Have you ever wondered how massive metal structures like wind turbines and ships get their precise shapes? This article unveils the fascinating world of metal plate rolling machines, showcasing their types and applications. Learn how these powerful machines bend metal sheets into cylinders, cones, and more, revolutionizing industries from aerospace to home appliances.

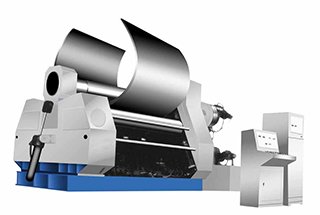

Metal plate rolling machine is a type of equipment that uses work rolls to bend sheet metal, allowing it to form cylindrical, conical, and other shaped parts.

It is a crucial piece of equipment in sheet metal fabrication.

Rolling machines are essential production equipment used in various industries, including home appliances, pressure vessels, wind power, shipping, aerospace, military, and automobile refurbishment.

The plate rolling machine has the capability to bend metal sheets into large arcs, cylinders, ellipses, squares, and multi-sectional arcs.

In this article, we will provide a brief overview of the types and applications of plate rolls.

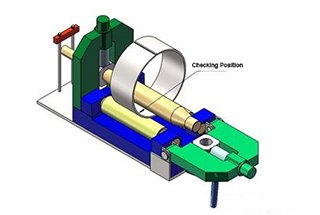

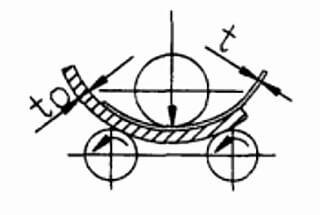

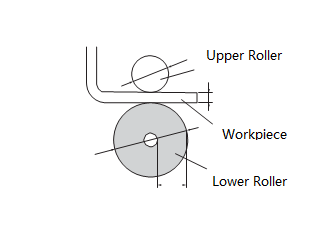

The twin roll plate bending machine features an upper roller made of rigid metal and a lower roller covered with high strength polyurethane material that can be adjusted vertically.

When the roller rotates, the upper roller and the feed plate are subjected to pressure, causing the elastic layer of the lower roller to deform. The constant volume of the elastomer results in uniform, continuous back pressure that forces the plate and rigid roller to remain in close contact, allowing the plate to be formed into a cylinder through rotation.

The depth of deformation of the elastic layer, or the indentation of the upper roller, is the main technological parameter that determines the bending radius. Studies have shown that as the reduction increases, the bending radius of the metal sheet decreases, but once a certain indentation value is reached, the bending radius tends to remain stable regardless of the reduction. This is an important characteristic of the twin roller plate bending technology.

Double roller plate bending machines are mainly designed for metal plates with a width of 2000mm and a thickness of less than 2mm for round rolling, making them ideal for batch production of thin containers in the household appliance industry. These machines often come equipped with automatic feeding and discharging systems, offering high levels of automation and increased efficiency.

Advantages:

The advantages of the twin roll plate bending machine include:

Disadvantages:

However, the twin roll plate bending machine has some limitations, including:

There are various types of three roll plate bending machines, which can be classified into mechanical and hydraulic categories.

From a structural standpoint, three roll plate bending machines can be further divided into inclined three roll plate rolling machines, horizontal under roller move type, and geometric variable type.

Asymmetrical 3 rolls plate bending machine

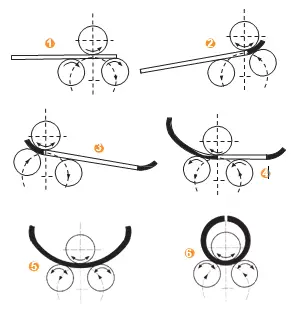

Asymmetrical 3 roll plate bending machines are typically powered by a mechanical motor. The upper and lower rollers are both fixed power rollers, with the upper roller being stationary and the lower roller capable of lifting and rotation. The lower roller works in conjunction with the upper roller to press the front end of the metal plate, while the side roller, serving as a subsidiary roller, lifts to deform the plate during bending. The upper and lower rollers work together to achieve round and arc rolling of the metal plate.

These machines are used to roll low carbon steel plates with lengths of less than 2500mm and thicknesses of less than 4mm into cylinders or arc segments. The rolling process is fast and efficient, saving energy and reducing production costs.

However, the pre-curving linear segment is twice the thickness of the plate, and the machine requires skilled operators, making the technical requirements for personnel higher.

Horizontal lower roller move type

Horizontal lower roller move 3 roll plate rolls are the most widely used and well-established plate rolling machines, both domestically and internationally. They are typically powered by hydraulic drive.

The working principle of horizontal lower roller move 3 roll plate rolls is as follows:

The upper roller is a fixed, powered rotating roller, and the two side rollers move along a predetermined arc track during operation to press the metal plate together with the top roller. The rotation of the upper roller completes the cylinder or cone rolling process.

Horizontal lower roller move type 3 roll plate bending machines can typically roll plates with a width of up to 4000mm and a thickness of 6-40mm. The main advantage of these machines is their relatively low cost. However, they require highly skilled operators as the roll forming process cannot be completed in a single pass, and the pre-curving linear segment is greater than twice the thickness of the plate.

Geometric variable plate rolling machine

Geometric variable plate rolling machines are the most advanced plate rolling equipment available both domestically and internationally. They are capable of rolling metal plates with a thickness ranging from 20-250mm.

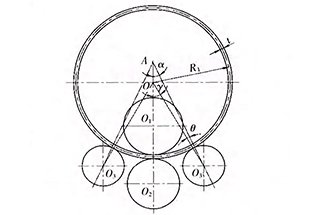

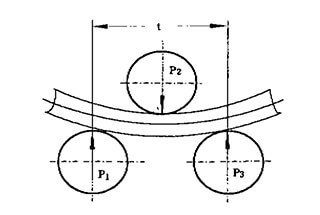

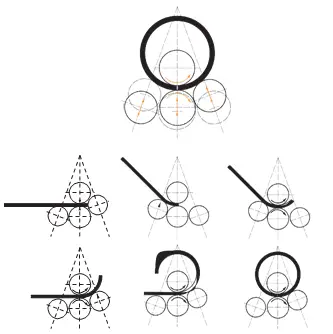

The working principle of geometric variable plate rolling machines is shown in the following image.

In a geometric variable plate rolling machine, the upper roller is a powered roller that can move up and down, while the two side rollers serve as driver rollers that can move horizontally independently.

The movement of each roller can create a specific geometric shape, giving rise to the name “geometric variable plate rolling machine.”

During operation, the machine employs horizontal plate feeding and pre-curving, eliminating the need for side push devices and side roller movement outside. Additionally, the bending capacity increases significantly, and the pre-curving linear segment is not greater than the thickness of the plate.

Advantage:

The geometric variable plate rolling machine offers several advantages, including:

Disadvantage:

However, the geometric variable plate rolling machine has some limitations, including:

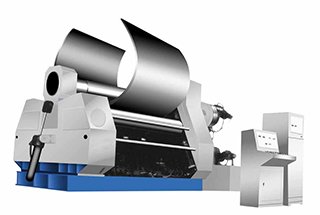

Four roller plate bending machines are highly reliable and widely used in the manufacturing industry. They are versatile machines capable of rolling multi-segment arc shapes, o-shapes, squares, circles, arcs, and more. These machines can also be equipped with a highly automated man-machine dialogue CNC system.

Four roller plate bending machines come in both mechanical and hydraulic varieties, with the mechanical type suitable for rolling metal plates under 6mm thick and the hydraulic type capable of rolling plates up to 6-200mm thick.

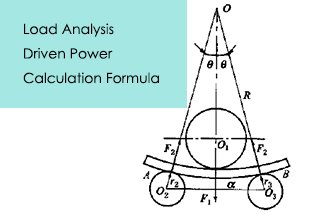

The following image demonstrates the working principle of a 4 roll plate bending machine.

The upper roller in a 4 roll plate bending machine is a powered rotating roller that is fixed in place, while the lower roller can move up and down. The lower roller works in conjunction with the upper roller to clamp the metal plate. The two side rollers move up and down in an oblique direction, serving to position and form the plate.

While the working principle of 4 roll plate bending machines is consistent across the market, there are structural differences, such as the use of planetary arc guides or linear guides for side roller movement.

Before 2003, 4 roll plate bending machines primarily used linear guides. Since then, planetary arc guides have become the dominant technology.

Some manufacturers still choose to use linear guides, despite their higher cost, because they are easier to maintain. Linear guides also offer significant advantages when rolling high alloy plates or titanium alloys.

For metal plates with yield strengths less than 500Mpa, the difference between linear and planetary arc guides is minimal. Planetary arc guides offer a much lower cost of use.

Advantage:

Four roll plate bending machines are capable of satisfying the entire range of sheet metal rolling requirements and can be equipped with high levels of automation, including automatic up and down feeding devices.

Disadvantage:

However, the pre-curving linear segment is greater than 1.5 times the thickness of the plate.

Aside from the common plate rolls mentioned above, there are also specialized rolls available, such as vertical rolls, stiffened drum rolls, and ship rolls, among others.