial investment cost is approximately 25% of a CO2 laser cutter and 50% of a CNC punching machine, offering significant capital savings.

Low operational costs:

The machine employs a YAG solid-state laser, with primary consumables limited to electrical energy, cooling water, auxiliary gases, and laser medium. This results in an average operational cost of about $28 per hour, contributing to overall cost efficiency.

Core technologies:

Metal laser cutting machine manufacturers are companies specializing in the design, production, and distribution of laser cutting systems used for precision cutting of metal materials. These manufacturers play a crucial role in various industries, including automotive, aerospace, electronics, and general manufacturing, by providing advanced technology solutions for metal fabrication processes.

Key players in the metal laser cutting machine market include:

These manufacturers continually invest in research and development to improve their products’ cutting speed, precision, and energy efficiency. Many are also integrating advanced features such as automation, artificial intelligence, and IoT connectivity to enhance productivity and reduce operational costs for end-users.

When selecting a metal laser cutting machine manufacturer, factors to consider include:

Related reading: Top 20 Metal Laser Cutting Machine Manufacturers

The cost of a metal laser cutting machine is influenced by multiple critical factors, primarily determined by the specific cutting requirements and desired capabilities. Key considerations include:

1. Laser Source: The type (CO2, fiber, or solid-state) and power output (typically ranging from 500W to 12kW for industrial applications) significantly impact price and cutting performance.

2. Workpiece Specifications:

3. Cutting Capabilities:

4. Automation Features:

5. Additional Technologies:

6. Brand and Origin: Established manufacturers from regions with advanced manufacturing capabilities often command premium prices.

As a reference point, entry-level 1000W fiber laser cutting machines suitable for light to medium industrial use typically start around $30,000 to $50,000. However, high-end systems with advanced features and higher power outputs can range from $100,000 to over $1,000,000 for fully automated production lines.

For accurate pricing tailored to specific requirements, it is advisable to consult directly with manufacturers or authorized distributors. They can provide detailed quotes based on your exact needs, including installation, training, and ongoing support considerations.

Metal laser cutting machine

A metal laser cutting machine utilizes a high-power density laser beam to rapidly heat the material surface to temperatures ranging from thousands to tens of thousands of degrees Celsius. This intense heat causes the material to melt or vaporize. High-pressure assist gas then expels the liquefied or vaporized material from the kerf, effectively achieving material separation.

Unlike conventional mechanical cutting methods, laser cutting employs an invisible light beam, eliminating physical contact between the laser head and the workpiece. This non-contact process prevents surface scratches and minimizes material distortion.

Laser cutting offers several advantages:

CNC plasma cutting machine

A CNC plasma cutting machine is a thermal cutting system that employs a high-temperature plasma arc to locally melt metal at the cutting zone. The process utilizes the kinetic energy of the high-velocity plasma jet to expel the molten metal, creating the cut.

The choice of working gas significantly influences the cutting characteristics, quality, and speed of the plasma arc. Common plasma arc working gases include:

Each gas or mixture offers specific advantages depending on the material and application requirements.

Plasma cutting machines find widespread use in industries such as:

When comparing cutting accuracy, plasma typically achieves tolerances around ±1mm, while laser cutting can maintain accuracies within ±0.2mm. In terms of cutting efficiency, laser systems excel in combining speed and precision, with capabilities of cutting 1mm thick plates at rates up to 26 meters per minute.

Generally, plasma cutting is better suited for rougher processing and often requires additional finishing operations such as grinding or secondary machining. In contrast, laser cutting machines are designed for precision processing, often completing the task in a single operation with minimal need for post-processing.

Metal laser cutting machines, particularly CO2 laser systems, are highly recommended for cutting carbon steel plates up to 20mm thick, stainless steel plates up to 10mm thick, as well as non-metallic materials such as acrylic and wood. These advanced systems offer numerous advantages in modern manufacturing:

1. Precision and Versatility:

2. Material Adaptability and Tool Longevity:

3. Efficiency and Automation:

4. Environmental and Safety Benefits:

5. Flexibility and Future-Proofing:

6. Production Advantages:

When selecting a laser cutting machine, it’s crucial to consider factors such as:

Laser cutting machines have revolutionized sheet metal processing, becoming the central “processing hub” in modern fabrication facilities. Their combination of flexibility, speed, efficiency, and long-term technological viability makes them an indispensable asset in the metal fabrication industry, capable of meeting diverse customer needs and market demands.

Market demand

Although still in the preliminary development stage, the laser industry in China has made a significant leap forward under the leadership of international science and technology, and has gained significant prominence on the global stage.

The market demand for laser cutting machines in China is very high, with a market size of tens of millions of dollars, providing new opportunities for growth in the industry.

Since the birth and application of the first laser equipment in the 1960s, several Chinese experts have made significant contributions to the development of the laser industry, achieving international standards.

The production of complete sets of industrial equipment for laser technology has enabled China to overcome its reliance on foreign technology, filling the gap in the domestic laser industry.

The rapid growth of the domestic economy has made the laser industry a high-growth backbone of the market, with an annual growth rate of more than 20%, becoming a driving force for the global laser market.

Experts predict that the domestic laser market will continue to grow rapidly, possibly doubling in the future, and expanding the market for laser cutting equipment, filling the gap in the domestic market.

This growth will enable China’s high-end laser equipment to break free from its current limitations, and become a leading force in the international market.

Breakthrough technology

Since all machines and equipment are not perfect, metal laser cutting machines also suffer from certain shortcomings.

If the metal laser cutting machine wants to further develop, it must break through the following technology.

If a metal laser cutting machine wants a better development, it must break through the lightness and flexibility of the metal laser cutting machine beam as well as the high rigidity and high stability of the machine structure.

This will further improve the cutting accuracy of the metal laser cutting machine and the use of flexibility.

A perfect modern machine needs to have a high-quality control system.

High-quality control system can make operation more simple, improve efficiency and reduce the error due to manual operation.

The quality of the beam is the key to the cutting quality of the metal laser cutting machine.

Good focusing technology can make the object to be processed more beautiful, so as to achieve the effect you want.

These include edge monitoring, capacitance height tracking, cutting monitoring, and penetration detection.

In this way, it can better cooperate with the conversion of laser cutting graphics, making it simple and smooth to write complex part programs, and it is also very convenient to edit and modify.

Therefore, it is very important to develop and design a special CAD/CAM software system.

Metal laser cutting is currently one of the best processing equipment, I believe that in the near future our metal laser cutting machine will be further perfected. So as to meet the needs of our market.

Notes

It should strictly in accordance with the laser start-up procedures to start the laser, dimming and test machine.

If it is necessary to leave, the operator should stop the machine or cut off the power switch.

Turn off the laser or shutter when not working;

Do not place paper, cloth, or other flammable materials near the unprotected laser beam.

The use and transportation of gas cylinders shall comply with gas cylinder supervision regulations.

It is forbidden to explode gas cylinders in the sun or close to heat sources.

When opening the bottle valve, the operator must stand on the side of the bottle’s mouth.

Every 1 day of operation or weekly maintenance, every 1000 hours of operation or every six months of maintenance, which must be carried out in accordance with regulations and procedures.

Every product requires good maintenance to ensure a higher service life, and this is no exception for metal laser cutting machines. So, how should we maintain them to achieve high and stable life expectancy?

Cleaning dust and metal impurities

Cleaning dust is a part of daily maintenance for every machine, and a clean and tidy machine is essential for product quality assurance. Metal laser cutting machines are mainly used for metal processing, and although cut metal is usually blown away, there may still be some residues left, so it is important to clean these impurities.

Regular maintenance and usage statistics

Each part of the metal laser cutting machine should be inspected and recorded on a regular basis. Ineffective parts should be replaced promptly to ensure that the machine operates in an optimal working environment. Defective parts can adversely affect the machine’s overall performance.

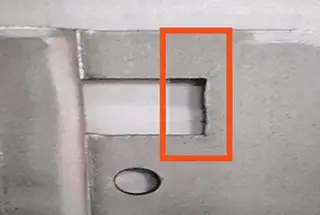

After analysis, the following shows the main conditions that cause processing instability:

According to the working and design principles of CO2 laser cutting, solutions to these common problems can be made based on the processing method of metal laser cutting machines and material analysis.

Materials processed by metal laser cutting machines have high reflectivity to infrared energy at room temperature, although CO2 lasers emitting 10.6um beams in the far-infrared band are successfully applied in many metal laser cutting practices.

The initial absorption of 10.6um laser beams by metals is only 0.5% to 10%, but when focused laser beams with power densities in excess of 106w/cm2 are directed at a metal surface, the surface quickly begins to melt in microseconds.

The absorption rate of most metals in the molten state increases dramatically, typically by 60% to 80%.

Carbon steel:

Modern laser cutting systems can cut carbon steel plates up to a maximum thickness of 20mm. Using oxidative fusion cutting mechanism to cut carbon steel can control the width of the cut slit in a satisfactory range, with the slit of thin plates being as narrow as 0.1mm.

Stainless steel:

Laser cutting is an effective tool for manufacturing industries that use thin stainless steel sheets as the main component. By strictly controlling the heat input to the laser cutting process, the heat-affected zone at the cutting edge can be limited to a minimum, which is very effective in maintaining the material’s good corrosion resistance.

Alloy steels:

Most alloyed structural and tool steels can be laser cut to achieve good edge quality. Even for some high-strength materials, straight and non-sticky slag cutting edges can be obtained as long as the process parameters are properly controlled. However, for high-speed tool steels and hot-die steels containing tungsten, melting and slagging can occur during laser cutting.

Aluminum and alloys:

Aluminum cutting uses a melting and cutting mechanism, and the auxiliary gas used is mainly to blow away the molten product from the cutting area to obtain a better cut surface quality. For some aluminum alloys, attention must be paid to prevent intergranular microcracks on the cut surface.

Copper and alloys:

Pure copper (copper) with too high reflectivity cannot be cut with a CO2 laser beam. Brass (copper alloy) uses higher laser power, and the auxiliary gas uses air or oxygen, which can cut thinner plates.

Titanium and alloys:

Pure titanium can be well coupled to the thermal energy of the focused laser beam. The auxiliary gas uses oxygen when the chemical reaction is intense, leading to faster cutting speed, but an oxide layer can be generated at the cutting edge, and carelessness will also cause overburning. To be on the safe side, the use of air as an auxiliary gas is better to ensure the quality of cutting. The quality of titanium laser cutting commonly used in aircraft manufacturing is better, although there will be a little slag at the bottom of the kerf, it is easy to remove.

Nickel alloy:

Nickel-based alloys, also known as superalloys, come in many varieties. Most of them can be cut using oxidative fusion cutting.